The ABC Suspension Thread

#1

MBWorld Fanatic!

Thread Starter

The ABC Suspension Thread

Hi Guys, I'm attempting to pull together all my posts on ABC into one thread. I've been meaning to do this for a long time, so the holidays may be the opportunity. There are hundreds of posts to review and filter, and some of them are worth saving for reference.

I'm a great advocate of ABC, but others think its the invention of the Devil, and can't wait to remove every last vestige of ABC from their vehicles at the earliest opportunity.

Its a fraught subject that (I hesitate to suggest) almost deserves its own forum. Even main dealers and specialist garages can struggle to get to grips with it, so I'm going to start the ball rolling to consolidate the information that's available.

Many thanks,

Nick

I'm a great advocate of ABC, but others think its the invention of the Devil, and can't wait to remove every last vestige of ABC from their vehicles at the earliest opportunity.

Its a fraught subject that (I hesitate to suggest) almost deserves its own forum. Even main dealers and specialist garages can struggle to get to grips with it, so I'm going to start the ball rolling to consolidate the information that's available.

Many thanks,

Nick

Last edited by Welwynnick; 12-27-2015 at 03:58 PM.

The following 16 users liked this post by Welwynnick:

289cobra1 (05-31-2020),

booesq (09-28-2016),

CorporalD (07-15-2019),

djjokerdavid (01-16-2022),

DoctorV8 (01-09-2019),

and 11 others liked this post.

#2

MBWorld Fanatic!

Thread Starter

INTRODUCTION

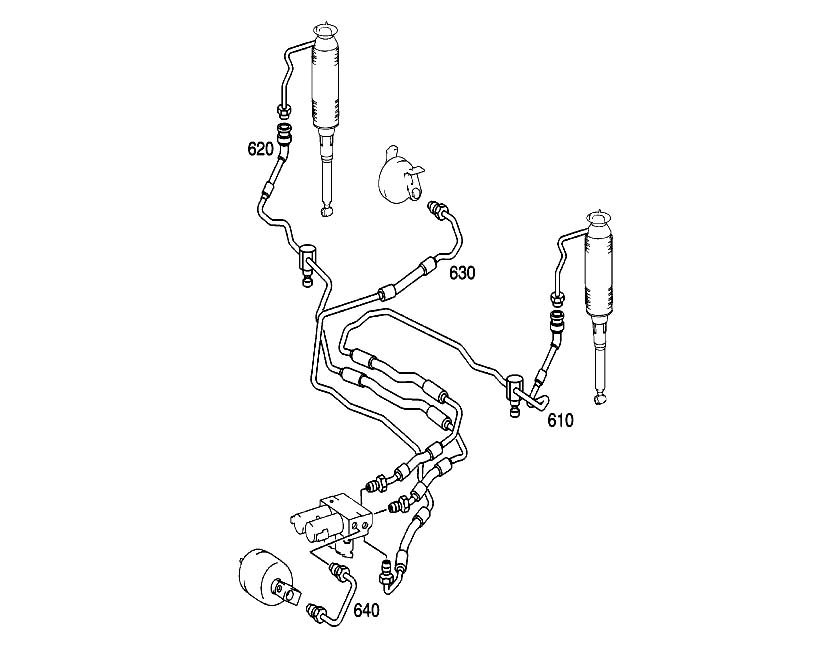

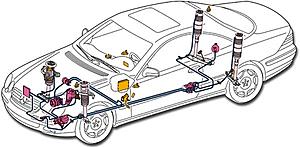

Mercedes is a great innovator, and one of their great achievements IMHO is Active Body Control suspension, where engine power is used to actively and dynamically compensate for body motion due to acceleration, braking and especially cornering. There is virtually no pitch and roll, no-matter how hard you throw the car around, but it does this with soft springs and great ride comfort.

However, its also a great liability due to its complexity and novelty. ABC had been developed over a period of decades, was introduced in the W215 CL-class coupe in 1998, and the W220 shortly after that. Owners of those cars in particular became guinea pigs due to the immaturity of the implementation. Springs and dampers have been developed over a very long period of time, but the mixture of hydraulics and electronics had not. At least not in an automotive environment.

I've owned four W220's with ABC, but only one has given me any problems, and the intensive practical experience of finding solutions is the starting point for this thread.

I'm not going to attempt to write the book on ABC - I have to spend my free time working on my car, and in any case the book has already been written by Daren B:

http://mercedes-abc-drive-carefully.blogspot.co.uk/

If you've had a problem with ABC, you've probably read that already, and its definitely the place to start. I think many MB dealers and specialist garages could do much worse than to study that blog. The other superb DIY maintenance thread is by Howard, and many of you will have seen this as well. Both are compulsory reading for ABC:

https://mbworld.org/forums/s-class-w...2003-s600.html

This thread is quite a long-standing ambition for me, as ABC is such a great stumbling block for so many owners. It can make you lose confidence in your ability to drive from A to B, and make it financially unviable to keep a perfectly good car on the road. Over the last three years I found a lot of practical and economical solutions to ABC problems, and I want to share them and discuss them.

Why this forum? It's kind of home for me in some ways, being the owner of two V12s, but the cars that use the V12 engine are also the cars that use ABC. Its a pretty quiet technical forum, and I wanted a bit time to put this together before it got noisy. ABC is used on S-class, SL-class and CL-class cars, across two or three generations of those cars, and across Mercedes and AMG models in each case. So there are lots of permutations of models, each with their own forum, where ABC is a significant point of discussion. There are over 1000 threads about ABC, and they're pretty evenly distributed over the various forums. If a moderator wanted to put this somewhere else more appropriate, that would fine.

Nick

Mercedes is a great innovator, and one of their great achievements IMHO is Active Body Control suspension, where engine power is used to actively and dynamically compensate for body motion due to acceleration, braking and especially cornering. There is virtually no pitch and roll, no-matter how hard you throw the car around, but it does this with soft springs and great ride comfort.

However, its also a great liability due to its complexity and novelty. ABC had been developed over a period of decades, was introduced in the W215 CL-class coupe in 1998, and the W220 shortly after that. Owners of those cars in particular became guinea pigs due to the immaturity of the implementation. Springs and dampers have been developed over a very long period of time, but the mixture of hydraulics and electronics had not. At least not in an automotive environment.

I've owned four W220's with ABC, but only one has given me any problems, and the intensive practical experience of finding solutions is the starting point for this thread.

I'm not going to attempt to write the book on ABC - I have to spend my free time working on my car, and in any case the book has already been written by Daren B:

http://mercedes-abc-drive-carefully.blogspot.co.uk/

If you've had a problem with ABC, you've probably read that already, and its definitely the place to start. I think many MB dealers and specialist garages could do much worse than to study that blog. The other superb DIY maintenance thread is by Howard, and many of you will have seen this as well. Both are compulsory reading for ABC:

https://mbworld.org/forums/s-class-w...2003-s600.html

This thread is quite a long-standing ambition for me, as ABC is such a great stumbling block for so many owners. It can make you lose confidence in your ability to drive from A to B, and make it financially unviable to keep a perfectly good car on the road. Over the last three years I found a lot of practical and economical solutions to ABC problems, and I want to share them and discuss them.

Why this forum? It's kind of home for me in some ways, being the owner of two V12s, but the cars that use the V12 engine are also the cars that use ABC. Its a pretty quiet technical forum, and I wanted a bit time to put this together before it got noisy. ABC is used on S-class, SL-class and CL-class cars, across two or three generations of those cars, and across Mercedes and AMG models in each case. So there are lots of permutations of models, each with their own forum, where ABC is a significant point of discussion. There are over 1000 threads about ABC, and they're pretty evenly distributed over the various forums. If a moderator wanted to put this somewhere else more appropriate, that would fine.

Nick

Last edited by Welwynnick; 12-27-2015 at 03:58 PM.

The following users liked this post:

sker66 (05-09-2022)

#3

MBWorld Fanatic!

