HRE3D+ | The WORLDS FIRST 3D-Printed Titanium Wheel

#1

Former Vendor of MBWorld

Thread Starter

HRE3D+ | The WORLDS FIRST 3D-Printed Titanium Wheel

HRE WHEELS PARTNERS WITH GE ADDITIVE TO CREATE FIRST 3D-PRINTED TITANIUM WHEEL

HRE and GE Additive’s AddWorks team have used Electron Beam Melting (EBM) technology to create a new prototype wheel made from an advanced titanium powder, unveiling the first automotive wheel to be made with this process.

Vista, Calif. (November, 2018) – HRE Wheels and GE Additive announced a partnership agreement today and unveiled the first titanium wheel created using EBM technology (a type of 3D printing). Known as “HRE3D+”, this new prototype wheel shows what the future of wheel technology will bring and how advanced materials like titanium can be harnessed to create complex designs.

The goal of the “HRE3D+” project was to test the capabilities of additive manufacturing in a practical application and to create a highly-sophisticated wheel design with an elusive material like titanium. With a traditional aluminum Monoblok wheel, 80% of material is removed from a 100-pound forged block of

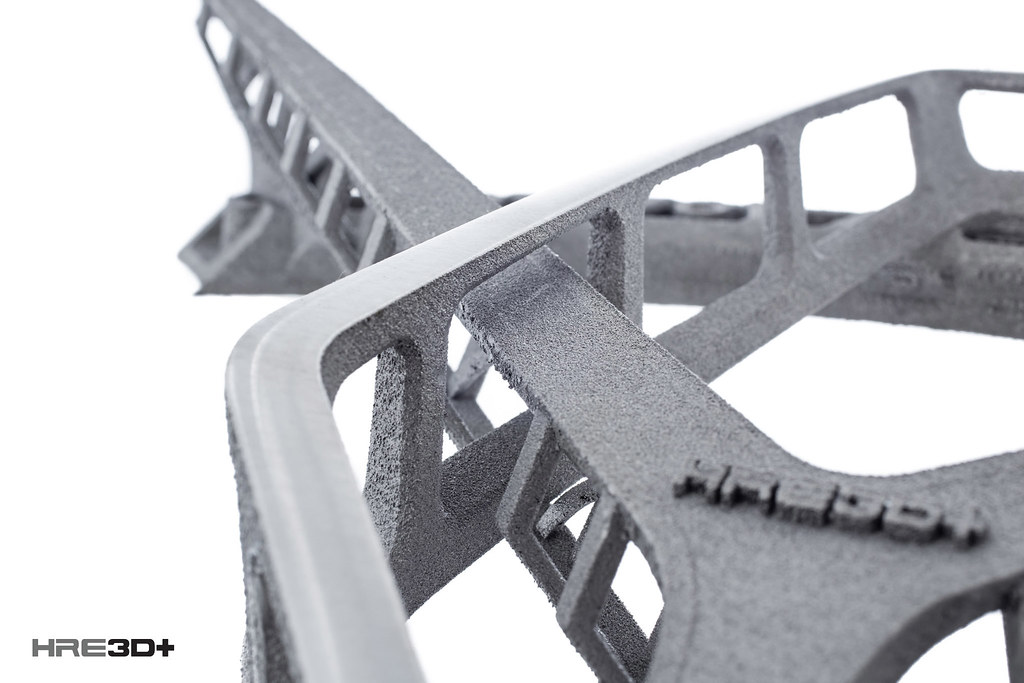

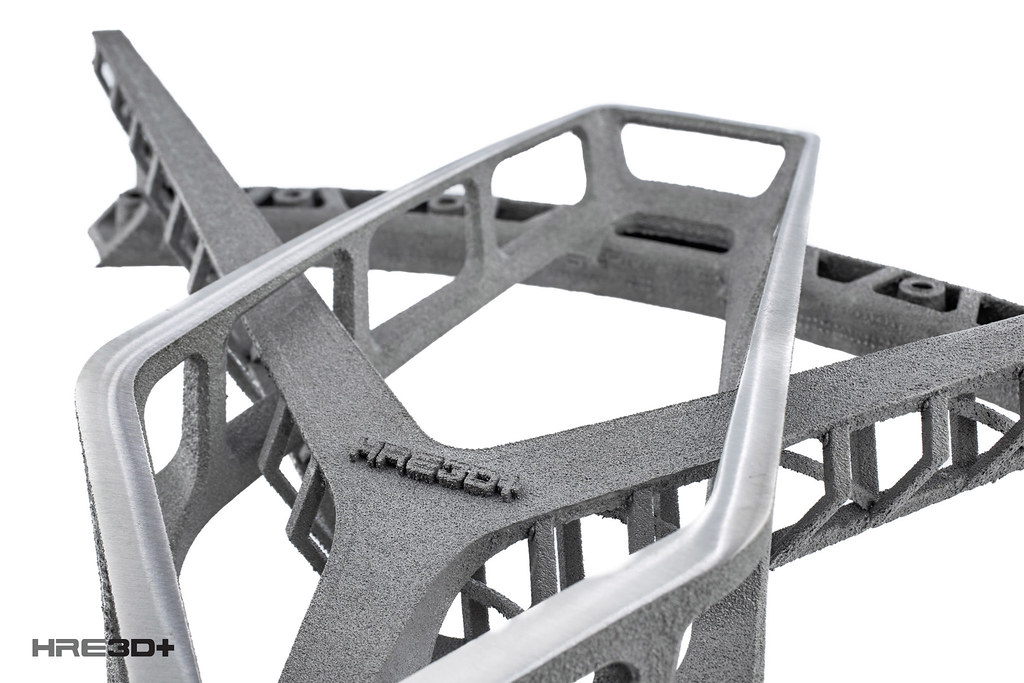

aluminum to create the final product. With additive manufacturing, only 5% of the material is removed and recycled, making the process far more efficient. Titanium also has a much higher specific strength than aluminum and is corrosion resistant, allowing it to be extremely lightweight and to be shown in its raw finish.

There was an intensive design collaboration between the Vista, California based team at HRE and the GE AddWorks team out of Ohio. Using design queues from two existing models of HRE wheels, the two companies worked together to create a stunning example of what is possible with additive manufacturing.

The wheel was produced on two Arcam EBM machines - Q20 and a Q10 in five separate sections,, then combined using a custom center section and titanium fasteners.

"This is an incredibly exciting and important project for us as we get a glimpse into what the future of wheel design holds,” said HRE President Alan Peltier. “Working with GE Additive’s AddWorks team gave us access to the latest additive technology and an amazing team of engineers, allowing us to push the boundaries of wheel design beyond anything possible with current methods. To HRE, this partnership with GE Additive moves us into the future.”

“HRE prides itself on its commitment to excellence and superior quality in the marketplace. It was a natural fit for AddWorks to work on this project with them and really revolutionize the way wheels can be designed and manufactured,” said Robert Hanet, senior design engineer, GE Additive AddWorks

