Header Types Defined/Discussed + Photos of all C63 Headers and Manifolds

#26

Hi sorry for maybe a stupid question. I will soon buy a C63 and will be looking for longtube headers but I will keep stock midpipes and exhaust.

I a shop install the headers where to they cut in the OEM midpipe? Will they cut first cats and then install or keep the first cats whit sensors?

Im coming from a stage 3 335i. I changed my DP on the car but on the new ones they still had 02 sensors so the car didnt get CELīs also installed 02 sims. I want a C63 whit a tune and longtube headers but I want it to go trough exhaust test that we have every year in sweden and no CELīs. Last question how many hours does it take for a shop to install the longtube headers?

I a shop install the headers where to they cut in the OEM midpipe? Will they cut first cats and then install or keep the first cats whit sensors?

Im coming from a stage 3 335i. I changed my DP on the car but on the new ones they still had 02 sensors so the car didnt get CELīs also installed 02 sims. I want a C63 whit a tune and longtube headers but I want it to go trough exhaust test that we have every year in sweden and no CELīs. Last question how many hours does it take for a shop to install the longtube headers?

#28

Super Member

I am speaking in regards to the MHP headers as those are what I am currently running, but you will want to use the mid pipes that come with the long tubes. They bolt right up to the OEM resonator, and NO cutting is required. The long tubes and mid pipes will eliminate the primary AND secondary cats, however you can request high flow cats as an option, as I have done. I had them welded in the new mid pipe section.

Also, the mid pipes that come with the MHP long tube headers have bungs to mount your O2 sensors, and combined with the tune will not cause a CEL. I have not had to undergo an emissions/exhaust test yet, however I am confident the car will pass.

Expect a shop to quote roughly 8 hours of labor to install the headers.

Hope this helps, and great job on the post Superlubricity. I didn't realize there were this many options available!

Also, the mid pipes that come with the MHP long tube headers have bungs to mount your O2 sensors, and combined with the tune will not cause a CEL. I have not had to undergo an emissions/exhaust test yet, however I am confident the car will pass.

Expect a shop to quote roughly 8 hours of labor to install the headers.

Hope this helps, and great job on the post Superlubricity. I didn't realize there were this many options available!

#29

MBWorld Fanatic!

Cell count? How does it compare to Super's w/his sound attenuation device? Still louder I imagine?

#30

Super Moderator Alumni

Thread Starter

Join Date: Dec 2009

Location: USA

Posts: 2,189

Likes: 0

Received 6 Likes

on

4 Posts

2011 GLK 350, 2013 GT-R, & 2013 RAM 1500

) but offer nothing in terms of emission control.

) but offer nothing in terms of emission control. https://mbworld.org/forums/c63-amg-w...ml#post4389636

#32

Member

I am glad we are having a technical discussion on headers, but it is not like headers are a mysterious, little known science. People have been making custom exhaust manifolds/headers for all kinds of cars since the beginning of racing and hotroding.

In my humble opinion, the best way to learn about aftermarket headers and exhaust modifications is by looking at the American hotrod/muscle car/sports car scene. The American car aftermarket is a huge industry compared to the MB and other Euro car aftermarkets. The market is also very competitive. It is logical to assume much, much more research has been done on headers by the American car aftermarket than Euro car aftermarket. If you take a look at the American aftermarket scene, you will see that full length, long tube headers, with one merger/collector per cylinder bank dominate the market in both power production and popularity. Why, because they work well in nearly every application. The MHP guy obviously knows this. His background is in Mustangs and SRT8s. He simply took a formula for what worked on American cars and applied it (seemingly successfully) to the C63. I am in no way endorsing MHP headers. I could never endorse headers that cost over $4k. That is absolutely ridiculous. And before someone starts talking about research and development costs, the only development cost was the cost of a skilled tradesman to build the first set and then to build the template for producing the headers. Again it is not rocket science.

But what about headers with tri-y collectors? I have never seen any evidence that they produce measurable gains over a single high velocity merge collector in any rpm range. They are almost none existent in the American car aftermarket. If that is not enough evidence for you, they are also nearly none existent in the racing world either. I do believe however that there is some evidence that high velocity merge collectors produce some gains in the upper rpm range. These gains in the upper rpm range come at a significant price increase over standard single merge collectors.

