Mercedes-Benz C-Class: Why is My Suspension Noisy?

Despite the quality and craftsmanship of the Mercedes-Benz C-Class, suspension components still wear out and occasionally fail. Fortunately, the w204 models have been out for quite some time now and have logged plenty of miles, so common areas of suspension noise can be identified rather quickly.

This article applies to the Mercedes-Benz C-Class w204 (2007-2014)

Mercedes-Benz combines the elements of luxury and performance, which is evident from the first time you sit in one of their cars. The brand has created a product that reeks of quality, and feels as robust as a German World War II Panzer tank. The ride and comfort of the model continuously receives positive reviews, and this is no different for the C-Class. With a suspension that errs on the firm side, the w204 C-Class is versatile enough to cruise in style while still being able to carve a corner or two. However, a few common suspension issues that have plagued its predecessor (w203) still linger on the w204 model that can hamper driving enjoyment. Whether you are experiencing a clunking, grinding, squeaking, or creaking noise emanating from your suspension, they can be quickly identified if one knows where to look. This article will review some of the common suspension problems that can create a noisy ride on the w204 C-Class.

Materials Needed

- Floor jack and jack stands

- Tire iron

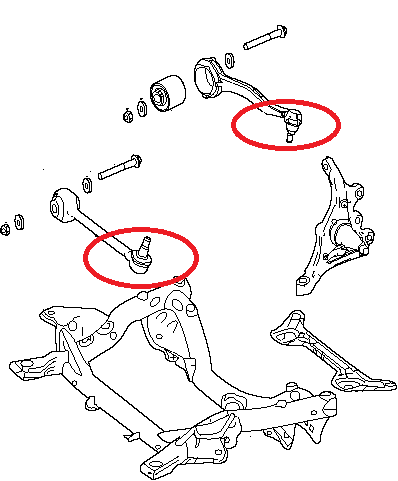

Step 1 – Check thrust arm bushings

Perhaps the most common area of suspension noise on the w204 C-Class lies within the thrust arm bushings (also referred to as castor or torque arm bushings). The thrust arm on the suspension counters the longitudinal forces placed upon the wheels when driving. These fore and aft forces place a heavy load upon the thrust arm, and are therefore quite abusive to the thrust arm bushings. These bushing are fluid filled rubber isolators that are placed between the thrust arm and the chassis to reduce noise as well as vibration, while providing adequate support. Unfortunately, despite re-designs of the failure prone w203 bushings, the w204 bushings suffer from the same cracking and splitting problems, which will result in a popping or clunking noise when the wheels are turned. Typical bushing life is approximately 30,000 miles, but if you are experiencing a suspension noise or have significantly more miles on your car, it may be worthwhile to replace the thrust arm bushings.

Figure 1. Thrust arm bushing location.

Figure 2. Thrust arm bushing detail.

Pro Tip

If the bushing has torn or ruptured, it is possible for the surrounding area to be wet with fluid. This is a clear sign of a bushing failure.

Step 2 – Check strut assemblies and springs

Another area where owners have experienced suspension noise has been in the strut assemblies and springs. Surprisingly, these have been replaced quite regularly on the w204 models.

-

Top Mounts: The top of the suspension strut is attached to the body via a top mount. These top mounts have integral bearings that aid in smooth rotation of the strut as the wheels are turned back and forth. These bearings support the load of the front suspension and will become noisy when they have failed. Usually, these bearings corrode and no longer turn freely; however, Mercedes issued a service bulletin a while back on noisy suspension that specifically referred to the strut's top mount bearings.

-

Springs: While not as common, a broken coil spring on the front or rear suspension can be a source of a creak or groan when going over bumps. These noises are often from the two pieces of spring binding and making contact as the spring compresses. Similarly, if any suspension work or lowering springs have been installed on the car, the springs may not be seated in their perches properly and can make noise. This is especially the case on the front suspension, as the spring can get hung up or bind instead of rotating freely when trying to turn. The result is a creaking and groaning noise.

- Shock Absorbers: Owners have reported dealer service departments replacing their shocks (often times the complete front strut assemblies) as they were unable to completely isolate the suspension noise. A shock rarely fails to the point of becoming noisy, although a binding or frozen piston rod on the shock absorber may squeak. The best course of action when experiencing noisy suspension components is to inspect the shock body, and look for signs of oil that would indicate a seal failure or similar.

Step 3 – Check sway bar bushings and end links

-

Sway Bar Bushings: The sway bar bushings, that are the isolators between the sway bar and the vehicles chassis, are a known area for squeaking noises. The sway bar is under torsional loads while the car is maneuvering, and dried, hardened, or loose bushings will become noisy. As with all rubber components, the bushings tend to dry out and harden with age. Being that the sway bar is located on the underside of the car, it is pretty exposed to the elements that may cause the bushing to deteriorate. The bushings can be lubricated with vaseline or a similar grease if dry. Additionally, if the bushings look aged or cracked, they should be replaced. Be sure they are securely fastened to the chassis as well, since the sway bar can move inside of a loose bushing and squeak.

-

Sway Bar End Links: The attachment of the sway bar to the suspension is accomplished with the use of sway bar end links. On the front axle, the end links use a sealed ball joint design that has a significant range of motion sufficient for the various movements of the front suspension. The boots on the end links can tear, and the ball joint will corrode. The result is a clunking noise from the worn joint. Similarly, if the mounting fasteners have loosened on either end of the links, a clunking will be evident as well. On the rear sway bar links, rubber bushings are used instead of ball joints. As previously mentioned with sway bar bushings, the rubber rear sway bar end link bushings can age and squeak. Lubricant can temporarily resolve the squealing, although it is recommended new end links be installed.

Step 4 – Check ball joints

The front suspension components utilize ball joints at the control arms and tie rod ends. The extensive range of motion of these spherical links are quite robust and meant to last; however, contamination of the joint can lead to premature failure often accompanied by a clunking or knocking noise. Unfortunately, almost all ball joints are now factory sealed and do not allow for individuals to grease them as they were once able to. These sealed ball joints have a "lifetime" lubricant from the factory, but the lubricant can harden over time and lead to joint wear. Similarly, a torn boot will leak grease and allow moisture, dirt, as well as debris to damage the joint. The ball joint boots on the C-Class are easily inspected with the wheels removed. Additionally, with a firm grasp on a front wheel, the wheel can be worked in and out to test for excessive ball joint play.

Step 5 – Check CV joints

Individuals with 4MATIC all wheel drive models may experience a clicking noise that may seem to be coming from the front suspension when turning; however, it is likely a worn front CV joint. CV joints, or constant velocity joints, are widely used on many cars today to transfer power from the drive axles to the driving wheels because of their superior range of motion. In the case of all wheel drive cars, the front CV joints are asked to do a tremendous amount of work as they have to provide power through extreme angles while the front wheels turn. CV joints can wear, especially with a torn boot exposed to dirt and grime, which will begin to click. These clicks will become highly noticeable while moving with the steering wheel turned.

Pro Tip

If a boot is found to be torn, it is highly recommended it be replaced as soon as possible to prevent loss of lubrication and excessive wear to the CV joint.

Related Discussions

- Torque Arm Bearings Popping Again - MBWorld.org

- Front Suspension Clunk- MBWorld.org

- Suspension Noise in Cold Weather - MBWorld.org

- Common Suspension Noise Solutions - MBWorld.org

- 2010 C Shock Problem - MBWorld.org