CLS55/63 fun facts

#26

Super Member

Thread Starter

#27

Super Member

Thread Starter

#28

Super Member

Thread Starter

CLS63 sound bite

CLS63 sound bite:

http://www.youtube.com/watch?v=WpNaRyJuhHg

.

CLS55 crashed:

http://www.youtube.com/watch?v=0nxz6viTzgk

CLS55 slide:

http://www.youtube.com/watch?v=5Nq4xyHQb7o

CLS55 burning:

http://www.youtube.com/watch?v=Kq8DbprCN6o

http://www.youtube.com/watch?v=43WTlgGjKUE

CLS63 burning:

http://www.youtube.com/watch?v=N16ze2HlDJQ

.

http://www.youtube.com/watch?v=WpNaRyJuhHg

.

CLS55 crashed:

http://www.youtube.com/watch?v=0nxz6viTzgk

CLS55 slide:

http://www.youtube.com/watch?v=5Nq4xyHQb7o

CLS55 burning:

http://www.youtube.com/watch?v=Kq8DbprCN6o

http://www.youtube.com/watch?v=43WTlgGjKUE

CLS63 burning:

http://www.youtube.com/watch?v=N16ze2HlDJQ

.

Last edited by turbotom1; 06-06-2008 at 02:41 PM.

#29

Super Member

Thread Starter

ASMA

Last edited by turbotom1; 06-06-2008 at 02:29 PM.

#30

Super Member

Thread Starter

#31

Super Member

Thread Starter

Carlsson Tuning

Carlsson

CK55 is capable of achieving a top speed limited to a tidy 198.8 mph.

http://www.carlsson.de

a rhombus quilting stitch pattern give the CK55 a truly unique appearance. Interior elements featuring Carlsson's exclusive styling include the CK55's seating, door panels, center console, and steering wheel.

CK55 is capable of achieving a top speed limited to a tidy 198.8 mph.

http://www.carlsson.de

a rhombus quilting stitch pattern give the CK55 a truly unique appearance. Interior elements featuring Carlsson's exclusive styling include the CK55's seating, door panels, center console, and steering wheel.

#32

Super Member

Thread Starter

#33

Super Member

Thread Starter

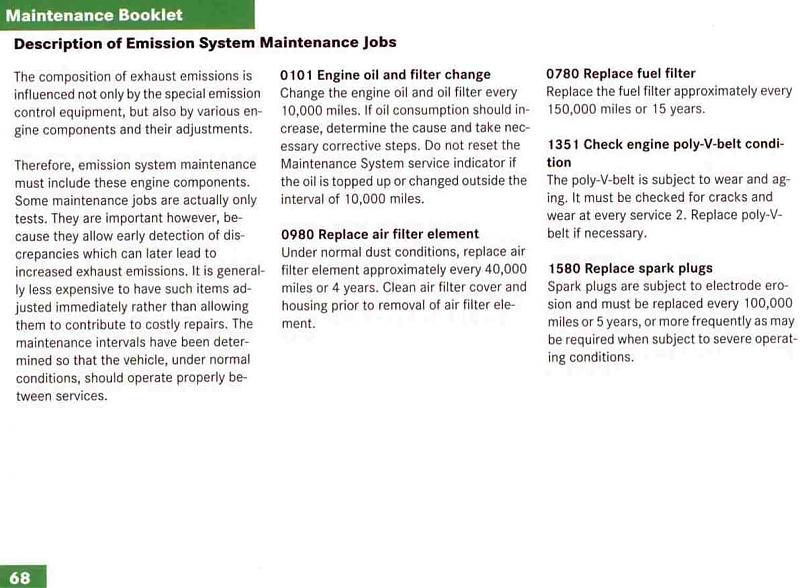

63 motor - hand assembled -

SKILLED HANDS: An individual AMG technician takes personal responsibility for the assembly of each AMG engine and signs it off with his name on a cylinder-head plate. Below is a completed motor.

Design and materials:

Know-how from motor sports

Particularly rigid bedplate crankcase of closed-deck design

Cylinder walls with a unique, revolutionary TWAS coating

Completely new dual-length intake manifold with integral throttle flaps

Vertical air ducts, valve control by bucket tappets

Completely autonomous development from Affalterbach

http://www.ae-plus.com/Technology%20...AMG%206.3l.htm

.

Last edited by turbotom1; 06-09-2008 at 09:55 PM.

#34

Super Member

Thread Starter

63 motors design

Mercedes-AMG reveals the world's most powerful naturally aspirated 8-cylinder engine

July 05

STUTTGART, Germany – Outstanding performance and a wide usable engine speed range, a good power-to-weight ratio and sound design, a low specific fuel consumption and exhaust emission values, ease of maintenance and pedestrian protection – the requirements for newly developed engines are both varied and demanding. The same applied to the completely new AMG 6.3 litre V8 engine. The primary development goals for the engineers and product strategists at Mercedes-AMG were dynamic responsiveness, great agility, exhilarating liveliness and a high torque even at low engine speeds.

A glance at the key technical data shows that the aim of developing a naturally aspirated, fast-running V8 engine with a decidedly sporty character was achieved in full: the new AMG engine generates a maximum output of 375 kW/510 hp at 6,800 rpm from a displacement of 6,208 cubic centimetres.

The new powerpack also reaches new heights where maximum torque is concerned: 630 Newton metres are on tap at 5,200 rpm. This makes it the world’s most powerful naturally aspirated eight-cylinder engine, as no other unit in this output and displacement class is able to achieve these figures. A look at the torque curve also reveals its extraordinary characteristics: the new AMG V8 already delivers 500 Newton metres to the crankshaft at 2,000 rpm, increasing to no less than 560 Newton metres at 3,000 rpm – considerably more than the maximum values comparable engines are able to achieve at much higher engine speeds.

Cylinder arrangement

Cylinder angle

Valves per cylinder

Displacement

Bore/stroke

Dist. between cylinders

Compression ratio

Output

Output per litre

Max torque

Torque per litre Maximum engine speed

Weight (dry)

Power-to-weight ratio

V8

90 deg

4

6208 cc

102.2/94.6 mm

109 mm

11.3 : 1

375 kW/510 hp @ 6800 rpm

60.4 kW/82.1 hp

630 Nm @ 5200 rpm

101.5 Nm

7200 rpm

199 kg

1.88 kW/kg

These remarkable figures reflect the Mercedes-AMG philosophy of building powerful engines with superlative output and torque characteristics, combined with dynamic and immediate responsiveness, which will enable drivers to use a sporty style of driving to the full.

With its unique, sporty AMG sound which was designed during an extensive series of tests, the eight-cylinder unit from Affalterbach offers the excitement of a naturally-aspirated, fast-running V8 engine in unmistakable audible and palpable form at low, medium and high engine speeds. Despite its pronounced sportiness, its smooth running characteristics and wide usable torque range also allow more leisurely progress when preferred – guaranteeing the long-distance comfort which is so typical of a Mercedes.

Completely autonomous development from Affalterbach

In conceptual and design terms the new eight-cylinder powerplant by Mercedes-AMG is a completely autonomous development which shares no features or common parts with other eight-cylinder engines by Mercedes-Benz. The new 6.3 litre unit differs from the other AMG V8 engines based on Mercedes designs in the distance between cylinders, the completely new crankcase concept, the sophisticated intake and exhaust manifolds and the valve train. The bore/stroke ratio is also a completely new departure for Mercedes-AMG.

Focusing on outstanding output and torque characteristics and decidedly sporty performance requires sophisticated technologies and solutions which are often based on motor sports engineering – which means that for mile after mile, the AMG driver benefits from more than 35 years of experience in international motor racing.

Design and materials:

Know-how from motor sports

Particularly rigid bedplate crankcase of closed-deck design

Cylinder walls with a unique, revolutionary TWAS coating

Completely new dual-length intake manifold with integral throttle flaps

Vertical air ducts, valve control by bucket tappets

Completely autonomous development from Affalterbach

More than three decades of know-how gained in GT and Touring Car championships, as well as great experience in the production of powerful, high-performance engines, went into the design of the new AMG 6.3 litre eight-cylinder engine. The special production facilities at the Affalterbach location were already taken into consideration during the development and conceptual phases, which allowed freedom of action and new possibilities for the engine’s designers. The resulting masterpiece was only made possible by a unique combination of extremely advanced engine and materials technology.

Sophisticated air ducting for a high output

Apart from the large overall displacement of precisely 6,208 cc, the extremely high output and torque is above all due to the sophisticated intake system – a completely new departure for AMG. Together with the innovative, variable intake manifold of magnesium with two integral throttle flaps, the large air intake cross-sections familiar from motorsport, the streamlined design of the intake and exhaust ducting and the vertical arrangement of the intake and exhaust ducts ensure that all eight cylinders are perfectly charged.

Patented variable intake manifold with two internal throttle flaps

The patented, dual-length intake manifold with two internal throttle flaps is a world first. Its task is to ensure a strong torque curve by lengthening the airflow distance at low engine speeds. At higher engine speeds the intake manifold switches to short airflow distances to achieve a high peak performance. The switching process is monitored by the electronic engine management system, vacuum-controlled depending on the engine load and engine speed, and imperceptible to the vehicle’s occupants.

The interior of the light, die-cast magnesium intake manifold features two electronically operated throttle flaps which are adjustable within fractions of a second: they can be opened to their maximum in just 100 milliseconds, and the driver perceives this as extraordinary responsiveness. The air intake at the front of the vehicle is of dual-flow design; two integral hot film airflow sensors behind the air filters provide the engine electronics with the necessary information about the temperature and density of the intake air.

