Understanding Intercooling, Charge-Coolers, Heat Exchangers and Circulation Pumps

#52

MBWorld Fanatic!

Thread Starter

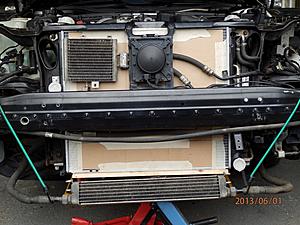

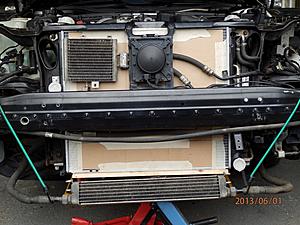

And here's how some of the hardware looks when installed, starting with the Mercedes W124 radiator:

This is a thick rad with a 40mm core, same as the S600 engine rad. Its a tight fit, but does have one great advantage - I can use the transmission oil cooler as the ABC cooler, and get rid of that horrible little stock cooler. That's essential actually, as there's not enough clearance between the rad and the Distronic radar for the ABC hoses.

The real problem, though, is that the top outlet sits so far forwards that there's no room for an elbow pipe when the hood's closed. I even cut the outlet short and tried to fit a 35mm plumbing elbow, but there's not quite enough space (and it would be difficult to remove afterwards). At best, it would mean cutting away the radiator grille and mounting it on spacers.

Here's a BMW X3 rad, with a 32mm core. Its has particularly slim end-tanks, and has the largest core frontal area that will fit - larger than the W220 condenser, and taller than the W220 rad, in fact. It needs several mods to fit - the condenser and radiator mounting brackets need to be trimmed due to the size of the rad, and I had to make some space for the inlet & outlet. This is taller than the W220 engine rad, and I was very pleased to fit it in with the hood and under-tray in position. I had to bend up the flange on the radiator top rail, while on the lower mounting brackets, I drilled new holes for the under-tray mounting clips - otherwise the screws would go into the X3 end tanks.

It seems that the X3 radiator is the largest one that will fit, but it does take some work. The BMW E46 3-series rad is all-but identical - but 50mm shorter. That would allow it to fit with few modifications - just for the inlet & outlet, so for most people I think that would be the ideal solution.

Nick

This is a thick rad with a 40mm core, same as the S600 engine rad. Its a tight fit, but does have one great advantage - I can use the transmission oil cooler as the ABC cooler, and get rid of that horrible little stock cooler. That's essential actually, as there's not enough clearance between the rad and the Distronic radar for the ABC hoses.

The real problem, though, is that the top outlet sits so far forwards that there's no room for an elbow pipe when the hood's closed. I even cut the outlet short and tried to fit a 35mm plumbing elbow, but there's not quite enough space (and it would be difficult to remove afterwards). At best, it would mean cutting away the radiator grille and mounting it on spacers.

Here's a BMW X3 rad, with a 32mm core. Its has particularly slim end-tanks, and has the largest core frontal area that will fit - larger than the W220 condenser, and taller than the W220 rad, in fact. It needs several mods to fit - the condenser and radiator mounting brackets need to be trimmed due to the size of the rad, and I had to make some space for the inlet & outlet. This is taller than the W220 engine rad, and I was very pleased to fit it in with the hood and under-tray in position. I had to bend up the flange on the radiator top rail, while on the lower mounting brackets, I drilled new holes for the under-tray mounting clips - otherwise the screws would go into the X3 end tanks.

It seems that the X3 radiator is the largest one that will fit, but it does take some work. The BMW E46 3-series rad is all-but identical - but 50mm shorter. That would allow it to fit with few modifications - just for the inlet & outlet, so for most people I think that would be the ideal solution.

Nick

#53

MBWorld Fanatic!

Thread Starter

The other appealing option for me is the Mercedes W201 2.0 diesel/auto/air-con. It's almost identical to the W124 rad, and also has the integral oil cooler on the ABC side. Its a bit wider and a bit shorter, and has almost identical dimensions to the BMW E46 rad, but thicker. Even though its "only a C-class", its a big rad, larger than the X3, and similar to a mid-range 7-series or E-class.

Using the oil cooler for the ABC would mean cutting the metal pipe from the ABC thermostat output and fitting a compression hosetail (its only a low-pressure return hose). The connection from the cooler to the reservoir is just a flexible hose. That would be so neat, but I think I'm going to stick with the X3 rad.

Nick

Using the oil cooler for the ABC would mean cutting the metal pipe from the ABC thermostat output and fitting a compression hosetail (its only a low-pressure return hose). The connection from the cooler to the reservoir is just a flexible hose. That would be so neat, but I think I'm going to stick with the X3 rad.

Nick

Last edited by Welwynnick; 02-23-2014 at 09:04 AM.

#54

MBWorld Fanatic!

Thread Starter

OK, here’s an open question for everyone. I’m happy that I’ve arrived at a potentially ideal charge cooler configuration,with the BMW radiator and pump, and the Tecomotive controller. The controller measures the charge coolant temp using an in-line sensor, compares that with the target temperature, and modulates the pump speed accordingly. Most in-line temp sensor adapters are used on ENGINE coolant pipes, but I eventually found one for ¾” pipes. But the question is – where should it go? There are essentially four options, and each has a good reason to be used:

1) Charge cooler inlet – may give the best correlation with IAT

2) Charge cooler outlet – indicates how much work the cooling system has to do, and fastest response to increased load

3) Heat exchanger inlet – probably the worst case for high coolant temp

4) Heat exchanger outlet – shows whether the cooling system is actually doing its job

Although I really want to know what’s going on, I’m not inclined to fit a sensor at each position, and play tunes with them. In the name of science I might fit a cheap aftermarket in-line temp sensor with a digital dash display, and see how that squares with the controller’s display.

