CLK convertible top problem solving: common electrical and hydraulic system failures

#101

Newbie

Join Date: Aug 2014

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

Mercedes clk 200 komp cabrio w208

Quick cable repair

For those of you who are having problems with the cables and want to do a quick and easy repair, try the following part.

http://www.inox-expert.com/en/ware/11

Use the KLE02.

I had the usual problem of the cable ends coming off. With this all you need to do is remove the plastic bushing located in the cross beam (sorry no pics, it was a bit dark), this can be a bit awkward but can be pushed out using a small screwdriver. Then fit the crimp at the end of the cable. Remove the Allen key tensioning screw if the cable is a bit frayed, push a good part of the cabel into the crimp and slide the crimp right to the end of the cable. Refit the Allen key screw and tighten (a lot). Press the plastic bushings over the cable and pull through the hole in the cross beam.

I work as a yacht rigger and have used these parts for many years. It wont rust and can be adjusted easily to increase or decrease cable tension easily.

Hope this helps.

http://www.inox-expert.com/en/ware/11

Use the KLE02.

I had the usual problem of the cable ends coming off. With this all you need to do is remove the plastic bushing located in the cross beam (sorry no pics, it was a bit dark), this can be a bit awkward but can be pushed out using a small screwdriver. Then fit the crimp at the end of the cable. Remove the Allen key tensioning screw if the cable is a bit frayed, push a good part of the cabel into the crimp and slide the crimp right to the end of the cable. Refit the Allen key screw and tighten (a lot). Press the plastic bushings over the cable and pull through the hole in the cross beam.

I work as a yacht rigger and have used these parts for many years. It wont rust and can be adjusted easily to increase or decrease cable tension easily.

Hope this helps.

#102

Junior Member

Join Date: May 2006

Location: chicago

Posts: 62

Received 0 Likes

on

0 Posts

clk 430 cabriolet

Great thread. I recently ran into an issue with my top but not sure where to start. All of a sudden, nothing happens when I unlatch the top. The windows do not go down. In fact, when the top is secured, the none of the windows even work. I open the trunk to check fuses and noticed that the trunk light is every few seconds flickers and I can hear a light clicking. Also, when I am driving and start to slow down, the passenger side mirrors begins to turn and go downward as if I am in reverse. I start to speed up an it corrects....Seems a bit bizarre...

#103

MBWorld Fanatic!

lawrdent.....I believe the problem with your power roof operation, has nothing to do with the usual issues pertaining to power roof failures, but your posting history of electrical issues and the other currently mentioned bizarre occurrences, I suspect your issue is within the CAN-Buss (e.g. ControllerAreaNetwork).

While when the main power roof switch is activated, passes an electrical current flows to ground from the the power-roof/rollbar controller. This current has different values, corresponding to electrical resistance (e.g. voltage encoding), such that the controller can recognize the window switch positions (e.g. on the center console).

That said, enclosed is a CAN-Bus diagram.

Note that the control of the outside mirrors, windows all relate to an issue within the CAN-Bus.

At this time, having a STAR diagnostic analysis done on your vehicle, would be in order.

While when the main power roof switch is activated, passes an electrical current flows to ground from the the power-roof/rollbar controller. This current has different values, corresponding to electrical resistance (e.g. voltage encoding), such that the controller can recognize the window switch positions (e.g. on the center console).

That said, enclosed is a CAN-Bus diagram.

Note that the control of the outside mirrors, windows all relate to an issue within the CAN-Bus.

At this time, having a STAR diagnostic analysis done on your vehicle, would be in order.

#104

MBWorld Fanatic!

Join Date: Oct 2012

Location: Florida

Posts: 1,425

Received 98 Likes

on

88 Posts

2002 CLK 55 AMG cabriolet Eurocharged

lawrdent,

Serendipity could be right, My theory is the alternator is not charging properly or there is a main power/ground connection problem somewhere in the car.

Front or rear SAM connections or a corroded battery connection.

Hunch: as the engine revs the voltage climbs high enough to restore all control and memory functions.

You might have to get dirty here with the multi-meter.

Cheers, Gator

Serendipity could be right, My theory is the alternator is not charging properly or there is a main power/ground connection problem somewhere in the car.

Front or rear SAM connections or a corroded battery connection.

Hunch: as the engine revs the voltage climbs high enough to restore all control and memory functions.

You might have to get dirty here with the multi-meter.

Cheers, Gator

#105

CLK convertible top problem solving: common electrical and hydraulic system failures

First time poster so please excuse my mistakes

I have the following issue with my 2003 CLK 430.The mechanic has told me that the leak in question is coming from my convertible top drive pump area with the following required.

"The lines now come with a "ram", which acts like an actuator in the system. There is no longer a separate, serviceable o-ring for each of the two lines into the ram. Each line is $383.060, (two are required) and the ram is $1261.25. Once our technician has a chance to re inspect the condition of the fluid, we would know if we need to flush the rest of the system, or if we could simply top up the hydraulic fluid. If we did not need to flush the fluid, your total investment would be $2753, taxes included, with only the addition of the amount of fluid we would need to top up. The parts are still only available from Germany. "

Can you help? I have attached a diagram illustrating that was sent to me.

Many thanks in advance.

I have the following issue with my 2003 CLK 430.The mechanic has told me that the leak in question is coming from my convertible top drive pump area with the following required.

"The lines now come with a "ram", which acts like an actuator in the system. There is no longer a separate, serviceable o-ring for each of the two lines into the ram. Each line is $383.060, (two are required) and the ram is $1261.25. Once our technician has a chance to re inspect the condition of the fluid, we would know if we need to flush the rest of the system, or if we could simply top up the hydraulic fluid. If we did not need to flush the fluid, your total investment would be $2753, taxes included, with only the addition of the amount of fluid we would need to top up. The parts are still only available from Germany. "

Can you help? I have attached a diagram illustrating that was sent to me.

Many thanks in advance.

#106

SPONSOR

First time poster so please excuse my mistakes

I have the following issue with my 2003 CLK 430.The mechanic has told me that the leak in question is coming from my convertible top drive pump area with the following required.

"The lines now come with a "ram", which acts like an actuator in the system. There is no longer a separate, serviceable o-ring for each of the two lines into the ram. Each line is $383.060, (two are required) and the ram is $1261.25. Once our technician has a chance to re inspect the condition of the fluid, we would know if we need to flush the rest of the system, or if we could simply top up the hydraulic fluid. If we did not need to flush the fluid, your total investment would be $2753, taxes included, with only the addition of the amount of fluid we would need to top up. The parts are still only available from Germany. "

Can you help? I have attached a diagram illustrating that was sent to me.