With the help of complex flow simulations the engineers at Mercedes-AMG have precisely configured all the intake ducting to meet the requirements of the large engine displacement and the resulting large air volumes.

Valve operation by bucket tappets, as in the racing engines

Another special feature of the new AMG V8 engine is the sophisticated valvetrain, which is also derived from the powerful AMG racing engines. The 32 valves in the cylinder heads are operated by bucket tappets. Their space-saving design allows a stiff valve train and therefore high engine speeds with large valve opening cross-sections, which in turn benefits output and torque. The large intake valves have a diameter of 40 millimetres, while their opposite numbers on the exhaust side measure 34 millimetres. In contrast to a racing engine, the valve clearances are automatically adjusted by a hydraulic mechanism – the customer benefits from long, variable service intervals and low costs.

Four continuously variable overhead camshafts

All four overhead camshafts are continuously variable over a range of 42 degrees. Both the intake and exhaust camshafts are adjusted as a function of engine load and engine speed, ensuring extremely high output and torque values and smooth idling, and especially low exhaust emissions. Depending on the engine speed, the valve overlap can be varied to ensure an optimal supply of fuel/air mixture to the combustion chambers and efficient venting of the exhaust gases. This variable camshaft adjustment is controlled electro-hydraulically and monitored by the engine management system; the system is driven by a duplex roller chain and intermeshing pairs of gear wheels.

Crankcase with bedplate and closed-deck design

When designing the crankcase, the engineers and technicians in Affalterbach opted for a sophisticated bedplate construction on the closed-deck principle, which is well established in the motor racing sector and is also used in the powerful, supercharged AMG 5.5-litre V8 engine of the Mercedes-Benz SLR McLaren. Amongst engine specialists, this configuration stands for a high-performance sporting engine which is uncompromisingly designed for the utmost robustness.

The lower section of the crankcase in the AMG 6.3 litre V8 engine is an enclosed unit, which particularly benefits the torsional rigidity of the engine. This type of construction also permits higher combustion pressures and reduces pulsation losses within the crankcase itself. This not only minimises the internal friction losses, but also produces more rigid bearing bridges for the crankshaft. More efficient integration of the oil scavenger also allows foaming on the part of the engine oil to be reduced. The crankcase is also equipped with special, cast-in steel components which improve the strength of the engine block even further, benefit the engine acoustics and ensure a reliable oil supply.

Unique process for cylinder wall coating

The engine block and cylinder heads are of cast aluminium-silicon alloys (AlSi7 and AlSi17) which represent the state of the art in terms of weight, thermal and mechanical resistance and long-term strength. The engine specialists at Mercedes-AMG use a particularly advanced process for the eight cylinder walls to produce a tribologically optimal surface, namely a coating applied by twin wire arc spraying (TWAS). The advantages of this technology are extremely low friction and wear accompanied by outstanding long-term durability. A considerably harder surface is achieved compared to conventionally coated cylinder walls. In fact the cylinder walls of the new AMG V8 engine are twice as hard as conventional cast iron liners – a quantum leap for engine specialists.

No other series-production engine apart from the new AMG 6.3 litre V8 unit can boast such sophisticated technology – which means that once again, Mercedes-AMG has underlined its pioneering role in the development and production of innovative high-performance engines.

During the TWAS process, two metallic wires and an atomising gas are brought together in a coating unit. Passing a high voltage through the tips of the wires breaks the gas molecules down to form a plasma, and the wire tips begin to melt. The atomising gas removes molten metal from the wire tips and sprays these particles onto the cylinder walls to be coated, where they solidify. This is preceded by a high-pressure water jet which roughens the cylinder walls so that the individual sprayed particles adhere to the surface during the TWAS coating process.

The cylinder walls are then honed to achieve a perfect surface structure. During this process the micro-pores in the sprayed coating are partially exposed, which enables them to retain oil when the engine is running and ensure tribologically favourable lubrication of the pistons and piston rings.

This trailblazing process was developed in close collaboration between the DaimlerChrysler process engineering department and Mercedes-AMG, and has been brought to series production maturity for the first time in the AMG V8 engine.

Crank assembly optimised for the lowest possible inertia

The finely balanced crankshaft is designed for the highest stresses, consists of the high-quality forged steel alloy 42CRMo4V, rotates in five crankshaft bearings and features six counterweights for perfectly balanced masses. Torsional rigidity, long-term structural strength and inertia characteristics are also to the very highest standards. As a detail normally only found in racing engines, the counterweights feature heavy metal core plugs, which means that they can be made significantly more compact. As a result the complete crank assembly can be optimised for particularly low rotational and oscillatory inertia, which enormously benefits responsiveness and flexibility.

Two lightweight connecting rods forged by the cracking process are connected to each of the four crank pins. During this process, the utmost production precision is made possible by a predetermined breaking point created by a laser beam. Extremely close weight tolerances between the eight connecting rods are also ensured by precision machining. The same principle is also used for the cast, lightweight pistons. They are made from a durable high-temperature alloy. Pressure-controlled oil spray nozzles in the crankcase ensure optimal cooling of the highly stressed piston crowns.

Owing to the large overall displacement, a highly efficient oil pump with a high throughput is used in the new AMG eight-cylinder. Even at high rates of lateral acceleration, the intelligent arrangement of all the components in the oil circuit ensures a consistent supply of lubricant. The engine oil is cooled on a vehicle-specific basis, i.e. the sump and the arrangement of the coolers may vary. The cooling performance itself always remains constant.

Engine cooling on the sophisticated cross-flow principle

As in thoroughbred racing engines, the engine is cooled on the sophisticated cross-flow principle. This means that the eight individual cylinders have a uniform temperature by virtue of the homogenous coolant flow, thereby avoiding critical temperature peaks. The coolant flows from the exhaust side of the crankcase across the cylinder heads, then back to the thermostat and radiator via the collector on the intake side. The thermally highly stressed cylinder heads are also cooled according to this principle, which particularly benefits the operating life. Even the cylinder head bolts are included in the coolant circuit. This technology was developed with the help of complex flow calculations and perfected during an extended series of tests.

Variable coolant control for optimised friction

In addition the temperature of the coolant is variably controlled. In the interests of optimal in-engine friction and fuel economy, the temperature of the coolant can for example be lowered to 80 degrees Celsius under partial load. Under full load conditions the temperature is raised to 100 degrees within milliseconds to achieve the best possible engine cooling. The thermostat controlling the coolant temperature receives its instructions from the engine electronics.

Fuel supply monitored by a computer

The fuel supply of the AMG eight-cylinder is likewise computer-controlled and monitored. The fuel pressure is variably and instantly adjusted depending on the performance requirement and ambient temperature. The engine electronics execute commands from the accelerator pedal within milliseconds, leading to outstanding responsiveness. A high-pressure pump configured for the engine is integrated into the fuel tank.

Highly efficient engine electronics for every function

All engine functions are controlled and executed by a particularly efficient Bosch ME 9.7 control unit. Fuel injection, ignition, the variable intake manifold, camshaft adjustment and variable cooling are all controlled by the state-of-the-art engine computer, which also communicates with all the other onboard control units. The microprocessor has 10,000 different characteristic maps and functions in its memory, and is able to carry out up to 70 million individual operations per second.

To reduce the load on the engine control unit, the eight individual ignition coils have an integral electronic module known as an ignition amplifier at each cylinder. These ensure a strong ignition spark at all engine speeds and under all load conditions.

Exhaust technology and sound design:

Low emissions and a designer sound

Continuous camshaft adjustment for low untreated emissions

Four ceramic catalytic converters of thin-wall substrate design for efficient emissions control

Characteristic engine sound as a result of extensive tests

AMG sports exhaust system with two twin tailpipes

Despite its high output and torque values, the new AMG 6.3 litre eight-cylinder engine meets all current exhaust emission standards without difficulty. Both the European EU4 standard and the stringent US standards presently in force and planned are complied with. The new AMG engine easily meets specific requirements for the US market, e.g. Onboard Diagnosis II and oxygen sensor diagnosis.

This is due to highly sophisticated engine and exhaust technology. Continuous camshaft adjustment makes a major contribution to efficient emissions control. Under partial load it ensures need-related internal exhaust gas recirculation by conducting the gases directly from the combustion chamber to the intake ducts. While the intake valves are being opened the exhaust valves also remain open for a short time, and at this point some of the exhaust gases flow from the exhaust to the intake side. The engineers at AMG have used this principle of valve overlap to achieve a dual advantage, for both untreated emissions and fuel consumption can be lowered by reducing gas cycle losses.

An exhaust system specially developed for the large-displacement AMG V8 engine is used to support the in-engine emissions control measures. Effective aftertreatment begins in the air-gap-insulated manifolds, which have a wall thickness of only 1.0 milimetres. Ten seconds after starting, these already allow an exhaust temperature of 280 degrees Celsius – a precondition for rapid response by the close-coupled catalytic converters. All four ceramic catalytic converters feature thin-wall substrates; thanks to their maximised surface area these not only provide the best conditions for effective emissions control, but also aid performance with their low exhaust counter-pressure. Four oxygen sensors are used to control and monitor the exhaust system: the two front sensors ensure an optimal controlled engine range, while the two sensors behind the catalytic converters are responsible for Onboard Diagnosis II.

