M271 Timing marks off TDC

#1

Newbie

Thread Starter

Join Date: Jun 2016

Location: Lewisville (DFW area), TX

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

2003 C230 Kompressor

M271 Timing marks off TDC

Hi all,

I was having a misfire on P4 and tried everything I saw on these sites to remedy it. Nothing worked, so I took the head off and had it resurfaced and a valve job too.

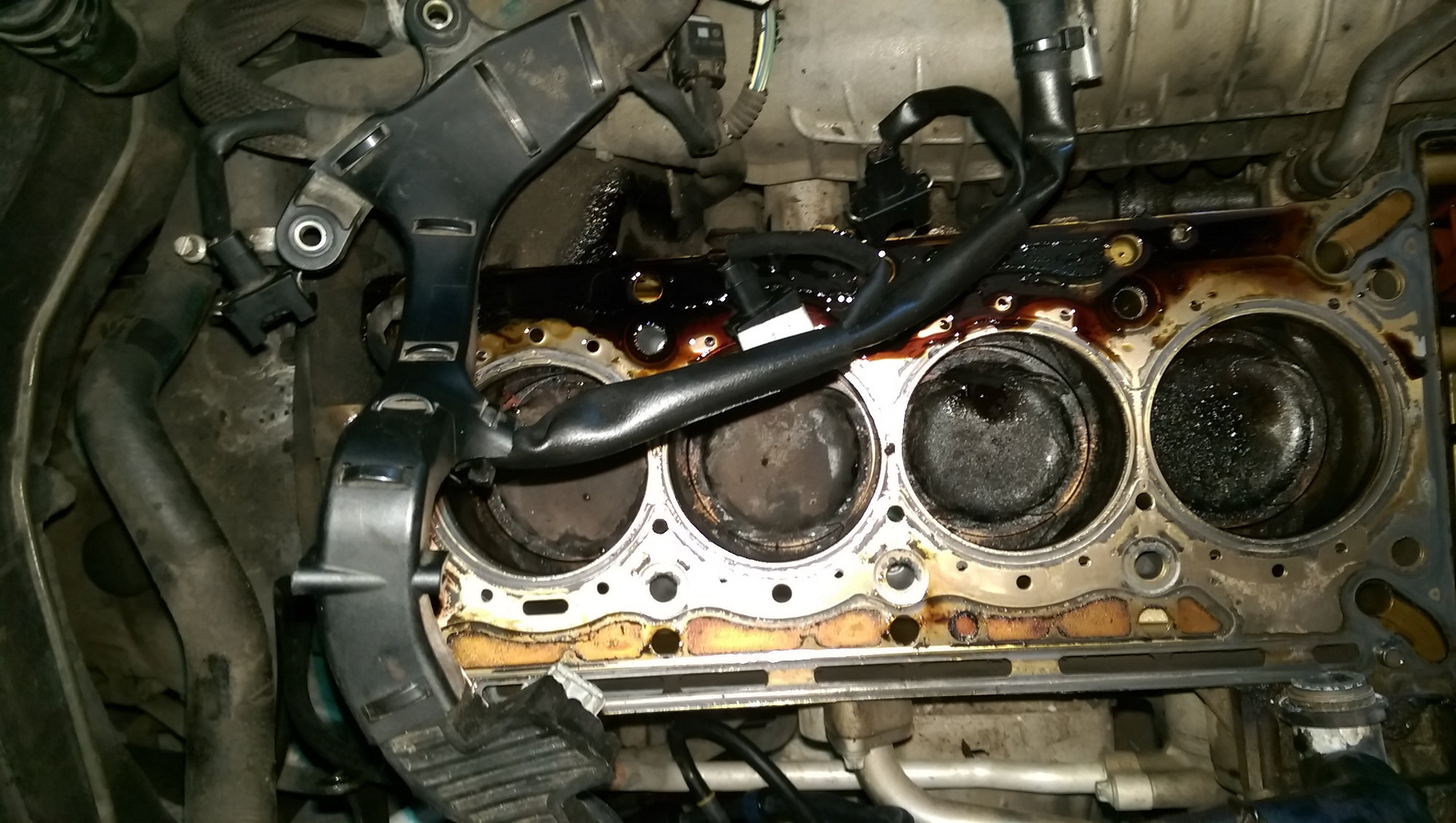

When I took the camshaft cover and shafts off, I set the harmonic balancer to TDC (0T). At that time I didn't check the piston to see it's position, but after taking the head off, all 4 pistons were at mid-stroke.