Many thanks in advance.

I have the following issue with my 2003 CLK 430.The mechanic has told me that the leak in question is coming from my convertible top drive pump area with the following required.

"The lines now come with a "ram", which acts like an actuator in the system. There is no longer a separate, serviceable o-ring for each of the two lines into the ram. Each line is $383.060, (two are required) and the ram is $1261.25. Once our technician has a chance to re inspect the condition of the fluid, we would know if we need to flush the rest of the system, or if we could simply top up the hydraulic fluid. If we did not need to flush the fluid, your total investment would be $2753, taxes included, with only the addition of the amount of fluid we would need to top up. The parts are still only available from Germany. "

Can you help? I have attached a diagram illustrating that was sent to me.

Many thanks in advance.

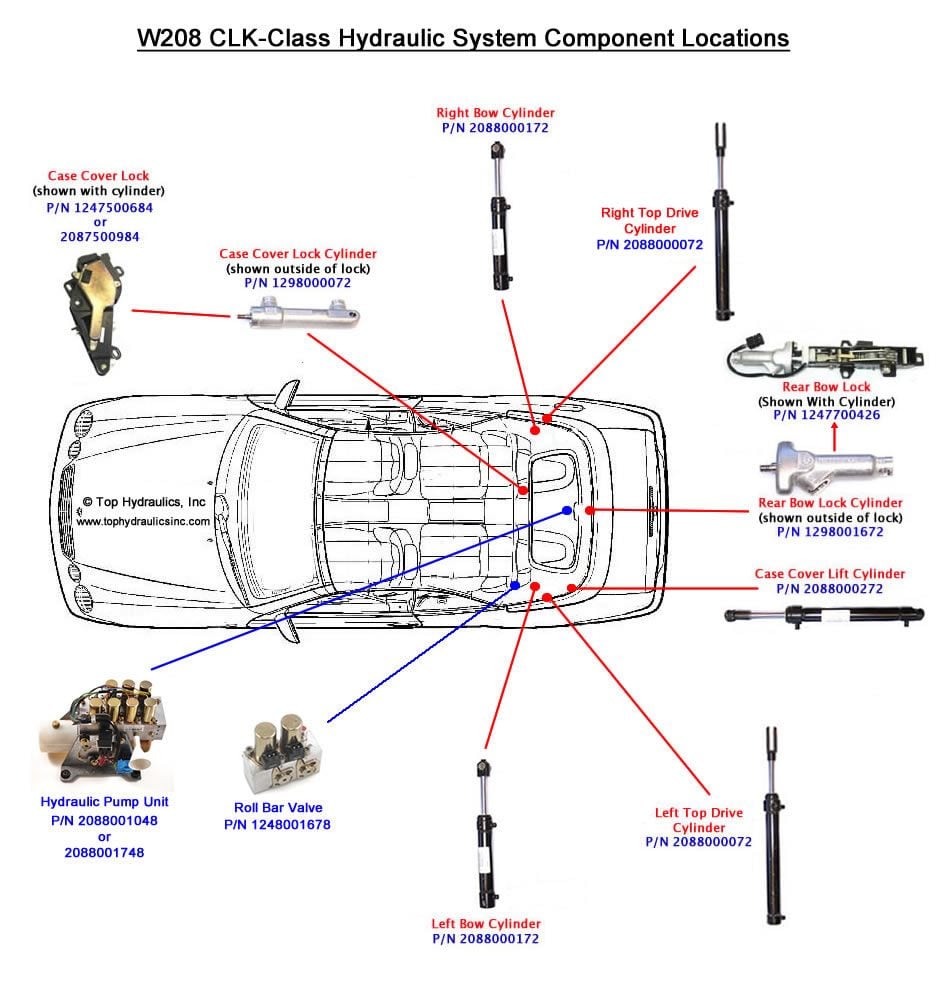

I am attaching below the diagram that you are referencing, which you sent me in a separate email.

Folks, I believe that Guytho is located in Canada, where Mercedes parts tend to be more expensive.

Guytho, could you please get clarification from your mechanic as to what is really leaking, and whether he is positive that the lines cannot be purchased separately?

Your mechanic has highlighted items 340, 350, and 160. That would be the following parts in Mercedes' database:

340: p/n A 208 800 07 81 "Line, valve block to cylinder for soft top bow right, piston side no. 96"

350: p/n A 208 800 08 72 "Line, valve block to cylinder for soft top bow right, rod side no. 87"

160: p/n A 208 800 01 72 "Cylinder, fabric retaining bow to folding top"

Why does your mechanic want you to buy two hydraulic lines? Are they both cut or damaged?

I refer to the cylinder as the "bow cylinder" or the "bow tension cylinder". See location diagram below. The cylinder p/n 2088000172 has an MSRP of some $670 in the US. Top Hydraulics rebuilds it and makes it better than a brand new one for $160. We also offer core exchange, for $190 plus core deposit. See http://www.tophydraulicsinc.com/en/w...-bow-w208.html.

I have never seen an o-ring between the hydraulic lines and the cylinders on a W208 - I always thought the MB parts drawing was wrong.

We can also manufacture the hydraulic lines for you. The hydraulic lines that fail most frequently, are lines 44 & 47 going to the rear bow lock (p/n A 208 800 13 81 and A 208 800 14 81). See http://www.tophydraulicsinc.com/en/w...nvertible.html. I haven't heard yet that the lines cannot be purchased separately from the cylinder, but maybe that is true in Canada.

Maybe your mechanic mistook a leak from the top of the bow cylinder, with fluid subsequently running down the cylinder and the hydraulic lines, as a leak from a hydraulic line. Maybe he even thought there was an o-ring between the cylinder and the line, and one thing led to another with him finally quoting you the cylinder and lines together for some awful price. I'm not saying that your mechanic is bad or dishonest. You may just want to get clarification.

Let's not get ahead of ourselves, and find out first what is really needed.

Below is Top Hydraulics' location diagram, and at the bottom of the post is the highlighted drawing that you emailed me.

Location of your W208 CLK-Class Cabriolet Hydraulics

Klaus

www.tophydraulicsinc.com

#107

Klaus,

Thank you for your prompt response.

I am asking the shop, who are usually pretty reliable, the hard questions. I noted from the invoice identifying the resolution of the problem that

" during close one line is spraying hydraulic fluid causing the leak".