Secondary air injection reduces carbon monoxide and hydrocarbons

The afterburning effect of the secondary air injection system leads to higher exhaust gas temperatures and supports the heating-up process. As a result of this complex system the carbon monoxide and hydrocarbon content in the exhaust gases is reduced. The oxygen sensors continuously monitor the constituents of the mixture and supply this information to the computer, which readjusts the mixture as soon as the temperature of the catalytic converters has reached its nominal level.

The new AMG engine also has a demand-related oxygen control system. This means that in all operating conditions, the constituents of the intake mixture can be precisely controlled to avoid damaging the catalytic converters. This also benefits the fuel consumption under full load, as the mixture can be leaner than in engines without this intelligent control system.

Designer engine sound adds to the power experience

Customers expect a new AMG high-performance engine to possess a characteristic and throaty sound. The primary aim of the technicians was also to create a synthesis of palpable dynamism and the long-distance comfort typical of a Mercedes. During acceleration the driver experiences the emotional sound of the fast-running engine and the exceptional power of the naturally aspirated eight-cylinder. At the same time this powerpack must for instance exhibit the smooth running characteristics and effortless progress required when covering long motorway distances. During this work the specialists at AMG were at pains to avoid disturbing noises and emphasise the pleasant frequencies which are typical of a sports car. At the same time it was important to comply with all the relevant regulations – for example when measuring drive-by noise. These varying requirements were a major challenge for the engineers and technicians at Mercedes-AMG GmbH, and they passed the test with flying colours – the results are well worth hearing.

Research in the acoustics laboratory and during test drives

Complex test series both in the acoustics laboratory and during vehicle trials led to a completely newly designed, twin-pipe exhaust system with pipe cross-sections and silencer volumes precisely suited to the engine displacement. Depending on the vehicle model, not only the routing of the pipes and the position and size of the rear silencers, but also the location of the catalytic converters and oxygen sensors had to be defined. The two oval, chrome twin tailpipes of the AMG sports exhaust system are not only a striking visual characteristic - the dynamic AMG V8 exhaust note instantly tells the knowledgeable person that this is a genuine AMG.

Close attention was also paid to the intake noise. The aim was to create a sporty but in no way irritating sound for the AMG eight-cylinder. To this end various components were used during the development phase. When designing the dual-flow intake system, numerous variations of intake ducts, air filters and intake noise dampers were experimented with before the final result was achieved.

Trials and test bench technology:

Endurance trials as a development standard

Systematic development work in two parallel programmes

The latest high-tech test benches for engines with up to 735 kW/1000 hp

Extended trials in all the world’s climatic zones

Maximum stress in the most extreme endurance trials

Trials of the new AMG 6.3 litre eight-cylinder engine were conducted in two stages. In addition to in-vehicle trials on every continent, the engine had to prove its worth on the newly constructed high-tech test benches in Affalterbach. But the development work started with analyses of basic mechanical functions, the oil circuit, power characteristics with various intake duct and camshaft configurations, plus the definition of fuel injection quantities, fuel consumption and exhaust emission values – all these were studied on the dynamic simulation test benches at Mercedes-AMG. Nine of the very latest, high-tech test benches are available in the completely new Mercedes-AMG test bench laboratory, which was taken into commission in 2004; engines with outputs exceeding 735 kW/1000 hp can be dynamically tested in this facility.

After completion of the basic work in Affalterbach, the first test vehicles equipped with the new AMG eight-cylinder engine were sent onto public roads and test tracks in all the climatic regions of the earth. All of them were required to undergo the standardised trials to which all AMG high-performance cars are subjected. These place the most extreme demands on the vehicles and their components in terms of practicality, reliability and long-term durability – after all, the new engine must operate perfectly anywhere in the world, and under all climatic and road conditions.The individual trial stages at a glance:

Engine and transmission development

High-altitude trials in Denver , Colorado ( USA ), Lesotho ( South Africa ) and Granada ( Spain )

Heat trials in Death Valley , California ( USA ), Upington ( South Africa ), Idiada test track ( Spain ) and Phoenix , Arizona ( USA )

Road trials in Los Angeles , California ( USA )

Cold trials in Arctic Falls ( Sweden )

Cooling and fuel system

Various test runs on the high-speed circuits in Nardo ( Italy ) and Papenburg ( Germany )

Trials in Upington ( South Africa ) and Death Valley , California ( USA )

Tests in the DaimlerChrysler wind tunnel

In addition, various endurance trials were carried out with the aim of simulating the engine’s entire operating life under the most extreme conditions:

Nürburgring north loop: The engine was tested under predominantly full load conditions on the world’s most demanding racetrack.

Mixed road endurance trials: Testing under everyday conditions. The vehicles were loaded up to their gross vehicle weight and subjected to a precisely defined test programme on country roads, motorways and in city traffic.

Stress endurance trials at the DaimlerChrysler test site in Papenburg: Extreme acceleration and deceleration cycles under predominantly full load conditions, with high stresses on the oil circuit, cooling system and fuel supply.

Endurance trials in the hills of the Swabian Alb region: The vehicles were loaded up to their gross vehicle weight and towed a two-tonne trailer. The route covered country roads with numerous uphill and downhill gradients, and subjected the engine, transmission and cooling system to very high stresses.

In parallel with the road and racetrack trials in various test vehicles, the new AMG 6.3 litre V8 engine was subjected to rigorous tests on the ultra-modern dynamic test benches at AMG. These facilities are able to simulate any road and environmental conditions to represent any conceivable type of operation. Cold or hot starting, mountain passes, stop-and-go traffic or fast laps on the Grand Prix circuit in Hockenheim – the engines were required to give their utmost. Even the intake air temperatures and densities can be varied by computer control, and the engines can be alternately filled with hot and cold coolant. Fuels of different grades are also available.

The aim of these extended test bench trials, which also included various endurance tests of up too 800 hours, was to confirm the performance of all the engine components and the peripheral units. All the stored measuring results for the tested engines were systematically compared and evaluated with the help of reproducible test procedures.

Production:

"One man, one engine" in Affalterbach

AMG engine workshops with an effective floorspace of 9950 sq. m.

Only one technician assembles each high-performance V8 engine

Engine lifecycle data record as a new standard in production

Unsurpassed precision, attention to detail and know-how

The special production techniques used at the Affalterbach location were already taken into account during the development and conceptual work on the new AMG 6.3 litre eight-cylinder engine; these ensure freedom of action and open up new possibilities during the engine design stage. Assembly of the complex valve train with bucket tappets in the cylinder heads must be done by hand, for example, and that is only possible in the highly specialised environment of the AMG engine workshops.

Approx 100 AMG high-performance engines assembled per day

It is a tradition at Mercedes-AMG that every engine is built by hand according to the "one man, one engine " philosophy. This means that one technician assembles the entire engine and confirms this by his signature on the AMG engine badge. The AMG engine shop has three storeys with an effective total floorspace of 9950 square metres and produces around 100 high-performance engines for various vehicle models each day. Production of AMG engines is geared to the highest flexibility, and can be rapidly adjusted to the current market conditions and order intake.

One AMG technician builds an entire engine, and is responsible for everything from installation of the crankshaft in the engine block, the camshafts and right up to the electrical wiring and the engine oil – clearly witnessed by his signature on the engine badge. After completion, a technician checks the engine’s operation with simulated resistances and pressure charges on the so-called cold-test bench.

Electronic documentation of the entire production process

The electronic production documentation system known as "AMG Trace" is a completely new feature in the AMG engine shop. This system provides full documentation of various process parameters such as the tightening torques of all bolted connections, fluid levels, component and batch information and test results. Special PCs are mounted on the assembly trolleys which have a wireless link to a documentation database. They display the relevant online information depending on the assembly stage. This state-of-the-art system guarantees exemplary production quality at the highest level. At the same time its unique architecture combines the traditional approach to AMG engine production with the production trends of the future.

Only highly qualified technicians with many years of experience are employed at the AMG engine workshops. The utmost precision and attention to detail are a matter of course during the hand-assembly process – even in peak periods when demand is particularly strong. All work stages are subject to the stringent Mercedes-Benz quality criteria which also apply to all other series-production engines. After all, even an AMG high-performance engine must exhibit the reliability and long operating life typical of a Mercedes.

Fully automatic high-bay warehouse, ultra-modern data management

Concentration of all the functional areas is a special characteristic of the AMG engine workshops. The resulting, short distances and optimisation of all processes directly benefit the working conditions of all the employees. The most up-to-date logistics ensure highly flexible and efficient production: after assembly, the AMG engines are automatically conveyed from the ground floor to the high-bay warehouse on the top floor. More than 1000 engines are stored here, and a state-of-the-art data management system enables the inventory to be continuously optimised, while the current stock levels can be easily obtained at any time.

Since 2004 only powerful V8 and V12 engines for AMG high-performance cars have been produced in the AMG engine workshops.

Tradition:

Reviewing almost 40 years of top performance

1971: premiere of the famous 300 SEL 6.8 AMG with the V8 racing engine

1986: the 300 CE 5.6 AMG achieves a maximum speed of 300 km/h

1993: the C 36 AMG appears as the first cooperation project

2001: new AMG 5.5-litre supercharged V8 engine with an output of 368 kW/500 hp

2003: the AMG 6.0-litre V12 biturbo engine with 450 kW/612 hp and the 460 kW/626 hp AMG 5.5-litre supercharged V8 engine of the SLR McLaren set new standards

Powerful acceleration, effortless torque, high-tech derived from motorsport and typical Mercedes long-distance comfort – AMG high-performance engines have been providing these for almost 40 years. These impressive qualities are based on the unique AMG philosophy which governs the design, testing and production of its engines. AMG was the first company to provide a professional engine customising service for Mercedes-Benz cars, and is acknowledged as the pioneer by the entire industry.