Thread Starter

USEFUL LINKS:

https://mbworld.org/forums/cl55-amg-...sure-hose.html

http://www.benzworld.org/forums/w220...lpppppp-2.html

http://www.benzworld.org/forums/w220...need-help.html

http://www.benzworld.org/forums/w220...2001-s600.html

http://www.benzworld.org/forums/r230...placement.html

http://www.micro-tronik.com/mercedes...nsion_233.html

http://bayhas.com/mercedes/cl215/contents/abc.htm

http://www.benzworld.org/forums/w215...block-hpe.html

http://www.benzworld.org/forums/r230-sl-class/1635269-abc-valve-cleaning-diy.html

http://forums.mercedesclub.org.uk/showthread.php?p=664081#post664081

https://mbworld.org/forums/cl55-amg-...refully-2.html

https://mbworld.org/forums/s-class-w...ement-diy.html

http://www.benzworld.org/forums/w215...sues-more.html

http://www.benzworld.org/forums/w215...ml#post3572012

http://www.hopespare.com/trade-counters/

http://www.exclusiv-automobile.de/ww..._Fahrwerk.html

http://fotifixes.com/2015/01/24/how-...rubber-mounts/

https://mbworld.org/forums/cl55-amg-...sure-hose.html

http://www.benzworld.org/forums/w220...lpppppp-2.html

http://www.benzworld.org/forums/w220...need-help.html

http://www.benzworld.org/forums/w220...2001-s600.html

http://www.benzworld.org/forums/r230...placement.html

http://www.micro-tronik.com/mercedes...nsion_233.html

http://bayhas.com/mercedes/cl215/contents/abc.htm

http://www.benzworld.org/forums/w215...block-hpe.html

http://www.benzworld.org/forums/r230-sl-class/1635269-abc-valve-cleaning-diy.html

http://forums.mercedesclub.org.uk/showthread.php?p=664081#post664081

https://mbworld.org/forums/cl55-amg-...refully-2.html

https://mbworld.org/forums/s-class-w...ement-diy.html

http://www.benzworld.org/forums/w215...sues-more.html

http://www.benzworld.org/forums/w215...ml#post3572012

http://www.hopespare.com/trade-counters/

http://www.exclusiv-automobile.de/ww..._Fahrwerk.html

http://fotifixes.com/2015/01/24/how-...rubber-mounts/

Last edited by Welwynnick; 12-27-2015 at 12:22 PM.

The following users liked this post:

S65Dreamer (11-12-2020)

#4

MBWorld Fanatic!

Thread Starter

I can't start this from scratch, so my approach for this thread is to pull together the worthwhile ABC posts that I found using forum searches, and copy them here in chronological order. Each post will be a collection of posts from a particular thread, which will be linked at the top of the post. Its not very original, but its what I think I can do. Here's the first one, back in 2012:

https://mbworld.org/forums/s-class-w...00-advice.html

Seems like no-one has much good to say about 2000-2002 N/A S600's. I've owned two, and they were the best cars I'd owned.

I had to repair the C/L vacuum pump on the first, which is common, and no big deal. The second needed a new front lower arm, and I think the ABC pump was beginning to get slightly noisy. Otherwise it was difficult to find fault with them. I love the V12's over the V8's, and I see ABC as an advantage rather than aliability.

I've also owned a very rare Toyota Soarer with active suspension for several years. Its a real blast to drive, and I always wished other manufacturers had the courage and commitment to put proper active suspension into serious, volume production. Rather than a curious, niche, option. Its a hell of a difficult thing to make at all, let alone make it fit for high volume and long life.

Besides the no-roll cornering, the Soarer has an extraordinary ability to change direction like it weighed nothing. You can do that with active suspension, but its not a talent that Mercedes have learned. However, Mercedes have succeeded in other areas, like ride comfort, power consumption and cost of implementation. Its not a cheap option, but its nothing like as expensive as on the Toyota, which is truly scary, in case it ever goes seriously wrong.

I think Merc have done an amazing job bringing active suspension to the market, and the likelihood of paying 1500-odd for a new pump after 100,000 miles (which both my cars did) doesn't seem so unreasonable considering the cost, complexity and relative immaturity of the system.

I have a V12TT now, which is a wonderful car of course, but it does fell worryingly fragile in comparison.

Nick

https://mbworld.org/forums/s-class-w...00-advice.html

Seems like no-one has much good to say about 2000-2002 N/A S600's. I've owned two, and they were the best cars I'd owned.

I had to repair the C/L vacuum pump on the first, which is common, and no big deal. The second needed a new front lower arm, and I think the ABC pump was beginning to get slightly noisy. Otherwise it was difficult to find fault with them. I love the V12's over the V8's, and I see ABC as an advantage rather than aliability.

I've also owned a very rare Toyota Soarer with active suspension for several years. Its a real blast to drive, and I always wished other manufacturers had the courage and commitment to put proper active suspension into serious, volume production. Rather than a curious, niche, option. Its a hell of a difficult thing to make at all, let alone make it fit for high volume and long life.

Besides the no-roll cornering, the Soarer has an extraordinary ability to change direction like it weighed nothing. You can do that with active suspension, but its not a talent that Mercedes have learned. However, Mercedes have succeeded in other areas, like ride comfort, power consumption and cost of implementation. Its not a cheap option, but its nothing like as expensive as on the Toyota, which is truly scary, in case it ever goes seriously wrong.

I think Merc have done an amazing job bringing active suspension to the market, and the likelihood of paying 1500-odd for a new pump after 100,000 miles (which both my cars did) doesn't seem so unreasonable considering the cost, complexity and relative immaturity of the system.

I have a V12TT now, which is a wonderful car of course, but it does fell worryingly fragile in comparison.

Nick

Last edited by Welwynnick; 12-27-2015 at 07:10 AM.

#5

MBWorld Fanatic!

Thread Starter

https://mbworld.org/forums/cl55-amg-...e-odd-one.html

My car had an ABC problem recently, and I did as much research as I could. There's a huge number of threads on MBW spread across many, many forums.

I know its been said before, but isn't it time to consolidate all the threads that are specifically about ABC into a single ABC Forum?

Nick

My car had an ABC problem recently, and I did as much research as I could. There's a huge number of threads on MBW spread across many, many forums.

I know its been said before, but isn't it time to consolidate all the threads that are specifically about ABC into a single ABC Forum?

Nick

Last edited by Welwynnick; 12-27-2015 at 04:00 PM.

#6

MBWorld Fanatic!

Thread Starter

https://mbworld.org/forums/s-class-w...uidelines.html

My impression is because ABC is so unfamiliar to most people, even mechanics fight shy of it ("if it ain't broke, don't fix it") just as I did with my first two ABC cars. My first was a five year old S600 NA that really caused me no problem at all. It did have a slight wiggle from the rear end over single, large bumps, which I thought was down to suspension or subframe bushes. I even asked the dealer to investigate, but they found nothing. I wondered if I was imagining things, but I now know I wasn't. That car had 225/55 tyres on 17" wheels, and they weren't enough to give the ABC any work to do.

My second car was much older by the time I bought it, but had the great advantage of 245/45/18 tyres. That was the sweet spot for the chassis, it had a magic carpet ride and unbelievable handling; there was real, physics-defying talent there.

My third is the 155k mile S600 TT, which has been much more of a challenge. Its had at least one ABC pump, two rear struts and three ABC hoses. It has 265/40/18 rear tyres (and is much worse for it) and it wriggled and shook itself down every bumpy road, like the first car, but worse. Again, I presumed it had bad subframe or suspension bushes, but they all semed OK, so I dug deeper, and I think I found another underlying ABC problem that I haven't heard people talking about.

ABC struts have a ball joint at the bottom, and a large rubber bush at the top. Both of them wear out, but its not very apparent even with the wheels in the air - as always you have to disconnect the suspension strut before find out what makes the suspension tick (or clank). The bushes on the suspension links are pre-loaded so that their natural position is normal ride height. With the car jacked up and the wheels in the air, the bushes are pushing the wheel upwards quite firmly - more then enough to lift the wheel and brake, and push the strut upwards into its mounting. This keeps the upper bush in compression, so any bush damage isn't apparent when you inspect. When you go over sharp bumps at speed, the unsprung weight tends to oscillate fast against the compliance of the tyre, but the damper damps this out. However, if the bush is degraded, the damper can't pull on the bush and it just comes away, so the wheel is completely undamped, and it bounces against the tyre.

Depending on the degree of degradation of the bush, this is horrible. It was subtle on my first car and severe on the current one. On smooth surfaces its fine, but as soon as the suspension has to do any real work, it fall to pieces. The afflicted end of the car bump steers all over the road, and it shakes over any sharp bump, especially when you're going fast. Because the suspension keeps the bush in compression in the static condition, this is difficult to diagnose by inspection, but there is a way.

Jack up the car so the wheel is off the ground, then push the wheel down hard with your foot. It shouldn't move, but if the top bush is worn, you'll find that the whole wheel/brake/suspension unit may move downwards relatively freely, once you overcome the suspension's natural upwards pre-load. That's what mine did, so I replaced a rear strut with a good used one, and for a few hour's work the problem entirely went away.