I look forward to the explanation from the shop and will respond to this post accordingly.

Once again, thanks for your help.

Thank you for your prompt response.

I am asking the shop, who are usually pretty reliable, the hard questions. I noted from the invoice identifying the resolution of the problem that

" during close one line is spraying hydraulic fluid causing the leak".

I look forward to the explanation from the shop and will respond to this post accordingly.

Once again, thanks for your help.

#108

Klaus,

I have spoken with shop and they believe your suggestions may work but are looking into it. I will be posting again when I here back.

Thank you for your assistance. Hopefully this works

I have spoken with shop and they believe your suggestions may work but are looking into it. I will be posting again when I here back.

Thank you for your assistance. Hopefully this works

#109

Klaus,

The shop have been helpful with your input. The essence of they response to my question is as follows:

"Where the one identified line was leaking, we inspected the other and confirmed it looked very weak at the same point. (Aged) Our technician had identified the need to replace both of them, due to the condition of the second one, and the labor overlap to do them both verses just one. (It was explained to me there is flex with those lines.) Knowing the system needs to get up to pressure, his concern was fixing the one leak would amplify the pressure on the second deteriorating hose - cause the leak to occur on the second hose, thus starting all over again, and paying the same labor again.

The ram was an experienced precautionary replacement due to the O-rings inside. The technician was explaining where these lines are removed from the ram tends to leak due to the o-ring. Having said that, he would not be able to confirm it will/wont leak until the system is filled and back up to pressure. Much like the lines, this was suspected to be an issue, however unable to completely confirm at the time of inspection due to the size of the leak from the one confirmed line."

I would be happy to replace both lines but do not think I want to proceed with the ram. I find the O ring issue to be one I could live with.Your thoughts?You have been extremely helpful in this matter. I commend your interest and expertise.

Do you carry the following parts:

line # 208 800 07 81

line # 208 800 08 81

and if so what cost shipped to Calgary Canada.

I am being quoted 383.06 per line plus an extra 50/hour on top of the shop rate to install (due to not being their parts).

The shop have been helpful with your input. The essence of they response to my question is as follows:

"Where the one identified line was leaking, we inspected the other and confirmed it looked very weak at the same point. (Aged) Our technician had identified the need to replace both of them, due to the condition of the second one, and the labor overlap to do them both verses just one. (It was explained to me there is flex with those lines.) Knowing the system needs to get up to pressure, his concern was fixing the one leak would amplify the pressure on the second deteriorating hose - cause the leak to occur on the second hose, thus starting all over again, and paying the same labor again.

The ram was an experienced precautionary replacement due to the O-rings inside. The technician was explaining where these lines are removed from the ram tends to leak due to the o-ring. Having said that, he would not be able to confirm it will/wont leak until the system is filled and back up to pressure. Much like the lines, this was suspected to be an issue, however unable to completely confirm at the time of inspection due to the size of the leak from the one confirmed line."

I would be happy to replace both lines but do not think I want to proceed with the ram. I find the O ring issue to be one I could live with.Your thoughts?You have been extremely helpful in this matter. I commend your interest and expertise.

Do you carry the following parts:

line # 208 800 07 81

line # 208 800 08 81

and if so what cost shipped to Calgary Canada.

I am being quoted 383.06 per line plus an extra 50/hour on top of the shop rate to install (due to not being their parts).

#110

SPONSOR

Klaus,

The shop have been helpful with your input. The essence of they response to my question is as follows:

"Where the one identified line was leaking, we inspected the other and confirmed it looked very weak at the same point. (Aged) Our technician had identified the need to replace both of them, due to the condition of the second one, and the labor overlap to do them both verses just one. (It was explained to me there is flex with those lines.) Knowing the system needs to get up to pressure, his concern was fixing the one leak would amplify the pressure on the second deteriorating hose - cause the leak to occur on the second hose, thus starting all over again, and paying the same labor again.

The ram was an experienced precautionary replacement due to the O-rings inside. The technician was explaining where these lines are removed from the ram tends to leak due to the o-ring. Having said that, he would not be able to confirm it will/wont leak until the system is filled and back up to pressure. Much like the lines, this was suspected to be an issue, however unable to completely confirm at the time of inspection due to the size of the leak from the one confirmed line."

I would be happy to replace both lines but do not think I want to proceed with the ram. I find the O ring issue to be one I could live with.Your thoughts?You have been extremely helpful in this matter. I commend your interest and expertise.

Do you carry the following parts:

line # 208 800 07 81

line # 208 800 08 81

and if so what cost shipped to Calgary Canada.

I am being quoted 383.06 per line plus an extra 50/hour on top of the shop rate to install (due to not being their parts).

The shop have been helpful with your input. The essence of they response to my question is as follows:

"Where the one identified line was leaking, we inspected the other and confirmed it looked very weak at the same point. (Aged) Our technician had identified the need to replace both of them, due to the condition of the second one, and the labor overlap to do them both verses just one. (It was explained to me there is flex with those lines.) Knowing the system needs to get up to pressure, his concern was fixing the one leak would amplify the pressure on the second deteriorating hose - cause the leak to occur on the second hose, thus starting all over again, and paying the same labor again.

The ram was an experienced precautionary replacement due to the O-rings inside. The technician was explaining where these lines are removed from the ram tends to leak due to the o-ring. Having said that, he would not be able to confirm it will/wont leak until the system is filled and back up to pressure. Much like the lines, this was suspected to be an issue, however unable to completely confirm at the time of inspection due to the size of the leak from the one confirmed line."

I would be happy to replace both lines but do not think I want to proceed with the ram. I find the O ring issue to be one I could live with.Your thoughts?You have been extremely helpful in this matter. I commend your interest and expertise.

Do you carry the following parts:

line # 208 800 07 81

line # 208 800 08 81

and if so what cost shipped to Calgary Canada.

I am being quoted 383.06 per line plus an extra 50/hour on top of the shop rate to install (due to not being their parts).

We would be happy to sell you the lines you need for less than half of what you are quoted. We can manufacture them with OEM fittings and brand new OEM hose. However, the explanation you were given does not feel quite right. It's only a gut feel - I'm not saying that your mechanic is dishonest or incompetent; they may just not have much experience with this particular issue. In the first place, I am perplexed about them charging extra if you do not use their expensive parts.