AMG V8 engines have always been in a class of their own. It all started in 1971, with the 6.8 litre, 309 kW/420 hp racing engine in the legendary 300 SEL 6.8 AMG. At the 24-hour race in Spa-Francorchamps ( Belgium ) this fast Mercedes saloon immediately secured a highly acclaimed class victory and second place overall. The powerful eight-cylinder racing engine made AMG known throughout the world overnight. Soon AMG also had a suitable engine available for S-Class customers in search of more power: on the basis of the 184 kW/250 hp V8 engine of the 300 SEL 6.3, the company developed a 206 kW/280 hp eight-cylinder unit which gave the luxury saloon the performance characteristics of a sports car.

The first four-valve Mercedes engine was developed by AMG

Subsequent AMG high-performance engines also provided unprecedented driving pleasure in other Mercedes models. For example the 5.0 litre V8 engine with 203 kW/276 hp, which gave the Mercedes-Benz 280 CE 5.0 AMG a dynamism previously unknown in this vehicle class in 1983. Just one year later AMG came up with a completely independently developed V8 unit featuring four-valve technology and an output of 250 kW/340 hp – a sensational figure at the time.

In 1986 the V8 engine, which had meanwhile been uprated to 5.6 litres and an output of 265 kW/360 hp, gave the 300 CE 5.6 AMG a maximum speed of no less than 300 km/h – as was even reported on the evening television news . American fans respectfully referred to the fast AMG Coupé as "The Hammer". The last evolutionary stage of the eight-cylinder powerpack appeared in 1988: from a displacement of six litres the four-valve unit developed a maximum output of 283 kW/385 hp and an unrivalled torque of 566 Newton metres.

Co-operation between Daimler-Benz and AMG with the C 36 AMG

The C 36 AMG appeared in 1993, as the first car jointly produced under the cooperation agreement between AMG and Daimler-Benz AG. Its 3.6 litre in-line six-cylinder engine developed a maximum output of 206 kW/280 hp. In 1996 the E 50 AMG with a 5.0 litre AMG V8 engine developing 255 kW/347 hp was introduced as the top-of-the-line model in the completely new Mercedes-Benz E-Class with its distinctive twin-headlamp look. One year later AMG surprised the world with a 4.3 litre V8 engine in the C-Class: the C 43 AMG had an output of 225 kW/306 hp and was also available as an estate model.

In 1997 AMG also presented the newly developed 5.5 litre eight-cylinder engine with three-valve technology and twin-spark ignition. This was initially designed to give a fulminating performance to the E 55 AMG, but within a short time it was also powering other AMG high-performance cars such as the CLK 55 AMG, ML 55 AMG, SL 55 AMG, S 55 AMG, CL 55 AMG and G 55 AMG. Uprated to 270 kW/367 hp and 510 Newton metres, it now provides dynamic performance at the highest level in the current models C 55 AMG, CLK 55 AMG Coupé and Cabriolet, as well as the SLK 55 AMG.

The supercharged V8 engine of the Mercedes-Benz SLR McLaren presented in 2003 is a special case: this super sports car is powered by a completely AMG-designed, high-tech eight-cylinder engine with dry sump lubrication. Its outstanding performance figures: an output of 460 kW/626 hp and 780 Newton metres of torque.

AMG V12 engines with outputs from 525 to 612 hp

AMG can also look back on an impressive tradition where V12 engines are concerned. 1998 saw the appearance of the CLK-GTR, a limited edition of 25 vehicles as the road version of the extremely successful racing car from the FIA-GT Championships. The four-valve twelve-cylinder engine developed 440 kW/600 hp from a displacement of 6.9 litres. In 1999 the new SL 73 AMG with its 7.3 litre V12 engine (386 kW/525 hp, 750 Nm) made an unprecedented level of dynamism and driving refinement possible.

New dimensions in power characteristics and dynamic performance were opened up by the new AMG 6.0 litre V12 biturbo engine in 2003. This powerpack offers unrivalled performance, with an output of 450 kW/612 hp and 1000 Newton metres of torque. To reduce the stresses on the powertrain the torque is electronically limited from 1,200 to 1,000 Newton metres – a record-breaking value. The AMG V12 engine offered in the S 65 AMG, CL 65 AMG and SL 65 AMG was able to continue the success of the supercharged V8 engine introduced in 2003.

AMG C-Class with a V8 racing engine in the DTM series

AMG engines also achieve impressive results on the racetrack. The AMG-Mercedes C-Class racks up victory after victory in the German Touring Car Masters (DTM). These racing tourers from Affalterbach are powered by 4.0 litre eight-cylinder engines generating around 350 kW/475 hp at 7,500 rpm.

The most important highlights of the new AMG V8 engine

Cylinder walls in revolutionary TWAS technology

Vertical intake and exhaust ducts

Four-valve technology with two overhead camshafts and bucket tappets

Dual-length variable intake manifold in magnesium technology with two interior throttle flaps

Continuous camshaft adjustment on the intake and exhaust sides

Close-coupled catalytic converters

Oil-water heat exchanger

Solid aluminium crankcase with bedplate and closed-deck design with cast-in steel components.

http://www.ae-plus.com/Technology%20...AMG%206.3l.htm

July 05

STUTTGART, Germany – Outstanding performance and a wide usable engine speed range, a good power-to-weight ratio and sound design, a low specific fuel consumption and exhaust emission values, ease of maintenance and pedestrian protection – the requirements for newly developed engines are both varied and demanding. The same applied to the completely new AMG 6.3 litre V8 engine. The primary development goals for the engineers and product strategists at Mercedes-AMG were dynamic responsiveness, great agility, exhilarating liveliness and a high torque even at low engine speeds.

A glance at the key technical data shows that the aim of developing a naturally aspirated, fast-running V8 engine with a decidedly sporty character was achieved in full: the new AMG engine generates a maximum output of 375 kW/510 hp at 6,800 rpm from a displacement of 6,208 cubic centimetres.

The new powerpack also reaches new heights where maximum torque is concerned: 630 Newton metres are on tap at 5,200 rpm. This makes it the world’s most powerful naturally aspirated eight-cylinder engine, as no other unit in this output and displacement class is able to achieve these figures. A look at the torque curve also reveals its extraordinary characteristics: the new AMG V8 already delivers 500 Newton metres to the crankshaft at 2,000 rpm, increasing to no less than 560 Newton metres at 3,000 rpm – considerably more than the maximum values comparable engines are able to achieve at much higher engine speeds.

Cylinder arrangement

Cylinder angle

Valves per cylinder

Displacement

Bore/stroke

Dist. between cylinders

Compression ratio

Output

Output per litre

Max torque

Torque per litre Maximum engine speed

Weight (dry)

Power-to-weight ratio

V8

90 deg

4

6208 cc

102.2/94.6 mm

109 mm

11.3 : 1

375 kW/510 hp @ 6800 rpm

60.4 kW/82.1 hp

630 Nm @ 5200 rpm

101.5 Nm

7200 rpm

199 kg

1.88 kW/kg

These remarkable figures reflect the Mercedes-AMG philosophy of building powerful engines with superlative output and torque characteristics, combined with dynamic and immediate responsiveness, which will enable drivers to use a sporty style of driving to the full.

With its unique, sporty AMG sound which was designed during an extensive series of tests, the eight-cylinder unit from Affalterbach offers the excitement of a naturally-aspirated, fast-running V8 engine in unmistakable audible and palpable form at low, medium and high engine speeds. Despite its pronounced sportiness, its smooth running characteristics and wide usable torque range also allow more leisurely progress when preferred – guaranteeing the long-distance comfort which is so typical of a Mercedes.

Completely autonomous development from Affalterbach

In conceptual and design terms the new eight-cylinder powerplant by Mercedes-AMG is a completely autonomous development which shares no features or common parts with other eight-cylinder engines by Mercedes-Benz. The new 6.3 litre unit differs from the other AMG V8 engines based on Mercedes designs in the distance between cylinders, the completely new crankcase concept, the sophisticated intake and exhaust manifolds and the valve train. The bore/stroke ratio is also a completely new departure for Mercedes-AMG.

Focusing on outstanding output and torque characteristics and decidedly sporty performance requires sophisticated technologies and solutions which are often based on motor sports engineering – which means that for mile after mile, the AMG driver benefits from more than 35 years of experience in international motor racing.

Design and materials:

Know-how from motor sports

Particularly rigid bedplate crankcase of closed-deck design

Cylinder walls with a unique, revolutionary TWAS coating

Completely new dual-length intake manifold with integral throttle flaps

Vertical air ducts, valve control by bucket tappets

Completely autonomous development from Affalterbach

More than three decades of know-how gained in GT and Touring Car championships, as well as great experience in the production of powerful, high-performance engines, went into the design of the new AMG 6.3 litre eight-cylinder engine. The special production facilities at the Affalterbach location were already taken into consideration during the development and conceptual phases, which allowed freedom of action and new possibilities for the engine’s designers. The resulting masterpiece was only made possible by a unique combination of extremely advanced engine and materials technology.