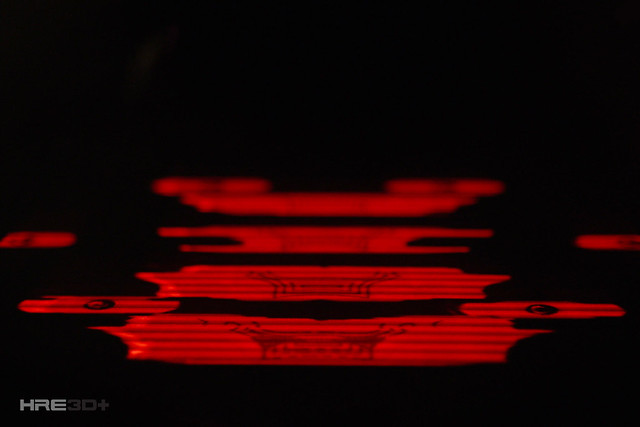

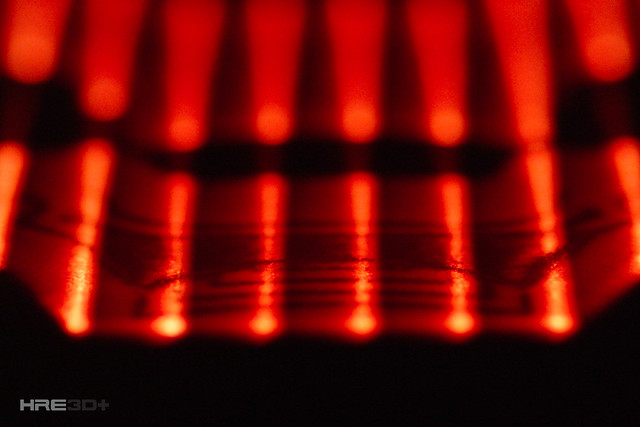

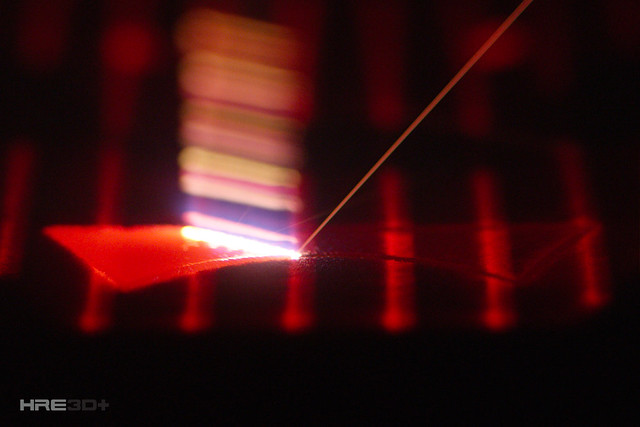

EBM Printing: Electron Beam Melting is an additive technology that uses and electron beam to melt and fuse fine layers of titanium powder into a solid. These fine layers are built up one at a time to create the full design.

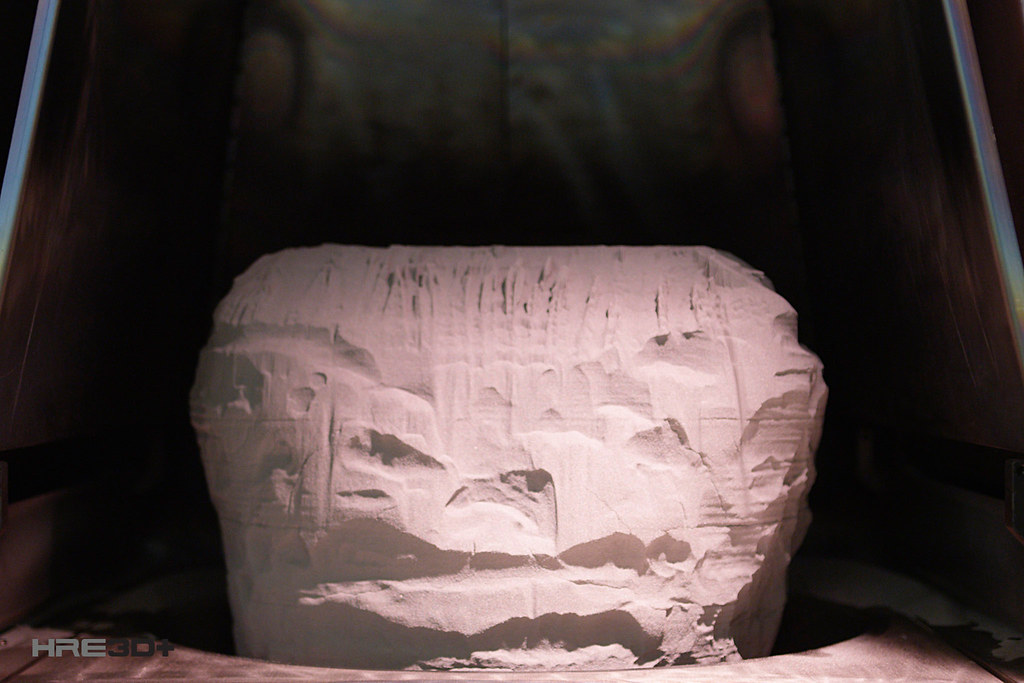

Titanium Powder Bed: The additive design is built up in a bed of fine titanium powder which results in very little wasted material, unlike traditional subtractive methods like machining from a solid forging.

