Alfa 159 1.9 Jtdm 300HP- Heat Exchange or Pump or Charce Cooler problem High Boost.

#1

Alfa 159 1.9 Jtdm 300HP- Heat Exchange or Pump or Charce Cooler problem High Boost.

Hi,

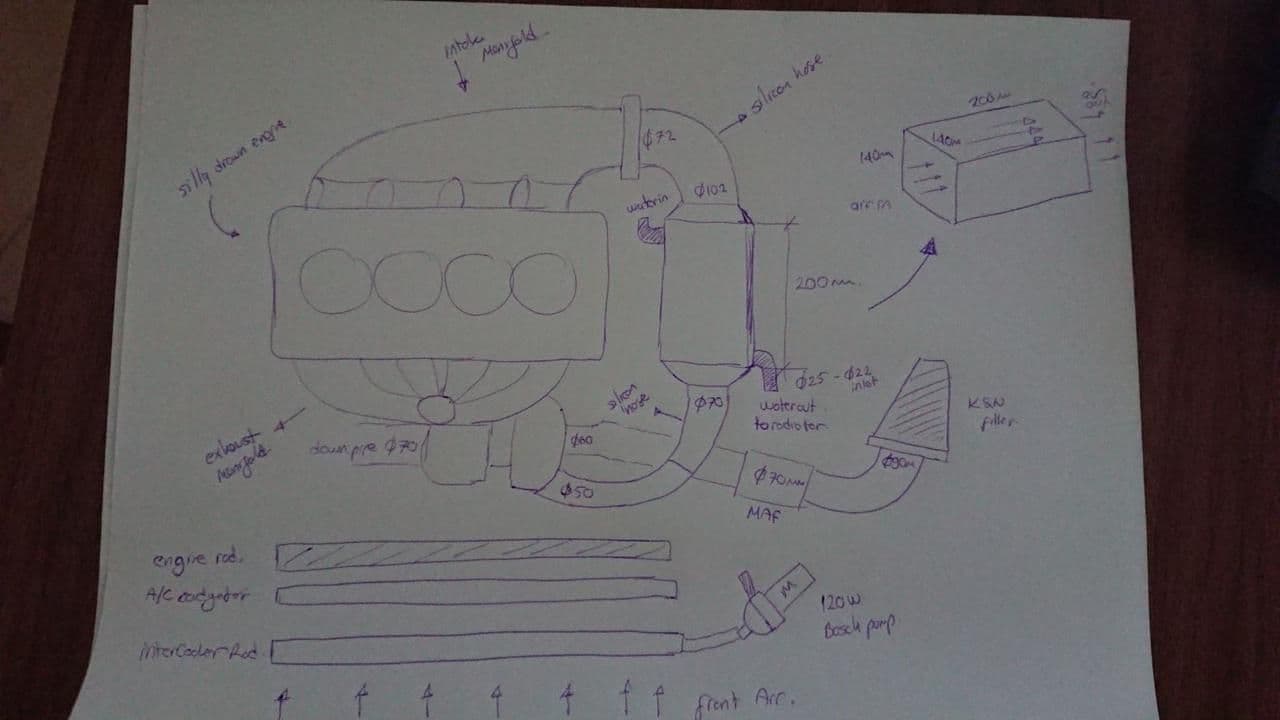

I want to give some information about my project and I want a little help from you if it is possible. You all know lots of information about Charge cooling and Pumps and HE. All I need some information about them. Because other that low pressure gasoline engine. I want to cool high pressure Diesel. Like 3 Bars of Boost. I'm lack of information about heating and Cooling. that's why I'm in trouble. . I have an Alfa romeo 159 Diesel. And I'm making modification to it. I'm Electrical engineer and This car is my hobby. It is helping me about learning lots of information about cars and diesel tuning.

Now I use Turbo from 350CDI , GTB2060VKLR, with original Electrical Actuator. Normally, my friends suggested that I use Air2Air intercooler for this setup. But I wanted to challenge myself. And tried Water 2 Air intercooler. One of my friend is tuning only Mercs in Turkey. He suggested that I use a bosch pump, 0392 022 010 .

With an uninterested tuner - he is good with gasoline engines, but diesel - from Turkey, I get 260HP and 550Nm torque , with 104 Degree Celc IAT . Now I'm having some IAT problems. I think there is something about HE capacity. I don't know yet. I've tried to search the forum, I found very useful information. But I could not ask you before..