Sophisticated air ducting for a high output

Apart from the large overall displacement of precisely 6,208 cc, the extremely high output and torque is above all due to the sophisticated intake system – a completely new departure for AMG. Together with the innovative, variable intake manifold of magnesium with two integral throttle flaps, the large air intake cross-sections familiar from motorsport, the streamlined design of the intake and exhaust ducting and the vertical arrangement of the intake and exhaust ducts ensure that all eight cylinders are perfectly charged.

Patented variable intake manifold with two internal throttle flaps

The patented, dual-length intake manifold with two internal throttle flaps is a world first. Its task is to ensure a strong torque curve by lengthening the airflow distance at low engine speeds. At higher engine speeds the intake manifold switches to short airflow distances to achieve a high peak performance. The switching process is monitored by the electronic engine management system, vacuum-controlled depending on the engine load and engine speed, and imperceptible to the vehicle’s occupants.

The interior of the light, die-cast magnesium intake manifold features two electronically operated throttle flaps which are adjustable within fractions of a second: they can be opened to their maximum in just 100 milliseconds, and the driver perceives this as extraordinary responsiveness. The air intake at the front of the vehicle is of dual-flow design; two integral hot film airflow sensors behind the air filters provide the engine electronics with the necessary information about the temperature and density of the intake air.

With the help of complex flow simulations the engineers at Mercedes-AMG have precisely configured all the intake ducting to meet the requirements of the large engine displacement and the resulting large air volumes.

Valve operation by bucket tappets, as in the racing engines

Another special feature of the new AMG V8 engine is the sophisticated valvetrain, which is also derived from the powerful AMG racing engines. The 32 valves in the cylinder heads are operated by bucket tappets. Their space-saving design allows a stiff valve train and therefore high engine speeds with large valve opening cross-sections, which in turn benefits output and torque. The large intake valves have a diameter of 40 millimetres, while their opposite numbers on the exhaust side measure 34 millimetres. In contrast to a racing engine, the valve clearances are automatically adjusted by a hydraulic mechanism – the customer benefits from long, variable service intervals and low costs.

Four continuously variable overhead camshafts

All four overhead camshafts are continuously variable over a range of 42 degrees. Both the intake and exhaust camshafts are adjusted as a function of engine load and engine speed, ensuring extremely high output and torque values and smooth idling, and especially low exhaust emissions. Depending on the engine speed, the valve overlap can be varied to ensure an optimal supply of fuel/air mixture to the combustion chambers and efficient venting of the exhaust gases. This variable camshaft adjustment is controlled electro-hydraulically and monitored by the engine management system; the system is driven by a duplex roller chain and intermeshing pairs of gear wheels.

Crankcase with bedplate and closed-deck design

When designing the crankcase, the engineers and technicians in Affalterbach opted for a sophisticated bedplate construction on the closed-deck principle, which is well established in the motor racing sector and is also used in the powerful, supercharged AMG 5.5-litre V8 engine of the Mercedes-Benz SLR McLaren. Amongst engine specialists, this configuration stands for a high-performance sporting engine which is uncompromisingly designed for the utmost robustness.

The lower section of the crankcase in the AMG 6.3 litre V8 engine is an enclosed unit, which particularly benefits the torsional rigidity of the engine. This type of construction also permits higher combustion pressures and reduces pulsation losses within the crankcase itself. This not only minimises the internal friction losses, but also produces more rigid bearing bridges for the crankshaft. More efficient integration of the oil scavenger also allows foaming on the part of the engine oil to be reduced. The crankcase is also equipped with special, cast-in steel components which improve the strength of the engine block even further, benefit the engine acoustics and ensure a reliable oil supply.

Unique process for cylinder wall coating

The engine block and cylinder heads are of cast aluminium-silicon alloys (AlSi7 and AlSi17) which represent the state of the art in terms of weight, thermal and mechanical resistance and long-term strength. The engine specialists at Mercedes-AMG use a particularly advanced process for the eight cylinder walls to produce a tribologically optimal surface, namely a coating applied by twin wire arc spraying (TWAS). The advantages of this technology are extremely low friction and wear accompanied by outstanding long-term durability. A considerably harder surface is achieved compared to conventionally coated cylinder walls. In fact the cylinder walls of the new AMG V8 engine are twice as hard as conventional cast iron liners – a quantum leap for engine specialists.

No other series-production engine apart from the new AMG 6.3 litre V8 unit can boast such sophisticated technology – which means that once again, Mercedes-AMG has underlined its pioneering role in the development and production of innovative high-performance engines.

During the TWAS process, two metallic wires and an atomising gas are brought together in a coating unit. Passing a high voltage through the tips of the wires breaks the gas molecules down to form a plasma, and the wire tips begin to melt. The atomising gas removes molten metal from the wire tips and sprays these particles onto the cylinder walls to be coated, where they solidify. This is preceded by a high-pressure water jet which roughens the cylinder walls so that the individual sprayed particles adhere to the surface during the TWAS coating process.

The cylinder walls are then honed to achieve a perfect surface structure. During this process the micro-pores in the sprayed coating are partially exposed, which enables them to retain oil when the engine is running and ensure tribologically favourable lubrication of the pistons and piston rings.

This trailblazing process was developed in close collaboration between the DaimlerChrysler process engineering department and Mercedes-AMG, and has been brought to series production maturity for the first time in the AMG V8 engine.

Crank assembly optimised for the lowest possible inertia

The finely balanced crankshaft is designed for the highest stresses, consists of the high-quality forged steel alloy 42CRMo4V, rotates in five crankshaft bearings and features six counterweights for perfectly balanced masses. Torsional rigidity, long-term structural strength and inertia characteristics are also to the very highest standards. As a detail normally only found in racing engines, the counterweights feature heavy metal core plugs, which means that they can be made significantly more compact. As a result the complete crank assembly can be optimised for particularly low rotational and oscillatory inertia, which enormously benefits responsiveness and flexibility.

Two lightweight connecting rods forged by the cracking process are connected to each of the four crank pins. During this process, the utmost production precision is made possible by a predetermined breaking point created by a laser beam. Extremely close weight tolerances between the eight connecting rods are also ensured by precision machining. The same principle is also used for the cast, lightweight pistons. They are made from a durable high-temperature alloy. Pressure-controlled oil spray nozzles in the crankcase ensure optimal cooling of the highly stressed piston crowns.

Owing to the large overall displacement, a highly efficient oil pump with a high throughput is used in the new AMG eight-cylinder. Even at high rates of lateral acceleration, the intelligent arrangement of all the components in the oil circuit ensures a consistent supply of lubricant. The engine oil is cooled on a vehicle-specific basis, i.e. the sump and the arrangement of the coolers may vary. The cooling performance itself always remains constant.

Engine cooling on the sophisticated cross-flow principle

As in thoroughbred racing engines, the engine is cooled on the sophisticated cross-flow principle. This means that the eight individual cylinders have a uniform temperature by virtue of the homogenous coolant flow, thereby avoiding critical temperature peaks. The coolant flows from the exhaust side of the crankcase across the cylinder heads, then back to the thermostat and radiator via the collector on the intake side. The thermally highly stressed cylinder heads are also cooled according to this principle, which particularly benefits the operating life. Even the cylinder head bolts are included in the coolant circuit. This technology was developed with the help of complex flow calculations and perfected during an extended series of tests.

Variable coolant control for optimised friction

In addition the temperature of the coolant is variably controlled. In the interests of optimal in-engine friction and fuel economy, the temperature of the coolant can for example be lowered to 80 degrees Celsius under partial load. Under full load conditions the temperature is raised to 100 degrees within milliseconds to achieve the best possible engine cooling. The thermostat controlling the coolant temperature receives its instructions from the engine electronics.

Fuel supply monitored by a computer

The fuel supply of the AMG eight-cylinder is likewise computer-controlled and monitored. The fuel pressure is variably and instantly adjusted depending on the performance requirement and ambient temperature. The engine electronics execute commands from the accelerator pedal within milliseconds, leading to outstanding responsiveness. A high-pressure pump configured for the engine is integrated into the fuel tank.

Highly efficient engine electronics for every function

All engine functions are controlled and executed by a particularly efficient Bosch ME 9.7 control unit. Fuel injection, ignition, the variable intake manifold, camshaft adjustment and variable cooling are all controlled by the state-of-the-art engine computer, which also communicates with all the other onboard control units. The microprocessor has 10,000 different characteristic maps and functions in its memory, and is able to carry out up to 70 million individual operations per second.

To reduce the load on the engine control unit, the eight individual ignition coils have an integral electronic module known as an ignition amplifier at each cylinder. These ensure a strong ignition spark at all engine speeds and under all load conditions.

Exhaust technology and sound design:

Low emissions and a designer sound

Continuous camshaft adjustment for low untreated emissions

Four ceramic catalytic converters of thin-wall substrate design for efficient emissions control

Characteristic engine sound as a result of extensive tests

AMG sports exhaust system with two twin tailpipes

Despite its high output and torque values, the new AMG 6.3 litre eight-cylinder engine meets all current exhaust emission standards without difficulty. Both the European EU4 standard and the stringent US standards presently in force and planned are complied with. The new AMG engine easily meets specific requirements for the US market, e.g. Onboard Diagnosis II and oxygen sensor diagnosis.

This is due to highly sophisticated engine and exhaust technology. Continuous camshaft adjustment makes a major contribution to efficient emissions control. Under partial load it ensures need-related internal exhaust gas recirculation by conducting the gases directly from the combustion chamber to the intake ducts. While the intake valves are being opened the exhaust valves also remain open for a short time, and at this point some of the exhaust gases flow from the exhaust to the intake side. The engineers at AMG have used this principle of valve overlap to achieve a dual advantage, for both untreated emissions and fuel consumption can be lowered by reducing gas cycle losses.

