ABC Valve Block Functional Diagram

#1

Junior Member

Thread Starter

Join Date: May 2012

Location: Shanghai, China

Posts: 49

Likes: 0

Received 4 Likes

on

4 Posts

2004 S600 Twin Turbo V12

ABC Valve Block Functional Diagram

While disassembling my ABC valve blocks for off-the-car cleaning and o-ring replacement, I analyzed how the blocks function and exactly where the fluid leaks if the suspension level drops when the car is parked.

The picture shows one of the small solenoid valves.

The red arrow points to the sealing face of the valve.

The blue arrow points to the o-ring that would allow the suspension to drop if fluid leaked past it.

The original o-rings are 1.6 mm cross section diameter.

But I might try 2 mm cross section diameter viton o-rings in all of the solenoid valves.

They will fit, and they should be more robust in terms of not letting the fluid pass by.

You can see in the picture there's a lot of empty space in the o-ring grooves (2.55 mm wide) which is not occupied by the 1.6 mm o-rings.

The picture shows one of the small solenoid valves.

The red arrow points to the sealing face of the valve.

The blue arrow points to the o-ring that would allow the suspension to drop if fluid leaked past it.

The original o-rings are 1.6 mm cross section diameter.

But I might try 2 mm cross section diameter viton o-rings in all of the solenoid valves.

They will fit, and they should be more robust in terms of not letting the fluid pass by.

You can see in the picture there's a lot of empty space in the o-ring grooves (2.55 mm wide) which is not occupied by the 1.6 mm o-rings.

Last edited by drewk88; 05-26-2014 at 08:00 PM.

The following users liked this post:

gotglasses (11-17-2016)

#2

MBWorld Fanatic!

Thanks Drew. I'm all in favour of owners helping themselves when it comes to ABC maintenance.

Regarding the grooves, I would say that if there's a gap, its probably there for a reason, and I wouldn't be worried about not knowing what it was.

Therefore I'd suggest using the same size o-rings.

What would be useful for a lot of people is knowing the OD and thickness for each 0-ring the valve assembly? Then we'd be able to buy the right parts before removing the valve block.

Cheers, Nick

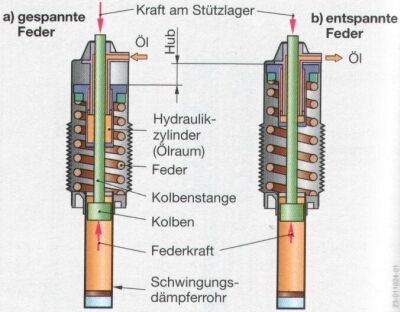

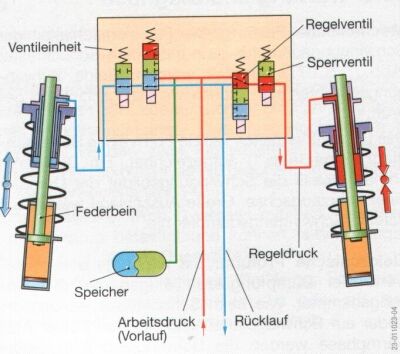

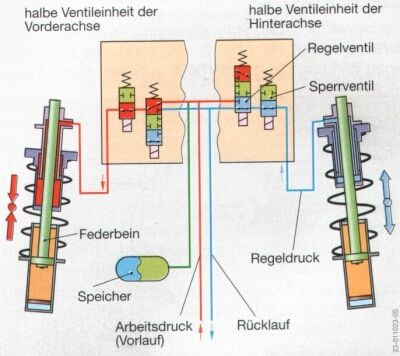

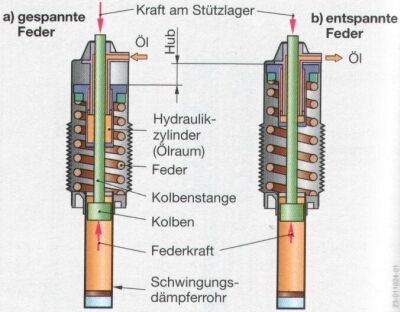

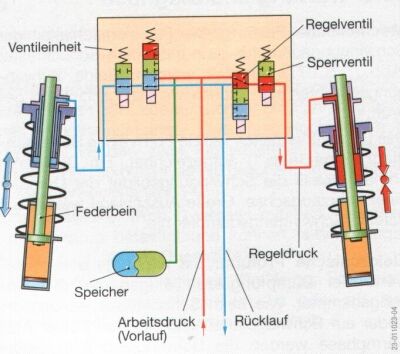

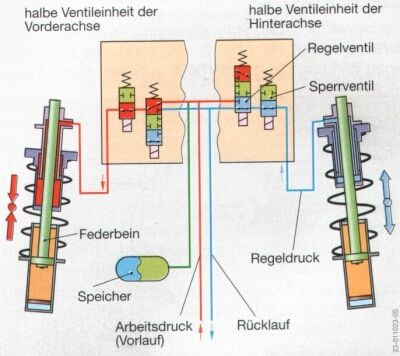

PS. Did you see these pictures?