Conventional wisdom is that the thermostat and temp sensor should go at the hottest part of the system, but I’m not sure that will tell us what we really want to know. If the engine is working hard, we KNOW that the turbo outlet temperature is high. But I think we want to know whether the charge cooling system is doing its job properly, and that means keeping the coolant temp down at the charge cooler inlets.

One of the unknown quantities is what happens to the coolant temp as it passes alongside the exhaust manifolds. Maybe it actually heats up as it travels to and from the charge coolers? That’s why I think 3) is the worst case. My answer may be that the controllers job is to control the pump, so it needs to know when to speed up, and that depends on the HIGHEST temperature in the system.

What do you think?

Nick

1) Charge cooler inlet – may give the best correlation with IAT

2) Charge cooler outlet – indicates how much work the cooling system has to do, and fastest response to increased load

3) Heat exchanger inlet – probably the worst case for high coolant temp

4) Heat exchanger outlet – shows whether the cooling system is actually doing its job

Although I really want to know what’s going on, I’m not inclined to fit a sensor at each position, and play tunes with them. In the name of science I might fit a cheap aftermarket in-line temp sensor with a digital dash display, and see how that squares with the controller’s display.

Conventional wisdom is that the thermostat and temp sensor should go at the hottest part of the system, but I’m not sure that will tell us what we really want to know. If the engine is working hard, we KNOW that the turbo outlet temperature is high. But I think we want to know whether the charge cooling system is doing its job properly, and that means keeping the coolant temp down at the charge cooler inlets.

One of the unknown quantities is what happens to the coolant temp as it passes alongside the exhaust manifolds. Maybe it actually heats up as it travels to and from the charge coolers? That’s why I think 3) is the worst case. My answer may be that the controllers job is to control the pump, so it needs to know when to speed up, and that depends on the HIGHEST temperature in the system.

What do you think?

Nick

Last edited by Welwynnick; 06-12-2013 at 10:56 AM.

#55

Nick,

I disconnected the hose that returns the coolant from the intercooler on the drivers side and ran a dedicated 3/4" heater hose all the way to heat exchanger. I passed it right along the outer engine bay next to the condenser hose securing it with tie straps.

Why would anyone design a steel tube right over the exhaust manifolds and pass the coolant there superheating it further....?? I know .....production reasons. Not every Merc would have received this monster motor, so why plumb lines on the chassis that are not going to be used with every model. Makes sense...I guess. So they built it right on the engine itself.

How about this...when the coolant tries to reach ambient temperature in the heat exchanger it gets pumped right next to the passenger's side of the engine. In a steel pipe that is scorching hot bolted on the head and the exhaust side???!!! What were they thinking.

Point is, reroute all intercooler hoses away from the engine. We do not need the coolant heating up before it enters the intercoolers. What's the purpose of cooling it in the first place ... It defeats the purpose.

I disconnected the hose that returns the coolant from the intercooler on the drivers side and ran a dedicated 3/4" heater hose all the way to heat exchanger. I passed it right along the outer engine bay next to the condenser hose securing it with tie straps.

Why would anyone design a steel tube right over the exhaust manifolds and pass the coolant there superheating it further....?? I know .....production reasons. Not every Merc would have received this monster motor, so why plumb lines on the chassis that are not going to be used with every model. Makes sense...I guess. So they built it right on the engine itself.

How about this...when the coolant tries to reach ambient temperature in the heat exchanger it gets pumped right next to the passenger's side of the engine. In a steel pipe that is scorching hot bolted on the head and the exhaust side???!!! What were they thinking.

Point is, reroute all intercooler hoses away from the engine. We do not need the coolant heating up before it enters the intercoolers. What's the purpose of cooling it in the first place ... It defeats the purpose.

#56

Junior Member

Join Date: Jan 2013

Posts: 60

Likes: 0

Received 1 Like

on

1 Post

'06 S65 AMG W220 12.31@119_MPH (Stock)

I'm just thinking out loud here. From what I understand, the function of the thermostat is to allow the engine to quickly get up to operating temperature and to maintain that temperature set by the thermostat for better fuel efficiency and lower emission which doesn't always mean the most power output and not to mention to have decent heat in the cabin for when it's cold out. But with the intercooler fluid temp, I don't think you would really have to follow that rule unless you'll be spending a lot of time below 0* F.

With that said, wouldn't you want the intercooler fluid to be cool as long as possible and to have it take forever to heat up? If the intercooler pump is wired to run continuously while the engine is running and also have an override switch for when waiting to run the next round at the track or just whenever, would that delay the fluid from getting hot especially with your new oversize heat exchanger? Isn't that the goal or am I missing something?

With that said, wouldn't you want the intercooler fluid to be cool as long as possible and to have it take forever to heat up? If the intercooler pump is wired to run continuously while the engine is running and also have an override switch for when waiting to run the next round at the track or just whenever, would that delay the fluid from getting hot especially with your new oversize heat exchanger? Isn't that the goal or am I missing something?

