722.9 7GTRONIC Fluid Change

#1

MBworld Guru

Thread Starter

722.9 7GTRONIC Fluid Change

Finally I have all the parts I need for the fluid change:

Additional one-time purchase parts:

Since the dealer was going to charge over $500, and my total outlay is just under $350, I am in good shape even if I never use the Assenmacher pump again.

Notes:

- 12qt of Shell 134 ATF = $72.51

- Transmission Pan Gasket = $6.29

- Filter = $16.14

- Transmission Pan Bolts (6 @ $0.90) = $5.40

- Overflow Tube = $1.72

- Torque Converted Drain Washer = $0.24

Additional one-time purchase parts:

- Transmission pan = $62.19

- Assenmacher 5qt Fluid pump for 722.9 = $179.99

Since the dealer was going to charge over $500, and my total outlay is just under $350, I am in good shape even if I never use the Assenmacher pump again.

Notes:

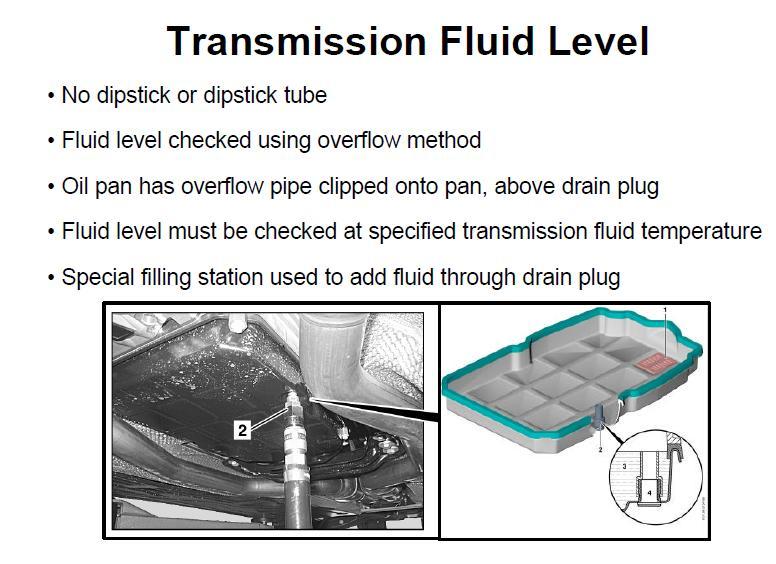

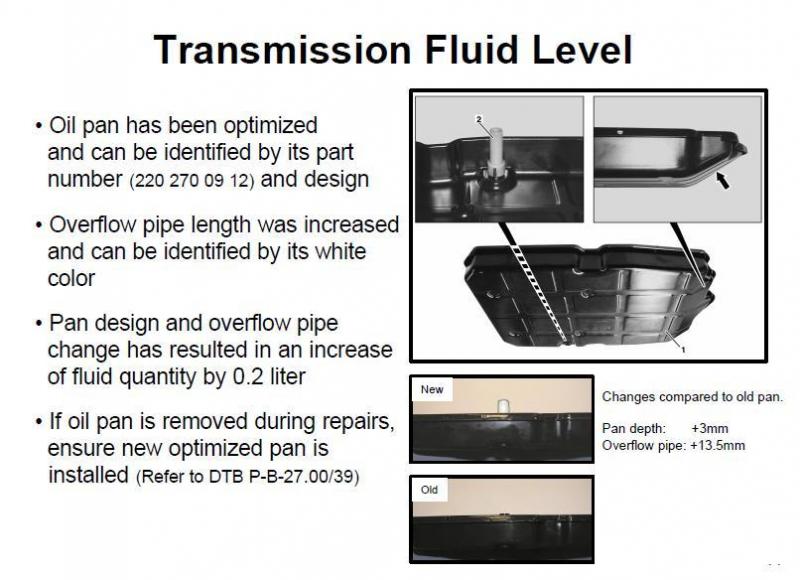

- The transmission pan must be replaced due to a revised design, so this is a one-time cost. The dealer wanted about $100 for it (no additional labor since it's already R&R'ed during the service).