Here is my comment about your mechanic's take on the o-ring. There is an o-ring in the Mercedes parts diagram, but to the best of my knowledge, that is a mistake. As far as I know, that o-ring does not exist, and it is not available for sale. On my end, I have never seen an o-ring where the hydraulic line goes into the steel cylinder (I have had thousands of CLK cylinders going through my hands), and there is no good reason to replace the cylinder only because the hydraulic line gets replaced, unless you have an early model R129 SL-Class that never had its cylinders replaced or upgraded. The cylinders have a port seal built into them, which is NOT a separate o-ring. The port seal is part of the cylinder, and it creates the seal between the cylinder and the hydraulic line. It is true that your CLK will sooner or later leak from the hydraulic cylinders, but that is not related to a hydraulic line replacement.

The only hydraulic lines that fail somewhat frequently on the W208 CLK, are lines 44 & 47 going to the rear bow lock (p/n A 208 800 13 81 & A 208 800 14 81) http://www.tophydraulicsinc.com/en/w...nvertible.html, as well as lines 37 & 54 going to the tonnau cover lift cylinder (p/n A 208 800 09 81 & 208 800 10 81). Please do the forum a favor and insist that your mechanic give you the old lines after the job is done. That way, you can take photos of the damage and ascertain that the second line was indeed "weak". Maybe lines 87 & 96 are indeed a trouble spot that needs to be pointed out in this thread.

Maybe the following explains the thinking of your mechanic: if they looked up the part numbers in Mercedes' database and tried to get pricing for lines 87 & 96 (p/n A 208 800 07 81 and A 208 800 08 81 as you are asking for) plus the o-ring in the database, then they were told that the o-ring cannot be purchased. [Comment: because having that o-ring in the parts diagram was a mistake in the first place.] That may have made them come to the conclusion that they must purchase cylinder and lines together because there may have been a change.

I hope this helps.

Klaus

www.tophydraulicsinc.com

#111

Hydraulic line replacement for 2003 CLK convertible top

OK so here goes! I booked into the mechanic April 7th with the replacement lines and will see if all works according to plan.I am still being charged a labor surcharge for providing my own lines. I am also asking for the old lines.

#112

2003 CLK convertible top

As the second part of my saga, my indy shop now reports that the control module for my convertible top needs replacing. I find this to be very coincidental to the work they just did to replace the hydraulic lines that Top Hydraulics supplied, which worked perfectly. Klaus's advice re the parts diagram being incorrect was confirmed by the indy shop so Klaus is a gem.Great service. Very happy with him not so much my indy shop.

I guess I am upset that the top worked for one cycle and suddenly I need a $1000 part plus $500 to install. (Cdn)

Does anyone have a less expensive source? Is there something going on with my shop I should be concerned about?

I guess I am upset that the top worked for one cycle and suddenly I need a $1000 part plus $500 to install. (Cdn)

Does anyone have a less expensive source? Is there something going on with my shop I should be concerned about?

#113

MBWorld Fanatic!

Guytho

My concern is that, without a detailed diagnosis (e.g. failure symptoms / analysis), if you keep throwing parts at the problem, soon the cost of repair may be more than the current value of the car.

That said, a far less expensive source for a replacement controller would be a part-out, EBay or from one of the large salvage yards for recycled parts. For example........Potomac German Auto.

http://www.pgauto.com/

If the trunk's access panel to the power roof components is still off, replacement of the controller should take less than 30 minutes time (e.g. remove connectors, unbolt controller and reinstall connectors).

However, before you go there, you need a better diagnosis of the problem.

Controller operation requires specific inputs, communication with the CANBus and then provides outputs. This is shown on page 1 of this thread, in the first thumbnail enclosed in post #16. The next thumbnail, shows the 12 stages that the power roof goes through to close (e.g. reverse the order for for opening). The next 2 thumbnails show the required conditions that each position/limit switch must provide as a controller input, during each stage, to continue operation. Likewise, the outputs should be verified, as well as the functionality of the associated systems / components (e.g. motors, relays, solenoid locks etc..

Point being that, much more often than not, failure of the power roof has been attributed to a fault with controller input/output and not the controller.

My concern is that, without a detailed diagnosis (e.g. failure symptoms / analysis), if you keep throwing parts at the problem, soon the cost of repair may be more than the current value of the car.

That said, a far less expensive source for a replacement controller would be a part-out, EBay or from one of the large salvage yards for recycled parts. For example........Potomac German Auto.

http://www.pgauto.com/

If the trunk's access panel to the power roof components is still off, replacement of the controller should take less than 30 minutes time (e.g. remove connectors, unbolt controller and reinstall connectors).

However, before you go there, you need a better diagnosis of the problem.

Controller operation requires specific inputs, communication with the CANBus and then provides outputs. This is shown on page 1 of this thread, in the first thumbnail enclosed in post #16. The next thumbnail, shows the 12 stages that the power roof goes through to close (e.g. reverse the order for for opening). The next 2 thumbnails show the required conditions that each position/limit switch must provide as a controller input, during each stage, to continue operation. Likewise, the outputs should be verified, as well as the functionality of the associated systems / components (e.g. motors, relays, solenoid locks etc..

Point being that, much more often than not, failure of the power roof has been attributed to a fault with controller input/output and not the controller.

#114

Thanks for the response S. An analysis was performed as follows:

Labor:

Scan And Print Fault Codes- 2 Current, 1 Stored

Fault In Soft Top Module. B1650-time For

Reaching Limit Switch Exceeded- For Soft Top

Closed.

B1647- Power Solenoid Valve/power Window

Motor Open Circuit

B1000 N52 Control Module Fault.

Cleared Fault Codes And Tested Roof Operation-

Roof Still Does Not Function- Indicator Light In

Switch For Roll Bar And Soft Top Do Not Function.

Roll Bar Also Does Not Work.

Scan Tool Indicates That The Lights Should Be

On.

( R ) Recommend To Replace The Soft Top

Control Module And Retest Operation

Do you see anything out of the ordinary? Is this a sufficient diagnosis or just cut to the heart and hope it works!

Labor:

Scan And Print Fault Codes- 2 Current, 1 Stored

Fault In Soft Top Module. B1650-time For

Reaching Limit Switch Exceeded- For Soft Top

Closed.

B1647- Power Solenoid Valve/power Window

Motor Open Circuit

B1000 N52 Control Module Fault.

Cleared Fault Codes And Tested Roof Operation-

Roof Still Does Not Function- Indicator Light In

Switch For Roll Bar And Soft Top Do Not Function.

Roll Bar Also Does Not Work.

Scan Tool Indicates That The Lights Should Be

On.