I think its something everyone should be aware of. Unfortunately you can't get the bushes on the their own (Mercedes what were you thinking of?) but used or re-manufactured struts aren't that expensive, nor difficult to replace.

My impression is because ABC is so unfamiliar to most people, even mechanics fight shy of it ("if it ain't broke, don't fix it") just as I did with my first two ABC cars. My first was a five year old S600 NA that really caused me no problem at all. It did have a slight wiggle from the rear end over single, large bumps, which I thought was down to suspension or subframe bushes. I even asked the dealer to investigate, but they found nothing. I wondered if I was imagining things, but I now know I wasn't. That car had 225/55 tyres on 17" wheels, and they weren't enough to give the ABC any work to do.

My second car was much older by the time I bought it, but had the great advantage of 245/45/18 tyres. That was the sweet spot for the chassis, it had a magic carpet ride and unbelievable handling; there was real, physics-defying talent there.

My third is the 155k mile S600 TT, which has been much more of a challenge. Its had at least one ABC pump, two rear struts and three ABC hoses. It has 265/40/18 rear tyres (and is much worse for it) and it wriggled and shook itself down every bumpy road, like the first car, but worse. Again, I presumed it had bad subframe or suspension bushes, but they all semed OK, so I dug deeper, and I think I found another underlying ABC problem that I haven't heard people talking about.

ABC struts have a ball joint at the bottom, and a large rubber bush at the top. Both of them wear out, but its not very apparent even with the wheels in the air - as always you have to disconnect the suspension strut before find out what makes the suspension tick (or clank). The bushes on the suspension links are pre-loaded so that their natural position is normal ride height. With the car jacked up and the wheels in the air, the bushes are pushing the wheel upwards quite firmly - more then enough to lift the wheel and brake, and push the strut upwards into its mounting. This keeps the upper bush in compression, so any bush damage isn't apparent when you inspect. When you go over sharp bumps at speed, the unsprung weight tends to oscillate fast against the compliance of the tyre, but the damper damps this out. However, if the bush is degraded, the damper can't pull on the bush and it just comes away, so the wheel is completely undamped, and it bounces against the tyre.

Depending on the degree of degradation of the bush, this is horrible. It was subtle on my first car and severe on the current one. On smooth surfaces its fine, but as soon as the suspension has to do any real work, it fall to pieces. The afflicted end of the car bump steers all over the road, and it shakes over any sharp bump, especially when you're going fast. Because the suspension keeps the bush in compression in the static condition, this is difficult to diagnose by inspection, but there is a way.

Jack up the car so the wheel is off the ground, then push the wheel down hard with your foot. It shouldn't move, but if the top bush is worn, you'll find that the whole wheel/brake/suspension unit may move downwards relatively freely, once you overcome the suspension's natural upwards pre-load. That's what mine did, so I replaced a rear strut with a good used one, and for a few hour's work the problem entirely went away.

I think its something everyone should be aware of. Unfortunately you can't get the bushes on the their own (Mercedes what were you thinking of?) but used or re-manufactured struts aren't that expensive, nor difficult to replace.

Last edited by Welwynnick; 12-27-2015 at 07:24 AM.

The following users liked this post:

Malone14 (09-06-2020)

#7

MBWorld Fanatic!

Thread Starter

https://mbworld.org/forums/s-class-w...-decision.html

My car is up to 156k miles, and I'm using it as a daily driver. The engine is smooth, quiet and surprisingly economical. It doesn't consume much, maybe a couple of litres of oil in year, and all the exhaust emissions on the annual UK MoT test are very low, which is a good sign of health. As always with large-engined, modern cars, it's the other things that wear out first. Sounds like you have a good idea of what to expect. Here's a check-list:

Preventive Maintenance at 85,000 miles?

Change the engine oil & filters

Change the transmission oil & filter

Change the ABC oil & filter

Change the anti-freeze

Replace the oil seal in the TCU cable connector on the transmission

Inspect all the ABC hoses and replace any wet ones

Clean the mud from behind all the fender liners

Clean the heater inlet and sunroof rainwater drains

Clean & feed the leather

My car is up to 156k miles, and I'm using it as a daily driver. The engine is smooth, quiet and surprisingly economical. It doesn't consume much, maybe a couple of litres of oil in year, and all the exhaust emissions on the annual UK MoT test are very low, which is a good sign of health. As always with large-engined, modern cars, it's the other things that wear out first. Sounds like you have a good idea of what to expect. Here's a check-list:

Preventive Maintenance at 85,000 miles?

Change the engine oil & filters

Change the transmission oil & filter

Change the ABC oil & filter

Change the anti-freeze

Replace the oil seal in the TCU cable connector on the transmission

Inspect all the ABC hoses and replace any wet ones

Clean the mud from behind all the fender liners

Clean the heater inlet and sunroof rainwater drains

Clean & feed the leather

Last edited by Welwynnick; 12-27-2015 at 07:26 AM.

Trending Topics

#8

MBWorld Fanatic!

Thread Starter

https://mbworld.org/forums/cl-class-...bc-issues.html

Lots of potential issues, but there's lots you can do about, rather than waiting for something to go wrong.

Mercedes say there's no routine maintenance, but that's a big mistake. First thing is to change the oil and filter, and use the later 3 micron filter.

Pumps always fail eventually, and they're difficult (i.e. expensive) to replace, but clean oil helps.

The front and rear valves often get contaminated and the suspension sags over time, but they're reasonably straightforward to service.

The other big fail is the flexible hoses, which give you advance warning by seeping at the crimp connections. Its essential that these are ALL inspected every year, and repaired / replaced as necessary.

Vibration dampers sometimes fail from time to time and give strange symptoms, but aren't the end of the World.

If the worst comes the worst, and something big fails causing a red ABC warning message - stop and get the car trailered home.

Don't drive the car if there's a red ABC warning.

Check the oil level in the ABC reservoir.

Check for leaks and nasty noises.

Check the suspension level at each corner.

If oil's not coming out anywhere and the ride height is OK, you've probably lost pressure, and can drive to a dealer or good MB specialist.

Lots of potential issues, but there's lots you can do about, rather than waiting for something to go wrong.

Mercedes say there's no routine maintenance, but that's a big mistake. First thing is to change the oil and filter, and use the later 3 micron filter.

Pumps always fail eventually, and they're difficult (i.e. expensive) to replace, but clean oil helps.

The front and rear valves often get contaminated and the suspension sags over time, but they're reasonably straightforward to service.

The other big fail is the flexible hoses, which give you advance warning by seeping at the crimp connections. Its essential that these are ALL inspected every year, and repaired / replaced as necessary.

Vibration dampers sometimes fail from time to time and give strange symptoms, but aren't the end of the World.

If the worst comes the worst, and something big fails causing a red ABC warning message - stop and get the car trailered home.

Don't drive the car if there's a red ABC warning.

Check the oil level in the ABC reservoir.

Check for leaks and nasty noises.

Check the suspension level at each corner.

If oil's not coming out anywhere and the ride height is OK, you've probably lost pressure, and can drive to a dealer or good MB specialist.

Last edited by Welwynnick; 12-27-2015 at 07:28 AM.

#9

MBWorld Fanatic!

Thread Starter

https://mbworld.org/forums/cl55-amg-...r-replace.html

If you drain the fluid, THEN replace the fluid, you need to do a pressurized flush. Meaning that you have to force the fluid into the pump. The pump doesn't self-prime, even when the reservoir is full, so you have to pressurize the reservoir.

Alternatively, you can simply connect a drain pipe to the return pipe (top of the ABC reservoir) and start the engine - keeping the reservoir filled up!

I found another alternative: I could prime an empty pump by removing the poly-V belt and turn the pump pulley by hand until it firms up.

However, all those processes only replace the oil in the "clean" part of the system - where the oil circulates continuously. Downstream of the valves (in the pipes from the valves to the struts, and in the struts themselves) the oil doesn't circulate, and gets very dirty. Flushing doesn't clean this, but you can drain it using the drain ports in the pipes to each strut. That takes some explaining - you gotta know what you're doing.

To drain the old oil out of the struts and feed pipes, you need to:

Questions:

1. If the "normal" flush does not replace the pipe/strut fluid how does ABC pump charge the struts after they are drained according to your procedure above?