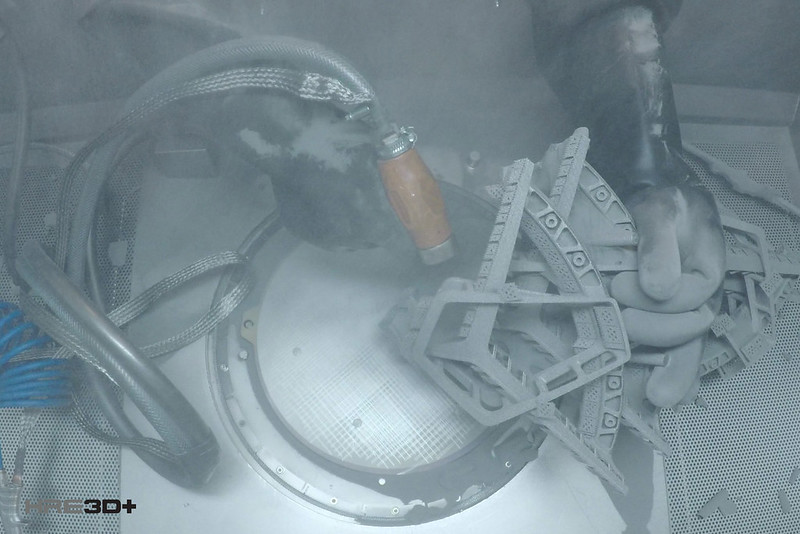

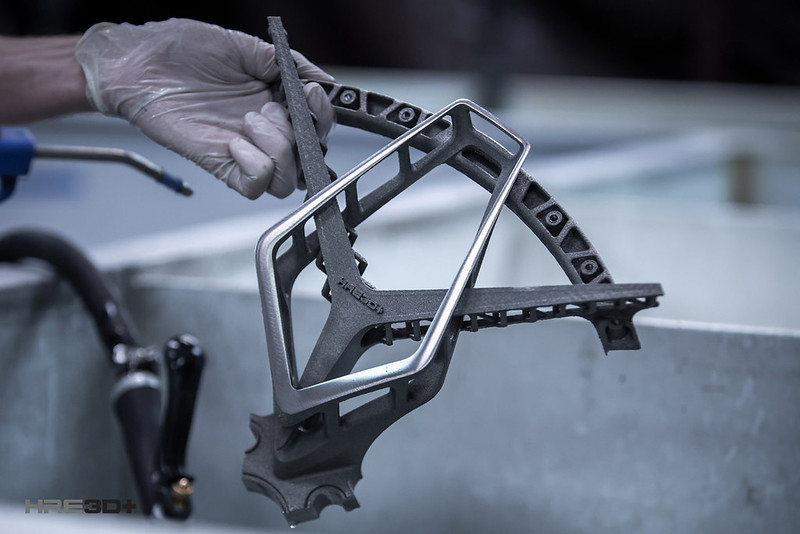

Powder Recovery: The excess titanium powder is removed to reveal the final design and recycled for future parts.

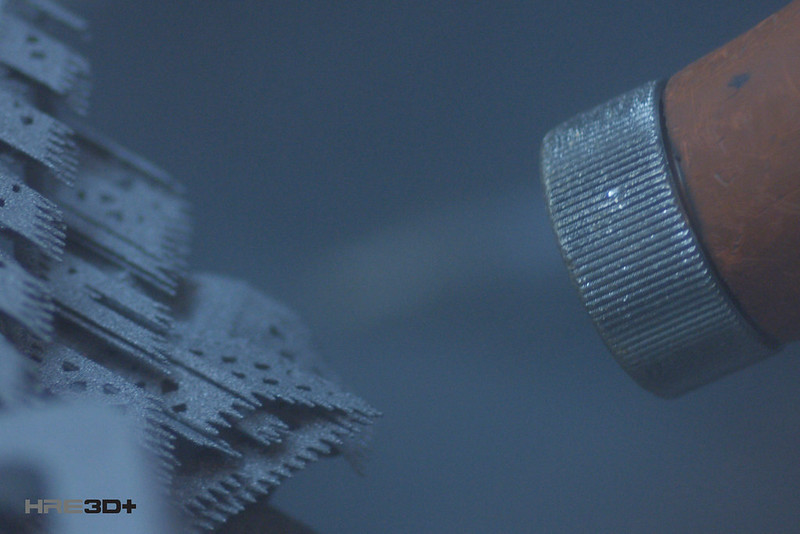

Support Removal: Temporary internal support structures are printed along with the part to provide support to the structure and to facilitate extremely complex designs. These are removed by hand and recycled after printing.