Regarding the grooves, I would say that if there's a gap, its probably there for a reason, and I wouldn't be worried about not knowing what it was.

Therefore I'd suggest using the same size o-rings.

What would be useful for a lot of people is knowing the OD and thickness for each 0-ring the valve assembly? Then we'd be able to buy the right parts before removing the valve block.

Cheers, Nick

PS. Did you see these pictures?

Last edited by Welwynnick; 05-27-2014 at 06:51 AM.

#4

Junior Member

What about the springs?

While disassembling my ABC valve blocks for off-the-car cleaning and o-ring replacement, I analyzed how the blocks function and exactly where the fluid leaks if the suspension level drops when the car is parked.

The picture shows one of the small solenoid valves.

The red arrow points to the sealing face of the valve.

The blue arrow points to the o-ring that would allow the suspension to drop if fluid leaked past it.

The original o-rings are 1.6 mm cross section diameter.

But I might try 2 mm cross section diameter viton o-rings in all of the solenoid valves.

They will fit, and they should be more robust in terms of not letting the fluid pass by.

You can see in the picture there's a lot of empty space in the o-ring grooves (2.55 mm wide) which is not occupied by the 1.6 mm o-rings.

The picture shows one of the small solenoid valves.

The red arrow points to the sealing face of the valve.

The blue arrow points to the o-ring that would allow the suspension to drop if fluid leaked past it.

The original o-rings are 1.6 mm cross section diameter.

But I might try 2 mm cross section diameter viton o-rings in all of the solenoid valves.

They will fit, and they should be more robust in terms of not letting the fluid pass by.

You can see in the picture there's a lot of empty space in the o-ring grooves (2.55 mm wide) which is not occupied by the 1.6 mm o-rings.

Your valve picture looks a lot like a Moen Bathtub/shower valve! Works pretty much the same way - pull in and out. Those Moen valves tend to stick shut, but never leak!

I notice that there are springs at the ends of the valves. One poster believes that the springs should be stretched to increase their tension and thereby assist sealing. I don't agree with that, but would want to replace any wearing parts if I do take this thing apart. That would mean the O-Rings and springs and perhaps Accumulators as a preventive measure. O-Rings can now be found on eBay, but I have found no source for the springs. How critical are these springs to the sealing? Perhaps stiffer replacements would help?

Final Question - how do you avoid the mess when you disconnect the hoses? Are there any fittings available to seal the ends and minimize fluid loss?

Thanks for a great post.

#5

Even if you don't drive it , it's much better to start the car once a week for 10-15 minutes to charge the battery and work the suspension . Letting these cars sit is the worst thing for them

OK, this is interesting - since I now have an R230. I have been using the car regularly and have never gotten an ABC warning. It does sink an inch or so in the left rear after a few days. Living in New York we get salt on the roads in late November and I do not want to expose the SL to that. I do expect it to settle more during the winter storage months and may pull the valve blocks if I am bored. Normally I put a car up on jack stands for storage and wonder if that would prevent the valve leakage you discuss? The Mercedes TB on the subject pretty much says that if the car does not drop on its tires after a week it is fine! I do not agree. The suspension should have a lock position for parking so that this does not happen at all.

Your valve picture looks a lot like a Moen Bathtub/shower valve! Works pretty much the same way - pull in and out. Those Moen valves tend to stick shut, but never leak!

I notice that there are springs at the ends of the valves. One poster believes that the springs should be stretched to increase their tension and thereby assist sealing. I don't agree with that, but would want to replace any wearing parts if I do take this thing apart. That would mean the O-Rings and springs and perhaps Accumulators as a preventive measure. O-Rings can now be found on eBay, but I have found no source for the springs. How critical are these springs to the sealing? Perhaps stiffer replacements would help?

Final Question - how do you avoid the mess when you disconnect the hoses? Are there any fittings available to seal the ends and minimize fluid loss?

Thanks for a great post.

Your valve picture looks a lot like a Moen Bathtub/shower valve! Works pretty much the same way - pull in and out. Those Moen valves tend to stick shut, but never leak!

I notice that there are springs at the ends of the valves. One poster believes that the springs should be stretched to increase their tension and thereby assist sealing. I don't agree with that, but would want to replace any wearing parts if I do take this thing apart. That would mean the O-Rings and springs and perhaps Accumulators as a preventive measure. O-Rings can now be found on eBay, but I have found no source for the springs. How critical are these springs to the sealing? Perhaps stiffer replacements would help?

Final Question - how do you avoid the mess when you disconnect the hoses? Are there any fittings available to seal the ends and minimize fluid loss?

Thanks for a great post.

#6

MBWorld Fanatic!

I think that starting a stored car for a short period of time is worse than letting it sit undisturbed. Most engine wear is in the first few minutes after starting. If you don't run it long enough to get it hot enough to clear out the moisture created, you generate condensate and a nasty brew of acids in the engine and exhaust. Remember that a gasoline engine generates over a gallon of water for every gallon of fuel burned.

If I lived in snow and salt country, I would take the car for a long run on clear, dry days after other traffic had cleared the dry salt.

If I lived in snow and salt country, I would take the car for a long run on clear, dry days after other traffic had cleared the dry salt.