2. How many litres of Pentosin +/- do I need to drain/fill the struts and feed pipes?

3. The dealer estimated 3-4 hours to perform the pipe/strut fluid and the rodeo. Does this sound right?

(The dealer tech said I needed 10 litres of Pentosin HOWEVER I think he was referring to the normal "flush" - even though - I thought we were talking about the pipe/strut flush. I had the normal "flush" done last year and changed the filter at that time. I will change the ABC filter this time also.)

Many thanks!

1. Very good question. The oil doesn't circulate round the struts - the pipe connections are single ended, so the fluid only goes in and out. That's why you compress the strut to get the oil out, then close the drain valve. Some air will probably get into the pipe, but not too much. Remember that ABC runs at 200 bar, so that air will be greatly compressed (it squeaks when you start the engine and raise the suspension). I think the idea is that those bubbles are pulled out when you do the rodeo, but its not really a very robust bleeding process.

2. Most people reckon about 10 litres.

3. To be honest, that's what I'd expect from an amateur.

Nick

If you drain the fluid, THEN replace the fluid, you need to do a pressurized flush. Meaning that you have to force the fluid into the pump. The pump doesn't self-prime, even when the reservoir is full, so you have to pressurize the reservoir.

Alternatively, you can simply connect a drain pipe to the return pipe (top of the ABC reservoir) and start the engine - keeping the reservoir filled up!

I found another alternative: I could prime an empty pump by removing the poly-V belt and turn the pump pulley by hand until it firms up.

However, all those processes only replace the oil in the "clean" part of the system - where the oil circulates continuously. Downstream of the valves (in the pipes from the valves to the struts, and in the struts themselves) the oil doesn't circulate, and gets very dirty. Flushing doesn't clean this, but you can drain it using the drain ports in the pipes to each strut. That takes some explaining - you gotta know what you're doing.

To drain the old oil out of the struts and feed pipes, you need to:

- Jack up the front of the car and support on stands.

- Open the drain valve and drain the oil using a clear plastic 8mm pipe into a bucket.

- Do this carefully, using one ring spanner on the bleed nipple and one ring spanner on the valve body.

- Jack up the suspension arm using a trolley jack, until it just takes the weight of the car.

- This forces almost all of the fluid out of the strut.

- Close the drain valves and drop the car back down without starting the engine.

- Its best to use the car's jack for this, as the car ends up on the floor.

- Repeat the above process for the rear end.

- Top up the ABC reservoir, start the engine, and keep the reservoir topped-up.

- Run a rodeo or cycle the suspension height several times.

Questions:

1. If the "normal" flush does not replace the pipe/strut fluid how does ABC pump charge the struts after they are drained according to your procedure above?

2. How many litres of Pentosin +/- do I need to drain/fill the struts and feed pipes?

3. The dealer estimated 3-4 hours to perform the pipe/strut fluid and the rodeo. Does this sound right?

(The dealer tech said I needed 10 litres of Pentosin HOWEVER I think he was referring to the normal "flush" - even though - I thought we were talking about the pipe/strut flush. I had the normal "flush" done last year and changed the filter at that time. I will change the ABC filter this time also.)

Many thanks!

1. Very good question. The oil doesn't circulate round the struts - the pipe connections are single ended, so the fluid only goes in and out. That's why you compress the strut to get the oil out, then close the drain valve. Some air will probably get into the pipe, but not too much. Remember that ABC runs at 200 bar, so that air will be greatly compressed (it squeaks when you start the engine and raise the suspension). I think the idea is that those bubbles are pulled out when you do the rodeo, but its not really a very robust bleeding process.

2. Most people reckon about 10 litres.

3. To be honest, that's what I'd expect from an amateur.

Nick

#10

MBWorld Fanatic!

Thread Starter

Active Curve System

ABC lite - Active Curve System:

https://mbworld.org/forums/new-m-cla...ve-system.html

Here's interesting detailed info on the Active Curve System, which is part of the Dynamic Handling Package in the US.

Active Curve System

On the subjectof ABC suspension, Mercedes introduced some more technology that had passed me by. The latest ML and GL series 4x4s have an option for Active Curve System, which looks like ABC Lite. It just applies roll-control to the sway bars, rather than individually to each spring strut. Therefore it only controls roll –and not dive, squat or self-levelling. This is just like BMW Dynamic Drive, introduced over a decade ago on the E60, E63 & E65 (and by Land Rover on the Discovery)

What I like about ACS is that it isolates the springing, damping and roll-control functions (at least at the rear, where the dampers are separate to the springs). This is quite different to ABC, where all functions are rolled into one, so an ABC failure can immobilize the car. If ACS fails, the springs and dampers carry on working, and you can still drive. It improves all aspects of maintainability, which is ABC’s Achilles’ Heel.

I believe it also relieves Mercedes of the packaging issues with ABC – I think they have difficulty embodying all the body control and levelling capabilities while still providing long wheel travel. There’s just not enough space for a long coil spring, especially at the front, where they’ve had to use an adverse track control arm lever ratio. ACS just doesn’t have that problem at all, though it obviously still needs a sway bar, to the detriment of roll-rock (which ABC doesn’t have at all). With ACS, the hydraulics can also be better protected from mud and salt spray (anybody ever tried to release an ABC “quick-release” connector?).

Self-levelling is still performed by Airmatic, which is a pre-requisite for ordering ACS in Mercedes' price lists. That’s a shame, as there’s no fundamental reason why you can’t have ACS with steel springs. Airmatic is an expensive system in its own right, so if you want ACS you have to buy TWO expensive suspension systems –the price of redundancy for you. When my W220 was new, the ABC option was only £2200, which is less than Mercedes now charge for ACS, which I struggle to comprehend. This is why mid-engined cars are good.

This is the bit I really like though, and where ABC missed a great opportunity:

Quote:

Badly worded, but I think this is what it means: The springs are no longer used to control roll or tune the handling balance (understeer vs oversteer etc). In corners, the weight transfer is managed by ACS, so the front/rear distribution of the weight transfer can be controlled by ACS, and it no longer has to be fixed or even linear. For example, you could tune for oversteer in gentle corners and understeer in hard corners if you wanted. But I think it’s the dynamic behaviour that’s the great opportunity. Because of the polar moment of inertia of our cars (it’s like mass, but for rotating objects), they’re slow to change direction and slow to stop changing direction. The longer the car, the worse the dynamic behaviour (regardless of where the centre of gravity is).

What ACS may be doing is sensing steering wheel movement, or the change in cornering force, and dynamically adjusting the weight transfer distribution. That means increasing the rear transfer when turning into the corner (giving more front grip), and increasing the front transfer on the way out (giving more rear grip). That makes it both quicker to change direction, and slower to spin. It’s a huge win, and one that Toyota used to great advantage in my old 1992 SC400/Soarer UZZ32– the first road car with active suspension (-which cost almost as much as the car itself!). It was as pointy as a go-cart, but stable as a limo. Obviously, there’s no reason why ABC can’t do this – I think it should have from the outset – and then we’d all be cheering it as a much better system.

http://www.daimler.com/dccom/0-5-1210218-1-1531792-1-0-0-1210228-0-0-135-0-0-0-0-0-0-0-0.html

https://mbworld.org/forums/new-m-class-w166/405488-active-curve-system.html

http://www.forum-mercedes.com/topic-...-freinage.html

Nick

The internet is a bottomless but disorganised pit of information, and I think one of the keys to finding something useful is knowing what its called.

For example, when I was repairing and modifying my ABC system, I wanted to find a 10mm compression pigtail, though I didn't know it was called that until later.

And when I modified my IC system, I needed a reducing elbow and a 19mm hose sensor, though it took a while to realise. You could say its all just plain english, but using combinations of words that I'd never thought of.

Similarly, when I get frustrated about all the things Mercedes don't do, its often a case of looking for the right thing. ABC ought to be able to vary the roll momentum distribution, or the weight transfer distribution. But the problem is that it's just not discussed anywhere, and when its mentioned in a press release, its actually called variable roll moment distribution.

Put that into Google and you get lots of returns, including patents, university theses, and this from Mercedes:

Quote:

Other notable features of Active Body Control are the variable roll moment distribution between the front and rear axles

http://www.emercedesbenz.com/autos/m...raking-system/

So Mercedes did actually introduce variable roll moment distribution on the 2010 S-class, along with Cross-Wind stabilization.

The CL and SL got it as well, so they got there in the end, but I don't think anybody realised.

The latest Porsche Panamera gets it as well, but uses active anti-roll bars.