So, what is the deal with these high priced headers? For example, why is a complete long tube header setup for the new generation CTS-V under $2k when a similar set up for the C63 is well over $4k? Some people will tell you that it is to cover the additional research and development cost caused by the complexity of the C63 , but I would be willing to bet that it really comes down to two words, economics and business. The current demand for C63 headers with the current supply is such suppliers can demand a high price and customers are willing to pay for it. Once the C63 ages some and the market becomes more competitive the price of headers will fall. I think that anyone who can afford this car can understand simple economics and business. That is not to say that some of these headers do not cost more than others to produce. Anyone familiar with fabrication costs knows that you pay by the man-hour or by the weld-inch. Simply speaking, more welds equals more cost to produce, equals more cost to you. Look at the pictures posted. Which of these do you think cost the most to produce? Are all those welds really necessary? By the way, more welds does not equal more horsepower. Smooth transitions with minimal welds are typically preferred for good flow characteristics. I would be willing to bet that the MHP headers are the cheapest to produce (not the cheapest to buy, see my comment about economics and business). I would also be willing to bet that the Fluid MotorUnion headers cost the most to produce and that they don’t flow as well as some of the others.

, but I would be willing to bet that it really comes down to two words, economics and business. The current demand for C63 headers with the current supply is such suppliers can demand a high price and customers are willing to pay for it. Once the C63 ages some and the market becomes more competitive the price of headers will fall. I think that anyone who can afford this car can understand simple economics and business. That is not to say that some of these headers do not cost more than others to produce. Anyone familiar with fabrication costs knows that you pay by the man-hour or by the weld-inch. Simply speaking, more welds equals more cost to produce, equals more cost to you. Look at the pictures posted. Which of these do you think cost the most to produce? Are all those welds really necessary? By the way, more welds does not equal more horsepower. Smooth transitions with minimal welds are typically preferred for good flow characteristics. I would be willing to bet that the MHP headers are the cheapest to produce (not the cheapest to buy, see my comment about economics and business). I would also be willing to bet that the Fluid MotorUnion headers cost the most to produce and that they don’t flow as well as some of the others.

In my humble opinion, the best way to learn about aftermarket headers and exhaust modifications is by looking at the American hotrod/muscle car/sports car scene. The American car aftermarket is a huge industry compared to the MB and other Euro car aftermarkets. The market is also very competitive. It is logical to assume much, much more research has been done on headers by the American car aftermarket than Euro car aftermarket. If you take a look at the American aftermarket scene, you will see that full length, long tube headers, with one merger/collector per cylinder bank dominate the market in both power production and popularity. Why, because they work well in nearly every application. The MHP guy obviously knows this. His background is in Mustangs and SRT8s. He simply took a formula for what worked on American cars and applied it (seemingly successfully) to the C63. I am in no way endorsing MHP headers. I could never endorse headers that cost over $4k. That is absolutely ridiculous. And before someone starts talking about research and development costs, the only development cost was the cost of a skilled tradesman to build the first set and then to build the template for producing the headers. Again it is not rocket science.

But what about headers with tri-y collectors? I have never seen any evidence that they produce measurable gains over a single high velocity merge collector in any rpm range. They are almost none existent in the American car aftermarket. If that is not enough evidence for you, they are also nearly none existent in the racing world either. I do believe however that there is some evidence that high velocity merge collectors produce some gains in the upper rpm range. These gains in the upper rpm range come at a significant price increase over standard single merge collectors.

So, what is the deal with these high priced headers? For example, why is a complete long tube header setup for the new generation CTS-V under $2k when a similar set up for the C63 is well over $4k? Some people will tell you that it is to cover the additional research and development cost caused by the complexity of the C63

, but I would be willing to bet that it really comes down to two words, economics and business. The current demand for C63 headers with the current supply is such suppliers can demand a high price and customers are willing to pay for it. Once the C63 ages some and the market becomes more competitive the price of headers will fall. I think that anyone who can afford this car can understand simple economics and business. That is not to say that some of these headers do not cost more than others to produce. Anyone familiar with fabrication costs knows that you pay by the man-hour or by the weld-inch. Simply speaking, more welds equals more cost to produce, equals more cost to you. Look at the pictures posted. Which of these do you think cost the most to produce? Are all those welds really necessary? By the way, more welds does not equal more horsepower. Smooth transitions with minimal welds are typically preferred for good flow characteristics. I would be willing to bet that the MHP headers are the cheapest to produce (not the cheapest to buy, see my comment about economics and business). I would also be willing to bet that the Fluid MotorUnion headers cost the most to produce and that they don’t flow as well as some of the others.

, but I would be willing to bet that it really comes down to two words, economics and business. The current demand for C63 headers with the current supply is such suppliers can demand a high price and customers are willing to pay for it. Once the C63 ages some and the market becomes more competitive the price of headers will fall. I think that anyone who can afford this car can understand simple economics and business. That is not to say that some of these headers do not cost more than others to produce. Anyone familiar with fabrication costs knows that you pay by the man-hour or by the weld-inch. Simply speaking, more welds equals more cost to produce, equals more cost to you. Look at the pictures posted. Which of these do you think cost the most to produce? Are all those welds really necessary? By the way, more welds does not equal more horsepower. Smooth transitions with minimal welds are typically preferred for good flow characteristics. I would be willing to bet that the MHP headers are the cheapest to produce (not the cheapest to buy, see my comment about economics and business). I would also be willing to bet that the Fluid MotorUnion headers cost the most to produce and that they don’t flow as well as some of the others.