( R ) Recommend To Replace The Soft Top

Control Module And Retest Operation

Do you see anything out of the ordinary? Is this a sufficient diagnosis or just cut to the heart and hope it works!

#115

MBWorld Fanatic!

Guytho

Glad to see an analysis using the MB SDS diagnostic tool was done. I take it that the fault codes, which may have been caused by malfunctioning of the hydraulic lines, were cleared and thereafter, the power roof only worked for 1 cycle. At present the lamps in the roll bar and soft top switches do not light and the scan tool indicates that the should. I would agree. Actually, as outlined the last thumb nail in post #16 above, illumination conditions of the lamp in main soft top switch, serves to provide some basic diagnostic information. Also note, from the first thumb nail, that these lamps (S84 and S81) are also outputs of the N52 roof/roll bar controller. While the controller is not operative, I'm not convinced that your shop's recommendation to replace the controller at this time is the proper course of action.

For example, a controller that is not receiving electrical power will also be inoperative.

See the following thread https://mbworld.org/forums/clk-class...top-fixed.html

Referring to the electrical diagram in the initial post, the battery (labeled G1) supply's power to operate the roof through several fuses. Specifically, in fuse block F4, located inside the trunk behind the battery, there are 2 fused circuits. The circuit to power the controller is provided through a 15A fuse at position #11.

If this fuse is blown or making poor contact with the fuse block, the controller will be inoperative. Additionally, there also a fuse in block F1 as well as the controller's electrical circuit ground returns (e.g. needed to complete the power flow and shown in the diagram's upper right corner going to W7 chassis ground), that bear checking.

Glad to see an analysis using the MB SDS diagnostic tool was done. I take it that the fault codes, which may have been caused by malfunctioning of the hydraulic lines, were cleared and thereafter, the power roof only worked for 1 cycle. At present the lamps in the roll bar and soft top switches do not light and the scan tool indicates that the should. I would agree. Actually, as outlined the last thumb nail in post #16 above, illumination conditions of the lamp in main soft top switch, serves to provide some basic diagnostic information. Also note, from the first thumb nail, that these lamps (S84 and S81) are also outputs of the N52 roof/roll bar controller. While the controller is not operative, I'm not convinced that your shop's recommendation to replace the controller at this time is the proper course of action.

For example, a controller that is not receiving electrical power will also be inoperative.

See the following thread https://mbworld.org/forums/clk-class...top-fixed.html

Referring to the electrical diagram in the initial post, the battery (labeled G1) supply's power to operate the roof through several fuses. Specifically, in fuse block F4, located inside the trunk behind the battery, there are 2 fused circuits. The circuit to power the controller is provided through a 15A fuse at position #11.

If this fuse is blown or making poor contact with the fuse block, the controller will be inoperative. Additionally, there also a fuse in block F1 as well as the controller's electrical circuit ground returns (e.g. needed to complete the power flow and shown in the diagram's upper right corner going to W7 chassis ground), that bear checking.

#116

Thanks S

I am going to ask my shop to check. What are the chances they will acknowledge it may be the issue, if their rep is on the line! I will try however.

I thank the forum, S and Klaus for their help.

I am going to ask my shop to check. What are the chances they will acknowledge it may be the issue, if their rep is on the line! I will try however.

I thank the forum, S and Klaus for their help.

#117

Newbie

Join Date: Apr 2015

Location: Mechelen, Belgium

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

w208 cabrio 1999

w208 softtop hydraulic pump motor

Hello everybody...

I've got a burned motor on the softtop hydraulics pump.

Can't find any MB partnr on the motor itself, do you know if I can buy it separately, or maybe an alternative to genuine MB?

I also read somewhere that the thermal protection in it (thermocouple or thermistor) is set too high and you should replace it.

You have any more info? Like what is the power rating of the motor, and what kind of protection does (should) it have?

That said... I still don't have a clue (yet) why the motor got fried in the first place.

A couple of days ago I closed my roof, and when the closing sequence ended the damn thing just kept on going when I released the control button, even when I switched the ignition off.

By the time I got to the correct fuse box and figured out which one to pull the damage was done...

It could have been the relay. I checked it and it worked, but it's always possible it got stuck on the moment of destruction. Another possibility would be one of the limit switches not working, but then I would assume it would stop iso continuing, I reckon it would stop in any case when you release the control button... right?

Any help is greatly appreciated...

Thanks in advance!!

I've got a burned motor on the softtop hydraulics pump.

Can't find any MB partnr on the motor itself, do you know if I can buy it separately, or maybe an alternative to genuine MB?

I also read somewhere that the thermal protection in it (thermocouple or thermistor) is set too high and you should replace it.

You have any more info? Like what is the power rating of the motor, and what kind of protection does (should) it have?

That said... I still don't have a clue (yet) why the motor got fried in the first place.

A couple of days ago I closed my roof, and when the closing sequence ended the damn thing just kept on going when I released the control button, even when I switched the ignition off.

By the time I got to the correct fuse box and figured out which one to pull the damage was done...

It could have been the relay. I checked it and it worked, but it's always possible it got stuck on the moment of destruction. Another possibility would be one of the limit switches not working, but then I would assume it would stop iso continuing, I reckon it would stop in any case when you release the control button... right?

Any help is greatly appreciated...

Thanks in advance!!

#118

Message Board / Thread Rookie

Sorry if this is in the wrong place...but I also have '99 CLK320 top issues:

My top had been working fine until I saw hydraulic fluid on the trunk lid (exterior). So, I replaced the rear bow lock, and on TopHydraulics' advice, the case cover lock as well. After replacing the hydraulic fluid and closing the screw valve, I got nothing but the slowly blinking light in the top switch when I tried to put the top down. I opened the screw valve on the hydraulic unit, manually locked the two locks with the top in the up position, closed the screw valve; still nothing - just the blinking light.

Suggestions appreciated!

My top had been working fine until I saw hydraulic fluid on the trunk lid (exterior). So, I replaced the rear bow lock, and on TopHydraulics' advice, the case cover lock as well. After replacing the hydraulic fluid and closing the screw valve, I got nothing but the slowly blinking light in the top switch when I tried to put the top down. I opened the screw valve on the hydraulic unit, manually locked the two locks with the top in the up position, closed the screw valve; still nothing - just the blinking light.

Suggestions appreciated!

#119

MBWorld Fanatic!

navy99clk320

When the soft top does not operate, the light on the main switch provides addition diagnostic error information, A complete description of it's functionality is on page 1 of this thread (see last thumbnail in post #16).

