2011 E350 4matic Engine Mounts - DIY Question

#1

Super Member

Thread Starter

2011 E350 4matic Engine Mounts - DIY Question

Hi all. I've done lots of searching but cannot find any DIY info specifically to the 2011 E350 4matic, which has the new transmission (7G Tronic Plus) and the old engine (the one without direct injection). Can someone point me in the right direction? I've seen some things about needing to drop the exhaust and removing the alternator/AC compressor, but I am wondering if it's really this complicated. Thanks in advance for any input on this!

#2

Senior Member

Join Date: Jul 2017

Location: Savannah, GA

Posts: 377

Received 96 Likes

on

69 Posts

2010 W212 E550 4matic

Hi all. I've done lots of searching but cannot find any DIY info specifically to the 2011 E350 4matic, which has the new transmission (7G Tronic Plus) and the old engine (the one without direct injection). Can someone point me in the right direction? I've seen some things about needing to drop the exhaust and removing the alternator/AC compressor, but I am wondering if it's really this complicated. Thanks in advance for any input on this!

Last edited by Oda112; 11-29-2017 at 11:21 AM.

#3

Super Member

I've done it on my V8 M273 with the 722.970 4matic transmission ( the regular 7g tronic) and it is not insanely difficult but also not an easy job. The most important thing is having the right tools, like the 17mm offset wrench to get to the top bolts of the mounts, which is by far the most important tool. I managed to take the mounts out without removing the exhaust headers, ac compressor or catalitic converters. The only things that need to be unbolted are the alternator and the steering rack( you only need to drop the steering rack 1 inch and you can wiggle the left hand mount out). It might actually be easier on the V6 since it's smaller. Another good tool to have is the good old extension with the wiggle adapter, I used 3 12 inch 3/8 extension bars with 2 wiggle adapters to get to the engine mount heat shield M10 bolts, those are the trickiest little devils to take out. The end result was worth it though, the car is so much smoother now, just like a Benz should be. Consider replacing the transmission mount as well, since they go out together. You'll know if your tranny mount is out if you have a vibration in the cabin at idle when in drive ( or using the hold function at stoplights). Good luck and let me know if you have other questions.

#4

Super Member

Thread Starter

I've done it on my V8 M273 with the 722.970 4matic transmission ( the regular 7g tronic) and it is not insanely difficult but also not an easy job. The most important thing is having the right tools, like the 17mm offset wrench to get to the top bolts of the mounts, which is by far the most important tool. I managed to take the mounts out without removing the exhaust headers, ac compressor or catalitic converters. The only things that need to be unbolted are the alternator and the steering rack( you only need to drop the steering rack 1 inch and you can wiggle the left hand mount out). It might actually be easier on the V6 since it's smaller. Another good tool to have is the good old extension with the wiggle adapter, I used 3 12 inch 3/8 extension bars with 2 wiggle adapters to get to the engine mount heat shield M10 bolts, those are the trickiest little devils to take out. The end result was worth it though, the car is so much smoother now, just like a Benz should be. Consider replacing the transmission mount as well, since they go out together. You'll know if your tranny mount is out if you have a vibration in the cabin at idle when in drive ( or using the hold function at stoplights). Good luck and let me know if you have other questions.

1. Is this what I need for the top bolt? https://www.ebay.com/itm/Mercedes-Be...h/263311648526 (I used the 16 MM version for the S430)

2. What do you mean by wiggle adapter? Is that like a "swivel socket"?

3. Can you describe more how to find the steering rack, or post a picture? I am not sure if I would need to do that with the V6 or not, but I would like to know where it is and what it looks like.

I don't think it's at a super critical point on my car yet, but I am starting to feel a little vibration at idle from time to time. I'd like to do it to prevent any potential issues down the line.

#5

Senior Member

Join Date: Jul 2017

Location: Savannah, GA

Posts: 377

Received 96 Likes

on

69 Posts

2010 W212 E550 4matic

Thanks for the feedback. I do have a few questions. I just did the mounts on my '04 S430 4matic so have a little bit of an idea what to expect on this one. The hardest part of the job is getting the mounts out. So, here are my questions for you:

1. Is this what I need for the top bolt? https://www.ebay.com/itm/Mercedes-Be...h/263311648526 (I used the 16 MM version for the S430)

2. What do you mean by wiggle adapter? Is that like a "swivel socket"?

3. Can you describe more how to find the steering rack, or post a picture? I am not sure if I would need to do that with the V6 or not, but I would like to know where it is and what it looks like.

I don't think it's at a super critical point on my car yet, but I am starting to feel a little vibration at idle from time to time. I'd like to do it to prevent any potential issues down the line.

1. Is this what I need for the top bolt? https://www.ebay.com/itm/Mercedes-Be...h/263311648526 (I used the 16 MM version for the S430)

2. What do you mean by wiggle adapter? Is that like a "swivel socket"?

3. Can you describe more how to find the steering rack, or post a picture? I am not sure if I would need to do that with the V6 or not, but I would like to know where it is and what it looks like.

I don't think it's at a super critical point on my car yet, but I am starting to feel a little vibration at idle from time to time. I'd like to do it to prevent any potential issues down the line.

