How Mercedes-AMG Builds the ONE

We take a closer look as Mercedes-AMG ONE production commences.

Mercedes-AMG dropped us a line during the week to remind us that production has finally commenced on its highly anticipated all-new Formula 1 technology ONE hypercar.

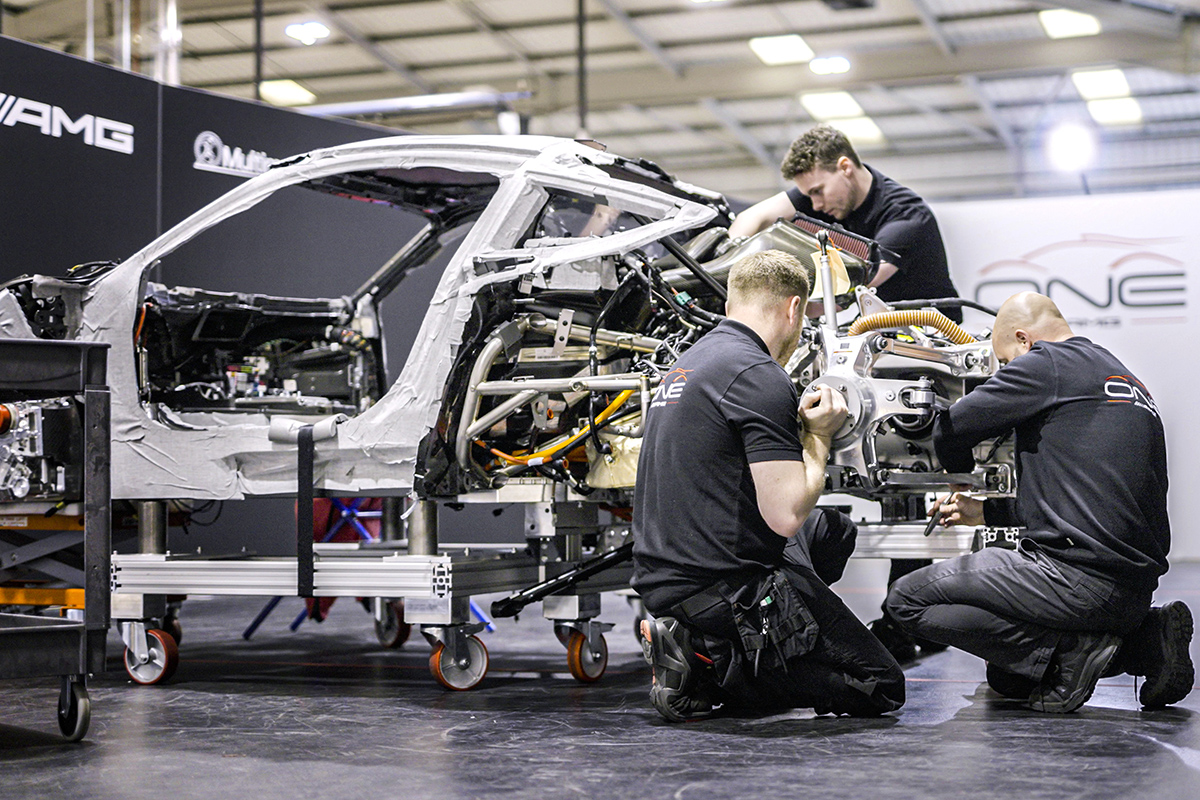

AMG went on to explain the car’s exclusive production process as it prepares for first customer deliveries later this year. Only 275 ONEs will be built.