#58

MBWorld Fanatic!

Thread Starter

Any chance of posting up some pictures of what you've done? I knew some people had already done this, so I've been thinking about doing it. I've bought lots of 3/4" tubing, but finding a way past the bulkhead seemed a bit tricky. The hood struts seem to take up the ideal space for pipes. Re-routing the pipes would also give me more flexibility to fit my new charge cooler header tank, and to locate the temp sensor in any position. There's no room next to the charge coolers themselves.

Nick

#59

MBWorld Fanatic!

Thread Starter

Continuous pump running is another quick win. I can understand the reasons for thermostatic pump control, so we'd have to accept that the pump is going to fail more frequently if it’s always on.

Having said that, the BMW pump is intended to run all the time, so it’s had to be engineered to be more reliable. It doesn’t have any rotating shaft seals, only static ones, and the commutator is electronic, not mechanical, so there are two problem areas avoided right away. TheTecomatic controller can run the Pierburg pump at slow speed continuously, regardless of the coolant temp. That would help to stop the pipes heating up when the IAT stays below the 116F threshold.

The more I think about pipe re-routing the more I like it. I wonder if it’s possible to route them in the wheel arches, behind the plastic liners? Its seems wasteful to take the 1½”connections on the BMW radiator and pump, and reduce them down to ¾” in order to use the stock pipes, so this sounds like the obvious opportunity to use 1”ID hose for many of the runs:

One of the things that I haven’t done is compare the volume of the stock HE and the big engine radiators. I’ll try that tonight.

Nick

Having said that, the BMW pump is intended to run all the time, so it’s had to be engineered to be more reliable. It doesn’t have any rotating shaft seals, only static ones, and the commutator is electronic, not mechanical, so there are two problem areas avoided right away. TheTecomatic controller can run the Pierburg pump at slow speed continuously, regardless of the coolant temp. That would help to stop the pipes heating up when the IAT stays below the 116F threshold.

The more I think about pipe re-routing the more I like it. I wonder if it’s possible to route them in the wheel arches, behind the plastic liners? Its seems wasteful to take the 1½”connections on the BMW radiator and pump, and reduce them down to ¾” in order to use the stock pipes, so this sounds like the obvious opportunity to use 1”ID hose for many of the runs:

One of the things that I haven’t done is compare the volume of the stock HE and the big engine radiators. I’ll try that tonight.

Nick

Last edited by Welwynnick; 06-12-2013 at 02:49 PM.

#60

Once you remove the fender liners everything will start to make more sense.

You can come up right next to the battery tray make a hole and enter the IC from the passenger's side. On the IC exit, make a hole and go down where the master cylinder is and route to the front HE.

The difference in temps is going to be worth this extra step. This is one of the best mods out there.

You can come up right next to the battery tray make a hole and enter the IC from the passenger's side. On the IC exit, make a hole and go down where the master cylinder is and route to the front HE.

The difference in temps is going to be worth this extra step. This is one of the best mods out there.

#61

Senior Member

Nick,

just a little thought.

A few years ago I also changed the factory HE on my former pullied SLK32 AMG to the massive Needswings HE. It was excellent in terms of reducing IATs. It was very BIG and THIN and was the first cooler in row where the air moved through. I also had CM90 Pump, bigger reservoir, special fluid in the system, heat insulation etc.

Don't know exactly anymore how much, but it definetely also affected the engine cooling, because some flow into the engine cooling radiator was blocked from the big Heatexchanger in the front.

Keep an eye on the engine cooling temperatures under sustained hard driving. I would not say it was dramatic but the engine coolant went up a little bit faster and higher under hard driving on the Autobahn.

B

just a little thought.

A few years ago I also changed the factory HE on my former pullied SLK32 AMG to the massive Needswings HE. It was excellent in terms of reducing IATs. It was very BIG and THIN and was the first cooler in row where the air moved through. I also had CM90 Pump, bigger reservoir, special fluid in the system, heat insulation etc.

Don't know exactly anymore how much, but it definetely also affected the engine cooling, because some flow into the engine cooling radiator was blocked from the big Heatexchanger in the front.

Keep an eye on the engine cooling temperatures under sustained hard driving. I would not say it was dramatic but the engine coolant went up a little bit faster and higher under hard driving on the Autobahn.

B

Last edited by AMG-Driver; 06-13-2013 at 08:32 AM.

#62

"Keep an eye on the engine cooling temperatures under sustained hard driving. I would not say it was dramatic but the engine coolant went up a little bit faster and higher under hard driving on the Autobahn."

The majority of us will never see the Autobahn with our cars, so top speed for extended periods of time is out of the question. We like to have fun on the street and blow the doors off anyone that comes to play. A few seconds of rush to put a smile on your face. Doing 200 mph is not realistic and could be fatal...not for us. I doubt engine temps will be a concern in this case.

The majority of us will never see the Autobahn with our cars, so top speed for extended periods of time is out of the question. We like to have fun on the street and blow the doors off anyone that comes to play. A few seconds of rush to put a smile on your face. Doing 200 mph is not realistic and could be fatal...not for us. I doubt engine temps will be a concern in this case.

#63

MBWorld Fanatic!