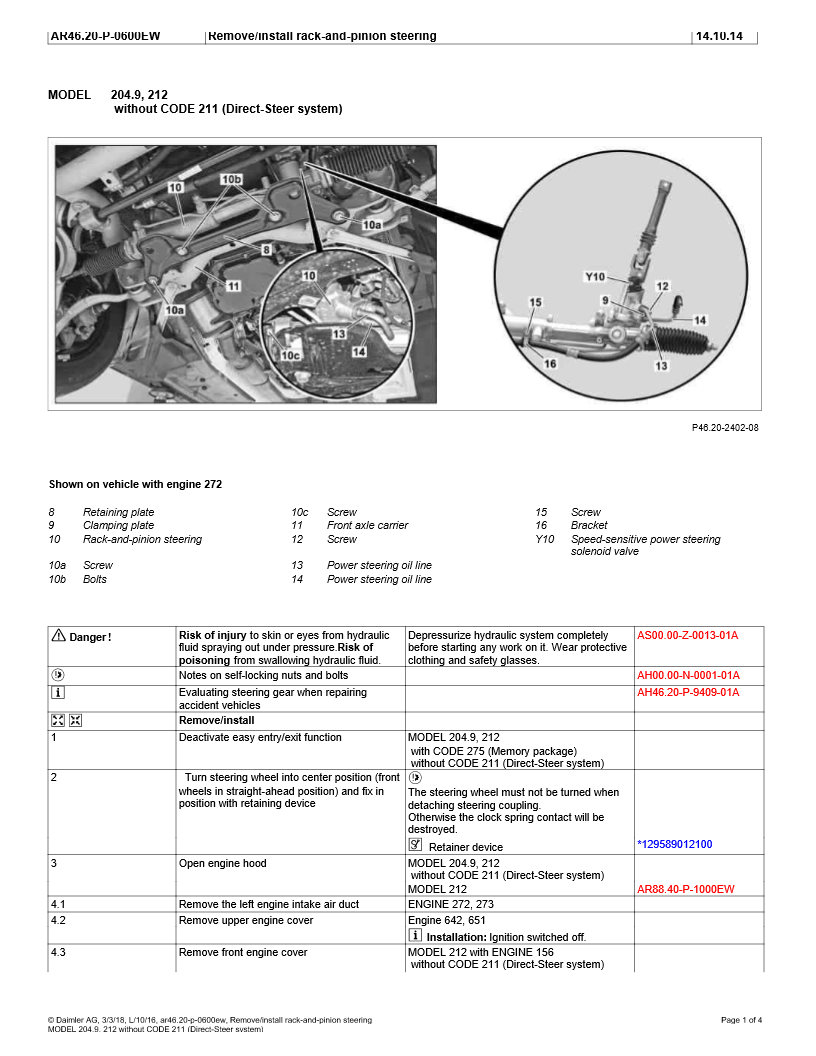

2. Yes, that is the proper term to describe it

3. I had to lower the steering rack to be able to get the driver side mount off without removing the AC compressor. You need to have the wheels pointing straight ahead ( there's a little green arrow on the steering column which aligns to a metal corresponding washer on the lower part of the steering column, that's how you know the wheels are straight), it's very easy to do, and since you're not unbolting anything your alignment shouldn't be affected. There are two bolts on each side of the steering rack carrier bracket ( if I remember correctly they're 18mm), you take them out and the whole assembly should lower just enough to give you some space to wiggle the mount off. If you're lucky you might not even have to lower the rack, the V6 might be more forgiving.