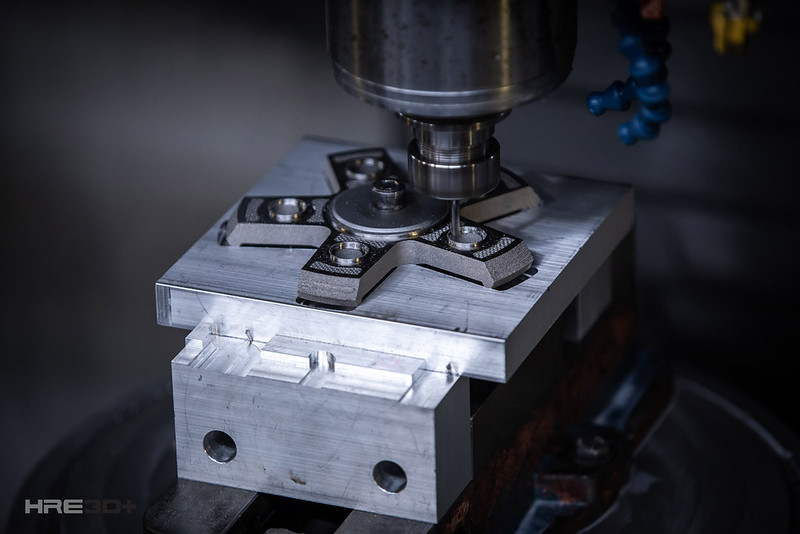

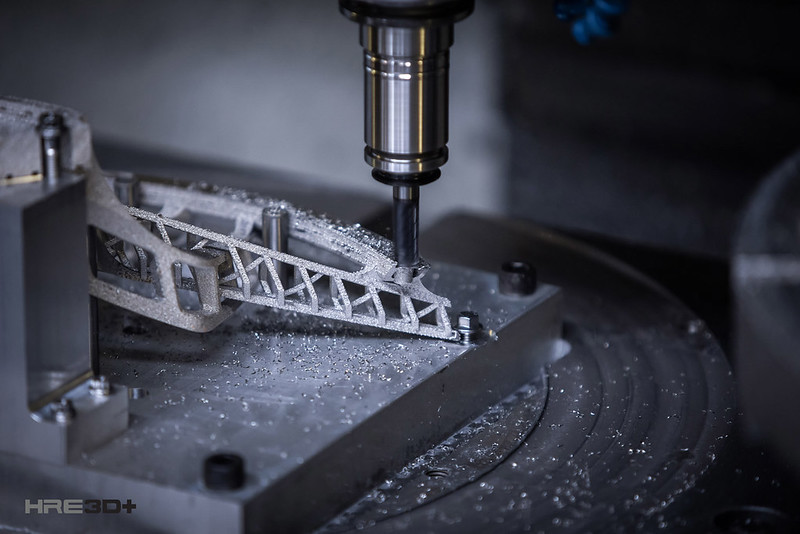

Post Machining: Mating surfaces and threads were CNC machined post-printing to ensure tight tolerances of assembly. Compared to traditional machining from forgings, this post-processing is minimal.

Hand Finishing: The tops of the spokes were hand brushed to create a beautiful decorative finish. Because Titanium has excellent corrosion resistance, no additional powder-coat or clear-coat was necessary.

Cleaning: Due to the minimal machining and finishing, cleaning is a simple process simply to remove any oils or remaining powder.

Assembly: All the parts were hand-assembled into a carbon-fiber rim barrel using titanium fasteners.