- All prices quoted are inclusive of shipping, but only the fluid (from Ryder Fleet Products) and the pan (from parts.com) had shipping charges. The other parts were free shipping due to the order total (I can always find something like a set of wiper blades, oil or air filters, etc. to make sure I get to the free shipping threshold).

- I originally ordered the filler pump from NXTools for $153.42, but they had very poor service. A week went by with no shipping update, then I sent a request, and several days go by and they tell me it's back ordered and would ship in another week. A week later, I ask for an update and hear nothing. I canceled the order and bought from an eBay seller - more expensive, but delivered in a few days. Oh, and FYI, NXTools goes by several other names - americastoolwarehouse.com and usatoolwarehous.com. I won't deal with them again.

#2

Super Moderator

Curious MB now insists upon a new pan. GMC requires fitting freshly minted differential covers when renewing hypoid lubricant, too.

TTY fasteners and encapsulated gaskets are the likely rationale.

Subscribed for your DIY pictures. “Assenmacher” is a heck of a name for any specialty tool manufacturer.

TTY fasteners and encapsulated gaskets are the likely rationale.

Subscribed for your DIY pictures. “Assenmacher” is a heck of a name for any specialty tool manufacturer.

#4

Super Moderator

Curious MB now insists upon a new pan. GMC requires fitting freshly minted differential covers when renewing hypoid lubricant, too.

TTY fasteners and encapsulated gaskets are the likely rationale.

Subscribed for your DIY pictures. “Assenmacher” is a heck of a name for any specialty tool manufacturer.

TTY fasteners and encapsulated gaskets are the likely rationale.

Subscribed for your DIY pictures. “Assenmacher” is a heck of a name for any specialty tool manufacturer.

Rodney - The pan & gasket mating surfaces require to be super clean or you will have a leak. Far more so than the 722.6. Benz recommends cleaning with a chamois. Even the meticulous Johnand suffered a leak at first attempt.

The following users liked this post:

krazzdav (05-18-2022)

#5

MBworld Guru

Thread Starter

OK, here are the parts. Clockwise from bottom left...

- New transmission pan

- Filter (new o-ring included and pre-installed)

- Shell ATF-134 (x12 qts, min. order qty from Ryder)

- Fill Tube and 6x Pan Bolts

- Gasket

#6

MBworld Guru

Thread Starter

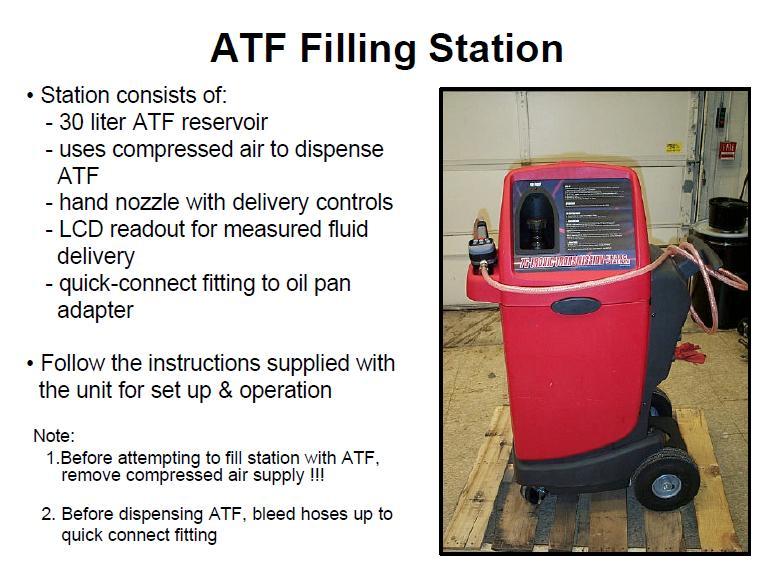

Assenmacher Driveline Filler with MB 722.9 adapter. I went ahead and filled it, then pumped it to fill the tube, and leveled in the container back up to 5 quarts so I could keep up with how much I was dispensing. Oh, I also bought a 5 gallon bucked from Home Depot that had quart marks on it so I could keep up with how much fluid I removed (plus have a handy way to transport it for disposal).