Here is the HE, it is from Dacia 1.6lt engine radiator. 550mm x 480mm x 16mm, Because it was cheap and it fitted without modification.

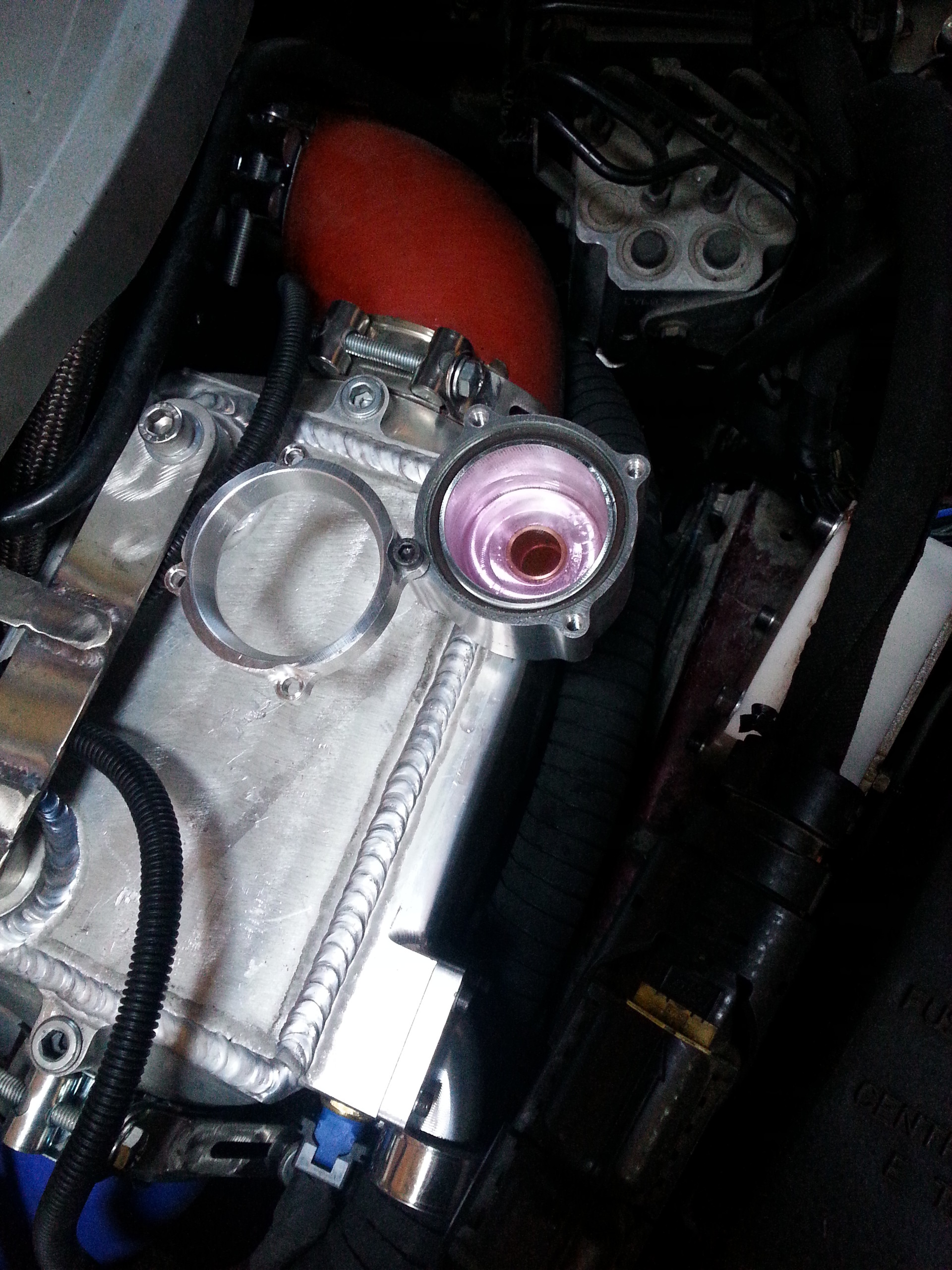

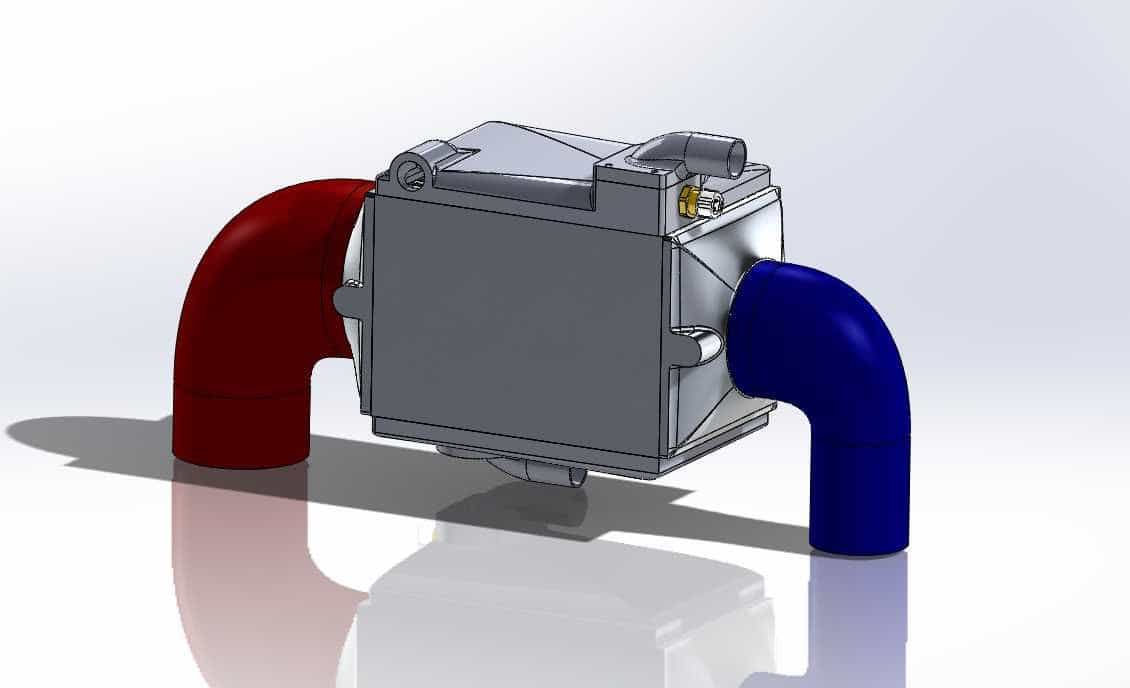

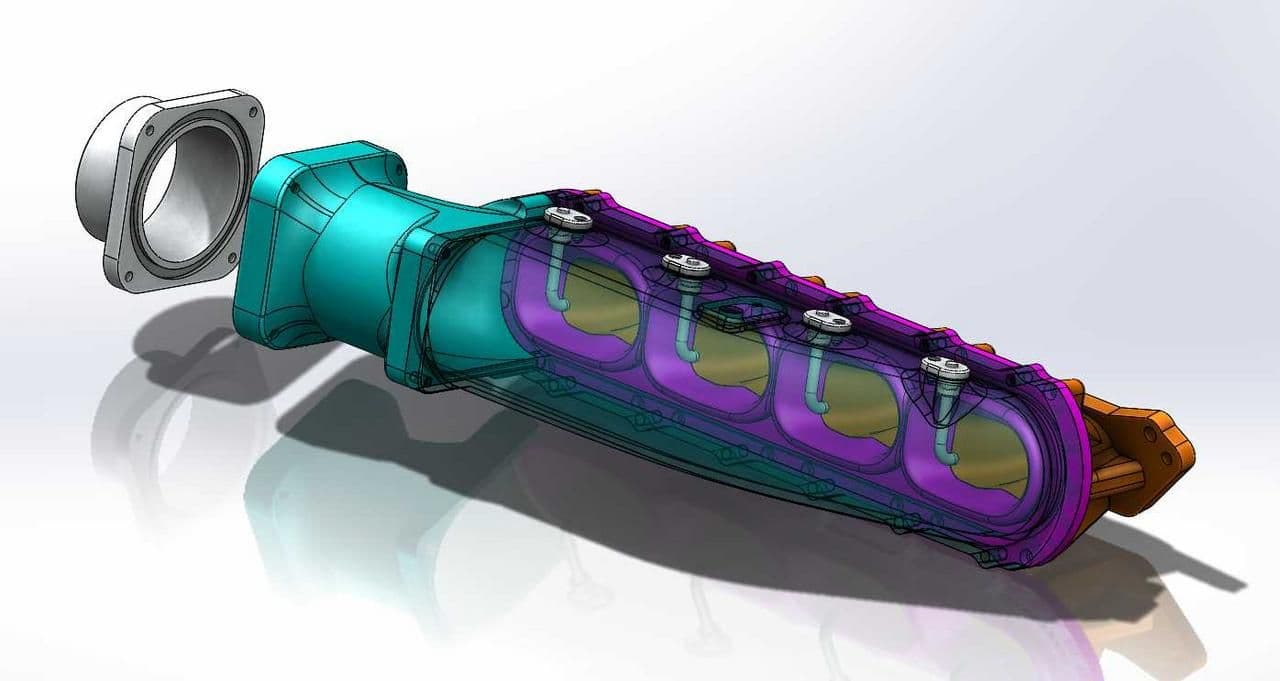

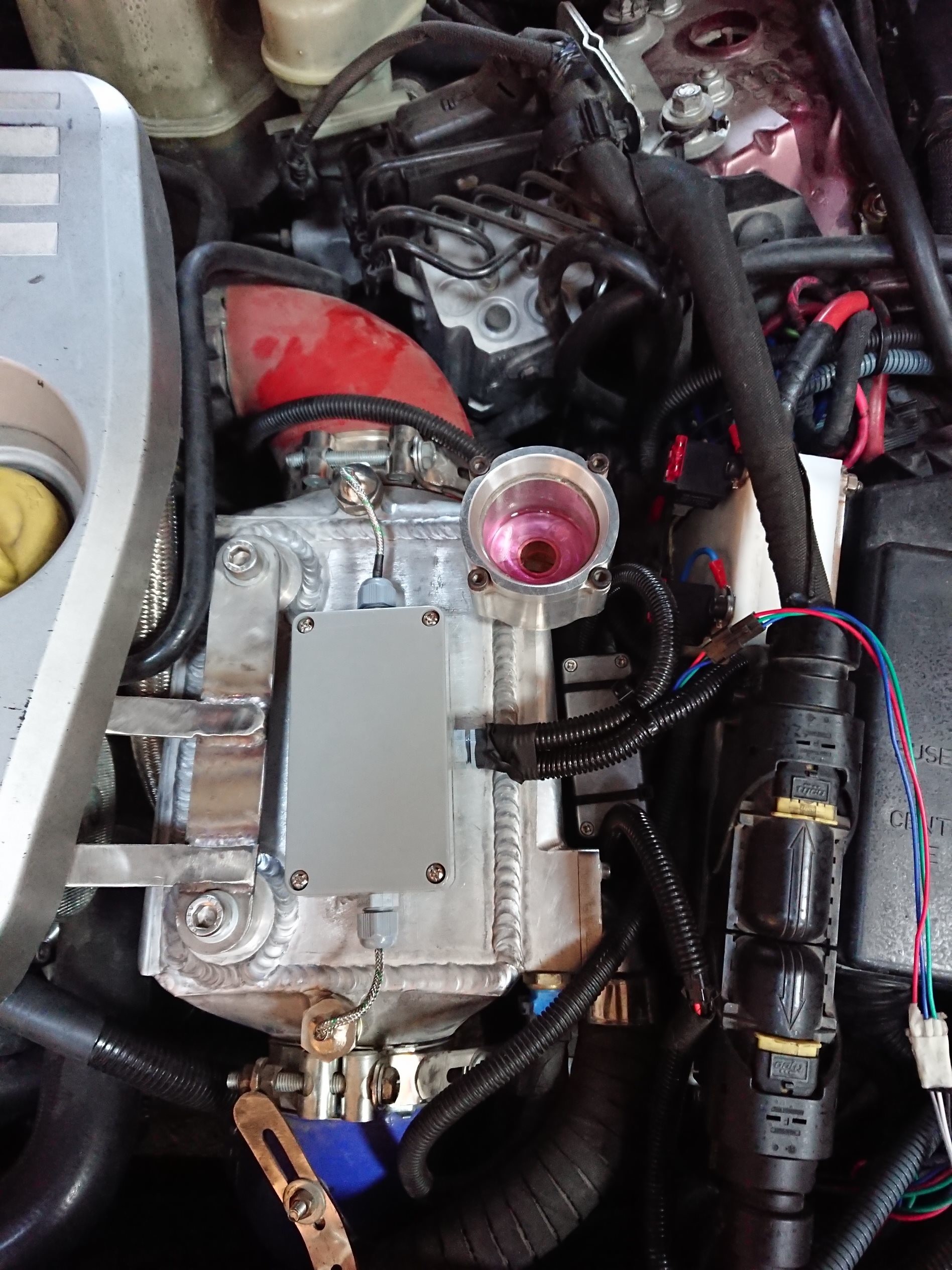

And Here is My Custom Charge Cooler : 141mm x 141mm X 200mm Length... Air is passing 200mm

End Caps for HE, My designs for the Radiator.

And We started welding

And Charge Cooler

After we Finished the Welding I've tried for fitment.

I want to give some information about my project and I want a little help from you if it is possible. You all know lots of information about Charge cooling and Pumps and HE. All I need some information about them. Because other that low pressure gasoline engine. I want to cool high pressure Diesel. Like 3 Bars of Boost. I'm lack of information about heating and Cooling. that's why I'm in trouble. . I have an