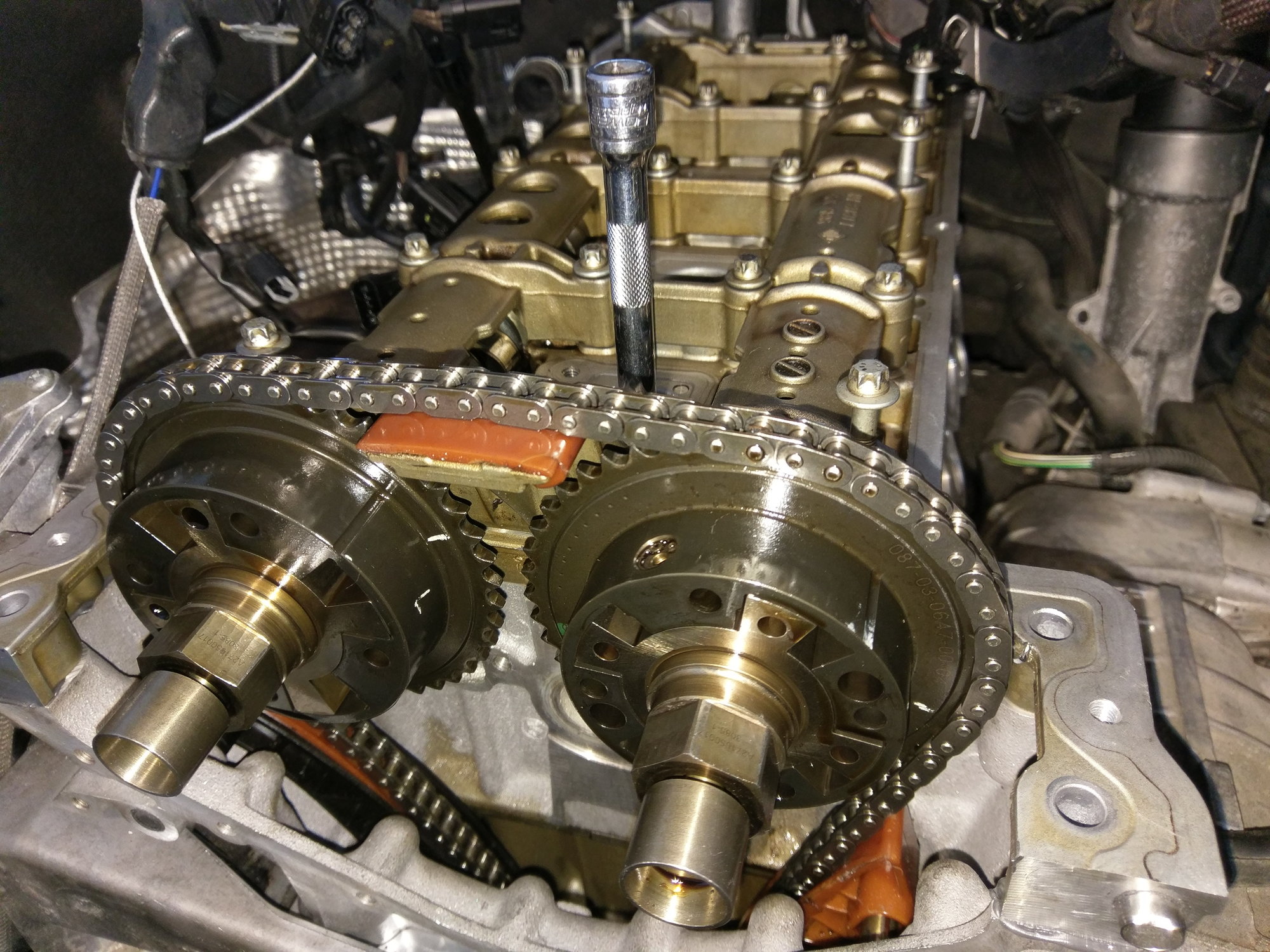

I'm reassembling everything and set the camshaft timing marks on the camshaft cover and camshaft adjusters so at TDC (0T), they match. Should be ok, right? I now find that when P1 is at the top of it's stroke, the marks are 45 degrees off, as seen in the picture. The harmonic balancer is also off 45 degrees. So I have no idea what the problem is.

I didn't mess with the crankshaft bolt while working on the engine, so I can't imagine anything slipped.

Can anyone give me an idea what is wrong, if anything? I appreciate any suggestions.