Nick

https://mbworld.org/forums/new-m-cla...ve-system.html

Here's interesting detailed info on the Active Curve System, which is part of the Dynamic Handling Package in the US.

Active roll stabilization in the form of the ACTIVE CURVE SYSTEM can be optionally combined with both the AIRMATIC air suspension with Adaptive Damping System (ADS) and the ON&OFFROAD package. This system uses active anti-roll bars on the front and rear axles, which it controls automatically as a function of the lateral acceleration, road speed and the ADS Comfort/Sport switch setting. The ACTIVE CURVE SYSTEM compensates for the roll angle of the body through bends, greatly increasing agility and driving pleasure in the process. The system has the additional effect of increasing handing stability and therefore safety, particularly at higher speeds. Further benefits of the ACTIVE CURVE SYSTEM include even greater ride comfort both when cornering and driving in a straight line, together with enhanced off-road abilities. The various control strategies in detail:

Comfort is improved when driving straight ahead as the rotary actuators decouple the two halves of the front and rear anti-roll bars in this situation, meaning that the anti-roll bars are "open" and do not react to a stimulus on just one side, such as bumps or potholes.

Increased ride comfort and more dynamic handling when cornering, because the system actively influences the anti-roll bars' torsional moments and twisting angles. The anti-roll bars' torsional moment furthermore remains constant in response to a stimulus on one side, such as is the case when driving over a pothole on the outside of the bend. Thanks to the individual control at the front and rear axles, distribution of the roll momentum can be varied, allowing the self-steering properties to be actively adapted to the prevailing driving situation. The handling characteristics are adjusted for extra agility when driving along country roads and for even greater stability on the highway.

When driving in extreme off-road conditions at low speeds, the two anti-roll bars at the front and rear axles are decoupled. This leaves the anti-roll bars "open", allowing greater axle articulation.

The key componentry of the ACTIVE CURVE SYSTEM comprises a belt-driven hydraulic pump and an oil reservoir in the engine compartment, as well as a valve block and active anti-roll bars at both the front and rear axles. In contrast to a passive anti-roll bar, the active variant is split into two in the middle, and the two halves are connected with one another by means of hydraulic rotary actuators. Using the CAN signals relayed to it by pressure sensors and a lateral acceleration sensor, the electronic control unit regulates the hydraulic pressure.

The complex workings of the ACTIVE CURVE SYSTEM:

The hydraulic pump feeds oil to the system from the oil reservoir. The pressure control valves and directional control valves integrated into the valve blocks at the front and rear axles set the desired pressure and twist the active anti-roll bars in the appropriate direction for the driving situation. Inside the hydraulic rotary actuators that are built into the active anti-roll bars there are six oil-filled chambers, three of which are pressurised for each direction of travel, i.e. a left or right-hand bend. The front valve block additionally assumes the task of distributing the oil flow between the two axles, irrespective of load.

Comfort is improved when driving straight ahead as the rotary actuators decouple the two halves of the front and rear anti-roll bars in this situation, meaning that the anti-roll bars are "open" and do not react to a stimulus on just one side, such as bumps or potholes.

Increased ride comfort and more dynamic handling when cornering, because the system actively influences the anti-roll bars' torsional moments and twisting angles. The anti-roll bars' torsional moment furthermore remains constant in response to a stimulus on one side, such as is the case when driving over a pothole on the outside of the bend. Thanks to the individual control at the front and rear axles, distribution of the roll momentum can be varied, allowing the self-steering properties to be actively adapted to the prevailing driving situation. The handling characteristics are adjusted for extra agility when driving along country roads and for even greater stability on the highway.

When driving in extreme off-road conditions at low speeds, the two anti-roll bars at the front and rear axles are decoupled. This leaves the anti-roll bars "open", allowing greater axle articulation.

The key componentry of the ACTIVE CURVE SYSTEM comprises a belt-driven hydraulic pump and an oil reservoir in the engine compartment, as well as a valve block and active anti-roll bars at both the front and rear axles. In contrast to a passive anti-roll bar, the active variant is split into two in the middle, and the two halves are connected with one another by means of hydraulic rotary actuators. Using the CAN signals relayed to it by pressure sensors and a lateral acceleration sensor, the electronic control unit regulates the hydraulic pressure.

The complex workings of the ACTIVE CURVE SYSTEM:

The hydraulic pump feeds oil to the system from the oil reservoir. The pressure control valves and directional control valves integrated into the valve blocks at the front and rear axles set the desired pressure and twist the active anti-roll bars in the appropriate direction for the driving situation. Inside the hydraulic rotary actuators that are built into the active anti-roll bars there are six oil-filled chambers, three of which are pressurised for each direction of travel, i.e. a left or right-hand bend. The front valve block additionally assumes the task of distributing the oil flow between the two axles, irrespective of load.

On the subjectof ABC suspension, Mercedes introduced some more technology that had passed me by. The latest ML and GL series 4x4s have an option for Active Curve System, which looks like ABC Lite. It just applies roll-control to the sway bars, rather than individually to each spring strut. Therefore it only controls roll –and not dive, squat or self-levelling. This is just like BMW Dynamic Drive, introduced over a decade ago on the E60, E63 & E65 (and by Land Rover on the Discovery)

What I like about ACS is that it isolates the springing, damping and roll-control functions (at least at the rear, where the dampers are separate to the springs). This is quite different to ABC, where all functions are rolled into one, so an ABC failure can immobilize the car. If ACS fails, the springs and dampers carry on working, and you can still drive. It improves all aspects of maintainability, which is ABC’s Achilles’ Heel.

I believe it also relieves Mercedes of the packaging issues with ABC – I think they have difficulty embodying all the body control and levelling capabilities while still providing long wheel travel. There’s just not enough space for a long coil spring, especially at the front, where they’ve had to use an adverse track control arm lever ratio. ACS just doesn’t have that problem at all, though it obviously still needs a sway bar, to the detriment of roll-rock (which ABC doesn’t have at all). With ACS, the hydraulics can also be better protected from mud and salt spray (anybody ever tried to release an ABC “quick-release” connector?).

Self-levelling is still performed by Airmatic, which is a pre-requisite for ordering ACS in Mercedes' price lists. That’s a shame, as there’s no fundamental reason why you can’t have ACS with steel springs. Airmatic is an expensive system in its own right, so if you want ACS you have to buy TWO expensive suspension systems –the price of redundancy for you. When my W220 was new, the ABC option was only £2200, which is less than Mercedes now charge for ACS, which I struggle to comprehend. This is why mid-engined cars are good.

This is the bit I really like though, and where ABC missed a great opportunity:

Quote:

Thanks to the individual control at the front and rear axles,

distribution of the roll momentum can be varied, allowing the self-steering properties to be actively adapted to the prevailing driving situation. The handling characteristics are adjusted for extra agility when driving along country roads and for even greater stability on the highway.

What ACS may be doing is sensing steering wheel movement, or the change in cornering force, and dynamically adjusting the weight transfer distribution. That means increasing the rear transfer when turning into the corner (giving more front grip), and increasing the front transfer on the way out (giving more rear grip). That makes it both quicker to change direction, and slower to spin. It’s a huge win, and one that Toyota used to great advantage in my old 1992 SC400/Soarer UZZ32– the first road car with active suspension (-which cost almost as much as the car itself!). It was as pointy as a go-cart, but stable as a limo. Obviously, there’s no reason why ABC can’t do this – I think it should have from the outset – and then we’d all be cheering it as a much better system.

http://www.daimler.com/dccom/0-5-1210218-1-1531792-1-0-0-1210228-0-0-135-0-0-0-0-0-0-0-0.html

https://mbworld.org/forums/new-m-class-w166/405488-active-curve-system.html

http://www.forum-mercedes.com/topic-...-freinage.html

Nick

The internet is a bottomless but disorganised pit of information, and I think one of the keys to finding something useful is knowing what its called.

For example, when I was repairing and modifying my ABC system, I wanted to find a 10mm compression pigtail, though I didn't know it was called that until later.

And when I modified my IC system, I needed a reducing elbow and a 19mm hose sensor, though it took a while to realise. You could say its all just plain english, but using combinations of words that I'd never thought of.

Similarly, when I get frustrated about all the things Mercedes don't do, its often a case of looking for the right thing. ABC ought to be able to vary the roll momentum distribution, or the weight transfer distribution. But the problem is that it's just not discussed anywhere, and when its mentioned in a press release, its actually called variable roll moment distribution.