Alfa romeo 159 Diesel. And I'm making modification to it. I'm Electrical engineer and This car is my hobby. It is helping me about learning lots of information about cars and diesel tuning.

Now I use Turbo from 350CDI , GTB2060VKLR, with original Electrical Actuator. Normally, my friends suggested that I use Air2Air intercooler for this setup. But I wanted to challenge myself. And tried Water 2 Air intercooler. One of my friend is tuning only Mercs in Turkey. He suggested that I use a bosch pump, 0392 022 010 .

With an uninterested tuner - he is good with gasoline engines, but diesel - from Turkey, I get 260HP and 550Nm torque , with 104 Degree Celc IAT . Now I'm having some IAT problems. I think there is something about HE capacity. I don't know yet. I've tried to search the forum, I found very useful information. But I could not ask you before..

Here is the HE, it is from Dacia 1.6lt engine radiator. 550mm x 480mm x 16mm, Because it was cheap and it fitted without modification.

And Here is My Custom Charge Cooler : 141mm x 141mm X 200mm Length... Air is passing 200mm

End Caps for HE, My designs for the Radiator.

And We started welding

And Charge Cooler

After we Finished the Welding I've tried for fitment.

#4

Turbo has different Compressor Wheel. It has GTX 2.GEN 10+0 .

And Here is my Intercooler Temperature Monitor.

Here is my test video

IN = Post Turbo , ChargeCooler Inlet Temp

OUT = ChargeCooler Outlet Temp , aka IAT

WIN = WaterInlet Temp of ChargeCooler

WOt = WaterOutlet Temp of ChargeCooler

EGT = EGT But this is in the Turbo exit . Inside the Downpipe

But this is in the Turbo exit . Inside the Downpipe

CP: Chip Temperature, inside the bonnet. I want to see that closed case temp. controller chip temperatures I don't want to burn them....

And Here is my Intercooler Temperature Monitor.

Here is my test video

IN = Post Turbo , ChargeCooler Inlet Temp

OUT = ChargeCooler Outlet Temp , aka IAT

WIN = WaterInlet Temp of ChargeCooler

WOt = WaterOutlet Temp of ChargeCooler

EGT = EGT

But this is in the Turbo exit . Inside the Downpipe

But this is in the Turbo exit . Inside the DownpipeCP: Chip Temperature, inside the bonnet. I want to see that closed case temp. controller chip temperatures I don't want to burn them....

#6

Hi Emre,

You've done some very nice work there. Those end tanks look extraordinary. Did you make them? Did you make the inlet manifold as well?

That radiator looks like a good heat exchanger, but are you sure the matrix is only 16 mm thick - that's typical for AC condensers? That's not an uncommon size, but it does look a bit thicker than that.

I notice that you have the pump mounted horizontally, low down, and at the outlet of the HE, which is all good. It's essential that you get all the air out of the IC system, and it looks like you have a swirl pot to ensure that.