An exhaust system specially developed for the large-displacement AMG V8 engine is used to support the in-engine emissions control measures. Effective aftertreatment begins in the air-gap-insulated manifolds, which have a wall thickness of only 1.0 milimetres. Ten seconds after starting, these already allow an exhaust temperature of 280 degrees Celsius – a precondition for rapid response by the close-coupled catalytic converters. All four ceramic catalytic converters feature thin-wall substrates; thanks to their maximised surface area these not only provide the best conditions for effective emissions control, but also aid performance with their low exhaust counter-pressure. Four oxygen sensors are used to control and monitor the exhaust system: the two front sensors ensure an optimal controlled engine range, while the two sensors behind the catalytic converters are responsible for Onboard Diagnosis II.

Secondary air injection reduces carbon monoxide and hydrocarbons

The afterburning effect of the secondary air injection system leads to higher exhaust gas temperatures and supports the heating-up process. As a result of this complex system the carbon monoxide and hydrocarbon content in the exhaust gases is reduced. The oxygen sensors continuously monitor the constituents of the mixture and supply this information to the computer, which readjusts the mixture as soon as the temperature of the catalytic converters has reached its nominal level.

The new AMG engine also has a demand-related oxygen control system. This means that in all operating conditions, the constituents of the intake mixture can be precisely controlled to avoid damaging the catalytic converters. This also benefits the fuel consumption under full load, as the mixture can be leaner than in engines without this intelligent control system.

Designer engine sound adds to the power experience

Customers expect a new AMG high-performance engine to possess a characteristic and throaty sound. The primary aim of the technicians was also to create a synthesis of palpable dynamism and the long-distance comfort typical of a Mercedes. During acceleration the driver experiences the emotional sound of the fast-running engine and the exceptional power of the naturally aspirated eight-cylinder. At the same time this powerpack must for instance exhibit the smooth running characteristics and effortless progress required when covering long motorway distances. During this work the specialists at AMG were at pains to avoid disturbing noises and emphasise the pleasant frequencies which are typical of a sports car. At the same time it was important to comply with all the relevant regulations – for example when measuring drive-by noise. These varying requirements were a major challenge for the engineers and technicians at Mercedes-AMG GmbH, and they passed the test with flying colours – the results are well worth hearing.

Research in the acoustics laboratory and during test drives

Complex test series both in the acoustics laboratory and during vehicle trials led to a completely newly designed, twin-pipe exhaust system with pipe cross-sections and silencer volumes precisely suited to the engine displacement. Depending on the vehicle model, not only the routing of the pipes and the position and size of the rear silencers, but also the location of the catalytic converters and oxygen sensors had to be defined. The two oval, chrome twin tailpipes of the AMG sports exhaust system are not only a striking visual characteristic - the dynamic AMG V8 exhaust note instantly tells the knowledgeable person that this is a genuine AMG.

Close attention was also paid to the intake noise. The aim was to create a sporty but in no way irritating sound for the AMG eight-cylinder. To this end various components were used during the development phase. When designing the dual-flow intake system, numerous variations of intake ducts, air filters and intake noise dampers were experimented with before the final result was achieved.

Trials and test bench technology:

Endurance trials as a development standard

Systematic development work in two parallel programmes

The latest high-tech test benches for engines with up to 735 kW/1000 hp

Extended trials in all the world’s climatic zones

Maximum stress in the most extreme endurance trials

Trials of the new AMG 6.3 litre eight-cylinder engine were conducted in two stages. In addition to in-vehicle trials on every continent, the engine had to prove its worth on the newly constructed high-tech test benches in Affalterbach. But the development work started with analyses of basic mechanical functions, the oil circuit, power characteristics with various intake duct and camshaft configurations, plus the definition of fuel injection quantities, fuel consumption and exhaust emission values – all these were studied on the dynamic simulation test benches at Mercedes-AMG. Nine of the very latest, high-tech test benches are available in the completely new Mercedes-AMG test bench laboratory, which was taken into commission in 2004; engines with outputs exceeding 735 kW/1000 hp can be dynamically tested in this facility.

After completion of the basic work in Affalterbach, the first test vehicles equipped with the new AMG eight-cylinder engine were sent onto public roads and test tracks in all the climatic regions of the earth. All of them were required to undergo the standardised trials to which all AMG high-performance cars are subjected. These place the most extreme demands on the vehicles and their components in terms of practicality, reliability and long-term durability – after all, the new engine must operate perfectly anywhere in the world, and under all climatic and road conditions.The individual trial stages at a glance:

Engine and transmission development

High-altitude trials in Denver , Colorado ( USA ), Lesotho ( South Africa ) and Granada ( Spain )

Heat trials in Death Valley , California ( USA ), Upington ( South Africa ), Idiada test track ( Spain ) and Phoenix , Arizona ( USA )

Road trials in Los Angeles , California ( USA )

Cold trials in Arctic Falls ( Sweden )

Cooling and fuel system

Various test runs on the high-speed circuits in Nardo ( Italy ) and Papenburg ( Germany )

Trials in Upington ( South Africa ) and Death Valley , California ( USA )

Tests in the DaimlerChrysler wind tunnel

In addition, various endurance trials were carried out with the aim of simulating the engine’s entire operating life under the most extreme conditions:

Nürburgring north loop: The engine was tested under predominantly full load conditions on the world’s most demanding racetrack.

Mixed road endurance trials: Testing under everyday conditions. The vehicles were loaded up to their gross vehicle weight and subjected to a precisely defined test programme on country roads, motorways and in city traffic.

Stress endurance trials at the DaimlerChrysler test site in Papenburg: Extreme acceleration and deceleration cycles under predominantly full load conditions, with high stresses on the oil circuit, cooling system and fuel supply.

Endurance trials in the hills of the Swabian Alb region: The vehicles were loaded up to their gross vehicle weight and towed a two-tonne trailer. The route covered country roads with numerous uphill and downhill gradients, and subjected the engine, transmission and cooling system to very high stresses.

In parallel with the road and racetrack trials in various test vehicles, the new AMG 6.3 litre V8 engine was subjected to rigorous tests on the ultra-modern dynamic test benches at AMG. These facilities are able to simulate any road and environmental conditions to represent any conceivable type of operation. Cold or hot starting, mountain passes, stop-and-go traffic or fast laps on the Grand Prix circuit in Hockenheim – the engines were required to give their utmost. Even the intake air temperatures and densities can be varied by computer control, and the engines can be alternately filled with hot and cold coolant. Fuels of different grades are also available.

The aim of these extended test bench trials, which also included various endurance tests of up too 800 hours, was to confirm the performance of all the engine components and the peripheral units. All the stored measuring results for the tested engines were systematically compared and evaluated with the help of reproducible test procedures.

Production:

"One man, one engine" in Affalterbach

AMG engine workshops with an effective floorspace of 9950 sq. m.

Only one technician assembles each high-performance V8 engine

Engine lifecycle data record as a new standard in production

Unsurpassed precision, attention to detail and know-how

The special production techniques used at the Affalterbach location were already taken into account during the development and conceptual work on the new AMG 6.3 litre eight-cylinder engine; these ensure freedom of action and open up new possibilities during the engine design stage. Assembly of the complex valve train with bucket tappets in the cylinder heads must be done by hand, for example, and that is only possible in the highly specialised environment of the AMG engine workshops.

Approx 100 AMG high-performance engines assembled per day

It is a tradition at Mercedes-AMG that every engine is built by hand according to the "one man, one engine " philosophy. This means that one technician assembles the entire engine and confirms this by his signature on the AMG engine badge. The AMG engine shop has three storeys with an effective total floorspace of 9950 square metres and produces around 100 high-performance engines for various vehicle models each day. Production of AMG engines is geared to the highest flexibility, and can be rapidly adjusted to the current market conditions and order intake.

One AMG technician builds an entire engine, and is responsible for everything from installation of the crankshaft in the engine block, the camshafts and right up to the electrical wiring and the engine oil – clearly witnessed by his signature on the engine badge. After completion, a technician checks the engine’s operation with simulated resistances and pressure charges on the so-called cold-test bench.

Electronic documentation of the entire production process

The electronic production documentation system known as "AMG Trace" is a completely new feature in the AMG engine shop. This system provides full documentation of various process parameters such as the tightening torques of all bolted connections, fluid levels, component and batch information and test results. Special PCs are mounted on the assembly trolleys which have a wireless link to a documentation database. They display the relevant online information depending on the assembly stage. This state-of-the-art system guarantees exemplary production quality at the highest level. At the same time its unique architecture combines the traditional approach to AMG engine production with the production trends of the future.

Only highly qualified technicians with many years of experience are employed at the AMG engine workshops. The utmost precision and attention to detail are a matter of course during the hand-assembly process – even in peak periods when demand is particularly strong. All work stages are subject to the stringent Mercedes-Benz quality criteria which also apply to all other series-production engines. After all, even an AMG high-performance engine must exhibit the reliability and long operating life typical of a Mercedes.

Fully automatic high-bay warehouse, ultra-modern data management

Concentration of all the functional areas is a special characteristic of the AMG engine workshops. The resulting, short distances and optimisation of all processes directly benefit the working conditions of all the employees. The most up-to-date logistics ensure highly flexible and efficient production: after assembly, the AMG engines are automatically conveyed from the ground floor to the high-bay warehouse on the top floor. More than 1000 engines are stored here, and a state-of-the-art data management system enables the inventory to be continuously optimised, while the current stock levels can be easily obtained at any time.