Last edited by TexasEngineer; 01-04-2011 at 08:42 PM.

#34

Member

#35

Super Moderator Alumni

Thread Starter

Join Date: Dec 2009

Location: USA

Posts: 2,189

Likes: 0

Received 6 Likes

on

4 Posts

2011 GLK 350, 2013 GT-R, & 2013 RAM 1500

Great follow-up, Tex. Thank you for adding to the technical discussion in a very data-driven manner.

This thread isn't about header pricing, etc. I'd prefer us not going down that road. It is what it is.

I'm 100% in favor of having an educated discussion of the various types of header designs.

Let's keep it civil & professional so this thread grows as a valuable resource.

This thread isn't about header pricing, etc. I'd prefer us not going down that road. It is what it is.

I'm 100% in favor of having an educated discussion of the various types of header designs.

Let's keep it civil & professional so this thread grows as a valuable resource.

#36

Former Vendor of MBWorld

Allow me to retort.. To say that Tri-y headers are non existent in racing is very very far from the truth.. Just about every NASCAR team (the biggest racing sport in the world) uses a Tri-Y header.

Being a company that makes just about every variety of long style headers, like the Tri-Y and the 4 into 1 and a 4 into 1 under the chassis (as seen on our SLK55 headers) I'll tell you this... On a stock 55NA M113 motor there is zero difference in power having the merge collector under the chassis of just before.

What you can take from the old school muscle car world is a few things. extreme mass production

mild steel being more prevalent

thin or cheaper stainless in some cases

maybe even over seas manufacturing

If you go to Burns Stainless and buy all that you need to build a set of long style headers. The price will climb fast just in parts alone. I will tell you this much the people buying from Burns Stainless are using them on their American hotrods. If we can take a guess as to why they are buying from Burns? Its most likely because the headers they used before have failed. Or simply an off the shelf header can not handle it. Is that true in all cases not, but I'm sure its true in a lot of them.

Its very easy to over look what is going on during R&D. Thats because no one is really there to see it. We are about to release our G55 long tube header. I will tell you this, We have built and rebuilt that header 6 times already before we got it right. Now going though literary 6 sets of almost fitting and performing headers and then tossing them in the scrap heap adds up extremely fast. Then you talk about paying your employees an hourly rate for a skilled trade. It just keeps adding up. Now we have to make a fixture so we can reproduce what we've just made. More materials, more labor.. Again the price keeps going up.

Using the same materials we use to build AMG headers, we also used on Dyno-Comp's champion Time Attack Subaru STI. And thats a Turbo application. For 2 years we have used 1 exhaust manifod turbo header and have had no failures. However before we started making headers and custom parts the Dyno-Comp STI would always carry a spare (no kidding around) exhaust header because the off the shelf ones would fail.

With that said we build our headers to last a lifetime and MBH and Dyno-Comp were both formed from racing. You can literary take any header that we build and run it on a car that is dedicated for track use only. They are built not to fail as they are race headers.

Look, going on popular believe got Obama elected. Sometimes what is thought to be one thing results in another. Like the myth that a 4 into 1 out performs a Tri-Y. Sure a 4 into 1 can beat out a Tri-Y, However on the flip side a Tri-Y can beat out a 4 into 1. Fact is its all about how the header is made. You have to think about what headers are being used when reading articles or web pages.

If calling into play the old test from a few years back. Pitting a 4 into 1 header vs a Tri-y on a Honda. The 4 into 1, Won the test in making about 5whp more. Now think about the quality of the Tri-Y being used in that test? fact of the matter is, Its easy to make power with a 4 into 1. Now if you pit that 4 into 1 against a properly made Tri-y the results i'm sure would be different.

When does myth become reality? It come down to the old story of the Tri-Y making more low end power vs a 4 into 1. where as the 4 into 1 makes more top end power. That myth becomes reality when the aftermarket is chalk full of quickly made, not necessarily thought out Tri-Y headers.

With that said, I make them both 4 into 1 and Tri-Y's. So I like them both. Just for S&G's In going to be switch my 4 into 1 header on my SL55 to a Tri-Y. My first guess is I will not even notice a power swing on my butt dyno.

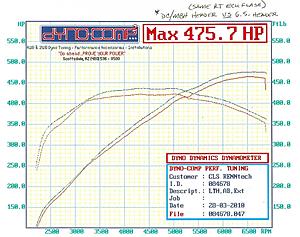

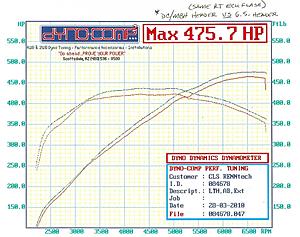

If you would like to see what our header did in a test pitted agains a 4 into 1 header on a CLS63 here is the chart. Also feel free to contact Rick "RARfinancial" and ask him what he thinks, who has had both.