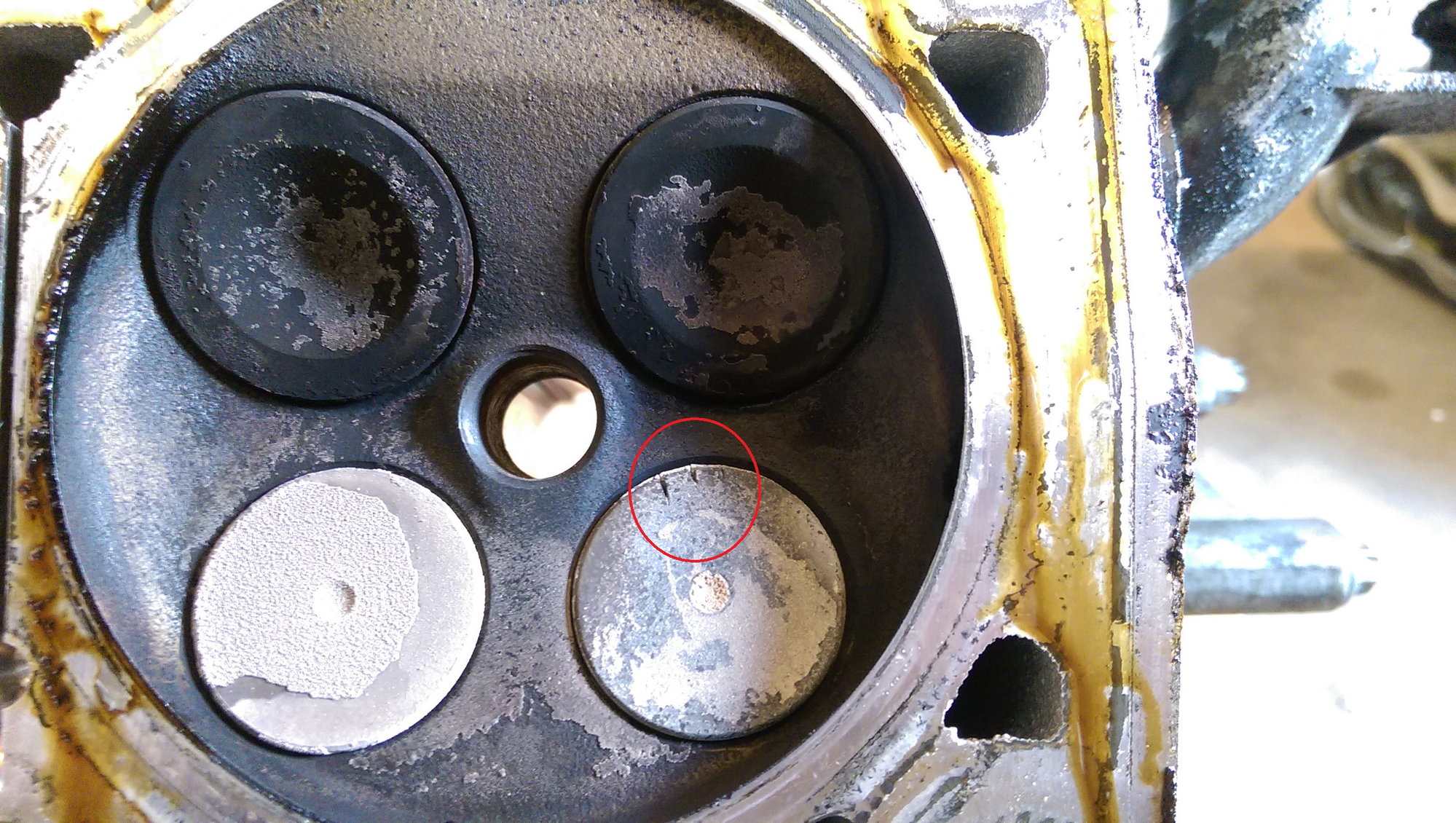

By the way, when the head shop took the valves off, the exhaust valve on P4 showed grooves in it, see picture and the piston heads had a lot of carbon buildup. I bought the used in 2011- it's a 2003.

#2

Super Member

Before you took the head off, you should've set the engine at TDC with the balancer at zero, and made sure everything was aligned correctly.

The engine is a 4-stroke engine. So, the valve train doesn't have a 1-to-1 movement with the crank.

Set the balancer at zero. The first piston should be at TDC. Set the camshafts at their marks.

Also, I hope you cleaned those pistons. #1 and #2 are very nasty. That ******* will do bad things to the piston rings, the block cylinder walls, the valves, the cats, etc.

Good Luck!

The engine is a 4-stroke engine. So, the valve train doesn't have a 1-to-1 movement with the crank.

Set the balancer at zero. The first piston should be at TDC. Set the camshafts at their marks.

Also, I hope you cleaned those pistons. #1 and #2 are very nasty. That ******* will do bad things to the piston rings, the block cylinder walls, the valves, the cats, etc.

Good Luck!