Trending Topics

#8

MBworld Guru

Thread Starter

OK, so here's where you probably wants some detail photos, and I don't have them. It was just too hard to take photos under the car. If I had a lift where I could walk underneath, it would have been easy, but crawling under the floor with the car on jack stands just wasn't conducive to good photos.

I put the car on four jack stands. I jacked the front first, using the jacking block under the engine (the big rubber block protruding from the center of the lower engine shroud). I used the third notch on my jack stands, placed under the jack points behind the front tires. I probably should have gone at least one notch higher, but I really wanted to make sure it was as stable as possible, so lower is better. I then jacked the rear under the differential with jack stands supporting the frame at the jack points in front of the rear tires.

I used a small level to check the pan. My garage floor is very level and I was able to get it just right. I think the rear jack stands were a notch higher than the front. The rear end really looked like it was much higher off the ground than the front. So, with the car raised and stable, I was ready to work.

The first thing I noticed when I crawled underneath was that I have the revised pan! I'm not sure how. My understanding is that the pan design wasn't changed until sometime in 2010, and I doubt the car had a flush before then, but it has the new pan. I also don't think they changed it when they did the timing gear TSB. Anyhow, I have a brand new pan if anyone needs it. I'll probably list it on eBay next week instead of returning it.

I put the car on four jack stands. I jacked the front first, using the jacking block under the engine (the big rubber block protruding from the center of the lower engine shroud). I used the third notch on my jack stands, placed under the jack points behind the front tires. I probably should have gone at least one notch higher, but I really wanted to make sure it was as stable as possible, so lower is better. I then jacked the rear under the differential with jack stands supporting the frame at the jack points in front of the rear tires.

I used a small level to check the pan. My garage floor is very level and I was able to get it just right. I think the rear jack stands were a notch higher than the front. The rear end really looked like it was much higher off the ground than the front. So, with the car raised and stable, I was ready to work.

The first thing I noticed when I crawled underneath was that I have the revised pan! I'm not sure how. My understanding is that the pan design wasn't changed until sometime in 2010, and I doubt the car had a flush before then, but it has the new pan. I also don't think they changed it when they did the timing gear TSB. Anyhow, I have a brand new pan if anyone needs it. I'll probably list it on eBay next week instead of returning it.

#9

MBworld Guru

Thread Starter

I used a very large pan to catch the oil. It's actually a water pan from an old tile wet saw I used to have (long story, it got stolen but the thieves left the pan...dumbasses). It's very sturdy and shallow, but about a foot longer and wider than the transmission pan. The first step was to remove the underbody shrouds. I removed both the engine and transmission shrouds to make it easier to get to the bolt on the harmonic balancer to rotate the engine to get to the torque converter drain.

I then removed the pan drain bolt and got less than a quart of fluid out. I used a large flat head screwdriver in place of the official MBZ drift tool to pop the fill tube off of the drain hole. Another quart or so of oil came out. After that, I replaced the drain plug (loosely) and went to work on the torque converter. The dust cap on the access port for the torque converter drain was missing (note to self - get a new one!).