Thread Starter

http://www.needswings.com/NeedsWings...r--srt6he.aspx

I expect that would be a beautiful fit for the V12TT if only the end-tanks were slimmer. As it is they would block the engine air intakes, but having the inlet & outlet at the ends is a great advantage.

I'm quite mindful of the effect of an upgraded HE on engine cooling. I've read a lot of radiator specs lately, and one of the common patterns is that when air-con is fitted, the engine cooling radiator is often deeper or thicker, in order to make up for the loss of cooling. An HE would probably have the same effect - though remember that the 6 litre TT has a lot more power AND a full-height HE compared with the 5.5 TT, but the engine radiator is the same.

Having said that, these days its normal for ordinary turbocharged cars to have a full-size HE sandwiched between the AC condenser and the engine rad. A typical configuration is: 16mm AC, 32mm HE & 32mm Rad. The latter is usually the same size for N/A and turbo cars, so it could be that a large HE simply isn't heating-up the incoming air very much. Of course, it will ideally be working at a relatively low temperature, and won't put too much thermal load on the engine rad.

Engine cooling has to be an issue of some sort though. Since it ain't that hot in the UK, I'm confident that I won't get too many problems, and I'm definitely going ahead with my upgraded HE. But part of the trial is to show that it does work without impacting engine cooling or AC operation etc.

Well, that's what I'm hoping.

Nick

Last edited by Welwynnick; 06-14-2013 at 11:14 AM.

#64

Senior Member

Yes Nick,

this was exactly this Needswings-Cooler. It was a quite tight fit.

If I remember correctly, in the 65 the Heatexchanger is also in the Front and in the 600 it is sandwiched between other coolers.

If I would have to reduce IAT-Temperatures with the M275 I would also keep an eye on insulating the Intercoolers themselves with aluminium foil etc., because of the near position to the hot engine.

I wish you good luck with your Project!

B

this was exactly this Needswings-Cooler. It was a quite tight fit.

If I remember correctly, in the 65 the Heatexchanger is also in the Front and in the 600 it is sandwiched between other coolers.

If I would have to reduce IAT-Temperatures with the M275 I would also keep an eye on insulating the Intercoolers themselves with aluminium foil etc., because of the near position to the hot engine.

I wish you good luck with your Project!

B

#65

MBWorld Fanatic!

Thread Starter

Having rationalized the HE/radiator options down to a coupe of units, I'm loathe to widen the net again, but I did come across these options that have some specific and worthwhile advantages:

http://www.ebay.co.uk/itm/3606717446...84.m1423.l2649

BMW rads are a good choice to avoid having the outlet foul the radiator grille when the hood is shut. The E46 rad is a safe bet and easy to fit, but the shear capacity isn't that great compared with the W124 or W201 rads. This is an uprated version with a 42mm core and 10.1 litres capacity.

http://www.ebay.co.uk/itm/3904777525...84.m1423.l2649

Neither does the E46 rad have an oil cooler. BMW have long used an oil/water heat exchanger to cool the transmission fluid on automatics. However, 20 years ago many of their 6-cylinder automatics used this radiator - its very similar to the E46 rad, but it has an integral oil cooler. That should allow me to get rid of the ABC oil cooler, which is very tempting.

http://www.ebay.co.uk/itm/4004709720...84.m1423.l2649

This is a particularly interesting purpose made HE. It has 19mm inlet & outlet, which are mounted on the side - like a proper HE - so easy to hook-up. Its similar to the stock cooler, but twice as thick. Best of all, its being sold directly by the manufacturer, not a distributor, and they're happy to do a customized version. I asked them if they could make it 20" tall instead of 12", and they said yes - for 25% more. I'm sure they can make a single-pass version, but I might ask if they can do the attachment brackets as well.

Some of their alloy "race" rads actually have integrated oil coolers. That's unusual for this sort of product, so it makes me wonder if they could integrate an ABC cooler into this as well?

Nick

http://www.ebay.co.uk/itm/3606717446...84.m1423.l2649

BMW rads are a good choice to avoid having the outlet foul the radiator grille when the hood is shut. The E46 rad is a safe bet and easy to fit, but the shear capacity isn't that great compared with the W124 or W201 rads. This is an uprated version with a 42mm core and 10.1 litres capacity.

http://www.ebay.co.uk/itm/3904777525...84.m1423.l2649

Neither does the E46 rad have an oil cooler. BMW have long used an oil/water heat exchanger to cool the transmission fluid on automatics. However, 20 years ago many of their 6-cylinder automatics used this radiator - its very similar to the E46 rad, but it has an integral oil cooler. That should allow me to get rid of the ABC oil cooler, which is very tempting.

http://www.ebay.co.uk/itm/4004709720...84.m1423.l2649

This is a particularly interesting purpose made HE. It has 19mm inlet & outlet, which are mounted on the side - like a proper HE - so easy to hook-up. Its similar to the stock cooler, but twice as thick. Best of all, its being sold directly by the manufacturer, not a distributor, and they're happy to do a customized version. I asked them if they could make it 20" tall instead of 12", and they said yes - for 25% more. I'm sure they can make a single-pass version, but I might ask if they can do the attachment brackets as well.

Some of their alloy "race" rads actually have integrated oil coolers. That's unusual for this sort of product, so it makes me wonder if they could integrate an ABC cooler into this as well?

Nick

Last edited by Welwynnick; 06-17-2013 at 06:03 PM.