The potential fault condition it indicates depends on whether the blinking is when you press the main switch and attempt to operate the power roof or when no actualization of the main switch is attempted, as well as the blinking rate (e.g. once/second or 3 times/second).

The enclosed thumbnail below explains the possible flashing lamp conditions in more detail.

Note: When checking that the trunk partition (a.ka. the luggage basket) is properly closed, make sure the roller wheels are properly in the track and contacting the micro position switch. Also make sure that the pressure relief screw has been turned back to the position required for power roof operation.

Additionally, your owner's manual also discusses the blinking light and what to do in the 'operating' section pertaining to operating the power roof.

If the condition relates to the locking/unlocking of the roof bow and/or soft top case cover, MB has provided for a easy to do procedure to subsequently exercise and synchronize them. In post #2 at:

https://mbworld.org/forums/clk-class...top-issue.html

If this does not restore operation of the power roof, upon certain conditions (e.g. loss of electrical power while operating the roof), MB recommends resynchronizing the roof. Basically, you open and close cycle the roof manually (e.g. after releasing the hydraulic pressure and unlocking the case cover with the tools provided in your vehicle's tool kit). The details of the procedure are explained in the 'practical hints section' of your owner's manual.

When the soft top does not operate, the light on the main switch provides addition diagnostic error information, A complete description of it's functionality is on page 1 of this thread (see last thumbnail in post #16).

The potential fault condition it indicates depends on whether the blinking is when you press the main switch and attempt to operate the power roof or when no actualization of the main switch is attempted, as well as the blinking rate (e.g. once/second or 3 times/second).

The enclosed thumbnail below explains the possible flashing lamp conditions in more detail.

Note: When checking that the trunk partition (a.ka. the luggage basket) is properly closed, make sure the roller wheels are properly in the track and contacting the micro position switch. Also make sure that the pressure relief screw has been turned back to the position required for power roof operation.

Additionally, your owner's manual also discusses the blinking light and what to do in the 'operating' section pertaining to operating the power roof.

If the condition relates to the locking/unlocking of the roof bow and/or soft top case cover, MB has provided for a easy to do procedure to subsequently exercise and synchronize them. In post #2 at:

https://mbworld.org/forums/clk-class...top-issue.html

If this does not restore operation of the power roof, upon certain conditions (e.g. loss of electrical power while operating the roof), MB recommends resynchronizing the roof. Basically, you open and close cycle the roof manually (e.g. after releasing the hydraulic pressure and unlocking the case cover with the tools provided in your vehicle's tool kit). The details of the procedure are explained in the 'practical hints section' of your owner's manual.

Last edited by Serndipity; 04-27-2015 at 05:39 PM.

#120

SPONSOR

Burnt motor in hydraulic pump 208 800 xxxx

Hello Frolius, welcome to the forum!

Those are some very specific questions, and I will do my best to reply below.

For general reference, the following part numbers apply for the pump:

2088000030 aka A 208 800 00 30 (model years 1998 - 2000, up to VIN -070017 in model year 2001)

2088001048 aka A 208 800 10 48 (model years 1998 - 2000, up to VIN -070017 in model year 2001)

2088000230 aka A 208 800 02 30 (model years 2002, 2003, and from VIN -070018 in model year 2001)

2088001748 aka A 208 800 17 48 (model years 2002, 2003, and from VIN -070018 in model year 2001)

This motor is part of the Mercedes pump assembly. The quick answer is, there is no MB part number for the electric motor, it cannot be bought separately, and there is no alternative part you can purchase. Your alternatives are as follows:

1) Buy a new (actually rebuilt) pump from Mercedes for big $$ - that would be foolish.

2) Find a used, similar pump on a junkyard. Junkyards know the value of these pumps, so you end up paying a lot more than for a rebuild by Top Hydraulics, but you risk getting a motor that is already compromised and will fail soon.

3) Have Top Hydraulics rebuild your pump. If the motor is burnt out, then replacing it is part of the service. There is a lot more to the rebuild & upgrade service by Top Hydraulics - see http://www.tophydraulicsinc.com/en/w...ulic-pump.html

Top Hydraulics replaces the thermal sensor with one that will act faster. I will not share the exact ratings of the motor, but I can share with you that it is actually a high power unit with lots of protection built in. This is a 4-pole DC motor with built-in thermal protection (albeit not good enough as originally done), and significant electro-magnetic noise protection circuitry both for incoming EM spikes and for outgoing noise. You will not find anything anywhere near matching on the market, and it was originally already an expensively made unit of high quality, except for the overheating problem in conjunction with stuck relays. Fixing a burnt out motor is VERY involved. Top Hydraulics can only rebuild and upgrade these motors economically, because we are doing it in fairly high volume.

The good news is, we truly make these motors better than the brand new ones. Not just a little, but a lot better. It involves far improved thermal management and power conversion. I will not share the exact details, but I can assure you that the motor will not burn out again.

Only one answer: your relay stayed stuck - it spot welded itself. The spot weld may have cracked once it cooled down.

Attached below is the picture of a partially melted motor that I originally attached to post # 28 in this thread.

Klaus

www.tophydraulicsinc.com

Those are some very specific questions, and I will do my best to reply below.

For general reference, the following part numbers apply for the pump:

2088000030 aka A 208 800 00 30 (model years 1998 - 2000, up to VIN -070017 in model year 2001)

2088001048 aka A 208 800 10 48 (model years 1998 - 2000, up to VIN -070017 in model year 2001)

2088000230 aka A 208 800 02 30 (model years 2002, 2003, and from VIN -070018 in model year 2001)

2088001748 aka A 208 800 17 48 (model years 2002, 2003, and from VIN -070018 in model year 2001)

1) Buy a new (actually rebuilt) pump from Mercedes for big $$ - that would be foolish.

2) Find a used, similar pump on a junkyard. Junkyards know the value of these pumps, so you end up paying a lot more than for a rebuild by Top Hydraulics, but you risk getting a motor that is already compromised and will fail soon.

3) Have Top Hydraulics rebuild your pump. If the motor is burnt out, then replacing it is part of the service. There is a lot more to the rebuild & upgrade service by Top Hydraulics - see http://www.tophydraulicsinc.com/en/w...ulic-pump.html

The good news is, we truly make these motors better than the brand new ones. Not just a little, but a lot better. It involves far improved thermal management and power conversion. I will not share the exact details, but I can assure you that the motor will not burn out again.

That said... I still don't have a clue (yet) why the motor got fried in the first place.