The engine must be rotated until the drain bolt in the torque converter is accessible. I was able to lie on my back from the front of the car so my head was at the TQ drain and the I could use my hands to manipulate a ratchet wrench on the balancer bolt to rotate the engine. With the V8, there is very little room between the balancer and the cooling fan, but I was able to get a socket and wrench in there. The drain bolt is very tiny. It's recessed and only about 10mm round, so I had to watch carefully. Also, there is a cable hold down bracket right in the way and it really isn't possibly to remove it since it's behind a couple of bell housing bolts. I found I could stop it just to the right of the bracket and then barely get a TORX screwdriver on it. I then used a socket on the end of the screwdriver handle and a ratchet wrench to loosen it. I also used this setup to tighten it and check the torque.

The fluid drained out of the TQ very smoothly and with very little mess. The last drops did splash against the housing and that bracket, but otherwise it was an easy operation. I replaced the drain bolt with a new one (with a new washer). That darned bracket is in the way and I had a really hard time getting it to torque. It actually stripped out the TORX head in the bolt, but it did finally "click" so it's good. It may just be a PITA to get out next time. I probably got four quarts of fluid out of the torque converter - much more than drained from the pan so far.

I then removed the pan drain bolt and got less than a quart of fluid out. I used a large flat head screwdriver in place of the official MBZ drift tool to pop the fill tube off of the drain hole. Another quart or so of oil came out. After that, I replaced the drain plug (loosely) and went to work on the torque converter. The dust cap on the access port for the torque converter drain was missing (note to self - get a new one!).

The engine must be rotated until the drain bolt in the torque converter is accessible. I was able to lie on my back from the front of the car so my head was at the TQ drain and the I could use my hands to manipulate a ratchet wrench on the balancer bolt to rotate the engine. With the V8, there is very little room between the balancer and the cooling fan, but I was able to get a socket and wrench in there. The drain bolt is very tiny. It's recessed and only about 10mm round, so I had to watch carefully. Also, there is a cable hold down bracket right in the way and it really isn't possibly to remove it since it's behind a couple of bell housing bolts. I found I could stop it just to the right of the bracket and then barely get a TORX screwdriver on it. I then used a socket on the end of the screwdriver handle and a ratchet wrench to loosen it. I also used this setup to tighten it and check the torque.

The fluid drained out of the TQ very smoothly and with very little mess. The last drops did splash against the housing and that bracket, but otherwise it was an easy operation. I replaced the drain bolt with a new one (with a new washer). That darned bracket is in the way and I had a really hard time getting it to torque. It actually stripped out the TORX head in the bolt, but it did finally "click" so it's good. It may just be a PITA to get out next time. I probably got four quarts of fluid out of the torque converter - much more than drained from the pan so far.

#10

MBworld Guru

Thread Starter

Next I removed the pan. At this point, I probably have almost 7 quarts of fluid drained. I removed the from bolts first, then left the rear bolts for last. The rear of the pan fits above the rear mount cross member, so it has to slide forward just a bit to be removed. As I loosened the rear two bolts the pan began to tilt down at the front and more oil drained out. I eventually just lowered the transmission pan into the wet saw pan. That big wet saw pan did a great job catching all the oil.

I pulled the filter out and let it drop into the pan. There were still some drips coming from the valve body, so I placed some rags down so I could slide the catch pan out along with the transmission pan and filter. Here's photo of what it looks like with the pan removed. You can see the torque converter drain access port at the bottom of photo. Note that the drain itself is only visible when looking in from the front of the car.

I pulled the filter out and let it drop into the pan. There were still some drips coming from the valve body, so I placed some rags down so I could slide the catch pan out along with the transmission pan and filter. Here's photo of what it looks like with the pan removed. You can see the torque converter drain access port at the bottom of photo. Note that the drain itself is only visible when looking in from the front of the car.

#11

MBworld Guru

Thread Starter

The next step was the clean everything. I used a spray cleaner (basically just alcohol) on the sealing surfaces. I have found that microfiber cloths soak up oil like crazy. I use only virgin cloths when washing and waxing the car, then they get washed and dried and become "shop rags". I buy them by the bag as Costco and they end up being about $0.50 each.