Being a company that makes just about every variety of long style headers, like the Tri-Y and the 4 into 1 and a 4 into 1 under the chassis (as seen on our SLK55 headers) I'll tell you this... On a stock 55NA M113 motor there is zero difference in power having the merge collector under the chassis of just before.

What you can take from the old school muscle car world is a few things. extreme mass production

mild steel being more prevalent

thin or cheaper stainless in some cases

maybe even over seas manufacturing

If you go to Burns Stainless and buy all that you need to build a set of long style headers. The price will climb fast just in parts alone. I will tell you this much the people buying from Burns Stainless are using them on their American hotrods. If we can take a guess as to why they are buying from Burns? Its most likely because the headers they used before have failed. Or simply an off the shelf header can not handle it. Is that true in all cases not, but I'm sure its true in a lot of them.

Its very easy to over look what is going on during R&D. Thats because no one is really there to see it. We are about to release our G55 long tube header. I will tell you this, We have built and rebuilt that header 6 times already before we got it right. Now going though literary 6 sets of almost fitting and performing headers and then tossing them in the scrap heap adds up extremely fast. Then you talk about paying your employees an hourly rate for a skilled trade. It just keeps adding up. Now we have to make a fixture so we can reproduce what we've just made. More materials, more labor.. Again the price keeps going up.

Using the same materials we use to build AMG headers, we also used on Dyno-Comp's champion Time Attack Subaru STI. And thats a Turbo application. For 2 years we have used 1 exhaust manifod turbo header and have had no failures. However before we started making headers and custom parts the Dyno-Comp STI would always carry a spare (no kidding around) exhaust header because the off the shelf ones would fail.

With that said we build our headers to last a lifetime and MBH and Dyno-Comp were both formed from racing. You can literary take any header that we build and run it on a car that is dedicated for track use only. They are built not to fail as they are race headers.

Look, going on popular believe got Obama elected. Sometimes what is thought to be one thing results in another. Like the myth that a 4 into 1 out performs a Tri-Y. Sure a 4 into 1 can beat out a Tri-Y, However on the flip side a Tri-Y can beat out a 4 into 1. Fact is its all about how the header is made. You have to think about what headers are being used when reading articles or web pages.

If calling into play the old test from a few years back. Pitting a 4 into 1 header vs a Tri-y on a Honda. The 4 into 1, Won the test in making about 5whp more. Now think about the quality of the Tri-Y being used in that test? fact of the matter is, Its easy to make power with a 4 into 1. Now if you pit that 4 into 1 against a properly made Tri-y the results i'm sure would be different.

When does myth become reality? It come down to the old story of the Tri-Y making more low end power vs a 4 into 1. where as the 4 into 1 makes more top end power. That myth becomes reality when the aftermarket is chalk full of quickly made, not necessarily thought out Tri-Y headers.

With that said, I make them both 4 into 1 and Tri-Y's. So I like them both. Just for S&G's In going to be switch my 4 into 1 header on my SL55 to a Tri-Y. My first guess is I will not even notice a power swing on my butt dyno.

If you would like to see what our header did in a test pitted agains a 4 into 1 header on a CLS63 here is the chart. Also feel free to contact Rick "RARfinancial" and ask him what he thinks, who has had both.

Last edited by MBH motorsports; 01-04-2011 at 09:51 PM.

#37

PREMIER SPONSOR

Join Date: Nov 2001

Location: Huntington Beach, CA

Posts: 2,922

Likes: 0

Received 0 Likes

on

0 Posts

None fast enough!

Hooley,

I agree with so much of what you said.

Again, NASCAR - ever heard of them. Yep, Tri-Y design. But them stuupid redneks dont know nuttin bout gurman cars. lol

Good material costs a LOT more then cheap material. US thick 304 costs more then thin Chinese 304 SS.

I will not go on.

I will add that we built and test 4 headers for the 63's. 4-1 and 4-2-1 designs. The Tri-Y FAR outperformed the 4-1 in every test (dyno, HP, driveability, compatibility with the factory electronic controls, etc).

Just to add, we were the FIRST in the world to have long tubes for the 63 and we spent a very long time perfecting them. To say there is not R&D costs is very naive and shows a total lack of understanding of these cars.

It is not as easy as taking a CTSV header and making it work. That might "work" but it is not optimal for many reasons and IMHO is a short cut and a band-aid approach.

thanks

Brad

I agree with so much of what you said.

Again, NASCAR - ever heard of them. Yep, Tri-Y design. But them stuupid redneks dont know nuttin bout gurman cars. lol

Good material costs a LOT more then cheap material. US thick 304 costs more then thin Chinese 304 SS.

I will not go on.