#66

MBWorld Fanatic!

Thread Starter

The Winner Racing HE is looking more attractive.

Their stock HE has core measurements of 21.5" x 12" x 1 5/8" and overall 25" x 12.5" x 2"

Having measured up carefully tonight, I think this would be a perfect fit at 19" height (maybe 20")

I have a better feel for all the brackets, pipes and mountings now, and this probably wouldn't need any metalwork modifications - just a few cut-outs to the plastic mouldings.

Basically, Winner say they can make an HE to my drawing, so that includes single-pass, the pipe positions and even the brackets. Considering this would be full-height HE, it would make sense to add two top mountings to pick-up on the condenser mountings. That way the HE would be fully mounted to the radiator, just as the stock HE is, and would control the location and spacing properly.

Best of all, they say they can incorporate an oil cooler, so I can do away with the ABC cooler. Fantastic.

Anybody else interested in the biggest bolt-on HE that you can fit into an S, SL or CL?

Nick

Their stock HE has core measurements of 21.5" x 12" x 1 5/8" and overall 25" x 12.5" x 2"

Having measured up carefully tonight, I think this would be a perfect fit at 19" height (maybe 20")

I have a better feel for all the brackets, pipes and mountings now, and this probably wouldn't need any metalwork modifications - just a few cut-outs to the plastic mouldings.

Basically, Winner say they can make an HE to my drawing, so that includes single-pass, the pipe positions and even the brackets. Considering this would be full-height HE, it would make sense to add two top mountings to pick-up on the condenser mountings. That way the HE would be fully mounted to the radiator, just as the stock HE is, and would control the location and spacing properly.

Best of all, they say they can incorporate an oil cooler, so I can do away with the ABC cooler. Fantastic.

Anybody else interested in the biggest bolt-on HE that you can fit into an S, SL or CL?

Nick

Last edited by Welwynnick; 06-19-2013 at 06:27 PM.

#67

MBWorld Fanatic!

Thread Starter

I think I have a better handle on what will fit in the W215/220. All versions essentially use the same radiator and condenser, though some of the other coolers vary. ABC has quite an impact on space and installability - there are lots of pipes in the way, plus all the brackets that support them, but all charge-cooled cars have ABC. I spent some time at the weekend looking at how a large HE would be installed, what has to be removed, what has to be fitted before the HE, and what has to go after the HE. Its all very well having the space, but a big HE is no-go if you can't re-fit the radiator mounts or what.

It seems to me that the largest HE that can fit is 25" x 19" x 2". Simple as that. That includes the tanks, but not the inlet & outlet. If you're prepared to do some modifications, you can go 21" tall. And as long as the car is reasonably high, it can go in without having to remove much else. There's no need to disconnect the engine radiator, condenser, engine oil cooler or most of the brackets, and even the front wheels and the headlamps can probably stay put.

But you do have to remove the lower radiator brackets and therefore the bumper. There's not enough width between the brackets to fit anything from below. If the HE is a radiator, the engine rad has to move back, which means removing the fan and the tranny oil line. All the complications are entirely down to the inlet & outlet - what space is available, how to fit it, and how to connect it.

A purpose made HE is much easier, as the inlet & outlet are at the side. That makes it easier to install and connect, but its more expensive.

That's about it, really, and I wish I knew all that beforehand. I've been concentrating on the W215/220, but I did look at the W216/221 for another MBW member, and I'm afraid that's rather different. A custom W220 HE will not fit the W221, and unlike the W220, the W221 S65/CL65 has a different configuration all of its own. This post comes from first-hand experience with my own car, and I'd only be able to advise on the newer cars when I can get my hands one, maybe in a few year's time.....

Nick

It seems to me that the largest HE that can fit is 25" x 19" x 2". Simple as that. That includes the tanks, but not the inlet & outlet. If you're prepared to do some modifications, you can go 21" tall. And as long as the car is reasonably high, it can go in without having to remove much else. There's no need to disconnect the engine radiator, condenser, engine oil cooler or most of the brackets, and even the front wheels and the headlamps can probably stay put.

But you do have to remove the lower radiator brackets and therefore the bumper. There's not enough width between the brackets to fit anything from below. If the HE is a radiator, the engine rad has to move back, which means removing the fan and the tranny oil line. All the complications are entirely down to the inlet & outlet - what space is available, how to fit it, and how to connect it.

A purpose made HE is much easier, as the inlet & outlet are at the side. That makes it easier to install and connect, but its more expensive.

That's about it, really, and I wish I knew all that beforehand. I've been concentrating on the W215/220, but I did look at the W216/221 for another MBW member, and I'm afraid that's rather different. A custom W220 HE will not fit the W221, and unlike the W220, the W221 S65/CL65 has a different configuration all of its own. This post comes from first-hand experience with my own car, and I'd only be able to advise on the newer cars when I can get my hands one, maybe in a few year's time.....

Nick

Last edited by Welwynnick; 06-24-2013 at 04:26 AM.

#68

MBWorld Fanatic!

Thread Starter

I’m slowly getting there, but I’m still finding reasons why nobody has done this before.....