Put that into Google and you get lots of returns, including patents, university theses, and this from Mercedes:

Quote:

Other notable features of Active Body Control are the variable roll moment distribution between the front and rear axles

http://www.emercedesbenz.com/autos/m...raking-system/

So Mercedes did actually introduce variable roll moment distribution on the 2010 S-class, along with Cross-Wind stabilization.

The CL and SL got it as well, so they got there in the end, but I don't think anybody realised.

The latest Porsche Panamera gets it as well, but uses active anti-roll bars.

Nick

Last edited by Welwynnick; 12-27-2015 at 05:36 PM.

The following users liked this post:

Flydutch (11-09-2020)

#11

MBWorld Fanatic!

Thread Starter

https://mbworld.org/forums/cl-class-...y-job-yes.html

Thanks to duhdenmark for this post:

Hi guys.

Just to let any doubters know, its very easy to flush the abc oil on your CL. You do not need a STAR for this job.

1. Do a good cleaning around the ABC container. - See awiners post below he also recommends that the entire container is drained first, because there can be lots of dirt in the buttom.

2. Disconnect the hose going to the big cap on top on the ABC container. Connect the end of this hose to a clear hose and put it in a bowl that can contain at least 10 liters of oil. You need a clear hose, because then you can watch when the oil running through is a nice clean green color.

3. Remove the lid and ABC oil filter, again take care so that dirt do not get into the ABC oil container. Ready 10 liters of Pentosin CHF 11S.

4. Have some good light available so you can always observe the oil level in the container during the flush.

5. Have a friend turn on the car.

6. From the inside of the car, use the raise button up and down to cycle the ABC oil. Take GREAT care not to let the ABC container run dry. The flow is not very fast, even when the car is being raised, but if you need a brake, just turn of the engine and fill the container again.

7. After flushing about 8 liters the oil should be nice green again. I used 10 liters because that was what I was recommended.

8. After you are finished, replace the ABC oil filter and make sure the oil level is correct.

9. You are done and its more easy that changing the engine oil!

David

Thanks to duhdenmark for this post:

Hi guys.

Just to let any doubters know, its very easy to flush the abc oil on your CL. You do not need a STAR for this job.

1. Do a good cleaning around the ABC container. - See awiners post below he also recommends that the entire container is drained first, because there can be lots of dirt in the buttom.

2. Disconnect the hose going to the big cap on top on the ABC container. Connect the end of this hose to a clear hose and put it in a bowl that can contain at least 10 liters of oil. You need a clear hose, because then you can watch when the oil running through is a nice clean green color.

3. Remove the lid and ABC oil filter, again take care so that dirt do not get into the ABC oil container. Ready 10 liters of Pentosin CHF 11S.

4. Have some good light available so you can always observe the oil level in the container during the flush.

5. Have a friend turn on the car.

6. From the inside of the car, use the raise button up and down to cycle the ABC oil. Take GREAT care not to let the ABC container run dry. The flow is not very fast, even when the car is being raised, but if you need a brake, just turn of the engine and fill the container again.

7. After flushing about 8 liters the oil should be nice green again. I used 10 liters because that was what I was recommended.

8. After you are finished, replace the ABC oil filter and make sure the oil level is correct.

9. You are done and its more easy that changing the engine oil!

David

The following users liked this post:

dgi (07-31-2023)

#13

MBWorld Fanatic!

Thread Starter

https://mbworld.org/forums/cl55-amg-...bc-struts.html

How to replace struts:

Sure, lots of people have replaced their own, including me. You just undo the old ones and refit the new ones. Ultimately they're just nuts and bolts.

Of course its a bit more complicated than that, as you have hydraulics, electrics and level sensors as well.

The electrical connector is removed from the top using pliers.

The level sensor is unbolted from the top wishbone, but its awkward. The nut will likely be seized, and the L-bracket at the end of the link is rather fragile.

There is just one hydraulic connection, and its a quick-release connector. The release collar is often seized, and may need to be freed with heavy and patient use of strong pliers. It can be a real pain.

The lower connection to the wishbone is the real problem. There are two hex grub screws, and they usually rust and seize. Many pro's say you have to undo them with an oxy-acetylene torch. Terrible design and a big problem.

Bleeding is no big deal. The best way is to run a rodeo using STAR, but most folks are happy to raise and lower lots of times, and keep the reservoir at the right level (ie: at the lower dipstick mark when the engine is running).

Nick

How to replace struts:

Sure, lots of people have replaced their own, including me. You just undo the old ones and refit the new ones. Ultimately they're just nuts and bolts.

Of course its a bit more complicated than that, as you have hydraulics, electrics and level sensors as well.

The electrical connector is removed from the top using pliers.

The level sensor is unbolted from the top wishbone, but its awkward. The nut will likely be seized, and the L-bracket at the end of the link is rather fragile.

There is just one hydraulic connection, and its a quick-release connector. The release collar is often seized, and may need to be freed with heavy and patient use of strong pliers. It can be a real pain.

The lower connection to the wishbone is the real problem. There are two hex grub screws, and they usually rust and seize. Many pro's say you have to undo them with an oxy-acetylene torch. Terrible design and a big problem.

Bleeding is no big deal. The best way is to run a rodeo using STAR, but most folks are happy to raise and lower lots of times, and keep the reservoir at the right level (ie: at the lower dipstick mark when the engine is running).

Nick

#14

MBWorld Fanatic!

Thread Starter

ABC Hose Insulation

https://mbworld.org/forums/m275-v12-...ml#post6242174

I'm convinced that many problems associated with the V12TT can be attributed to high under hood temps caused by the turbos. I never thought of adding turbo blankets though. I'm rather ignorant there unfortunately. I've seen lots of tuning shops sell them, and I appreciate the upsides, but I don't know about the downsides.

Presumably, by insulating the turbo, they increase its operating temperature. I guess that many people have done just that, and I'd sure like to know if they'd had faster turo failures as a consequence. Or not. Our turbos are water-cooled , so I'm sure that helps to protect them. I rebuilt my turbos this summer, and I looked at lots of ways of improving the under-hood heat management:

There are lots of different ways to do thermal management under hood, and they need to make sure the protection measure addresses the right threat to performance and reliability:

The coil packs on the other hand, are a rather different problem. They're in line of sight of the turbos, so they're subject to infra-red radiation, and they DON'T cool themselves. Mercedes solution is to screw insulating covers to the exposed center sections. The insulation does have a reflective outer layer, but there's insulation in between, and they're in contact with the coil pack.

I don't think this is a good idea, as there's no air under the shield, and heat will conduct through to the coil. When manufacturers insulate exhaust systems, they normally use single skin metal shields that provide a barrier for IR radiation and convecting air. They provide no insulation at all, but they're very effective. The key thing is that air is able to flow past both sides of the shield, so temps are never allowed to build up.

I think that's what's needed for the coil packs, so I built a pair of ally shields that stand off the coil, allowing air to flow down both sides. It took a few goes, and mounting them is tricky, as there's not much room, but it help if the stock shield is removed. I fitted one, and left the other off, to see what difference they make. I put temperature tape on the coil packs, and I'll take the intakes back off soon & look for any difference between them. What I did notice on Sunday is that on my first long journey for nine months, it never misfired and threw a CEL. Even with both new coil packs, that's still unusual on a long run.

I did similar things to the ABC pipes, and I've got lots of pictures of all these things...

Nick

I removed all the ABC pipes around the engine, and replaced them with new pipes with compression connections:

Taking a closer look at the pipes that were already protected by reflective insulating sleeves. I cleaned the sleeves, but the pipes are as they came off the car. They're in very good condition:

However, the feed pipe from the pump to the regulator wasn't protected, and looks horrible. Draw your own conclusions.

Therefore I protected all the new ones with firesleeve. This is 30mm ID, which is too large. 25mm is ideal.

1c35bbd5-fa8a-4d94-b7b1-ddef5d84a7cf_zpsfd082764.jpg?t=1416907582

If I was ever mad enough to buy another car with ABC, I would do all that straight away as a matter course, regardless of the condition of the pipes.

Fitting those pipes can be difficult. What I did was support the engine, undo the engine mounts and drop the front of the subframe.

In this picture you can see how easy it is to access the pipes, the PAS output connection, the diverter valves, and even the ABC output banjo - that's SO difficult otherwise.

Nick

I'm convinced that many problems associated with the V12TT can be attributed to high under hood temps caused by the turbos. I never thought of adding turbo blankets though. I'm rather ignorant there unfortunately. I've seen lots of tuning shops sell them, and I appreciate the upsides, but I don't know about the downsides.