I will add that we built and test 4 headers for the 63's. 4-1 and 4-2-1 designs. The Tri-Y FAR outperformed the 4-1 in every test (dyno, HP, driveability, compatibility with the factory electronic controls, etc).

Just to add, we were the FIRST in the world to have long tubes for the 63 and we spent a very long time perfecting them. To say there is not R&D costs is very naive and shows a total lack of understanding of these cars.

It is not as easy as taking a CTSV header and making it work. That might "work" but it is not optimal for many reasons and IMHO is a short cut and a band-aid approach.

thanks

Brad

Last edited by brad @ evosport; 01-04-2011 at 11:45 PM.

#38

Former Vendor of MBWorld

Hooley,

I agree with so much of what you said.

Again, NASCAR - ever heard of them. Yep, Tri-Y design. But them stuupid redneks dont know nuttin bout gurman cars. lol

Good material costs a LOT more then cheap material. US thick 304 costs more then thin Chinese 304 SS.

I will not go on.

I will add that we built and test 4 headers for the 63's. 4-1 and 3-2-1 designs. The Tri-Y FAR outperformed the 4-1 in every test (dyno, HP, driveability, compatibility with the factory electronic controls, etc).

Just to add, we were the FIRST in the world to have long tubes for the 63 and we spent a very long time perfecting them. To say there is not R&D costs is very naive and shows a total lack of understanding of these cars.

It is not as easy as taking a CTSV header and making it work. That might "work" but it is not optimal for many reasons and IMHO is a short cut and a band-aid approach.

thanks

Brad

I agree with so much of what you said.

Again, NASCAR - ever heard of them. Yep, Tri-Y design. But them stuupid redneks dont know nuttin bout gurman cars. lol

Good material costs a LOT more then cheap material. US thick 304 costs more then thin Chinese 304 SS.

I will not go on.

I will add that we built and test 4 headers for the 63's. 4-1 and 3-2-1 designs. The Tri-Y FAR outperformed the 4-1 in every test (dyno, HP, driveability, compatibility with the factory electronic controls, etc).

Just to add, we were the FIRST in the world to have long tubes for the 63 and we spent a very long time perfecting them. To say there is not R&D costs is very naive and shows a total lack of understanding of these cars.

It is not as easy as taking a CTSV header and making it work. That might "work" but it is not optimal for many reasons and IMHO is a short cut and a band-aid approach.

thanks

Brad

Thanks Brad, I think I can speak for you and myself by in saying.. A tri-y header is very hard to make. Not only during R&D, but reproducing them.

On another note: When I present a new order to the guys. They always joke around by saying.. "why can't we build 55 4 into 1 headers" In all honesty the 4 into 1 headers are easier to make and cost less to make them. Thats one of the reasons why our 55k header cost less than the 63.

Some of our 63 headers require what is called a 1-D tight radius 180 degree bend. Put it this way there are only so many places that have or even offer that type of mandrel bend. And when you need 6 of them... You better have paid the bill on the Amex.

#39

Super Moderator Alumni

Thread Starter

Join Date: Dec 2009

Location: USA

Posts: 2,189

Likes: 0

Received 6 Likes

on

4 Posts

2011 GLK 350, 2013 GT-R, & 2013 RAM 1500

Awesome . . . technical discussion.

Do you have a photo of the CLS63 4-into-1 header from the chart? Who made them? Were they full-length? long-tube? I'm not aware of any other full-length headers out there for the 63.

I'm surprised you mention NASCAR. That is a very specific application where headers are tuned for a narrow/high RPM band.

Can you share some data from the testing? Can you help us understand the deltas you experienced that equate to "FAR"?

I'd love to learn:

1) Where in the RPM range your long-tube Tri-Y outperformed your long-tube 4-into-1 headers. Dyno charts would be great!

2) What the HP deltas were between the two.

3) What characteristics determined outperformance in driveability.

4) What issues you ran into with electronic controls.

Thank you!

I'd love to learn:

1) Where in the RPM range your long-tube Tri-Y outperformed your long-tube 4-into-1 headers. Dyno charts would be great!

2) What the HP deltas were between the two.

3) What characteristics determined outperformance in driveability.

4) What issues you ran into with electronic controls.

Thank you!

Last edited by superlubricity; 01-04-2011 at 11:02 PM.

#40

Former Vendor of MBWorld

Awesome . . . technical discussion.

Do you have a photo of the CLS63 4-into-1 header from the chart? Who made them? Were they full-length? long-tube? I'm not aware of any other full-length headers out there for the 63.

I'm surprised you mention NASCAR. That is a very specific application where headers are tuned for a narrow/high RPM band.

Can you share some data from the testing? Can you help us understand the deltas you experienced that equate to "FAR"?

I'd love to learn:

1) Where in the RPM range your long-tube Tri-Y outperformed your long-tube 4-into-1 headers. Dyno charts would be great!

2) What the HP deltas were between the two.

3) What characteristics determined outperformance in driveability.