ONE Power Trains Built Alongside Hamilton’s

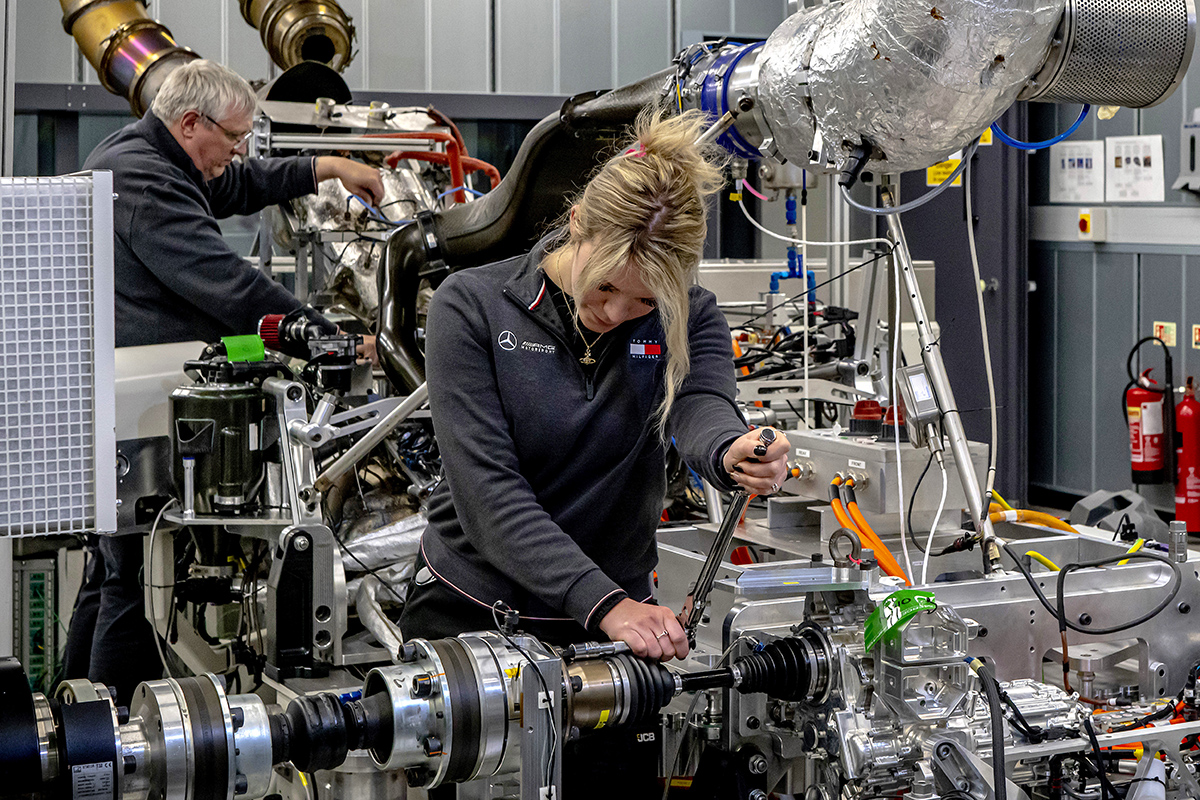

ONE’s Formula 1 based 1.6-litre turbo V6 engine is part of a hybrid powertrain with four electric motors. Power units are built alongside Lewis Hamilton and George Russell’s Mercedes-AMG F1 race units by the Formula 1 team at Mercedes-AMG High Performance Powertrains in Brixworth England. Assembled units are then sent to Multimatic in Coventry, England, where they will be mated to ONE’s chassis at the small, dedicated series production facility.

Mercedes-AMG ONE hand-built production passes 16 assembly and testing stations reminiscent of high-end luxury watch manufacture. Various components are first pre-assembled and tested before being stripped again and meticulously prepared for final installation.

ONE’s carbon-fiber monocoque and bonded roof, its individual body parts and entire outer skin are first to assembled with all fits meticulously adjusted to perfectly align.

Each ONE is Made to Exact Customer Needs

That process considers both final lacquering and the carbon-fiber components’ 1.2 millimeter gauge. Once positioned, the doors, hoods and panels are once again stripped and individually hand-painted to each owner’s particular taste. This also ensures a perfect color match across the entire vehicle. Then it’s time to mate the powertrain and the body-in-white.

Like Mercedes’ Formula 1 power units, ONE’s engine, four electric motors, their inverters, the high-voltage battery and each car’s power electronics arrive ready and bench tested to mount from Brixworth. Production continues with the assembly of essential powertrain components, mechanical and low-voltage components. High-voltage batteries and connections. The combustion engine is then fired up and it and the electric motors checked and tested.

Every Component is Meticulously Prepared

ONE then heads for the interior shop, before prepared body panels are fitted. The wheel shop includes headlamp alignment, before the all important dyno test on the rolling road. Noise, monsoon and final visual inspections follow. before roll-out concludes at a nearby proving ground. A factory driver then tests each car, before it is transported to AMG headquarters for handover.

“The Mercedes-AMG ONE is the most ambitious project we have ever undertaken,” AMG suit Philipp Schiemer explains. “It marks a high point in our strategic development towards an electrified Future of Driving Performance. Exclusive small series production is a truly unique challenge and ONE represents a proud world first for Mercedes-AMG in Affalterbach, the Formula 1 experts at Brixworth and our production partner Multimatic.

Photos: Mercdes-AMG