A couple of days ago I closed my roof, and when the closing sequence ended the damn thing just kept on going when I released the control button, even when I switched the ignition off.

By the time I got to the correct fuse box and figured out which one to pull the damage was done...

It could have been the relay. I checked it and it worked, but it's always possible it got stuck on the moment of destruction. Another possibility would be one of the limit switches not working, but then I would assume it would stop iso continuing, I reckon it would stop in any case when you release the control button... right?

A couple of days ago I closed my roof, and when the closing sequence ended the damn thing just kept on going when I released the control button, even when I switched the ignition off.

By the time I got to the correct fuse box and figured out which one to pull the damage was done...

It could have been the relay. I checked it and it worked, but it's always possible it got stuck on the moment of destruction. Another possibility would be one of the limit switches not working, but then I would assume it would stop iso continuing, I reckon it would stop in any case when you release the control button... right?

Attached below is the picture of a partially melted motor that I originally attached to post # 28 in this thread.

Klaus

www.tophydraulicsinc.com

#121

MBWorld Fanatic!

Hello Frolius

Your unfortunate experience, of a burnt out pump motor, has happened to others as well.

Upon inspection of the wiring diagram, you will find that the motor is directly connected to the battery via only a high current fuse and make/break relay contacts.

Because of the high current flow required to operate the motor, the motor starting relay frequently fails in 1 of 2 ways. When the contacts make/break a high current, an electrical arc occurs.

The resulting arc will either:

1. eventually pit the contact points, upon which there will be excessive resistance to current flow and the motor will not start.

2. permanently bond the contacts together, upon which the motor will run continuously.

Because the motor starting relay has been an ubiquitous problem (e.g. #1 more often than #2), it's not well fitted to the conditions it's required to deal with.

Specifically, while it does include a resistor to suppress the resulting arc on contact break, that's old technology (e.g. arc suppression using a diode is vastly superior).

You mentioned that you tested the relay thereafter and found it to be operating properly.

The relay has 4 contacts (e.g. 2 to energize the coil and 2 to make/break current flow to the motor). The make/break terminals are the 2 where the surfaces are orthogonal to one another (90 degrees opposed). If your relay is faulty, the resistance between these contacts will be 0 ohms, or alternately including the arc preventive resistor of a coupe of hundred ohms, indicating that the contacts have welded together.

Yes, there is an overload protection thermocouple intended to prevent motor burnout.

However, this protection is an input to the power roof controller (e.g. perhaps a watchdog timer), whereas the relay/motor circuits are outputs (e.g. left hand has no idea what the right hand is doing).

In the factory equipped units, not clear that the thermocouple specification and/or programing logic in the controller is faulty.

So if the relay contacts are stuck in an always on condition, the thermocouple was not surprisingly ineffective.

Likewise, it is possible to check out the motor (e.g. a high/infinite resistance across it's terminals = burnt out)

Bottom line:

MB no longer provides new pump motors. Some dealers do provide rebuilt motors. IMHO check out tophydralics http://www.tophydraulicsinc.com/en/23-w208-clk

Your unfortunate experience, of a burnt out pump motor, has happened to others as well.

Upon inspection of the wiring diagram, you will find that the motor is directly connected to the battery via only a high current fuse and make/break relay contacts.

Because of the high current flow required to operate the motor, the motor starting relay frequently fails in 1 of 2 ways. When the contacts make/break a high current, an electrical arc occurs.

The resulting arc will either:

1. eventually pit the contact points, upon which there will be excessive resistance to current flow and the motor will not start.

2. permanently bond the contacts together, upon which the motor will run continuously.

Because the motor starting relay has been an ubiquitous problem (e.g. #1 more often than #2), it's not well fitted to the conditions it's required to deal with.

Specifically, while it does include a resistor to suppress the resulting arc on contact break, that's old technology (e.g. arc suppression using a diode is vastly superior).

You mentioned that you tested the relay thereafter and found it to be operating properly.

The relay has 4 contacts (e.g. 2 to energize the coil and 2 to make/break current flow to the motor). The make/break terminals are the 2 where the surfaces are orthogonal to one another (90 degrees opposed). If your relay is faulty, the resistance between these contacts will be 0 ohms, or alternately including the arc preventive resistor of a coupe of hundred ohms, indicating that the contacts have welded together.

Yes, there is an overload protection thermocouple intended to prevent motor burnout.

However, this protection is an input to the power roof controller (e.g. perhaps a watchdog timer), whereas the relay/motor circuits are outputs (e.g. left hand has no idea what the right hand is doing).

In the factory equipped units, not clear that the thermocouple specification and/or programing logic in the controller is faulty.

So if the relay contacts are stuck in an always on condition, the thermocouple was not surprisingly ineffective.

Likewise, it is possible to check out the motor (e.g. a high/infinite resistance across it's terminals = burnt out)

Bottom line:

MB no longer provides new pump motors. Some dealers do provide rebuilt motors. IMHO check out tophydralics http://www.tophydraulicsinc.com/en/23-w208-clk

Last edited by Serndipity; 04-27-2015 at 09:07 PM.

#122

hey Guys..

first off i'd like to thank you guys for the awesome detailed write up regarding the w208 soft top.

Ive ran into the soft top issue before and was able to solve it by reading your posts regarding the relay.

It has happened again but how do i find a problem that doesn't always occur? and by that i mean sometimes which is now becoming less and less the top works great up and down and most of the times not.

hear is the symptoms from close;

open latch.. windows go down

pull on switch i hear the relay and nothing. starts blinking.

if i reset the ignition many many times i might get lucky and it will work so this makes me believe its an electrical issue such as a switch.

I've closed the switch on the pull curtain.

checked the switch under the bow and left bow cylinder.

all wires to fuses look good.

what would you do for your next trouble shoot?

thanks to all in advance

first off i'd like to thank you guys for the awesome detailed write up regarding the w208 soft top.

Ive ran into the soft top issue before and was able to solve it by reading your posts regarding the relay.

It has happened again but how do i find a problem that doesn't always occur? and by that i mean sometimes which is now becoming less and less the top works great up and down and most of the times not.

hear is the symptoms from close;

open latch.. windows go down

pull on switch i hear the relay and nothing. starts blinking.

if i reset the ignition many many times i might get lucky and it will work so this makes me believe its an electrical issue such as a switch.

I've closed the switch on the pull curtain.

checked the switch under the bow and left bow cylinder.

all wires to fuses look good.

what would you do for your next trouble shoot?

thanks to all in advance

#123

SPONSOR

Ive ran into the soft top issue before and was able to solve it by reading your posts regarding the relay.