4) What issues you ran into with electronic controls.

Thank you!

Do you have a photo of the CLS63 4-into-1 header from the chart? Who made them? Were they full-length? long-tube? I'm not aware of any other full-length headers out there for the 63.

I'm surprised you mention NASCAR. That is a very specific application where headers are tuned for a narrow/high RPM band.

Can you share some data from the testing? Can you help us understand the deltas you experienced that equate to "FAR"?

I'd love to learn:

1) Where in the RPM range your long-tube Tri-Y outperformed your long-tube 4-into-1 headers. Dyno charts would be great!

2) What the HP deltas were between the two.

3) What characteristics determined outperformance in driveability.

4) What issues you ran into with electronic controls.

Thank you!

The long tube headers Rick had were not RENNtech headers, It was only Renntech tuning.

#42

Super Moderator Alumni

Thread Starter

Join Date: Dec 2009

Location: USA

Posts: 2,189

Likes: 0

Received 6 Likes

on

4 Posts

2011 GLK 350, 2013 GT-R, & 2013 RAM 1500

Got your PM. Thanks, MBH. I really appreciate the data.

For those interested, the CLS63 dyno graph above was comparing the MBH Full-length Tri-Y headers with a set of Goodspeed Full-length long-tube 4-into-1 headers. Worth noting the Goodspeed Headers did not have high-velocity merge collectors. You can see this difference by comparing them to a set of long-tubes that use a high-velocity merge collector.

Here is the photo of the Goodspeed long-tube. More info in this thread. -> https://mbworld.org/forums/cls55-amg...e-headers.html

Visual comparison to a 4-into-1 long-tube with a high velocity merge:

For those interested, the CLS63 dyno graph above was comparing the MBH Full-length Tri-Y headers with a set of Goodspeed Full-length long-tube 4-into-1 headers. Worth noting the Goodspeed Headers did not have high-velocity merge collectors. You can see this difference by comparing them to a set of long-tubes that use a high-velocity merge collector.

Here is the photo of the Goodspeed long-tube. More info in this thread. -> https://mbworld.org/forums/cls55-amg...e-headers.html

Visual comparison to a 4-into-1 long-tube with a high velocity merge:

#43

PREMIER SPONSOR

Join Date: Nov 2001

Location: Huntington Beach, CA

Posts: 2,922

Likes: 0

Received 0 Likes

on

0 Posts

None fast enough!

Examples of race series where the top teams use Tri-Y: NASCAR Sprint, Craftsman Truck, GT1, Pro Cup, NHRA, Daytona Prototype, Grand Am, Rolex, IHRA (some of these are verifiable on google, some are known from first hand experience).

Sophisticated computer designed 4-2-1 designs are almost always superior IF they can be built to the design the computer spits out - and that is the tough part. It is expensive and VERY time consuming.

For example. many headers you posted are not welded from multiple tubes for each primary. That is because they are pre-bent on a machine. To make true equal length or pulse tuned headers, you cannot allow for all loose bends, you must have tight radius bends in many places. This means that you are hand forming each primary from 3,4,5,6+ pieces of pipe. That equals TIME.

We sent our headers out to multiple large header fabricators to see if they could make the primaries for us pre-bent to lower the costs. ALL of them said that only 2 out of 8 could be done. LOL. They all said, change the design and it will be easier to build. However, that is not our philosophy, we don't pick inferior designs to lower cost or ease the build process.

Can you share some data from the testing? Can you help us understand the deltas you experienced that equate to "FAR"?

I'd love to learn:

1) Where in the RPM range your long-tube Tri-Y outperformed your long-tube 4-into-1 headers. Dyno charts would be great!

2) What the HP deltas were between the two.

3) What characteristics determined outperformance in driveability.

4) What issues you ran into with electronic controls.

Thank you!

I'd love to learn:

1) Where in the RPM range your long-tube Tri-Y outperformed your long-tube 4-into-1 headers. Dyno charts would be great!

2) What the HP deltas were between the two.

3) What characteristics determined outperformance in driveability.

4) What issues you ran into with electronic controls.

Thank you!

1. Anything above 3K, the tri-y was much better. The 4-1 had more initial torque, but the car (already torquey did not like it at all)

2. 5-8 wheel hp from memory.

3. the 4-2-1 header was "smoother" and more progressive.

4. severe timing and torque limitations (even with tuning)

Hope this helps. Obviously we are very proud of our headers and I think that the results speak for them.

Thanks

Brad

#44

Super Moderator Alumni

Thread Starter

Join Date: Dec 2009

Location: USA

Posts: 2,189

Likes: 0

Received 6 Likes

on

4 Posts

2011 GLK 350, 2013 GT-R, & 2013 RAM 1500

NASCAR races a lot more than super speedway. Short track, road coarse, feeder series. To think that all nascar motors are tuned for narrow RPM is not correct. Many NASCAR tracks demand 4000-5000 RPM swings. And yes, they used to ALL be 4-1, now they are all 4-2-1 (at least the teams that win). 4-1 is old tech as far as headers.