Your system is ambitious, so the Bosch pump is the MINIMUM you should be considering. Popular options like the Johnson CM30 should NEVER be considered for IC's.

The first thing I would suggest is uprating the pump. The Pierburg CWA-50 or 100 is the obvious first place to go (it's what all the manufacturers use these days). Alternatively you could add a second Bosch pump in series in the circuit.

Considering how much resource you're putting into this, I'd suggest going the whole hog and get an EMP WP29 pump instead. More expensive, but absolutely the best.

The only other think you could do, and I'm sure it would be very worthwhile, is to increase the size of the water pipes from 3/4" to 1" or more.

All the best, Nick

You've done some very nice work there. Those end tanks look extraordinary. Did you make them? Did you make the inlet manifold as well?

That radiator looks like a good heat exchanger, but are you sure the matrix is only 16 mm thick - that's typical for AC condensers? That's not an uncommon size, but it does look a bit thicker than that.

I notice that you have the pump mounted horizontally, low down, and at the outlet of the HE, which is all good. It's essential that you get all the air out of the IC system, and it looks like you have a swirl pot to ensure that.

Your system is ambitious, so the Bosch pump is the MINIMUM you should be considering. Popular options like the Johnson CM30 should NEVER be considered for IC's.

The first thing I would suggest is uprating the pump. The Pierburg CWA-50 or 100 is the obvious first place to go (it's what all the manufacturers use these days). Alternatively you could add a second Bosch pump in series in the circuit.

Considering how much resource you're putting into this, I'd suggest going the whole hog and get an EMP WP29 pump instead. More expensive, but absolutely the best.

The only other think you could do, and I'm sure it would be very worthwhile, is to increase the size of the water pipes from 3/4" to 1" or more.

All the best, Nick

Last edited by Welwynnick; 11-24-2017 at 01:45 PM.

The following users liked this post:

Emre Suat (11-25-2017)

#7

Hello again,

Thank you very much for the compliment Yes I did all the parts by myself. All of them has flow simulations. And tested. But you know the real world is different. I cannot put all the variables to the simulations. So It gave me not false results but near results. I have to think and execute logic to get a better result.

Yes I did all the parts by myself. All of them has flow simulations. And tested. But you know the real world is different. I cannot put all the variables to the simulations. So It gave me not false results but near results. I have to think and execute logic to get a better result.

The radiator matrix is about 16mm yes. It is and engine radiator from Dacia Logan 1.6 petrol Engine. So it is designed to work with an engine pump and flow. Maybe that's why It does not work in my setup. But the End Case was designed by me. And It is 52mm inside diameter. I was suggested that I use bigger End Cases to have more fluid in front of the engine.

All the pumps are great but I can change the front radiator, It is easy for me to do. When I design this setup. I was afraid of the placement of the front radiator but. Now I can fit. like 10cm longer radiator to the front. And up to 55mm thickness I can design to the matrix of the radiator.

If I'm not wrong I think this thin radiator should be used with high pressure water pump. And that's why you recommend me one of them. Only for the knowledge of this kind of setup. I want to go with thicker radiator. that I think it will lower my pressure drop. Does it help?

My friend recommend me, before you wrote it. If we lower the pressure drop, it will speed up the water. And It's a good thing. Also 4lt total water capacity is low. Maybe we can double or triple it. And for the pump. It is sucking from under the HE. Lets put it under the water Tank. It is suck easier than HE. maybe this would help a little.

I don't want to be looking like I resist your pump advice here. Because of our greedy government our import taxes are very high. In Turkey it is a thing. Your advised pump is almost 2.5 times expensive in Turkey right now. So that's why I went other directions. Maybe second serial pump is a good thing. Also I have a VW Tsi engine water pump. Small like a Fist. I had bought two of them. And My older idea was to use them in parallel to keep the flow. But then I've read this forum. And My whole ideas changed First I did not had time. Because I had to get this car going, because It was 1 year he was sleeping. And I have to give my spare car back to my dad.

First I did not had time. Because I had to get this car going, because It was 1 year he was sleeping. And I have to give my spare car back to my dad.

Anyway. Thank you for the advise

Also I've realised that maybe I'm not using the whole Core. Core means the Air2Water Core. I will upload them soon. Because of the 90 degree silicone bends, flow does not want to share whole 14cm x 14cm area. I think I will using almost half of it. So its a bad thing right ?