Presumably, by insulating the turbo, they increase its operating temperature. I guess that many people have done just that, and I'd sure like to know if they'd had faster turo failures as a consequence. Or not. Our turbos are water-cooled , so I'm sure that helps to protect them. I rebuilt my turbos this summer, and I looked at lots of ways of improving the under-hood heat management:

- I fabricated a couple of heat shields to cover the whole length of the coil packs, sitting just outboard of the existing heat shields. I stuck some temperature tape on the coil packs to see if that lowered their peak surface temps. The results aren't in yet.

- I also wrapped the charge cooler lines in foil and fibreglass heat mats, to help insulate them from the turbos and reduce heat soak. I did the same to the IC's themselves, though I doubt that makes much difference.

- I can monitor my IC coolant temperature from my pump controller, and it does stay cool. I turned down the target temperature from 30C to 25C yesterday, and sure enough it ran 5C cooler today.

- The other thing I've done is replace all the ABC hoses in the engine compartment with compression-jointed removable hoses, and add reflective thermal insulation to those as well. I think that long term, that will probably be the biggest win.

- I did consider adding metal plates to the underside of the pipes between the compressors and the IC's, but I couldn't afford the time

- Of course, adding insulation to the turbos themselves may tackle the root cause of the problem, as long as the turbos themselves don't get too hot.

There are lots of different ways to do thermal management under hood, and they need to make sure the protection measure addresses the right threat to performance and reliability:

- infra-red radiation

- thermal conduction

- thermal convection

The coil packs on the other hand, are a rather different problem. They're in line of sight of the turbos, so they're subject to infra-red radiation, and they DON'T cool themselves. Mercedes solution is to screw insulating covers to the exposed center sections. The insulation does have a reflective outer layer, but there's insulation in between, and they're in contact with the coil pack.

I don't think this is a good idea, as there's no air under the shield, and heat will conduct through to the coil. When manufacturers insulate exhaust systems, they normally use single skin metal shields that provide a barrier for IR radiation and convecting air. They provide no insulation at all, but they're very effective. The key thing is that air is able to flow past both sides of the shield, so temps are never allowed to build up.

I think that's what's needed for the coil packs, so I built a pair of ally shields that stand off the coil, allowing air to flow down both sides. It took a few goes, and mounting them is tricky, as there's not much room, but it help if the stock shield is removed. I fitted one, and left the other off, to see what difference they make. I put temperature tape on the coil packs, and I'll take the intakes back off soon & look for any difference between them. What I did notice on Sunday is that on my first long journey for nine months, it never misfired and threw a CEL. Even with both new coil packs, that's still unusual on a long run.

I did similar things to the ABC pipes, and I've got lots of pictures of all these things...

Nick

I removed all the ABC pipes around the engine, and replaced them with new pipes with compression connections:

Taking a closer look at the pipes that were already protected by reflective insulating sleeves. I cleaned the sleeves, but the pipes are as they came off the car. They're in very good condition:

However, the feed pipe from the pump to the regulator wasn't protected, and looks horrible. Draw your own conclusions.

Therefore I protected all the new ones with firesleeve. This is 30mm ID, which is too large. 25mm is ideal.

1c35bbd5-fa8a-4d94-b7b1-ddef5d84a7cf_zpsfd082764.jpg?t=1416907582

If I was ever mad enough to buy another car with ABC, I would do all that straight away as a matter course, regardless of the condition of the pipes.

Fitting those pipes can be difficult. What I did was support the engine, undo the engine mounts and drop the front of the subframe.

In this picture you can see how easy it is to access the pipes, the PAS output connection, the diverter valves, and even the ABC output banjo - that's SO difficult otherwise.

Nick

Last edited by Welwynnick; 12-27-2015 at 04:49 PM.

#15

MBWorld Fanatic!

Thread Starter

Rebuilding Front Strut Top Mount Bushes

https://mbworld.org/forums/cl-class-...op-mounts.html

I think most well-used W215's and W220's will suffer from this problem, and it can be easily fixed. The improvement to the ride and handling is really worthwhile on broken surfaces.

On the rear strut, the bush appears to be bonded to the metal mounting. I don't think this causes problems as readily as the front, but the bush can come free due to corrosion or bonding failure. The only solution I found was to replace the strut. Buy a good used one off ebay, and its not too expensive or difficult (as long as the so-called quick-release connector isn't seized).

I cut some small doughnuts out of a 10mm rubber sheet and put them under the top bush nuts. You need a stout 35mm pin spanner. Don't even need to lift the car up - in fact its better if you don't.

The ride is much better now. You can't do the same trick with rear struts unfortunately.

Its an angle grinder type of spanner that you need; not a C spanner.

The one that you linked on ebay looks suitable.

You can't use adjustable ones; they're not up to the job. Ask me how etc.

You use the spanner to undo the large flat nut on the top of the front strut, in the centre. You remove the electrical connector first.

Don't jack the car up - you need the weight on the wheel to stop the rest of the strut from spinning round (which may damage the hydraulic pipe).

I think most well-used W215's and W220's will suffer from this problem, and it can be easily fixed. The improvement to the ride and handling is really worthwhile on broken surfaces.

On the rear strut, the bush appears to be bonded to the metal mounting. I don't think this causes problems as readily as the front, but the bush can come free due to corrosion or bonding failure. The only solution I found was to replace the strut. Buy a good used one off ebay, and its not too expensive or difficult (as long as the so-called quick-release connector isn't seized).

I cut some small doughnuts out of a 10mm rubber sheet and put them under the top bush nuts. You need a stout 35mm pin spanner. Don't even need to lift the car up - in fact its better if you don't.

The ride is much better now. You can't do the same trick with rear struts unfortunately.

Its an angle grinder type of spanner that you need; not a C spanner.

The one that you linked on ebay looks suitable.

You can't use adjustable ones; they're not up to the job. Ask me how etc.

You use the spanner to undo the large flat nut on the top of the front strut, in the centre. You remove the electrical connector first.

Don't jack the car up - you need the weight on the wheel to stop the rest of the strut from spinning round (which may damage the hydraulic pipe).

Last edited by Welwynnick; 12-27-2015 at 04:50 PM.

#16

MBWorld Fanatic!

Thread Starter

Remanufactured Chinese ABC struts

http://www.cnocars.com/pshow.asp?id=618

http://www.cnocars.com/pshow.asp?id=617

http://www.cnocars.com/pshow.asp?id=617

hey guys, here is a quote I got for rebuilt struts from china fob Florida. Jan 22 at 8:06 PM

Hello

The fob price for W215 front left ABC strut is $258/pcs,

The fob price for W215 rear right ABC strut is $265/pcs,

We rebuilt and sell this parts.

Thanks&Regards

Michael

Ocars Air Suspension

Tel: 0086-18-981854029

Fax:0086-28-87061780

Web: www.cnocars.com

Skype: ocars.air.suspension

Email:ocars-air-suspension@hotmail.com

they are really reasonable. please if anyone gets them please give me your feedback as i don't need them at the present time. thanks

Hello

The fob price for W215 front left ABC strut is $258/pcs,

The fob price for W215 rear right ABC strut is $265/pcs,

We rebuilt and sell this parts.

Thanks&Regards

Michael

Ocars Air Suspension

Tel: 0086-18-981854029

Fax:0086-28-87061780

Web: www.cnocars.com

Skype: ocars.air.suspension

Email:ocars-air-suspension@hotmail.com

they are really reasonable. please if anyone gets them please give me your feedback as i don't need them at the present time. thanks

Last edited by Welwynnick; 12-27-2015 at 04:45 PM.

#17

MBWorld Fanatic!

Thread Starter

https://mbworld.org/forums/s55-amg-s...bc-thread.html

Miscellaneous fixes: Quick Release Connectors:

When the weight is on the wheels, the connectors are held tight by hydraulic pressure, so the first thing to do is jack the car up so the wheel is hanging (incidentally, while you're doing that, shake the wheel up and down to see if the strut top bush is tight or slack - they're prone to wear).

Assuming there's no pressure in the line, pry the rubber cover up so the quick-release collar is uncovered. It should spin round, but often doesn't. I don't know an easy way round this. What I did with mine was manipulate it with Mole grips. It won't slide up and down straight away (like someone in some Mercedes Benz Ivory Tower imagined it would) but you should be able to rotate it a degree clockwise and back, then two degrees, then three...