I wiped as much oil as possible from the contact plate and scrubbed the gasket mating surfaces on the transmission housing thoroughly. There was some dirt build up around the edges of the gasket seat so that took extra scrubbing. I did the same on the pan. When I got through, it looked as good as the new pan. There was a significant amount of "sludge" on the magnets so they got a thorough cleaning, too. In fact, I was very surprised at how dirty the oil was. See below for a comparison of fresh oil vs. what come on on a white cloth:

I wiped as much oil as possible from the contact plate and scrubbed the gasket mating surfaces on the transmission housing thoroughly. There was some dirt build up around the edges of the gasket seat so that took extra scrubbing. I did the same on the pan. When I got through, it looked as good as the new pan. There was a significant amount of "sludge" on the magnets so they got a thorough cleaning, too. In fact, I was very surprised at how dirty the oil was. See below for a comparison of fresh oil vs. what come on on a white cloth:

#14

MBworld Guru

Thread Starter

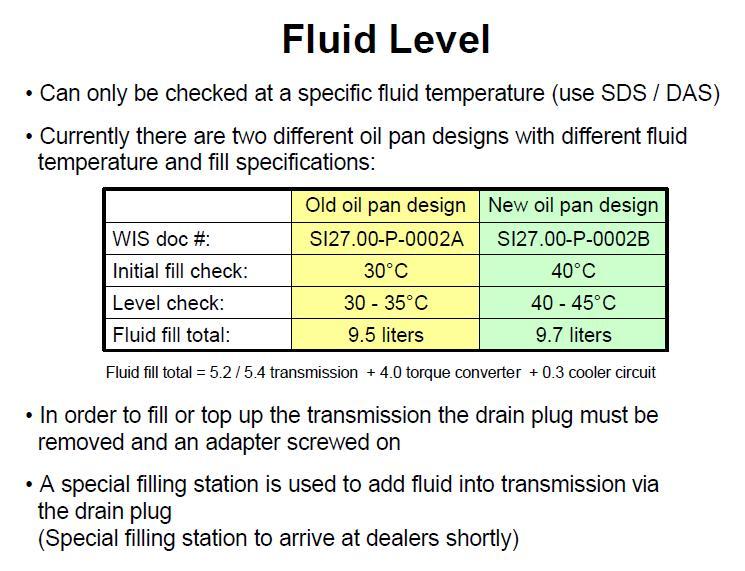

So, the next step was to replace the pan and fill. That went well. As indicated, I used new bolts. I connected the Filler to the drain port and pumped 6 quarts (well, actually liters) of fluid in as instructed by WIS. I went into SDS to the temperature monitor and started the engine. I let the fluid warm up to 115F and then shut it down (as per WIS). It was actually a bit unclear about how much more fluid to put in. WIS seemed to deal more with a rebuilt or empty transmission and said to add 4 liters if the TQ was empty or 2 if not. I added 3 liters and restarted the engine and ran through P, R, N and D several times as instructed. The problem I had was that the temperature was now around 125F so it was too hot to check the level. I shut it down, and temp climbed to 128F.

#15

MBworld Guru

Thread Starter

While I was waiting for things to cool down, I changed the oil, replaced my brake wear sensors, and re-bled the brake lines (more on the brake stuff later). I also had on the list to replace the sway bar busings, but I figured I'd have something to eat first and let the transmission cool more. My wife went down to the local sports bar/pub and got me 20 dry-rub Cajun spiced wings. Tasty!

So, after being properly nourished, I checked the temp and it was down to 110F. So I started the engine, range the gears, and go it to the prescribed 113F. I removed the fill adapter from he drain and got -zero- fluid. I should have gotten at least a slow drip. The design of the fill tube is that it snaps onto the top of the drain port, but it fits somewhat loosely, allowing some fluid to seep past. Without a full fill, but some fluid int he pan, you should get an intermittent drip. I was getting nothing. I pumped another liter of fluid and and checked again, and now I had a drip. Another liter pumped in, and then I was getting a full steady stream. Once it slowed to a drip, I replaced the drain plug, torqued it, and shut down the engine.