Thank you very much for the compliment

Yes I did all the parts by myself. All of them has flow simulations. And tested. But you know the real world is different. I cannot put all the variables to the simulations. So It gave me not false results but near results. I have to think and execute logic to get a better result.

Yes I did all the parts by myself. All of them has flow simulations. And tested. But you know the real world is different. I cannot put all the variables to the simulations. So It gave me not false results but near results. I have to think and execute logic to get a better result.The radiator matrix is about 16mm yes. It is and engine radiator from Dacia Logan 1.6 petrol Engine. So it is designed to work with an engine pump and flow. Maybe that's why It does not work in my setup. But the End Case was designed by me. And It is 52mm inside diameter. I was suggested that I use bigger End Cases to have more fluid in front of the engine.

All the pumps are great but I can change the front radiator, It is easy for me to do. When I design this setup. I was afraid of the placement of the front radiator but. Now I can fit. like 10cm longer radiator to the front. And up to 55mm thickness I can design to the matrix of the radiator.

If I'm not wrong I think this thin radiator should be used with high pressure water pump. And that's why you recommend me one of them. Only for the knowledge of this kind of setup. I want to go with thicker radiator. that I think it will lower my pressure drop. Does it help?

My friend recommend me, before you wrote it. If we lower the pressure drop, it will speed up the water. And It's a good thing. Also 4lt total water capacity is low. Maybe we can double or triple it. And for the pump. It is sucking from under the HE. Lets put it under the water Tank. It is suck easier than HE. maybe this would help a little.

I don't want to be looking like I resist your pump advice here. Because of our greedy government our import taxes are very high. In Turkey it is a thing. Your advised pump is almost 2.5 times expensive in Turkey right now. So that's why I went other directions. Maybe second serial pump is a good thing. Also I have a VW Tsi engine water pump. Small like a Fist. I had bought two of them. And My older idea was to use them in parallel to keep the flow. But then I've read this forum. And My whole ideas changed

First I did not had time. Because I had to get this car going, because It was 1 year he was sleeping. And I have to give my spare car back to my dad.

First I did not had time. Because I had to get this car going, because It was 1 year he was sleeping. And I have to give my spare car back to my dad.Anyway. Thank you for the advise

Also I've realised that maybe I'm not using the whole Core. Core means the Air2Water Core. I will upload them soon. Because of the 90 degree silicone bends, flow does not want to share whole 14cm x 14cm area. I think I will using almost half of it. So its a bad thing right ?

Last edited by Emre Suat; 11-25-2017 at 07:51 AM.

Trending Topics

#8

Your intercooler has 4 litres volume and your HE / radiator has 4.2 litres, so they both have a sensible volume. The same volume is a good starting point for a liquid cooler.

if you had an FMIC, it would probably measure around 600 x 400 x 30mm, so about the same TOTAL volume, and typical for modern turbo diesels.

Making the HE thicker would help, but the HE probably isn't much of a bottleneck, the IC more critical.

With IC's, bigger is generally better. If you doubled the thickness of the HE, it would help in two ways - it would increase the cooling capacity, and so lower coolant temp. It would also reduce liquid flow restriction, and so increase circulation rate, which is always good.

My opinion is that making the HE single pass, rather than dual pass as you currently have, would be better. The reason is that the HE is a significant flow restrictor in the whole system, due to the small coolant pipes, and their long length. When you have a dual pass cooler, you halve the number of pipes for the coolant to pass through, and double the length.

So if you went up to a 30 or 40mm radiator (and there are LOTS out there) and made it a single pass cooler, you would get more capacity and more flow, without making other changes.

I wouldn't be tempted to try to go any thicker than 40mm though. Car radiators are never any thicker than that. There's too much restriction on air flow, and you lose cooling rather than increase it.

Make sure you avoid any sharp turns in the cooling pipes - they're terrible for flow.

Nick

if you had an FMIC, it would probably measure around 600 x 400 x 30mm, so about the same TOTAL volume, and typical for modern turbo diesels.

Making the HE thicker would help, but the HE probably isn't much of a bottleneck, the IC more critical.

With IC's, bigger is generally better. If you doubled the thickness of the HE, it would help in two ways - it would increase the cooling capacity, and so lower coolant temp. It would also reduce liquid flow restriction, and so increase circulation rate, which is always good.