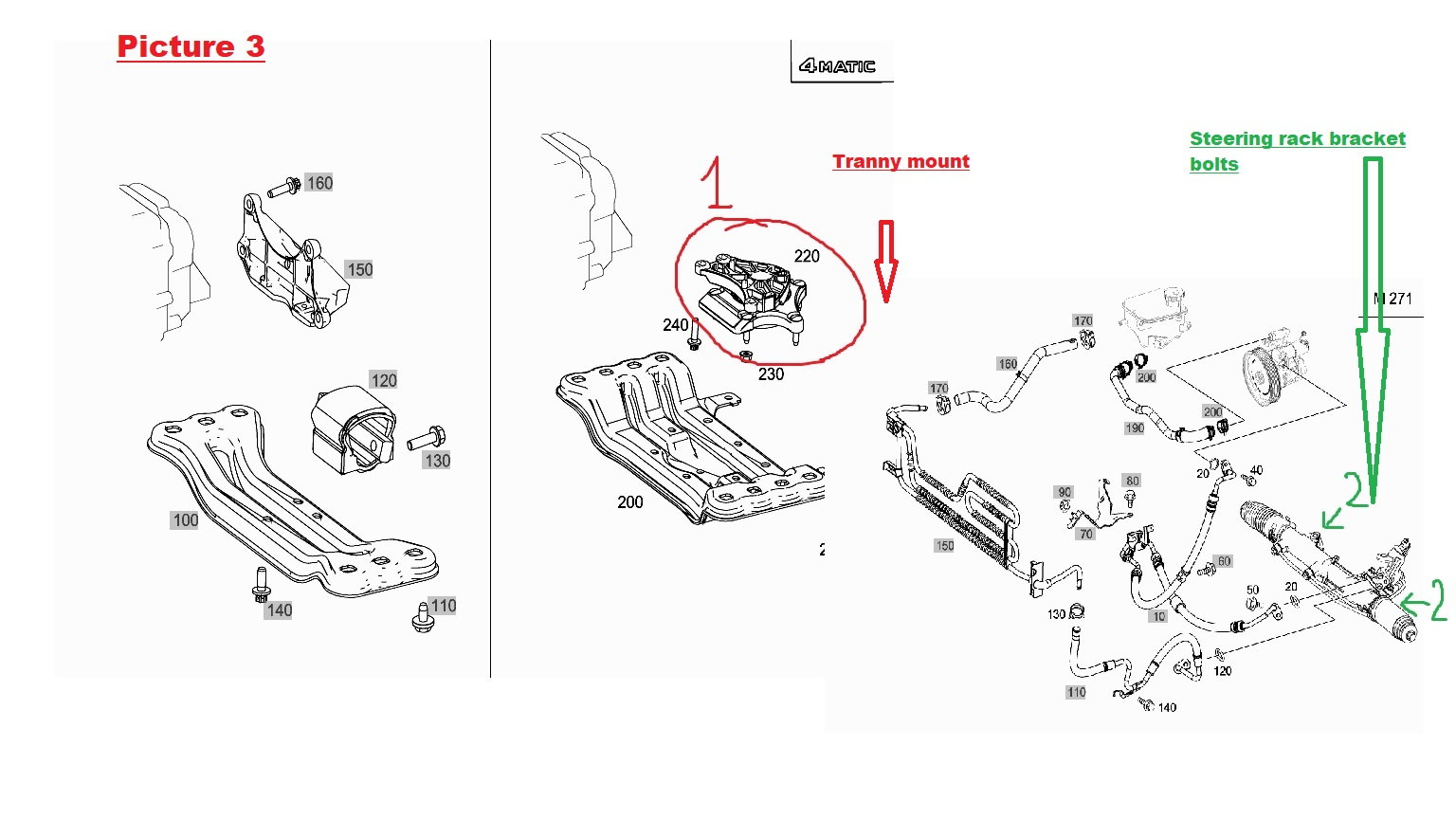

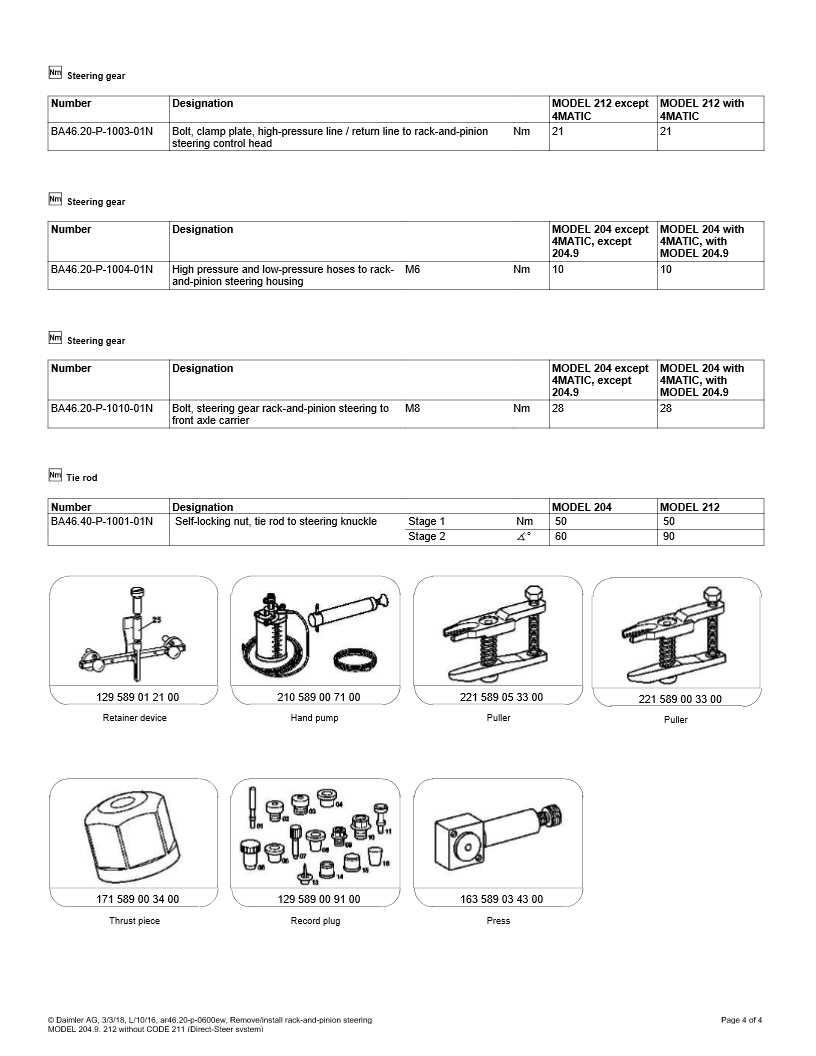

If your vibration at idle ONLY happens when you're at at stop light in Drive or with the car stopped (wheels not moving) in Reverse and there is no vibration at idle when in Park or Neutral then you don't need to replace the engine mounts, just the transmission one, Number 1 in the Picture 3 I attached( don't use Corteco as a replacement part, I did it and it failed after a few months, I'll have to replace mine again). On the right side of that pic you'll find the approximate position of the two steering rack bracket bolts, the ones you need to take out in order to lower the rack.

A general view of a MB steering rack setup is Picture 2 (and the 2 bolts you need to remove to drop the rack) and in Picture 1 you'll see the alignment notches I was talking about. As you sit under the car, looking at the steering column you should see on it a small green triangle/arrow on the plastic sleeve which will correspond to another arrow or some other sort of notch on the metal part of the column, right underneath the plastic sleeve, towards the front of the car. They should be perpendicular to the horizontal line of your car (pointing straight downwards) if the alignment on your car is correct. You can check this before unbolting anything.

Last edited by Oda112; 11-29-2017 at 11:20 AM.