At this pint, the temp was at 117F, 4 degrees above the proper fill temp. Honestly, I think this is as good as it gets. There is just no way to keep it at a steady 115F in the time it takes to remove the filler pump adapter, check the level, and then replace the drain plug. I figure at most, I'm a few ounces over or under, which is going to have to be good.

So, after being properly nourished, I checked the temp and it was down to 110F. So I started the engine, range the gears, and go it to the prescribed 113F. I removed the fill adapter from he drain and got -zero- fluid. I should have gotten at least a slow drip. The design of the fill tube is that it snaps onto the top of the drain port, but it fits somewhat loosely, allowing some fluid to seep past. Without a full fill, but some fluid int he pan, you should get an intermittent drip. I was getting nothing. I pumped another liter of fluid and and checked again, and now I had a drip. Another liter pumped in, and then I was getting a full steady stream. Once it slowed to a drip, I replaced the drain plug, torqued it, and shut down the engine.

At this pint, the temp was at 117F, 4 degrees above the proper fill temp. Honestly, I think this is as good as it gets. There is just no way to keep it at a steady 115F in the time it takes to remove the filler pump adapter, check the level, and then replace the drain plug. I figure at most, I'm a few ounces over or under, which is going to have to be good.

#16

MBworld Guru

Thread Starter

So, after all was done, subtracting time for Cajun wings and waiting on the temperature to stabilize, I think it took me about four hours. Now, I started just after 11:00am and did not go on my "test drive" until just before 8:00pm, so that's almost 9 hours, right? Well, it took about three hours for the transmission to cool down. Plus, I spent about two hours - yes TWO HOURS replacing the sway bar bushings while I had the car on jacks. The left bushing was literally melted onto the sway bar and i had to peel it off, layer by layer, with a razor blade.

The good news is that I find no leaks. The bad news is that I still have the annoying whine, so I suspect the pilot bearing is bad and will eventually die. I am especially concerned since I found the fluid to be so dirty and the magnets to be so sludgy. I guess the only thing to do would be replace the torque converter, and it doesn't look like a horrible job, but I'm not sure I'd want to try it in my garage. I might see what my local favorite indy shop wants. I have found the part for around $400.

Sorry I don't have better photos, but it's just not easy to do under the car. Oh, and I'll post about the brake sensors and the sway bar bushings later - I have some interesting info about that, but it;s late and I'm tired!

The good news is that I find no leaks. The bad news is that I still have the annoying whine, so I suspect the pilot bearing is bad and will eventually die. I am especially concerned since I found the fluid to be so dirty and the magnets to be so sludgy. I guess the only thing to do would be replace the torque converter, and it doesn't look like a horrible job, but I'm not sure I'd want to try it in my garage. I might see what my local favorite indy shop wants. I have found the part for around $400.

Sorry I don't have better photos, but it's just not easy to do under the car. Oh, and I'll post about the brake sensors and the sway bar bushings later - I have some interesting info about that, but it;s late and I'm tired!

#17

MBworld Guru

Thread Starter

Oh, and a few more things...final fluid fill was exactly 9 quarts (not liters). The Assenmacher tool is VERY well made and easy to use. I also noticed it was made in USA. They sell adapters for other makes of transmissions, too. It's a good investment if you plan to do this more than once. I just bought the 5 quart model and refilled it. They also sell 3 and 10 quart models, but I think the 5 is just fine. It was no problem to stop and add fluid to its tank.

#19

MBworld Guru

Thread Starter

#20

Super Moderator

Great job Rodney! did you break open filter to look for aluminium swarf?