My opinion is that making the HE single pass, rather than dual pass as you currently have, would be better. The reason is that the HE is a significant flow restrictor in the whole system, due to the small coolant pipes, and their long length. When you have a dual pass cooler, you halve the number of pipes for the coolant to pass through, and double the length.

So if you went up to a 30 or 40mm radiator (and there are LOTS out there) and made it a single pass cooler, you would get more capacity and more flow, without making other changes.

I wouldn't be tempted to try to go any thicker than 40mm though. Car radiators are never any thicker than that. There's too much restriction on air flow, and you lose cooling rather than increase it.

Make sure you avoid any sharp turns in the cooling pipes - they're terrible for flow.

Nick

#9

Ooo this is better I think. To make it like a free flow. So last thing that we accomplished is to have a HE wtth 30-40mm thickness and single pass. Single pass is like Cross Pass or Up to down single pass? As you know I will make new end cases to new radiator. so I can make more room for water and bigger diameter outlet and inlet ports. And my Intercooler Core is single pass. May be I will do a dual pass but I have to cut the welds for it. And I don't want to do it right now. First I need to make a better HE for the system.

PS: My older original Air2Air Intercooler has the size exactly that you mentioned. 600x400 but more thickness. it was like 50mm It was rated up to 220HP with original Turbo. But After they upgrade the Turbo in out 1.9 Jtdm engines. All the Owners goes up to 70mm thickness for Air2Air Intercooler....

PS: My older original Air2Air Intercooler has the size exactly that you mentioned. 600x400 but more thickness. it was like 50mm It was rated up to 220HP with original Turbo. But After they upgrade the Turbo in out 1.9 Jtdm engines. All the Owners goes up to 70mm thickness for Air2Air Intercooler....

#10

I will make new end cases to new radiator. so I can make more room for water and bigger diameter outlet and inlet ports.

Nick

#11

I'm using Solidworks since 2002, I've my own CNC machine since 2005, and I'm manufacturing Machinery since 2002. If it is aluminium. I can shape or design almost anything, believe me  All I'm lacking is some mechanical engineering formulas or as you see, heating or cooling stuff. I'm electrical engineer. Also I can design almost any special project, with PLC or MicroControllers

All I'm lacking is some mechanical engineering formulas or as you see, heating or cooling stuff. I'm electrical engineer. Also I can design almost any special project, with PLC or MicroControllers  I trust myself. Thats why I want to make something about my car. All need is some measurements and some CAD time with black coffee and Metal Music.....

I trust myself. Thats why I want to make something about my car. All need is some measurements and some CAD time with black coffee and Metal Music.....

All I'm lacking is some mechanical engineering formulas or as you see, heating or cooling stuff. I'm electrical engineer. Also I can design almost any special project, with PLC or MicroControllers

All I'm lacking is some mechanical engineering formulas or as you see, heating or cooling stuff. I'm electrical engineer. Also I can design almost any special project, with PLC or MicroControllers  I trust myself. Thats why I want to make something about my car. All need is some measurements and some CAD time with black coffee and Metal Music.....

I trust myself. Thats why I want to make something about my car. All need is some measurements and some CAD time with black coffee and Metal Music.....

#12

#14

Aluminium Welding that I cannot do right now, just because I don't have AC TIG welding machines. I have DC TIG Welding Machine and MIG for the rest. I can use both of them. I did all my weldings on the car especially stainless steel downpipe throıth the back silencer. And Also the Temp. Monitor is my design. It is wireless. A Box in the engine bay. And this monitor uses battery pack to run, In the cabinet. I will upload some images today.

#15

This is the board that measures the Inlet - Outlet of the Air and Water temps + EGT sensor Amplifier is in there. + It has a little wireless transceiver inside the box. In Alfa 159. There is no room for any more cabling between "engine bay" to the "driver's compartment" So I put wireless comm.

This is the monitor. OLED 2.7" - It will also monitor for additional sensor. Like it is ready for AFR , and It will control the Water/Meth pump & valves. It has also buttons and a rotary input wheel. But the software is not finished. My first priority is to finish my work. And earn some money

After that First job is HE. and getting proper IATs

After that First job is HE. and getting proper IATs

The following users liked this post:

Welwynnick (11-27-2017)