Examples of race series where the top teams use Tri-Y: NASCAR Sprint, Craftsman Truck, GT1, Pro Cup, NHRA, Daytona Prototype, Grand Am, Rolex, IHRA (some of these are verifiable on google, some are known from first hand experience).

Sophisticated computer designed 4-2-1 designs are almost always superior IF they can be built to the design the computer spits out - and that is the tough part. It is expensive and VERY time consuming.

For example. many headers you posted are not welded from multiple tubes for each primary. That is because they are pre-bent on a machine. To make true equal length or pulse tuned headers, you cannot allow for all loose bends, you must have tight radius bends in many places. This means that you are hand forming each primary from 3,4,5,6+ pieces of pipe. That equals TIME.

We sent our headers out to multiple large header fabricators to see if they could make the primaries for us pre-bent to lower the costs. ALL of them said that only 2 out of 8 could be done. LOL. They all said, change the design and it will be easier to build. However, that is not our philosophy, we don't pick inferior designs to lower cost or ease the build process.

Some, but i don't have all the dev notes in front of me (we just moved and they are boxed up), but I will try my best:

1. Anything above 3K, the tri-y was much better. The 4-1 had more initial torque, but the car (already torquey did not like it at all)

2. 5-8 wheel hp from memory.

3. the 4-2-1 header was "smoother" and more progressive.

4. severe timing and torque limitations (even with tuning)

Hope this helps. Obviously we are very proud of our headers and I think that the results speak for them.

Thanks

Brad

Examples of race series where the top teams use Tri-Y: NASCAR Sprint, Craftsman Truck, GT1, Pro Cup, NHRA, Daytona Prototype, Grand Am, Rolex, IHRA (some of these are verifiable on google, some are known from first hand experience).

Sophisticated computer designed 4-2-1 designs are almost always superior IF they can be built to the design the computer spits out - and that is the tough part. It is expensive and VERY time consuming.

For example. many headers you posted are not welded from multiple tubes for each primary. That is because they are pre-bent on a machine. To make true equal length or pulse tuned headers, you cannot allow for all loose bends, you must have tight radius bends in many places. This means that you are hand forming each primary from 3,4,5,6+ pieces of pipe. That equals TIME.

We sent our headers out to multiple large header fabricators to see if they could make the primaries for us pre-bent to lower the costs. ALL of them said that only 2 out of 8 could be done. LOL. They all said, change the design and it will be easier to build. However, that is not our philosophy, we don't pick inferior designs to lower cost or ease the build process.

Some, but i don't have all the dev notes in front of me (we just moved and they are boxed up), but I will try my best:

1. Anything above 3K, the tri-y was much better. The 4-1 had more initial torque, but the car (already torquey did not like it at all)

2. 5-8 wheel hp from memory.

3. the 4-2-1 header was "smoother" and more progressive.

4. severe timing and torque limitations (even with tuning)

Hope this helps. Obviously we are very proud of our headers and I think that the results speak for them.

Thanks

Brad

I'm on the naysayer side of the fence re: equal length and it's relevance at these horsepower levels. We'll have to agree to disagree there.

I'm certainly on the less bends, less welds and more straight pipe will lead to more power across the board side of the fence . . . especially right before the collector. In fact, I'm a firm believe in the effectiveness of the right high velocity merge collector. There is a great article with some independent data here. -> http://www.carcraft.com/techarticles...tem/index.html

When you guys get settled, please grab that test data. It would make a great addition to the thread. I'd love to see some of the previous designs as well.

#45

Former Vendor of MBWorld

Got your PM. Thanks, MBH. I really appreciate the data.

For those interested, the CLS63 dyno graph above was comparing the MBH Full-length Tri-Y headers with a set of Goodspeed Full-length long-tube 4-into-1 headers. Worth noting the Goodspeed Headers did not have high-velocity merge collectors. You can see this difference by comparing them to a set of long-tubes that use a high-velocity merge collector.

For those interested, the CLS63 dyno graph above was comparing the MBH Full-length Tri-Y headers with a set of Goodspeed Full-length long-tube 4-into-1 headers. Worth noting the Goodspeed Headers did not have high-velocity merge collectors. You can see this difference by comparing them to a set of long-tubes that use a high-velocity merge collector.

If a collector did not have the flow pyramid inside it would be known as a "stamped collector" basically enough. The term high volocity merge collector is more of an advertising term.

An example of this is our prototype 55 header. It had what you are referring to as a high velocity merge collector. We then dumped that design and eliminated the slip fit aspect of that header and went with a solid state merge collector. What I'm trying to say is... the internal workings of the header are exactly the same.