It has happened again but how do i find a problem that doesn't always occur? and by that i mean sometimes which is now becoming less and less the top works great up and down and most of the times not.

It has happened again but how do i find a problem that doesn't always occur? and by that i mean sometimes which is now becoming less and less the top works great up and down and most of the times not.

hear is the symptoms from close;

open latch.. windows go down

pull on switch i hear the relay and nothing. starts blinking.

if i reset the ignition many many times i might get lucky and it will work so this makes me believe its an electrical issue such as a switch.

I've closed the switch on the pull curtain.

checked the switch under the bow and left bow cylinder.

all wires to fuses look good.

what would you do for your next trouble shoot?

open latch.. windows go down

pull on switch i hear the relay and nothing. starts blinking.

if i reset the ignition many many times i might get lucky and it will work so this makes me believe its an electrical issue such as a switch.

I've closed the switch on the pull curtain.

checked the switch under the bow and left bow cylinder.

all wires to fuses look good.

what would you do for your next trouble shoot?

As Serndipity just stated in the previous post, the pump motor gets its power directly from the 40A fuse in the trunk. If that fuse is good, the relay is working, and the single wire from the fuse to the motor's relay pigtail is good, then you have a bad pump motor.

How can you find out? Do the following tests when the top is NOT working. I assume that you have already checked the 40A fuse in the trunk.

I also know that you know how to get access to the relay, which is plugged into the "relay pigtail connector" next to the trunk. For future readers, access to the pump is covered in the following DIY instructions: http://www.tophydraulicsinc.com/W208...eplacement.pdf

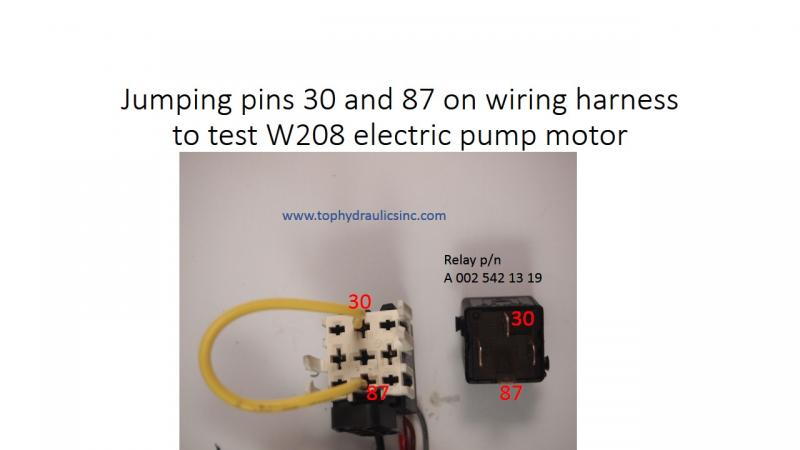

1) Check if the pump motor will run when you bypass or "hot wire" the relay. You need a piece of wire that will fit into the relay connector, but that can conduct a good amount of current. Once the wire is properly inserted between pins 30 and 87 of the connector according to the illustration below, the pump motor should turn.

Note: I have used regular solid copper wire gauge 10, 12, or 14 before, and pounded the ends flat (so that they fit into the connector). If you are using a thinner gauge wire, then put it in with pliers, because it may get hot. IF the motor works at that point, then you may get startled by a little arcing from the contact points between wire and connector.

Bypassing the relay A 002 542 13 19 on CLK convertible top pump - the following pump part numbers apply:

2088000030 aka A 208 800 00 30 (model years 1998 - 2000, up to VIN -070017 in model year 2001)2088001048 aka A 208 800 10 48 (model years 1998 - 2000, up to VIN -070017 in model year 2001)

2088000230 aka A 208 800 02 30 (model years 2002, 2003, and from VIN -070018 in model year 2001)

2088001748 aka A 208 800 17 48 (model years 2002, 2003, and from VIN -070018 in model year 2001)

2) If the motor does NOT turn, then check with a multimeter whether there is voltage on pin 87. There should be 12V between that pin an your car's chassis. You can also check this first. This voltage should always be there as long as the battery is connected.

If there is no voltage on pin 87, then double check your 40A pump fuse and the wiring between the fuse and the pump connector.

IF there is voltage on pin 87 AND the hot wiring does not make your pump motor turn, then you positively have a bad pump motor. In that case, take out the whole pump and send it to Top Hydraulics for rebuild: http://www.tophydraulicsinc.com/en/w...ulic-pump.html

I hope this helps, and please let us know what you find!

Klaus

www.tophydraulicsinc.com

Last edited by Top Hydraulics; 05-03-2015 at 02:21 PM. Reason: added part numbers

#124

hey Klaus,

i just took your diagram and tried that and there is 12v at relay and the motor does operate when i arch it.

i was fooling around with it earlier and rechecked my connections again. i unplugged the bow wire and it started to work. i didn't run the full cycles because i had wires and tools all over i didn't want it to get caught. i closed the top and reconnected the bow and it didn't.

i disconnect it again to see if it was a fluke and it worked again.

this is odd because shouldn't the bow circuit be in the closed position before operation?

secondly i then went to finish the cycle and i could hear the pump but the top didn't move.

i went to close and it just flashed and stopped working all in all.

i realize its very rare to have a bad computer but I'm starting to think its that!

what else would you try?

i just took your diagram and tried that and there is 12v at relay and the motor does operate when i arch it.

i was fooling around with it earlier and rechecked my connections again. i unplugged the bow wire and it started to work. i didn't run the full cycles because i had wires and tools all over i didn't want it to get caught. i closed the top and reconnected the bow and it didn't.

i disconnect it again to see if it was a fluke and it worked again.

this is odd because shouldn't the bow circuit be in the closed position before operation?

secondly i then went to finish the cycle and i could hear the pump but the top didn't move.

i went to close and it just flashed and stopped working all in all.

i realize its very rare to have a bad computer but I'm starting to think its that!

what else would you try?

#125

SPONSOR

Either it was not the pump relay that you heard earlier, or you hot wired the pump in one of those instances where it was still able to move. The latter can depend on the exact position in which the motor previously stopped.

Before you hot wired the pump, are you sure that the top wasn't working when pulling or pushing the red switch at that time? The hot wiring does not tell you anything when the top is still functioning with the switch.

Please clarify before we move on to the next details.

Klaus

www.tophydraulicsinc.com