The following users liked this post:

darkshinobi (10-11-2020)

#6

Senior Member

Join Date: Jul 2017

Location: Savannah, GA

Posts: 377

Received 96 Likes

on

69 Posts

2010 W212 E550 4matic

88000 miles. I was experiencing vibration in the cabin at idle when in Park or Neutral which was intensifying when the car was in Drive or Reverse, usually at stoplights or drive-throughs whenever I was using the Hold function. When driving at highway speeds or over 20mph the vibrations were not significant enough to spoil the driving experience, but after replacing all 3 mounts the vehicle felt smoother even at those speeds ( might also be a placebo effect).

#7

Super Member

Thread Starter

Thanks for the detailed reply! I will start with the transmission mount and go from there. I will probably tackle this job one of these weekends coming up. Would be nice if I don't have to mess with the engine mounts just yet, but the car is 7 years old and 179K miles, so I would assume they are at or near the end of their life.

Trending Topics

#8

Senior Member

Join Date: Jul 2017

Location: Savannah, GA

Posts: 377

Received 96 Likes

on

69 Posts

2010 W212 E550 4matic

Thanks for the detailed reply! I will start with the transmission mount and go from there. I will probably tackle this job one of these weekends coming up. Would be nice if I don't have to mess with the engine mounts just yet, but the car is 7 years old and 179K miles, so I would assume they are at or near the end of their life.

#9

Super Member

Thread Starter

You're welcome! I'm amazed yours lasted for so long without being replaced. From what I was reading online they only last for about 75k miles. Definitely start with the tranny one, it's the easiest to replace, but be careful with those tapered bolts on the transmission to frame bracket, they have a tendency to get stripped if not torqued at spec.

#12

Member

Join Date: Feb 2007

Location: Houston

Posts: 141

Likes: 0

Received 3 Likes

on

2 Posts

2020 E450 Coupe, 2022 Porsche Macan, 2001 Porsche 911

Hey Folks - I'm preparing to replace the engine and transmission mounts on my 2010 E550 with 83,000 miles. I have the 16mm MB offset wrench in hand, so thanks for the heads up about that!

I understand I need to lower the steering rack, so thanks about that too. Now...could anyone please let me know what the torque settings are for all bolts/nuts that I'll be removing and replacing? Is this documented somewhere?

Thanks in advance for your help!

I understand I need to lower the steering rack, so thanks about that too. Now...could anyone please let me know what the torque settings are for all bolts/nuts that I'll be removing and replacing? Is this documented somewhere?

Thanks in advance for your help!

#13

Senior Member

Join Date: Jul 2017

Location: Savannah, GA

Posts: 377

Received 96 Likes

on

69 Posts

2010 W212 E550 4matic

Hey Folks - I'm preparing to replace the engine and transmission mounts on my 2010 E550 with 83,000 miles. I have the 16mm MB offset wrench in hand, so thanks for the heads up about that!

I understand I need to lower the steering rack, so thanks about that too. Now...could anyone please let me know what the torque settings are for all bolts/nuts that I'll be removing and replacing? Is this documented somewhere?

Thanks in advance for your help!

I understand I need to lower the steering rack, so thanks about that too. Now...could anyone please let me know what the torque settings are for all bolts/nuts that I'll be removing and replacing? Is this documented somewhere?

Thanks in advance for your help!