Since 2004 only powerful V8 and V12 engines for AMG high-performance cars have been produced in the AMG engine workshops.

Tradition:

Reviewing almost 40 years of top performance

1971: premiere of the famous 300 SEL 6.8 AMG with the V8 racing engine

1986: the 300 CE 5.6 AMG achieves a maximum speed of 300 km/h

1993: the C 36 AMG appears as the first cooperation project

2001: new AMG 5.5-litre supercharged V8 engine with an output of 368 kW/500 hp

2003: the AMG 6.0-litre V12 biturbo engine with 450 kW/612 hp and the 460 kW/626 hp AMG 5.5-litre supercharged V8 engine of the SLR McLaren set new standards

Powerful acceleration, effortless torque, high-tech derived from motorsport and typical Mercedes long-distance comfort – AMG high-performance engines have been providing these for almost 40 years. These impressive qualities are based on the unique AMG philosophy which governs the design, testing and production of its engines. AMG was the first company to provide a professional engine customising service for Mercedes-Benz cars, and is acknowledged as the pioneer by the entire industry.

AMG V8 engines have always been in a class of their own. It all started in 1971, with the 6.8 litre, 309 kW/420 hp racing engine in the legendary 300 SEL 6.8 AMG. At the 24-hour race in Spa-Francorchamps ( Belgium ) this fast Mercedes saloon immediately secured a highly acclaimed class victory and second place overall. The powerful eight-cylinder racing engine made AMG known throughout the world overnight. Soon AMG also had a suitable engine available for S-Class customers in search of more power: on the basis of the 184 kW/250 hp V8 engine of the 300 SEL 6.3, the company developed a 206 kW/280 hp eight-cylinder unit which gave the luxury saloon the performance characteristics of a sports car.

The first four-valve Mercedes engine was developed by AMG

Subsequent AMG high-performance engines also provided unprecedented driving pleasure in other Mercedes models. For example the 5.0 litre V8 engine with 203 kW/276 hp, which gave the Mercedes-Benz 280 CE 5.0 AMG a dynamism previously unknown in this vehicle class in 1983. Just one year later AMG came up with a completely independently developed V8 unit featuring four-valve technology and an output of 250 kW/340 hp – a sensational figure at the time.

In 1986 the V8 engine, which had meanwhile been uprated to 5.6 litres and an output of 265 kW/360 hp, gave the 300 CE 5.6 AMG a maximum speed of no less than 300 km/h – as was even reported on the evening television news . American fans respectfully referred to the fast AMG Coupé as "The Hammer". The last evolutionary stage of the eight-cylinder powerpack appeared in 1988: from a displacement of six litres the four-valve unit developed a maximum output of 283 kW/385 hp and an unrivalled torque of 566 Newton metres.

Co-operation between Daimler-Benz and AMG with the C 36 AMG

The C 36 AMG appeared in 1993, as the first car jointly produced under the cooperation agreement between AMG and Daimler-Benz AG. Its 3.6 litre in-line six-cylinder engine developed a maximum output of 206 kW/280 hp. In 1996 the E 50 AMG with a 5.0 litre AMG V8 engine developing 255 kW/347 hp was introduced as the top-of-the-line model in the completely new Mercedes-Benz E-Class with its distinctive twin-headlamp look. One year later AMG surprised the world with a 4.3 litre V8 engine in the C-Class: the C 43 AMG had an output of 225 kW/306 hp and was also available as an estate model.

In 1997 AMG also presented the newly developed 5.5 litre eight-cylinder engine with three-valve technology and twin-spark ignition. This was initially designed to give a fulminating performance to the E 55 AMG, but within a short time it was also powering other AMG high-performance cars such as the CLK 55 AMG, ML 55 AMG, SL 55 AMG, S 55 AMG, CL 55 AMG and G 55 AMG. Uprated to 270 kW/367 hp and 510 Newton metres, it now provides dynamic performance at the highest level in the current models C 55 AMG, CLK 55 AMG Coupé and Cabriolet, as well as the SLK 55 AMG.

The supercharged V8 engine of the Mercedes-Benz SLR McLaren presented in 2003 is a special case: this super sports car is powered by a completely AMG-designed, high-tech eight-cylinder engine with dry sump lubrication. Its outstanding performance figures: an output of 460 kW/626 hp and 780 Newton metres of torque.

AMG V12 engines with outputs from 525 to 612 hp

AMG can also look back on an impressive tradition where V12 engines are concerned. 1998 saw the appearance of the CLK-GTR, a limited edition of 25 vehicles as the road version of the extremely successful racing car from the FIA-GT Championships. The four-valve twelve-cylinder engine developed 440 kW/600 hp from a displacement of 6.9 litres. In 1999 the new SL 73 AMG with its 7.3 litre V12 engine (386 kW/525 hp, 750 Nm) made an unprecedented level of dynamism and driving refinement possible.

New dimensions in power characteristics and dynamic performance were opened up by the new AMG 6.0 litre V12 biturbo engine in 2003. This powerpack offers unrivalled performance, with an output of 450 kW/612 hp and 1000 Newton metres of torque. To reduce the stresses on the powertrain the torque is electronically limited from 1,200 to 1,000 Newton metres – a record-breaking value. The AMG V12 engine offered in the S 65 AMG, CL 65 AMG and SL 65 AMG was able to continue the success of the supercharged V8 engine introduced in 2003.

AMG C-Class with a V8 racing engine in the DTM series

AMG engines also achieve impressive results on the racetrack. The AMG-Mercedes C-Class racks up victory after victory in the German Touring Car Masters (DTM). These racing tourers from Affalterbach are powered by 4.0 litre eight-cylinder engines generating around 350 kW/475 hp at 7,500 rpm.

The most important highlights of the new AMG V8 engine

Cylinder walls in revolutionary TWAS technology

Vertical intake and exhaust ducts

Four-valve technology with two overhead camshafts and bucket tappets

Dual-length variable intake manifold in magnesium technology with two interior throttle flaps

Continuous camshaft adjustment on the intake and exhaust sides

Close-coupled catalytic converters

Oil-water heat exchanger

Solid aluminium crankcase with bedplate and closed-deck design with cast-in steel components.

http://www.ae-plus.com/Technology%20...AMG%206.3l.htm

#35

Super Member

Thread Starter

More about the 63 motor

The most important highlights of the new AMG V8 engine

Cylinder walls in revolutionary TWAS technology

Vertical intake and exhaust ducts

Four-valve technology with two overhead camshafts and bucket tappets

Dual-length variable intake manifold in magnesium technology with two interior throttle flaps

Continuous camshaft adjustment on the intake and exhaust sides

Close-coupled catalytic converters

Oil-water heat exchanger

Solid aluminium crankcase with bedplate and closed-deck design with cast-in steel components

http://www.worldcarfans.com/2050713.001/1.html

Cool 3D model of 63 motor:

http://www.eitechnologygroup.com/gal...age_full/1135/

.

Cylinder walls in revolutionary TWAS technology

Vertical intake and exhaust ducts

Four-valve technology with two overhead camshafts and bucket tappets

Dual-length variable intake manifold in magnesium technology with two interior throttle flaps

Continuous camshaft adjustment on the intake and exhaust sides

Close-coupled catalytic converters

Oil-water heat exchanger

Solid aluminium crankcase with bedplate and closed-deck design with cast-in steel components

http://www.worldcarfans.com/2050713.001/1.html

Cool 3D model of 63 motor:

http://www.eitechnologygroup.com/gal...age_full/1135/

.

Last edited by turbotom1; 06-09-2008 at 10:37 PM.