First, I read that the impeller housings on the Pierburg pumps can be removed and rotated so the outlet points upwards (as they always should, to help avoid air-locks). Well, it can’t. Not on the two different pumps that I have here. Part of the outlet port is formed by the main pump housing, not just the removable inlet, which only fits one way. So to get the outlet pointing up I had to turn the whole pump round so it faces backwards. That would make it difficult to integrate with a stock HE, but it’s no problem with my X3 radiator, as the hose takes a different route. Perhaps the smaller CWA-50 and 100 pumps can rotate their plastic housings, but the much more common, all-alloy, CWA-200 can’t.

Looking inside was interesting though. My impression of the Pierburg pumps is that they’re properly developed for automotive prime-time, unlike some circulation pumps. They don’t just achieve high pressure and flow figures, they meet all the other real-life requirements as well – they’re compact, light, reliable, efficient, flexible and have low power consumption. When you look inside you see how they do some of this. The castings and machining are beautifully done – rigid, light-weight, interlocking shapes with no excess material anywhere, and the O-ring mating surfaces shine like mirrors. Of course they’re more expensive than belt-driven pumps, but for our charge-cooling application, with the programmable controller, I think they’re a gift.

The Pierburg pump is too big to fit the stock pump mounting plate, though that’s no show-stopper. A Pierburg will need itsown custom mounting, and the easiest way is to remove the stock mounting. My car has done 156k miles, and the mountings in the radiator are seized, so it’s going to have to stay where it is (unless I replace the radiator).

With the Pierburg in its reversed orientation, the electrical connector is low-down at the front, and it fouls the radiator mounting bracket. I have to admit I never thought of that, but the two problems are solved with a new mounting plate sitting on the stock plate, that lifts the pump higher up in what is actually quite a large space. I'll post some pictures tonight.

Nick

First, I read that the impeller housings on the Pierburg pumps can be removed and rotated so the outlet points upwards (as they always should, to help avoid air-locks). Well, it can’t. Not on the two different pumps that I have here. Part of the outlet port is formed by the main pump housing, not just the removable inlet, which only fits one way. So to get the outlet pointing up I had to turn the whole pump round so it faces backwards. That would make it difficult to integrate with a stock HE, but it’s no problem with my X3 radiator, as the hose takes a different route. Perhaps the smaller CWA-50 and 100 pumps can rotate their plastic housings, but the much more common, all-alloy, CWA-200 can’t.

Looking inside was interesting though. My impression of the Pierburg pumps is that they’re properly developed for automotive prime-time, unlike some circulation pumps. They don’t just achieve high pressure and flow figures, they meet all the other real-life requirements as well – they’re compact, light, reliable, efficient, flexible and have low power consumption. When you look inside you see how they do some of this. The castings and machining are beautifully done – rigid, light-weight, interlocking shapes with no excess material anywhere, and the O-ring mating surfaces shine like mirrors. Of course they’re more expensive than belt-driven pumps, but for our charge-cooling application, with the programmable controller, I think they’re a gift.

The Pierburg pump is too big to fit the stock pump mounting plate, though that’s no show-stopper. A Pierburg will need itsown custom mounting, and the easiest way is to remove the stock mounting. My car has done 156k miles, and the mountings in the radiator are seized, so it’s going to have to stay where it is (unless I replace the radiator).

With the Pierburg in its reversed orientation, the electrical connector is low-down at the front, and it fouls the radiator mounting bracket. I have to admit I never thought of that, but the two problems are solved with a new mounting plate sitting on the stock plate, that lifts the pump higher up in what is actually quite a large space. I'll post some pictures tonight.

Nick

Last edited by Welwynnick; 07-01-2013 at 03:29 PM.

#69

Hi Nick,

during a Mercedes-G build during the recent 5 years we had made some modifications and testing to the planned setup as well. first of all it was all about repositioning the whole cooler-package to the rear of the car. due to the engine, m113k, we planned to install a complete cooler-package from the CL55, C215. during our first season, we drove this thing with the package located the rear wall of the cabin with a very deep and tight fit just in front of the race tank. all the plumbing was done by aluminium. the ic-pump was exchanged to the cwa-100 as used in 2000 by amg in its C30 CDI AMG and now again in the sls.

the thermostat was modified to remove the outer valve by ginding it out, leaving the inner valve in place to allow closing of the inner circuit.

for the regulation we developed a special controller, which controls the rpm of the cooler-fan. as it has 850W, it was necessary not to have it toggle between off an on, as this thing sucks about 75amps. it was possible to use the ecu for controlling the fan, because we made some modifications to the air-conditioning side, going away from the pwm-controlled ac-compressor.

the controller not only controls the fan, it has inputs for other temp-sensors displayed on a 20x4 vfd-display as well for switches to have the fan on hold for water-xings, but the controller would take care, if this switch would have been forgotten in race-stress, switching the fan on again at a specifig engine temp etc.. and it had inputs for the air-cond system, to ramp the fan to some rpms when needed by the a/c-system etc..

diameter of the water-lines was approx 50mm for the engine-cooling and 30mm for the ic-circuit to avoid a specific water-reservoir and to reduce "friction" in the circuit itself.

the filling of the system is done by a vacuum-system, allowing the ic-circuit to be filled up to the max, because we had a dedicated reservoir for it incorporated as well.

the system works, but it shows that it was unable to have the needed cooling-power for longer deep-sand sections because the fan was the only thing forcing air through the coolers and because of the bad positioning .

so, besides some more modifications to stretch the whole car, we decided to change whole setup.