As seen here

merge collector with slip fit

with a solid state merge collector

collector pyramid making it a true merge collector

Last edited by MBH motorsports; 01-05-2011 at 12:11 AM.

#46

Super Moderator Alumni

Thread Starter

Join Date: Dec 2009

Location: USA

Posts: 2,189

Likes: 0

Received 6 Likes

on

4 Posts

2011 GLK 350, 2013 GT-R, & 2013 RAM 1500

Actually that is. the internal working of that collector are the same as one shown in the MHP pic. the extended part on the MHP collector in meant for slip-fit. Now say if you cut the slip fit area off and just welded the collector to the header it would be the same thing. A merge collector is a collector that has a flow pyramid inside that merges all teh exhaust gases together smoothly. Reducing internal turbulence and optimizing flow. We use this on out 55 headers.

If a collector did not have the flow pyramid inside it would be known as a "stamped collector" basically enough. The term high volocity merge collector is more of an advertising term.

An example of this is our prototype 55 header. It had what you are referring to as a high velocity merge collector. We then dumped that design and eliminated the slip fit aspect of that headerand went with a solid state merge collector. What I'm trying to say is... the internal workings of the header are exactly the same.

If a collector did not have the flow pyramid inside it would be known as a "stamped collector" basically enough. The term high volocity merge collector is more of an advertising term.

An example of this is our prototype 55 header. It had what you are referring to as a high velocity merge collector. We then dumped that design and eliminated the slip fit aspect of that headerand went with a solid state merge collector. What I'm trying to say is... the internal workings of the header are exactly the same.

I do believe it's more than just the pyramid. The length of pipe before the collector, the length of the collector and the right reduction in diameter (cone/funnel) right before entering the mid-pipes all play a big roll in the scavenging and power output.

#47

Former Vendor of MBWorld

Again, good data. Thank you.

I do believe it's more than just the pyramid. The length of pipe before the collector, the length of the collector and the right reduction in diameter (cone/funnel) right before entering the mid-pipes all play a big roll in the scavenging and power output.

I do believe it's more than just the pyramid. The length of pipe before the collector, the length of the collector and the right reduction in diameter (cone/funnel) right before entering the mid-pipes all play a big roll in the scavenging and power output.

Please note: I am a huge fan of slip fit collectors, however the amount a header grows on an AMG is about 1/4 inch during heat cycles. There is ample movement in the whole exhaust system to allow for that. Plus a lot of header system are using bolts rather than springs when using a slip fit merge collector. the problem with that is they are very ridged compared to springs. Secondly, i've seen and experimented with headers with springs to help coax the header back to its original point. Point is, some springs of that size are not able to return the header to its location after expansion. Due to some form of mechanical lock. I mean if you ever tried to pull a slip fit collector completely off... its not easy.

#48

Super Moderator Alumni

Thread Starter

Join Date: Dec 2009

Location: USA

Posts: 2,189

Likes: 0

Received 6 Likes

on

4 Posts

2011 GLK 350, 2013 GT-R, & 2013 RAM 1500

If you see the top pic above, of our old header. It looks shorter than the new version. Thats because the the old headers have the pipes fitted inside the slip fit collector. Where as the new one has them at full extension. you actually are not gaining anything in terms of length. If anything the new way we make the header is having more usable runner piping becasue a slip fit collector will never reach full extension under heat..

#49

Excellent thread Super!!!

A few points to be made:

1) No offense to Evosport but MHP was actually the first manufacturer to make LT headers for the C63, both in prototype and final production form.

2) Look at any F1 or Indy header made from 1990+ they are all 4 or 5 into 1. The Tri-Y design was originally conceived by Ford due to lack of space in the engine compartment in the late 1960s, so it's far from new tech.

3) You guys have some nice camera's, time for me to upgrade

I think at this point, meaning enough headers have been sold and cars raced to figure out on your own what design is making the most power. Everything else is just opinion no matter who you ask.

A few points to be made:

1) No offense to Evosport but MHP was actually the first manufacturer to make LT headers for the C63, both in prototype and final production form.

2) Look at any F1 or Indy header made from 1990+ they are all 4 or 5 into 1. The Tri-Y design was originally conceived by Ford due to lack of space in the engine compartment in the late 1960s, so it's far from new tech.

3) You guys have some nice camera's, time for me to upgrade

I think at this point, meaning enough headers have been sold and cars raced to figure out on your own what design is making the most power. Everything else is just opinion no matter who you ask.

#50

Super Moderator Alumni

Thread Starter

Join Date: Dec 2009

Location: USA

Posts: 2,189

Likes: 0

Received 6 Likes

on

4 Posts

2011 GLK 350, 2013 GT-R, & 2013 RAM 1500

I don't think evosport ever claimed that. They certainly pioneered 63 header development in early 2008 with their long-tube Tri-Y headers for the CLK63 BS. This was a full year before MHP started working on the C63 headers.