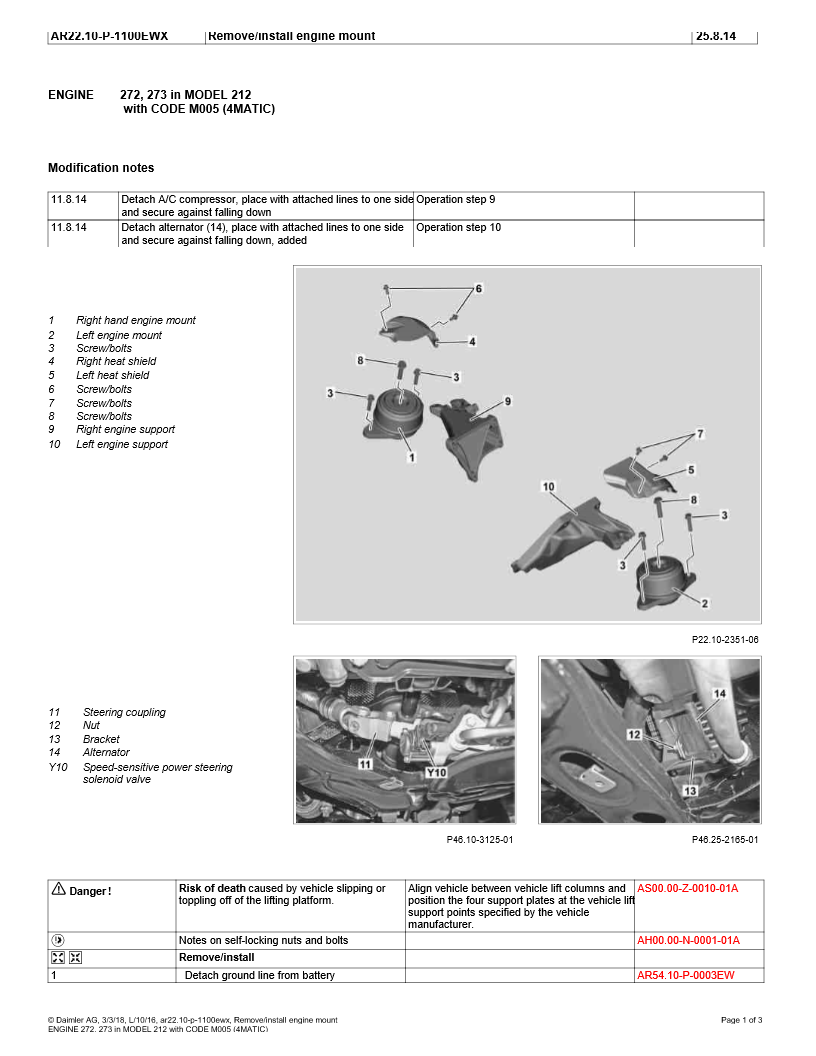

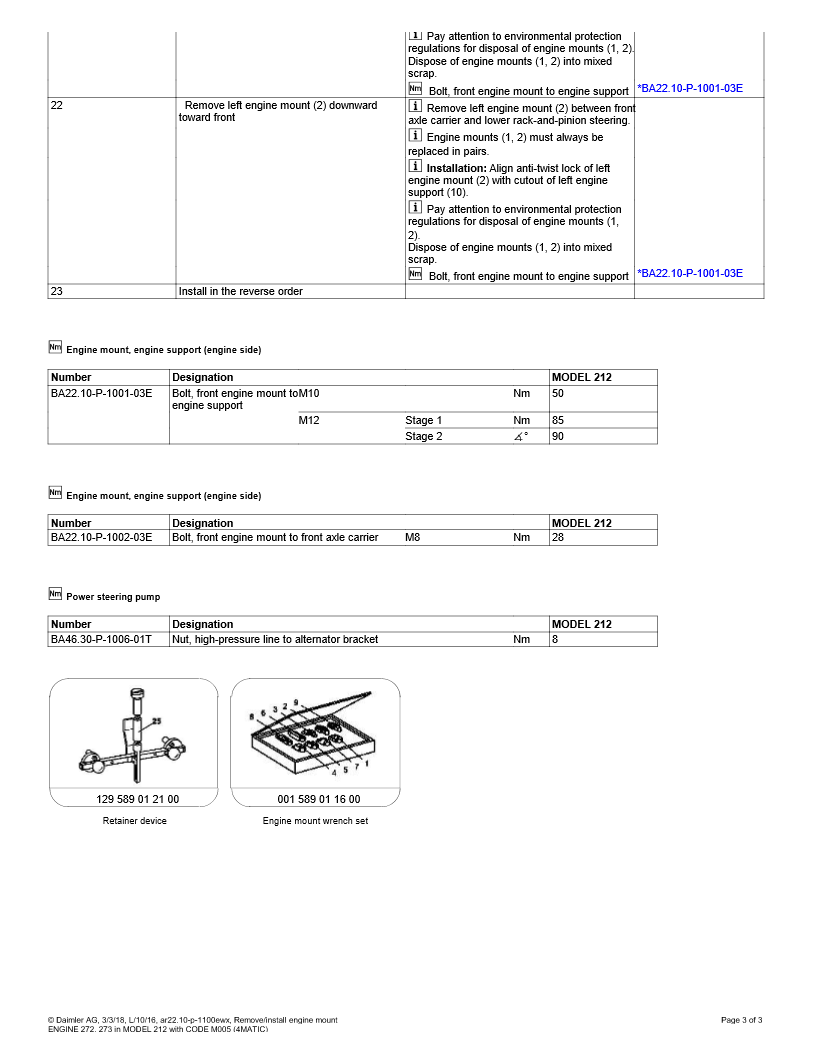

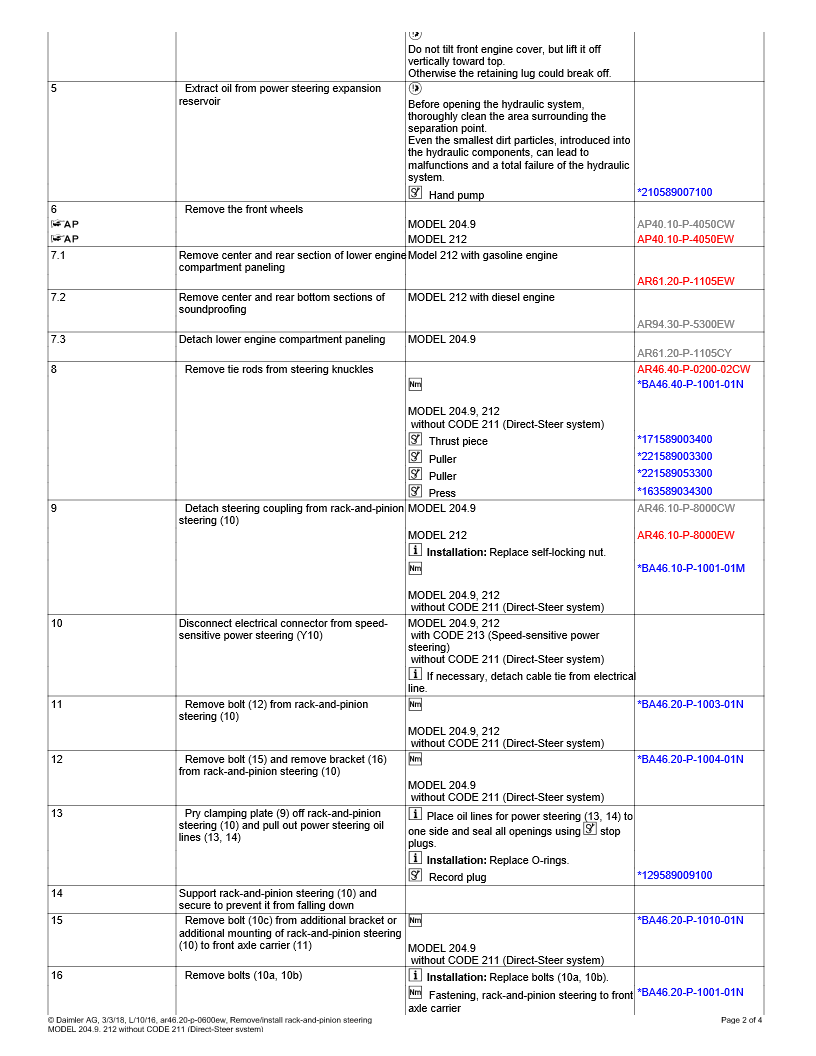

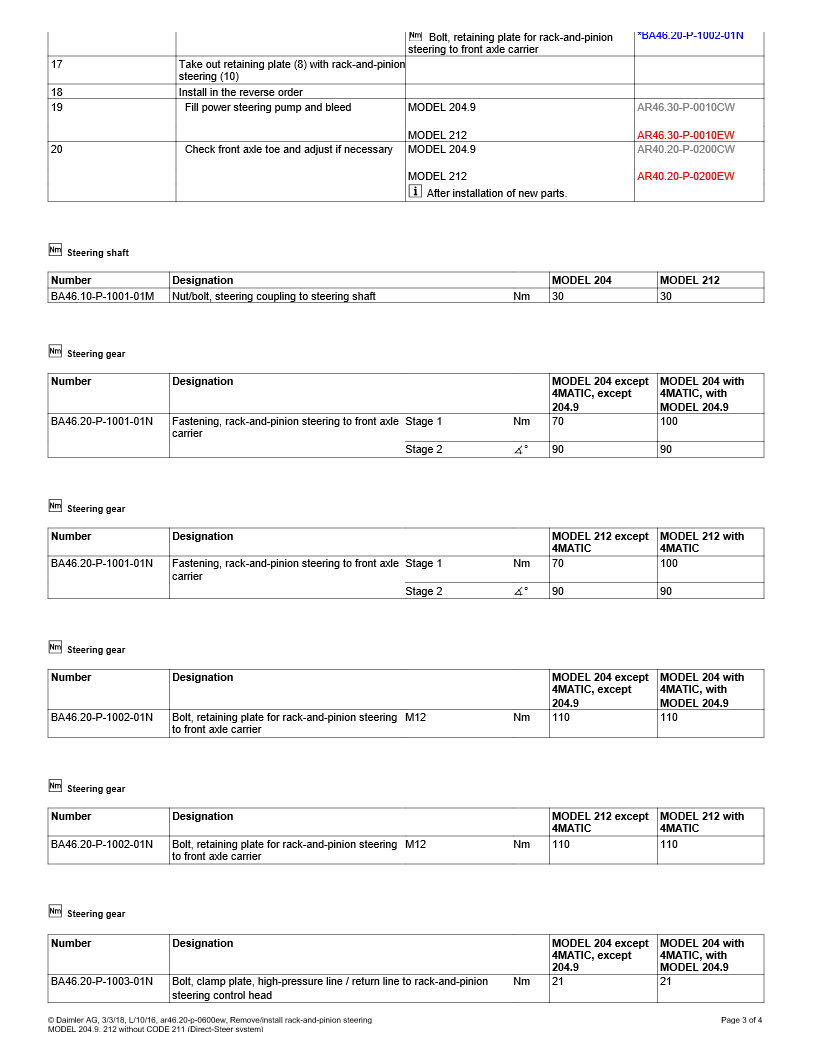

The pictures I posted show the MB recommended way of doing the job, I didn't do it that way, it would have taken way too long. You can use the pictures as reference, but in my experience, you don't need to unbolt all the things MB says to ( like the AC compressor, exhaust headers or the steering rack shaft).

When you're lifting the engine from underneath, undo the engine mount No 3 bolts 1/4 inch, the undo the No 8 bolts 1/4, alternate doing that until No 8 is completely out. After each 1/4 unfastening sessions on both sides, lift the motor by 1/4 inch. The reason for this is the No 8 will tend to bottom out against the exhaust headers if you try to undo it all the way. When installing the new mounts I also had difficulty lining the bolt wholes on the support bracket( No 9 and 10) to the No 8 bolt wholes, I eventually had to use a prying bar to slightly move the engine around until I was able to drop the No 8 bolt in there properly. It's going to take a little finagling but it's worth it.

Motor mounts 1

Motor mounts 2

Motor mounts 3

Steering rack 1

Steering rack 2

Steering rack 3

Steering rack 4

Last edited by Oda112; 03-03-2018 at 10:52 AM. Reason: Torque specs clarification

#14

MBWorld Fanatic!

Engine and trans mounts were done under warranty at about 30k miles. Symptoms were vibration at idle and low speeds < 40mph. I was not aware of issues related to the mounts and had taken it in thinking it was a possible engine issue.

#15

Member

Join Date: Feb 2007

Location: Houston

Posts: 141

Likes: 0

Received 3 Likes

on

2 Posts

2020 E450 Coupe, 2022 Porsche Macan, 2001 Porsche 911

Thanks All - I managed to to the job in 3 hours. I have rear wheel drive so I didn't have to take out any exhaust, alternator, or compressor. Once I dropped the steering rack, the mounts came out without any trouble. The 16mm MB wrench made all the difference in the world, so I recommend you don't skimp on this $19.00 part. The transmission mount was super easy too!

I'm very happy with the outcome, as it made a significant difference with ride comfort.

Thanks again for your help and for the torque settings Oda112 - I really appreciate it!