#21

Super Moderator

The first thing I noticed when I crawled underneath was that I have the revised pan! I'm not sure how. My understanding is that the pan design wasn't changed until sometime in 2010, and I doubt the car had a flush before then, but it has the new pan. I also don't think they changed it when they did the timing gear TSB. Anyhow, I have a brand new pan if anyone needs it. I'll probably list it on eBay next week instead of returning it.

#22

MBworld Guru

Thread Starter

Pan redesign was very early. It's in the Benz training course for tech's dated 06-25-04. However old pan is to be found on transmissions installed in W203 run-out in 2007. Go figure? I have never seen a W204 with the old pan. Either Benz had a huge stock of transmissions which I find hard to believe or a huge stock of old pans & tubes that they continued using.

#23

MBWorld Fanatic!

Join Date: Jun 2009

Location: Witness Protection Program

Posts: 1,314

Likes: 0

Received 1 Like

on

1 Post

06 CLK350 -SOLD! 2010 Cadillac SRX Premium Turbo

Great write up Rudeney. One of the best I have read.

You have accomplished a DIY very few would probably ever attempt.

At least the info is out there for everyone that has the fortitude to take it on.

Cajun dry rubbed wings do sound tasty.

You have accomplished a DIY very few would probably ever attempt.

At least the info is out there for everyone that has the fortitude to take it on.

Cajun dry rubbed wings do sound tasty.

#24

MBworld Guru

Thread Starter

Honestly, it's not that hard. I think there are two big mental challenges: having to lift all four wheels of the car to a level position with enough room to work underneath, and having to use a pump to refill the transmission. If it weren't for these two things, it wouldn't be much more difficult than an oil change on some cars. The fact that MBZ's have center jack points does make it easier, only having to jack twice to get all four wheels off the ground. And the Assenmacher pump is great. It's well made (and made in USA, go figure!).

Other than that, it's just the "grunt work" of crawling around under the car and draining fluids. I guess some might be scared of dealing with the temperature sensitivity of the oil, but it's just a scale on a gauge, like a dipstick. I used SDS, but an infrared thermometer would work just as well.

I also have to give kudos to Johnand as he was the pioneer of this as a DIY. I used his suggestions and documentation. In fact, had I used his instructions instead of WIS, I would have save a lot of time. WIS wanted me to fill 75%, then shut down the engine and add the remainder of the fluid, which caused the temperature to go high and required a three hour wait for a cool down. Johnand's method is to go ahead and fill 100% and then check the level at the magic 113F temp without a shutdown. I see no difference and will do it that way next time.

Other than that, it's just the "grunt work" of crawling around under the car and draining fluids. I guess some might be scared of dealing with the temperature sensitivity of the oil, but it's just a scale on a gauge, like a dipstick. I used SDS, but an infrared thermometer would work just as well.

I also have to give kudos to Johnand as he was the pioneer of this as a DIY. I used his suggestions and documentation. In fact, had I used his instructions instead of WIS, I would have save a lot of time. WIS wanted me to fill 75%, then shut down the engine and add the remainder of the fluid, which caused the temperature to go high and required a three hour wait for a cool down. Johnand's method is to go ahead and fill 100% and then check the level at the magic 113F temp without a shutdown. I see no difference and will do it that way next time.

#25

Super Moderator

Johnand has now done this many, many times. Twice on his own car and for many friends. I did it for a friend the other day & it was plain sailing - used the Johnand method & a Raytek IR thermometer. We were lucky - we had a 4 post hoist. I never get to do these things on my own cars because they are under Mobilodrive maintenance plan.

Some have a mental block to automatic transmissions period ~ which is unfounded.

Probably the biggest issue is just working cleanly & have lots of nice clean lint free disposable cloths available. Don't work in a sandpit with the wind blowing.

Some have a mental block to automatic transmissions period ~ which is unfounded.

Probably the biggest issue is just working cleanly & have lots of nice clean lint free disposable cloths available. Don't work in a sandpit with the wind blowing.

Last edited by Glyn M Ruck; 05-02-2012 at 09:41 AM.

)

)