The “HRE3D+” wheel will be on display from November 13-16 on GE Additive’s booth (D30) at the form next tradeshow in Frankfurt, Germany. For more information on HRE Wheels, visit https://www.hrewheels.com/wheels/concepts/hre3d

About HRE Performance Wheels:

HRE designs, engineers and manufactures 3-piece and 1-piece forged aluminum alloy wheels for Racing, Performance & Luxury cars and SUVs in their San Diego, California-based, TÜV-approved facility. HRE’s built-to-order wheel sets offer a customized choice of offsets, widths and finishes, resulting in a uniquely personal style and performance solution for each customer’s application. HRE wheels are sold through select high-end car dealerships, specialty retailers and performance companies worldwide. For more information, visit www.hrewheels.com or call an HRE wheel expert at (760) 598-1960.

About GE Additive:

GE Additive – part of GE (NYSE: GE) is a world leader in additive design and manufacturing, a pioneering process that has the power and potential to transform businesses. Through our integrated offering of AddWorks additive experts, advanced machines and quality materials, we empower our customers to build innovative new products. Products that solve manufacturing challenges, improve business outcomes and help change the world for the better. GE Additive includes additive machine providers Concept Laser and Arcam EBM; along with additive material provider AP&C. EBM machines create dimensionally accurate parts quickly and efficiently by using a high-power electron beam for high melting capacity and productivity. The EBM process takes place in vacuum and at high temperature, resulting in stress-relieved components with material properties better than cast and comparable to wrought material.

The following 3 users liked this post by HRE_Jurrian:

#2

Super Member

That's some serious and very cool wheel engineering!!!

#3

MBWorld Fanatic!

Those wheels look awesome, but I don't want to imagine undertaking the monumental task of cleaning all those nooks and pockets in the wheels....

#4

MBWorld Fanatic!

Completely agree - awesome tech and result, but that design is way too busy and a maintenance nightmare, hopefully there'll be more to come with a simpler design.

#7

I think the point of this first wheel was to demonstrate the possibilities of the technology. It’s a show wheel.

I’m sure there will be designs that make cleaning a more practical exercise. Plus, titanium is bling - bling.

I’m sure there will be designs that make cleaning a more practical exercise. Plus, titanium is bling - bling.

The following 2 users liked this post by Albuht813:

HRE_Jurrian (11-14-2018),

thewb (11-14-2018)

Trending Topics

#9

Former Vendor of MBWorld

Thread Starter

Only people cleaning this wheel will be us since it's a concept wheel, not a production wheel.

#11

Out Of Control!!

Join Date: Jun 2004

Posts: 11,412

Received 1,886 Likes

on

1,323 Posts

2014 E63S; AMS 100 octane ecu tune; edok tcu tune; BB intakes; dyno tuned

My guess is $15,000

#12

Member

Are these wheels fully functional and performant or are they just for show? Have they been through and passed all the typical stress, burst, dimensional, fatigue and metallurgical tests a wheel would typically go through - at the levels necessary for the high performance cars they are intended to someday serve? I’m just curious how strong (fatigue, sheer, brittleness, etc.) the titanium is through the additive process vs traditional forging.

BTW, if I'm doing the math right, the material cost of the Ti (even after the substantially reduced material quantities) is still about 80% more than Al for a single wheel (12 lbs @ $25.50/lb vs 100 lbs @ $1.70/lb). Do you expect the costs for the additive manufacturing process vs the forging/machining process to also drop in cost to make up more of the material difference -- disposables, equipment, labor, production yields, etc.? (I'm sure all very IP, so I don't expect an answer; just curious in general)

BTW, if I'm doing the math right, the material cost of the Ti (even after the substantially reduced material quantities) is still about 80% more than Al for a single wheel (12 lbs @ $25.50/lb vs 100 lbs @ $1.70/lb). Do you expect the costs for the additive manufacturing process vs the forging/machining process to also drop in cost to make up more of the material difference -- disposables, equipment, labor, production yields, etc.? (I'm sure all very IP, so I don't expect an answer; just curious in general)

Last edited by CrashTX; 11-18-2018 at 09:05 PM.

#13

MBWorld Fanatic!

Insane, we love it. .

Insane, we love it. .