I'm very happy with the outcome, as it made a significant difference with ride comfort.

Thanks again for your help and for the torque settings Oda112 - I really appreciate it!

#16

MBWorld Fanatic!

Join Date: Oct 2002

Location: Cincinnati

Posts: 4,081

Received 938 Likes

on

685 Posts

2010 E350 4Matic

You're welcome! I'm amazed yours lasted for so long without being replaced. From what I was reading online they only last for about 75k miles. Definitely start with the tranny one, it's the easiest to replace, but be careful with those tapered bolts on the transmission to frame bracket, they have a tendency to get stripped if not torqued at spec.

#17

Senior Member

Join Date: Jul 2017

Location: Savannah, GA

Posts: 377

Received 96 Likes

on

69 Posts

2010 W212 E550 4matic

Hi I looked through the your other posts for the transmission mount torque and I may have missed it in all the info but can you provide it or send me to the post where it is? Awesome instructions by the way and thanks for the advise on the Corteco mount. I had myself convinced that it was OEM was just about ready to pull the trigger on ordering one. I will buy through a dealership.

I found this on the forum. My copy of WIS is being annoying today.

I stripped mine because I followed the wrong document, ended up using 70Nm instead of 50

I haven't replaced mine yet since it's not too bad but once the weather gets better I'll get a OE one. Good luck with the repair!

Last edited by Oda112; 04-08-2018 at 06:13 PM.

#18

MBWorld Fanatic!

Join Date: Oct 2002

Location: Cincinnati

Posts: 4,081

Received 938 Likes

on

685 Posts

2010 E350 4Matic

I found this on the forum. My copy of WIS is being annoying today.

I stripped mine because I followed the wrong document, ended up using 70Nm instead of 50

I haven't replaced mine yet since it's not too bad but once the weather gets better I'll get a OE one. Good luck with the repair!

I stripped mine because I followed the wrong document, ended up using 70Nm instead of 50

I haven't replaced mine yet since it's not too bad but once the weather gets better I'll get a OE one. Good luck with the repair!

Do you agree that the mount to the transmission should be 28 Nm?

So on the engine mounts did you buy any new bolts? My indy made mention of new bolts being a portion of the parts cost.

You're the man by the way with the help! Really good stuff!

Last edited by MBNUT1; 04-08-2018 at 09:32 PM.

#19

Senior Member

Join Date: Jul 2017

Location: Savannah, GA

Posts: 377

Received 96 Likes

on

69 Posts

2010 W212 E550 4matic

As for the 28Nm I don't fully agree as I had one of the 5 bolts spin freely after torquing it down ( felt like it stripped it's threads) but that might have happened because I didn't get new bolts. I would do 25 first, see how it feels and if you think it needs more then go ahead and do it. That's what I'll do on mine. I also used blue threadlocker just to make sure they don't come out.

The following users liked this post:

MBNUT1 (04-09-2018)

#20

MBWorld Fanatic!

Join Date: Oct 2002

Location: Cincinnati

Posts: 4,081

Received 938 Likes

on

685 Posts

2010 E350 4Matic

I didn't replace any of the bolts, I reused all of them and I think it was a mistake. At least for the rear engine/tranny mount. I'm going to buy them soon and replace all of them. The engine ones seem to be fine ( also there's no way to properly torque them to spec, for most of them you'll have to use swivel adapters and that messes with the torque you apply - there's some sort of advanced math you can do to figure it out but it's overkill for this application).

As for the 28Nm I don't fully agree as I had one of the 5 bolts spin freely after torquing it down ( felt like it stripped it's threads) but that might have happened because I didn't get new bolts. I would do 25 first, see how it feels and if you think it needs more then go ahead and do it. That's what I'll do on mine. I also used blue threadlocker just to make sure they don't come out.

As for the 28Nm I don't fully agree as I had one of the 5 bolts spin freely after torquing it down ( felt like it stripped it's threads) but that might have happened because I didn't get new bolts. I would do 25 first, see how it feels and if you think it needs more then go ahead and do it. That's what I'll do on mine. I also used blue threadlocker just to make sure they don't come out.

The reason I mentioned the 28 Nm is that was what was called out for for the W204 4matic in the Wis you provided. I was kindof checking to see if you noted that when you did yours.

One last question, were the bad motor mounts obviously bad to the eye? IE could you tell just by looking at them that they needed to be replaced?

#21

Senior Member

Join Date: Jul 2017

Location: Savannah, GA

Posts: 377

Received 96 Likes

on

69 Posts

2010 W212 E550 4matic

The reason I mentioned the 28 Nm is that was what was called out for for the W204 4matic in the Wis you provided. I was kindof checking to see if you noted that when you did yours.

One last question, were the bad motor mounts obviously bad to the eye? IE could you tell just by looking at them that they needed to be replaced?

One last question, were the bad motor mounts obviously bad to the eye? IE could you tell just by looking at them that they needed to be replaced?

right is old

left is old

The following users liked this post:

MBNUT1 (04-09-2018)

#22

Super Member

Thread Starter

Hello again, revisiting this thread as I finally started poking around under the hood in preparation for doing this job. Right off the bat I've run into a major hurdle that I can't seem to figure out and I am hoping someone can help me. For the life of me, I cannot find a way to get the lower heat shield bolt off. I can get as far as getting the socket on the driver's side bolt from underneath, but I just cannot figure out what I am missing here, given that it's been stated you don't have to drop the exhaust and such to do this job.

Do I need to remove the lower engine mount to axle carrier bolts first and then raise the engine to get clearance to get the lower heat shield bolts out? Do I get them from the top?