#37

Super Member

Thread Starter

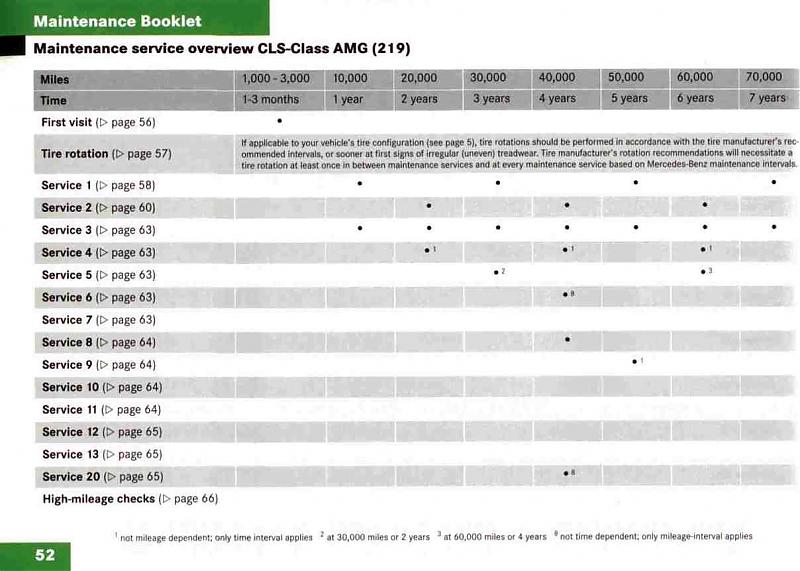

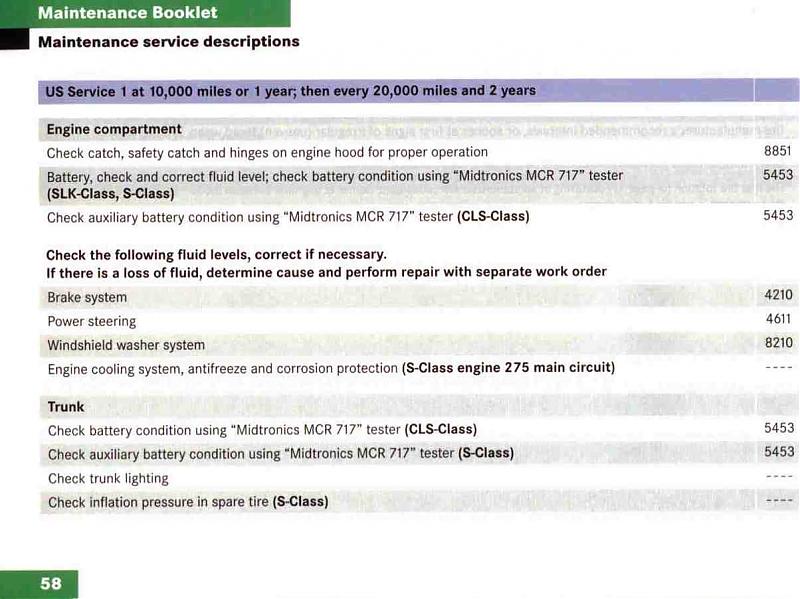

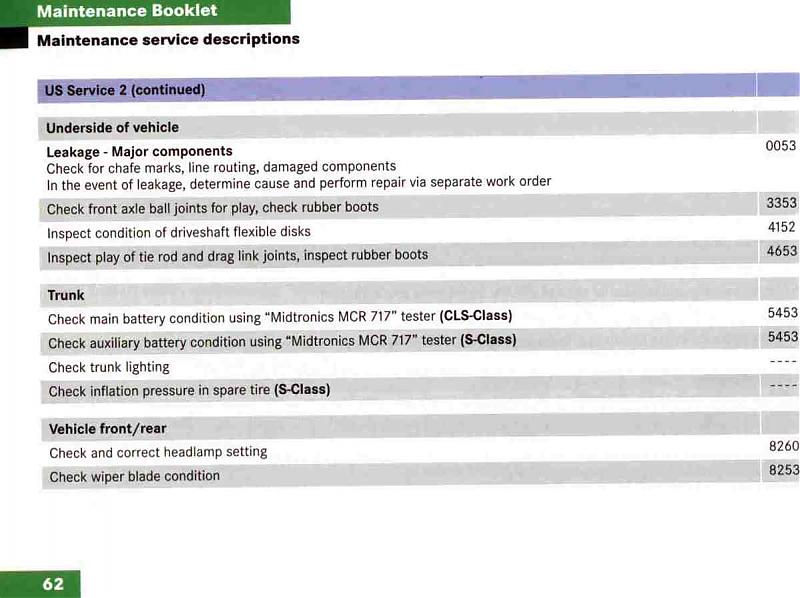

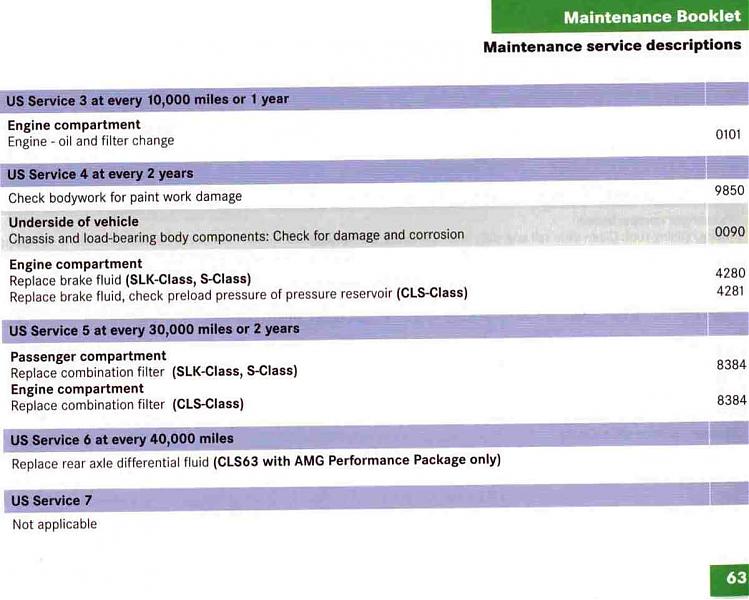

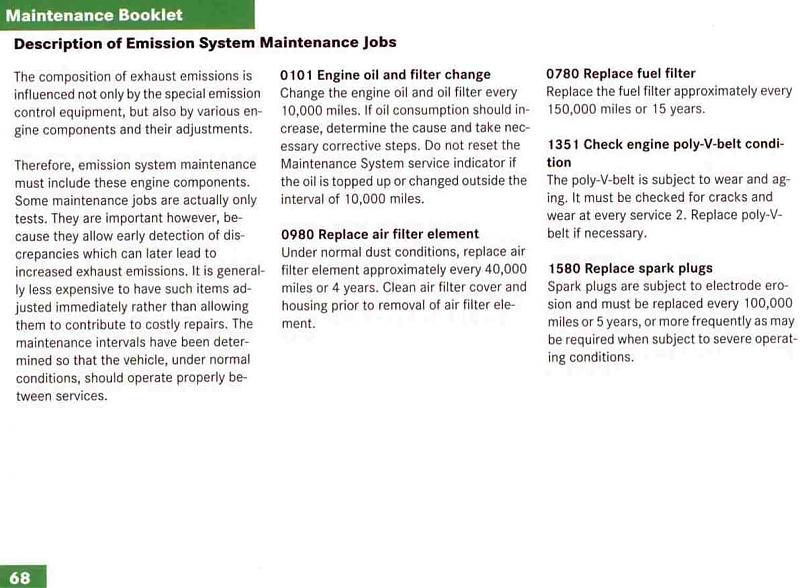

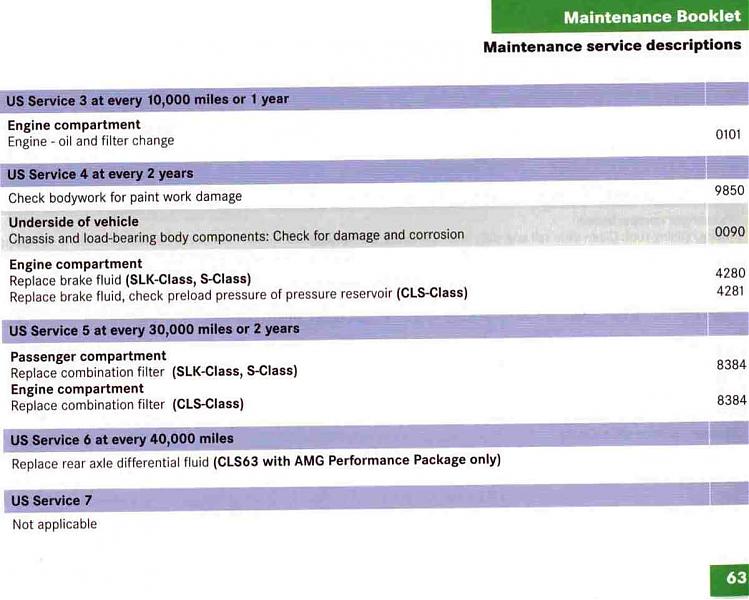

CLS63 Maintenance continued

CLS63 Maintenance Schedule Continued

The reference that under normal use spark plugs require change at 100,000 miles is for everyone but "Juicee63"

(Because Juicee's Plugs Are Subject Severe Operating Conditions )

)

The reference that under normal use spark plugs require change at 100,000 miles is for everyone but "Juicee63"

(Because Juicee's Plugs Are Subject Severe Operating Conditions

)

)

Last edited by turbotom1; 06-10-2008 at 06:11 PM.

#39

Super Member

Thread Starter

The DISTRONIC PLUS proximity control system keeps your vehicle at a previously chosen distance from the vehicle travelling in front and, if necessary brakes your vehicle to a complete standstill, depending on the traffic situation.

.

.

#40

Super Member

Thread Starter

MKB Tuning

MKB tuning:

http://www.mkb-power.de/upload/downl...r_CLS_W219.pdf

http://www.mkb-power-na.com/

63 upgrades:

http://www.mkb-power.de/upload/downl...e_MKB_63_8.pdf

USA

Company: MKB North America

Mr. Daniel Bird

Street: 7902 NE St. John's Road #103a

City: Vancouver, WA 98665

Phone: (888) 503-3663

Fax: (888) 503-3663

Mail: Danielb@mkb-power-NA.com

http://www.mkb-power.de/upload/downl...r_CLS_W219.pdf

http://www.mkb-power-na.com/

63 upgrades:

http://www.mkb-power.de/upload/downl...e_MKB_63_8.pdf

USA

Company: MKB North America

Mr. Daniel Bird

Street: 7902 NE St. John's Road #103a

City: Vancouver, WA 98665

Phone: (888) 503-3663

Fax: (888) 503-3663

Mail: Danielb@mkb-power-NA.com

Last edited by turbotom1; 06-13-2008 at 08:22 PM.

#41

Super Member

Thread Starter

J.D. Powers Rating

JD Powers 2008 rating:

Reviews