top inop

#1

Newbie

Thread Starter

Join Date: Jan 2018

Location: columbus georgia

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

2011 mercedes s550, 85 ford ltd (5.0L), 99 buick regal gs, kawaski versey 650, 08 dodge caliber

top inop

prod. date 02/03 clk 320 recent purchase. top would do nothing,checked all fuses first-all present and good.removed rear pkg.tray and by-passed switch with jumper wire,closed trunk and tried it-nothing.was going to remove the module and take it appart and check the internal circuits,but once I unbolted it and picked it up off the studs I flipped it over suddenly I heard relays and solenoids click. i thought module needed a case ground. so I bolted a ground wire to it and the neg battery terminal. tried it again,nothing...just for grins I flipped the module over heard a couple clicks and tried it again and the windows and head rest lowered and the top opened about half way then petered out to a stop-but the pump continued to run as long as I held the button.checked the resivour and found it was very low on fluid. I filled it and tried it again and all worked like its supposed to. worked it back and forth atleast 10 times.it was great. now to find the leak I raised it half way and inspected it and found the cover latch cylinder leaking,replaced it and tested system and all was good.now remover my ground wire and flipped module back over and bolted it back in place and right back to square one-nothing. unbolted module and flipped it over and BOOM the head rest shot up like a rocket. I thought I was gonna have a heart attack... and it still didn't work. added ground wire stll nothing.however I can move the module around(moving the harness with it) and can get it to work some times. to me that shows an open in one of the wires near the module. I have owned an automotive electrical- a/c shop for 5 years now and I was a ford factory trans and drivability tech for 25 yrs. seen many broken wires only broken on the inside, individually you pull on each wire and the broken one will come apart. did this and found no broken wires. my question is has anyone found any broken wires at or near the top module. I also bought a replacement module just to rule it out.its, as for as I can tell a wiring issue. any help would much appreciated.

#2

MBWorld Fanatic!

bgrimmett ...... welcome to the forum and congratulations on your recent 2003 CLK320. purchase. While the power roof system is quite complex, you'll find a treasure chest of existing information that, more often than not, has enabled numerous DIY repairs.

When the power roof malfunctions, given it's complexity, the troubleshooting approach that has worked best has been to reduce the possibilities, to a specific area. Once isolated, the troubleshooting is then isolated to only a handful of probable system / component faults.

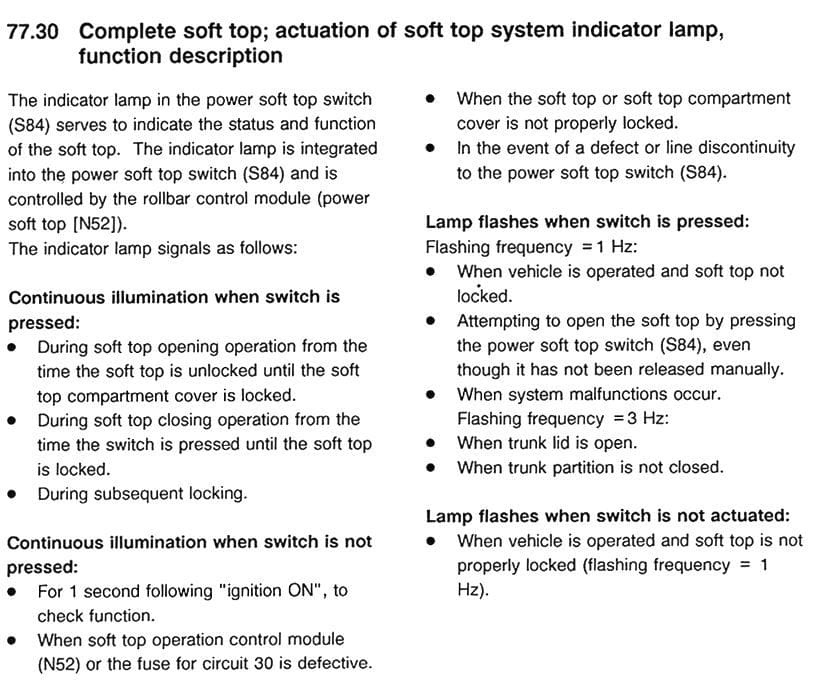

The lamp in the roof's main operating switch has some basic built in diagnostic information. See the enclosed document, regarding interruption.

Additionally, there is more comprehensive diagnostic/troubleshooting documentation, but it seems that documents can no longer be attached as thumbnails to open and are not included in this note.

Specifically, during each of the 12 stages, when opening or closing the roof, are details of what every position/limit switch and pump solenoid activation should be.

Following are some comments, hopefully helpful, pertaining to what you posted.

Re: .removed rear pkg.tray and by-passed switch

See diagnostics included.

Re: remove the module and take it appart and check the internal circuits.......but once I unbolted it and picked it up off the studs I flipped it over suddenly I heard relays and solenoids click and I can tell a wiring issue.......I also bought a replacement module just to rule it out.its, as for as I can tell a wiring issue. any help would much appreciated.

I believe you're referring to the power roof / roll-bar module.

Not withstanding the troubleshooting comments above, I have yet to read of any issues with the connector, but it's possible (e.g. failed solder connection inside the module, the harness interface has 55 connections with the possibility of open / short circuit or oxidized connectivity etc.). Thumbnail diagrams of the connector and its pin assignments, have been previously posted. With the connector disconnected, the module's supply voltages, every position/limit switches, wiring etc., can be probed with a multi-meter.

Also be aware, that in MY 2001, many power roof components were upgraded. Specially, the soft top controller, pump assembly and soft cover position switch are not compatible, between early and earlier production. If you know what to look for, the pump and switch is identifiable bu inspection, but the controller is only by a specific part number.

Re: checked the resivour and found it was very low on fluid

The hydraulic system developed a leak.

Most common suspects are the rear bow or soft top cover cylinders. They can be economically be rebuilt. Just make sure it's a complete rebuild. Typically, the end seals initially fail, but soon after, internal seals, that provide the differential (e.g. 2 way action), also fail.

Re: unbolted module and flipped it over and BOOM the head rest shot up like a rocket

The roll bar has 2 modes of operation (e.g. normally controlled the by the hydraulics or mechanically via spring loaded crash deployment).

Sounds like the roll bar extended in 'crash deployment' mode.

Hydraulic operation extension limits are orderly (e.g. controlled by position/limit switches, while crash deployment occurs when the loaded springs are unlocked, followed by fast, ratcheting extension.

If one of the crash sensors did not activate, the deployment was caused by an issue in it's valve block, locking clutch or deployment solenoid. The roll bar assembly, is located behind the rear seat and it's a PITA to lower the roll bar.

Again, the forum has lots of detailed details and documentation pertaining to troubleshooting and repairing roll bar issues.

By design, the power roof will not operate, whenever the roll bar is extended.