Even better, does anybody have a picture of the wrench setup they used to get the lower heat shield bolt? Any help is appreciated. once I am able to get this done. I think I will put together a DIY with pictures.

Do I need to remove the lower engine mount to axle carrier bolts first and then raise the engine to get clearance to get the lower heat shield bolts out? Do I get them from the top?

Even better, does anybody have a picture of the wrench setup they used to get the lower heat shield bolt? Any help is appreciated. once I am able to get this done. I think I will put together a DIY with pictures.

#23

MBWorld Fanatic!

Join Date: Oct 2002

Location: Cincinnati

Posts: 4,081

Received 938 Likes

on

685 Posts

2010 E350 4Matic

Hello again, revisiting this thread as I finally started poking around under the hood in preparation for doing this job. Right off the bat I've run into a major hurdle that I can't seem to figure out and I am hoping someone can help me. For the life of me, I cannot find a way to get the lower heat shield bolt off. I can get as far as getting the socket on the driver's side bolt from underneath, but I just cannot figure out what I am missing here, given that it's been stated you don't have to drop the exhaust and such to do this job.

Do I need to remove the lower engine mount to axle carrier bolts first and then raise the engine to get clearance to get the lower heat shield bolts out? Do I get them from the top?

Even better, does anybody have a picture of the wrench setup they used to get the lower heat shield bolt? Any help is appreciated. once I am able to get this done. I think I will put together a DIY with pictures.

Do I need to remove the lower engine mount to axle carrier bolts first and then raise the engine to get clearance to get the lower heat shield bolts out? Do I get them from the top?

Even better, does anybody have a picture of the wrench setup they used to get the lower heat shield bolt? Any help is appreciated. once I am able to get this done. I think I will put together a DIY with pictures.

BTW I had my transmission mount replaced as part of getting the transfer case rebuilt and it didn't do squat for idle vibration.

#24

Senior Member

Join Date: Jul 2017

Location: Savannah, GA

Posts: 377

Received 96 Likes

on

69 Posts

2010 W212 E550 4matic

Hello again, revisiting this thread as I finally started poking around under the hood in preparation for doing this job. Right off the bat I've run into a major hurdle that I can't seem to figure out and I am hoping someone can help me. For the life of me, I cannot find a way to get the lower heat shield bolt off. I can get as far as getting the socket on the driver's side bolt from underneath, but I just cannot figure out what I am missing here, given that it's been stated you don't have to drop the exhaust and such to do this job.

Do I need to remove the lower engine mount to axle carrier bolts first and then raise the engine to get clearance to get the lower heat shield bolts out? Do I get them from the top?

Even better, does anybody have a picture of the wrench setup they used to get the lower heat shield bolt? Any help is appreciated. once I am able to get this done. I think I will put together a DIY with pictures.

Do I need to remove the lower engine mount to axle carrier bolts first and then raise the engine to get clearance to get the lower heat shield bolts out? Do I get them from the top?

Even better, does anybody have a picture of the wrench setup they used to get the lower heat shield bolt? Any help is appreciated. once I am able to get this done. I think I will put together a DIY with pictures.

I should add that lifting the motor an inch and a bit and making sure it's well suspended ( I left my floor jack underneath the oil pan - use a wide piece of soft wood to make sure the load is distributed over a larger area) will help with better reaching of those dreaded heat shield bolts. It will not be easy, but once you figure out an attack angle it will work, and there's only 1 of them which is really hard to undo. Definitely get the tools I talked about in my other post, they helped a lot.

#25

Super Member

Thread Starter

It's definitely doable, even with my fat hand. It will require a lot of finagling, swearing, sweat and maybe bloody knuckles. Someone else had the same question yesterday and I responded on another thread. https://mbworld.org/forums/e-class-w...ml#post7602387

I should add that lifting the motor an inch and a bit and making sure it's well suspended ( I left my floor jack underneath the oil pan - use a wide piece of soft wood to make sure the load is distributed over a larger area) will help with better reaching of those dreaded heat shield bolts. It will not be easy, but once you figure out an attack angle it will work, and there's only 1 of them which is really hard to undo. Definitely get the tools I talked about in my other post, they helped a lot.

I should add that lifting the motor an inch and a bit and making sure it's well suspended ( I left my floor jack underneath the oil pan - use a wide piece of soft wood to make sure the load is distributed over a larger area) will help with better reaching of those dreaded heat shield bolts. It will not be easy, but once you figure out an attack angle it will work, and there's only 1 of them which is really hard to undo. Definitely get the tools I talked about in my other post, they helped a lot.

Here's the update on my progress. Basically I aborted the job because the special Mercedes wrench for the motor mount top bolt would not fit between the exhaust manifold and the top bolt on the passenger side. It fit fine on the driver's side which is really weird. I also did not have enough flex joints to do the rear lower 13 MM bolts on the mounts. It looks like you need a flex joint that connects to the socket, and then one higher up so you can make two angles.

Oh, and I have a socket wrench that has a flex end on it similar to those Amazon tools. That made all the difference in the world in getting out the lower heat shield bolts.

I was able to get the heat shield bolts removed. I saw your other thread about coming at it from the back of the cat. I removed the O2 sensor on the passenger side and I was able to reach my hand up there and hold the socket in place no problem. The one on the driver's side was easier but I ended up breaking something plastic (starter plastic tubing for wires??) when I was putting it all back together. I think I have enough information to be able to do the job now without too much trouble, but I wanted to button everything back up so I could drive the car while I wait for tools to arrive and plan the attack again. This is definitely not a job for a beginner!