during a Mercedes-G build during the recent 5 years we had made some modifications and testing to the planned setup as well. first of all it was all about repositioning the whole cooler-package to the rear of the car. due to the engine, m113k, we planned to install a complete cooler-package from the CL55, C215. during our first season, we drove this thing with the package located the rear wall of the cabin with a very deep and tight fit just in front of the race tank. all the plumbing was done by aluminium. the ic-pump was exchanged to the cwa-100 as used in 2000 by amg in its C30 CDI AMG and now again in the sls.

the thermostat was modified to remove the outer valve by ginding it out, leaving the inner valve in place to allow closing of the inner circuit.

for the regulation we developed a special controller, which controls the rpm of the cooler-fan. as it has 850W, it was necessary not to have it toggle between off an on, as this thing sucks about 75amps. it was possible to use the ecu for controlling the fan, because we made some modifications to the air-conditioning side, going away from the pwm-controlled ac-compressor.

the controller not only controls the fan, it has inputs for other temp-sensors displayed on a 20x4 vfd-display as well for switches to have the fan on hold for water-xings, but the controller would take care, if this switch would have been forgotten in race-stress, switching the fan on again at a specifig engine temp etc.. and it had inputs for the air-cond system, to ramp the fan to some rpms when needed by the a/c-system etc..

diameter of the water-lines was approx 50mm for the engine-cooling and 30mm for the ic-circuit to avoid a specific water-reservoir and to reduce "friction" in the circuit itself.

the filling of the system is done by a vacuum-system, allowing the ic-circuit to be filled up to the max, because we had a dedicated reservoir for it incorporated as well.

the system works, but it shows that it was unable to have the needed cooling-power for longer deep-sand sections because the fan was the only thing forcing air through the coolers and because of the bad positioning .

so, besides some more modifications to stretch the whole car, we decided to change whole setup.

#70

the tank was moved to the back of the drivers cabin, allowing to cooler to sit more exposed and higher. and we went to a much larger radiator, from a mercedes truck, Econic. with this thing, we got approx 4 times the capacitiy from the original mercedes g-radiator. the connectors had 70mm ID opposite to the 34mm of the original cooler :-)

the routing of the cooler-lines was changed significantly. i will post some pics later on.

during all these modifications we had the idea to install CWA200 or even the more powerful Continental SCPII. but doing this we would have installed a new possible point of failure and had to remove the mechnical pump. so, decision was to see if the mechanical pump can do the job. the cwa100 was left in place for the ic-circuit, still controlled by the ecu.

all temp-regulation is done with our fan-controller. we had installed the "normal" thermostat again, with opening temp 86°, but we got in trouble with long full-power runs. switching back to our modified thermostat, all was ok.

during our first races we had absolute no temperature-problems any more.

some pics to follow.

best regards

carsten

the routing of the cooler-lines was changed significantly. i will post some pics later on.

during all these modifications we had the idea to install CWA200 or even the more powerful Continental SCPII. but doing this we would have installed a new possible point of failure and had to remove the mechnical pump. so, decision was to see if the mechanical pump can do the job. the cwa100 was left in place for the ic-circuit, still controlled by the ecu.

all temp-regulation is done with our fan-controller. we had installed the "normal" thermostat again, with opening temp 86°, but we got in trouble with long full-power runs. switching back to our modified thermostat, all was ok.

during our first races we had absolute no temperature-problems any more.

some pics to follow.

best regards

carsten

#73

MBWorld Fanatic!

Thread Starter

Hi Carsten, that's an interesting account of an uncompromising installation for a presumably much more demanding application. What's a little surprising about road cars like the SL600 or CL55K is that the engine cooling rad is no bigger than the lesser models. I think the reason is that the engine only works hard for a short time, when the car is travelling fast and natural airflow is high. Rather unlike a truck or off-roader, in fact. Presumably a road car can get away with a modest IC HE for the same reasons.

So it sounds like you needed a very good charge cooler, and the obscured position wasn't suitable. Can I ask what monitoring you were able to perform in use? Intake air temperature? Charge cooler water temp? Charge cooler flow rate? Were you unable to have a radiator in the conventiional position - or did you have one there as well?

Regards, Nick

So it sounds like you needed a very good charge cooler, and the obscured position wasn't suitable. Can I ask what monitoring you were able to perform in use? Intake air temperature? Charge cooler water temp? Charge cooler flow rate? Were you unable to have a radiator in the conventiional position - or did you have one there as well?

Regards, Nick

#74

Senior Member

Join Date: Apr 2005

Location: Malibu, Ca

Posts: 314

Likes: 0

Received 0 Likes

on

0 Posts

SL65, 427 COBRA (CSX-3127)73 911S, 246GTS (DINO SPYDER), CORNICHE,1962 PORSCHE TWIN GRILLE ROADSTER+

For the SL65 The CL600 condenser with Meziere Pump works OK...

I have an 06 SL65 (R230) and I first installed the Renntech designed front condenser system.

Four years ago I went to buy the system from Renntech at $4,200 and I noticed an MB sticker with a part number on their condenser. I thought I should check the MB part number before dropping $4,200 (uninstalled) on a small box of parts and I discovered that they were just using a standard MB heater core found in numerous MBs. Their system had that condenser with a few custom brackets and small rubber hoses. I ordered the condenser from my local MB Dealer for $168 and ordered the brackets and hoses from Renntech @ $200 thus saving almost $3,900 for the exact same parts (sorry Renntech). The MB/Renntech condenser is about 4 inches tall 22 inches long and 2 inches deep.