Eventually you'll be able to spin it all the way round, then you can start trying to slide it up and down. Its a long, gradual process, but you'll get there. If you have a strut or hose fail, it will be painful, but if you just happen to have the car jacked up, a bit of preventative maintenance now and again doesn't hurt.

Funnily enough, all the other ABC threaded joints are a straightfoward to undo. Only possible exception is where the metal pipes go into the tops of the struts themselves, but that's only when you need to swap left and right struts (as those pipes are handed - otherwise the L&R struts are the same).

PS. Incidentally, its worth draining some fluid whenever you have a wheel off. Put a clear hose on the bleed/drain nipple and open it slightly to drain some dirty oil out. Jack the suspension arm up as far as it will go, so the strut is fully compressed. That will get almost all the oil out of the strut.

This helps because the oil in the pump/regulator/cooler/valves circuit is continuously circulating and filtered. The oil in the struts, and in the lines up to the valves, just goes backwards and forwards, and doesn't get filtered. Therefore it gets very dirty, so get it out whenever its convenient.

Jack the car using the car's pillar jack, as that corner will be slammed when you let it back down again. However, the strut will fill itself with clean oil once you start it up again.

The valves isolate the struts from the ABC circuit when the engine is off. So if you drain the oil at each corner, it can only come from the struts and the pipes between the struts and the valves.

I suggest draining the oil by raising the suspension so that you force the oil out, rather than simply letting it drain, which would let air in.

I wouldn't recommend opening the drains when the oil is pressurised by the weight of the car. That would be a lot of pressure.

Also, don't start the engine when the car ISN'T resting on its wheels.

Hopefully that's obvious to anyone who might want to try this.

Nick

Miscellaneous fixes: Quick Release Connectors:

When the weight is on the wheels, the connectors are held tight by hydraulic pressure, so the first thing to do is jack the car up so the wheel is hanging (incidentally, while you're doing that, shake the wheel up and down to see if the strut top bush is tight or slack - they're prone to wear).

Assuming there's no pressure in the line, pry the rubber cover up so the quick-release collar is uncovered. It should spin round, but often doesn't. I don't know an easy way round this. What I did with mine was manipulate it with Mole grips. It won't slide up and down straight away (like someone in some Mercedes Benz Ivory Tower imagined it would) but you should be able to rotate it a degree clockwise and back, then two degrees, then three...

Eventually you'll be able to spin it all the way round, then you can start trying to slide it up and down. Its a long, gradual process, but you'll get there. If you have a strut or hose fail, it will be painful, but if you just happen to have the car jacked up, a bit of preventative maintenance now and again doesn't hurt.

Funnily enough, all the other ABC threaded joints are a straightfoward to undo. Only possible exception is where the metal pipes go into the tops of the struts themselves, but that's only when you need to swap left and right struts (as those pipes are handed - otherwise the L&R struts are the same).

PS. Incidentally, its worth draining some fluid whenever you have a wheel off. Put a clear hose on the bleed/drain nipple and open it slightly to drain some dirty oil out. Jack the suspension arm up as far as it will go, so the strut is fully compressed. That will get almost all the oil out of the strut.

This helps because the oil in the pump/regulator/cooler/valves circuit is continuously circulating and filtered. The oil in the struts, and in the lines up to the valves, just goes backwards and forwards, and doesn't get filtered. Therefore it gets very dirty, so get it out whenever its convenient.

Jack the car using the car's pillar jack, as that corner will be slammed when you let it back down again. However, the strut will fill itself with clean oil once you start it up again.

The valves isolate the struts from the ABC circuit when the engine is off. So if you drain the oil at each corner, it can only come from the struts and the pipes between the struts and the valves.

I suggest draining the oil by raising the suspension so that you force the oil out, rather than simply letting it drain, which would let air in.

I wouldn't recommend opening the drains when the oil is pressurised by the weight of the car. That would be a lot of pressure.

Also, don't start the engine when the car ISN'T resting on its wheels.

Hopefully that's obvious to anyone who might want to try this.

Nick

#18

MBWorld Fanatic!

Thread Starter

https://mbworld.org/forums/cl-class-...r-setup-3.html

I understand ABC frustrations. I don't think a car is viable if you can't be sure that you'll get to your destination, or if it costs more to repair than to buy.

The manufacturer's and dealers' approach to ABC is to treat it as a fit-and-forget system - until it goes wrong - then throw money at it.

I think this is completely wrong. Its far too complex for that, and it needs appropriate regular maintenance.

This is my approach:

Every two or three years –

I understand ABC frustrations. I don't think a car is viable if you can't be sure that you'll get to your destination, or if it costs more to repair than to buy.

The manufacturer's and dealers' approach to ABC is to treat it as a fit-and-forget system - until it goes wrong - then throw money at it.

I think this is completely wrong. Its far too complex for that, and it needs appropriate regular maintenance.

This is my approach:

Every two or three years –

- Replace the ABC oil and filter.

- Remove all the plastic under-trays and wheel arch liners.

- Inspect every ABC component –paying particular attention to the flexible hoses.

- The crimped joints always fail eventually, so if the hose is wet, repair or replace it, or it will let you down badly.

- Cut the old pipe out and replace it with a new section with 10mm compression joints.

- When the wheels are off the ground, rotate the metal collars on the quick-release connectors – they always seize.

- On W215/220 front struts, loosen then tighten the TORX screws that fasten the lower attachments – they always seize.

- Allow a few hours for the pressure to drop, and take the weight off the wheels.

- Drain as much oil as possible by compressing the strut with the bleed valve open – this oil is usually dirty.

- Remove the bleed nipples & covers and fit new ones if corroded.

- Make sure you have a scissor jack or pillar jack to hand – there’s not much room for a trolley jack when the car’s on its bump stops.

- Check the condition of all the bushes and ball joints using force.

- If you get a red ABC warning, stop the car and fix the fault.

- Don’t run the engine – a few seconds is probably OK, but a few minutes is not.

- The pump must be primed – even if the reservoir is full it won’t prime itself.

- You can prime the pump with a few PSI of compressed air in the part-filled reservoir.

- Alternatively, you can remove the poly-V belt and spin the pump by hand until you feel resistance.

- If you need suspension fluid, buy CHF-11S from an accessory shop.

- If you need a suspension strut, buy a remanufactured one.

- If you need hydraulic hoses, go to a hydraulic hose shop.

- If you need a pump, buy a serviceable used one.

- If you need O-rings, find someone who sells O-rings.

Last edited by Welwynnick; 12-27-2015 at 04:51 PM.

#19

MBWorld Fanatic!

Thread Starter

Fitting wider rear wheels on the front to make the most of ABC

https://mbworld.org/forums/s-class-w...els-tyres.html

I started off wondering whether I could fit enormous wheels all round. Now I know the answer is yes, I'm not sure I want to. What I found is that width isn't as much a problem as I thought - you just need the right offset. Front wheels don't have to be 20-30mm narrower than rear wheels, they can safely be the same size, and there isn't too much to fear from the dynamic aspect.

20's aren't a problem in themselves - you just need the right profile %. If you go big, wide & lot profile, you simply pay the price in ride, noise and durability. I've been looking at used 20" wheels on ebay for a while, and I've been struck by the high proportion that have welded crack repairs. If you run 20's, you can be pretty sure of breaking a wheel.

I'm running 19's at the moment - 245/40 and 275/35. They look great, and the road noise isn't too bad, but the ride is very surface dependant. Its OK on good surfaces, but they react badly to broken surfaces. I assume 245/35 & 275/30 on 20's would be even worse, and I'm not sure I could put up with that.

Here's the interesting bit, though. I'm interested in the dynamics, and 265/40/18x9 grips and steers better than 245/40/19x8.5 at the front. 275/35/19 at the front are even better, but at the rear they add NOTHING except looks. They add nothing to grip, nothing to ride, nothing to noise, nothing to traction and nothing to steering.

So I think having 265-40-18 all round would be better than staggered 19's, in every respect except maybe looks. Take another look at post 4, picture 3 - the wide rear wheels fill the front arches well, even though they're "only" 9x18's. If you can run 4x18x9 (or 9.5), then 275-40's would probably be a good choice dynamically and aesthetically. Therefore:

4 x 275/40/18x9 is a good conservative choice - better than staggered 19's.

4 x 275/35/19x9.5 is a good ambitious choice - almost certainly better than staggered 20's.

4 x 275/30/20x10 may well work, but its starting to look a bit extreme to me. Bragging rights only, I suspect, and nothing wrong with that.