When I removed the front bumper I was surprised to see that on my SL65 from the factory was the exact same condenser and that Renntech was just adding a second condenser. That system worked better then stock but still heat soaked quickly. I already had the late upgraded Bosh 010 pump so I kept that.

About a year ago I installed the larger CL600 front condenser (pictured herein) that fits very tightly but required almost no mods, along with a BMW Meziere pump from Speedriven that they modify for the application. The system is extremely hard to bleed and takes hours of squeezing the hoses and letting the pump run but once bled does make a huge difference over the previous system. It still heat soaks but takes much longer and recovers much faster.

What I find is that while initially bleeding the system using clear plastic tubing I did notice that very tiny micro bubbles persisted. I have a feeling that either there are micro bubble attached inside that dislodge in the system OR more likely the impeller in the Meziere pump is cavitating and causing the micro bubbles. About every three months I have to re-bleed the system and do find large air bubbles that escape and allow 10-12OZ/300-500 ML more water into the system... I also still see those very tiny micro bubbles floating in the system even after hours of the pump running both with the water hot and ice cold.

Four years ago I went to buy the system from Renntech at $4,200 and I noticed an MB sticker with a part number on their condenser. I thought I should check the MB part number before dropping $4,200 (uninstalled) on a small box of parts and I discovered that they were just using a standard MB heater core found in numerous MBs. Their system had that condenser with a few custom brackets and small rubber hoses. I ordered the condenser from my local MB Dealer for $168 and ordered the brackets and hoses from Renntech @ $200 thus saving almost $3,900 for the exact same parts (sorry Renntech). The MB/Renntech condenser is about 4 inches tall 22 inches long and 2 inches deep.

When I removed the front bumper I was surprised to see that on my SL65 from the factory was the exact same condenser and that Renntech was just adding a second condenser. That system worked better then stock but still heat soaked quickly. I already had the late upgraded Bosh 010 pump so I kept that.

About a year ago I installed the larger CL600 front condenser (pictured herein) that fits very tightly but required almost no mods, along with a BMW Meziere pump from Speedriven that they modify for the application. The system is extremely hard to bleed and takes hours of squeezing the hoses and letting the pump run but once bled does make a huge difference over the previous system. It still heat soaks but takes much longer and recovers much faster.

What I find is that while initially bleeding the system using clear plastic tubing I did notice that very tiny micro bubbles persisted. I have a feeling that either there are micro bubble attached inside that dislodge in the system OR more likely the impeller in the Meziere pump is cavitating and causing the micro bubbles. About every three months I have to re-bleed the system and do find large air bubbles that escape and allow 10-12OZ/300-500 ML more water into the system... I also still see those very tiny micro bubbles floating in the system even after hours of the pump running both with the water hot and ice cold.

Last edited by EXECMALIBU; 07-27-2013 at 01:58 PM.

#75

MBWorld Fanatic!

Thread Starter

Filling and Bleeding

The system is extremely hard to bleed and takes hours of squeezing the hoses and letting the pump run but once bled does make a huge difference over the previous system. It still heat soaks but takes much longer and recovers much faster.

What I find is that while initially bleeding the system using clear plastic tubing I did notice that very tiny micro bubbles persisted. I have a feeling that either there are micro bubble attached inside that dislodge in the system OR more likely the impeller in the Meziere pump is cavitating and causing the micro bubbles. About every three months I have to re-bleed the system and do find large air bubbles that escape and allow 10-12OZ/300-500 ML more water into the system... I also still see those very tiny micro bubbles floating in the system even after hours of the pump running both with the water hot and ice cold.

What I find is that while initially bleeding the system using clear plastic tubing I did notice that very tiny micro bubbles persisted. I have a feeling that either there are micro bubble attached inside that dislodge in the system OR more likely the impeller in the Meziere pump is cavitating and causing the micro bubbles. About every three months I have to re-bleed the system and do find large air bubbles that escape and allow 10-12OZ/300-500 ML more water into the system... I also still see those very tiny micro bubbles floating in the system even after hours of the pump running both with the water hot and ice cold.

The water-antifreeze mixture is more viscous than water alone, and it bubbles easily. When any air gets into the pump, it turns the liquid into foam, chokes the pump and stops everything from circulating. The bubbles are very slow to clear. So slow in fact, that it takes less time to drain the system and modify it with a bottom filling port and re-fill it properly - than it does to bleed the system.

Because I (attempted) to measure the flow with several different combinations of pump and HE, I spent a lot of time emptying, filling and bleeding. After a few days of this I gave up and added a T-piece to the lowest point in the system at the HE inlet pipe, and connected a small header tank with a long hose. Filling the system this way takes minutes rather than hours. You have to take care not to overflow the stock filler, but having a header tank on a long hose makes everything very easy. The system can be slightly pressurized without having to switch on the pump, and you can bleed the IC inlet valves without generating more bubbles than you’re removing.

If I’ve learned anything from this protracted episode, is that you must remove ALL the air from the IC system, and you shouldn’t even THINK about trying to fill and bleed it without adding a bottom fill port.

Nick

Last edited by Welwynnick; 07-29-2013 at 05:56 AM.