#3

Super Member

Oh yea, as an fyi, you must use new head bolts. The head bolts are torque to yield.

http://www.felpro-only.com/blog/prop...e-t-t-y-bolts/

http://www.acl.co.nz/wp-content/uplo...-Headbolts.pdf

http://www.felpro-only.com/blog/prop...e-t-t-y-bolts/

http://www.acl.co.nz/wp-content/uplo...-Headbolts.pdf

#4

Newbie

Thread Starter

Join Date: Jun 2016

Location: Lewisville (DFW area), TX

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

2003 C230 Kompressor

Thanks for your reply RedGray. I understand what you've said, but what I did before starting any work was to set the crankshaft/balancer at 0T. When I took the head off, the pistons were at mid-stroke, as you saw in the picture with the dirty heads. That's the way the car was driving and I had no problems other than the misfire on P4.

Now when I turn the crankshaft, it moves fine, except when P1 gets to either the top or bottom of stroke and then I have to use a lot of force to continue turning it.

Yes, I did clean all four heads- took a lot of elbow grease, but they look like new now. I also did use new head bolts when reassembling.

Now when I turn the crankshaft, it moves fine, except when P1 gets to either the top or bottom of stroke and then I have to use a lot of force to continue turning it.

Yes, I did clean all four heads- took a lot of elbow grease, but they look like new now. I also did use new head bolts when reassembling.

#5

Senior Member

There have been several instances posted on this forum where the timing scale on the crankshaft pulley has moved, just like yours. The solution is to buy a new one.

https://mbworld.org/forums/c-class-w...ings-help.html

https://mbworld.org/forums/c-class-w...ings-help.html

Last edited by alecmascot; 02-05-2017 at 03:32 PM. Reason: added a link

#6

Super Member

@alecmascot Thanks for finding that thread!

@hannajc111 That's what I thought you meant. But, I wanted to be sure.

But, I wanted to be sure.

As alecmascot posted, having balencers creep/move isn't anything new. It happens on many engines. It often happens after ~~20 years on many engines. It varies by engine, balencer, etc.

@hannajc111 That's what I thought you meant.

But, I wanted to be sure.

But, I wanted to be sure. As alecmascot posted, having balencers creep/move isn't anything new. It happens on many engines. It often happens after ~~20 years on many engines. It varies by engine, balencer, etc.

Trending Topics

#8

Super Member

Hmm, I'm now going to have to decide if I want to replace the balencer on my car. It's often not an immediate critical failure. But, I don't want it to slip even a little bit, and then cause more stress on the POS timing chain.

FYI:

http://www.pelicanparts.com/More_Inf...VSVSI=3528.htm

Crankshaft Pulley

Corteco is an OEM supplier to Mercedes-Benz.

Part #: 271-030-00-03-M270

$201.50

http://www.pelicanparts.com/More_Inf...VSVSI=3528.htm

OEM MB Crankshaft Pulley

Part #: 271-030-00-03-MBZ

$337.00

You can see where there is rubber between the inner and outer sections. That rubber going bad is what causes the outer section to slip.

FYI:

http://www.pelicanparts.com/More_Inf...VSVSI=3528.htm

Crankshaft Pulley

Corteco is an OEM supplier to Mercedes-Benz.

Part #: 271-030-00-03-M270

$201.50

http://www.pelicanparts.com/More_Inf...VSVSI=3528.htm

OEM MB Crankshaft Pulley

Part #: 271-030-00-03-MBZ

$337.00

You can see where there is rubber between the inner and outer sections. That rubber going bad is what causes the outer section to slip.

#9

Newbie

Thread Starter

Join Date: Jun 2016

Location: Lewisville (DFW area), TX

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

2003 C230 Kompressor

Ahhh, ok, now I understand better. I was wondering how something with a key shaft could slip. Thanks for the clarification.

#10

Senior Member

The fact that the outer part of the crank pulley has slipped, throwing off the timing scale makes no difference to the actual cam timing. The crank pulley just drives the ancillaries belt. You only reference the scale when checking the cam timing relative to the crank position. Any slippage on the pulley makes no difference to the operation of the engine.

#11

Super Member

Imho, anytime, someone sees something that costs more, weighs more, or is more complicated than simple/basic, they should ask WHY?

Also, the correct name of the part is a big clue - it's not "pulley" - it's "harmonic balancer".

Why would they make a two part "pulley" and put rubber in between?

The firmness of the rubber (durometer) and the outer section (mass) are there to reduce engine/crankshaft vibrations.

http://www.genuinemercedesparts.com/...per-2710300003

https://en.wikipedia.org/wiki/Harmonic_balancer

https://en.wikipedia.org/wiki/Shore_durometer

If/When the rubber starts to fail, then not only will the engine vibrations not be properly damped, also the incorrect damping of the harmonic balancer could lead to destructive resonances.

With the POS under-designed M271 timing chain, people are asking for the engine to turn into a "boat anchor" (only good for scrap) if they have a bad harmonic balancer.

What happens when mechanical oscillations are not properly damped:

Tacoma Narrows Bridge 1940

https://en.wikipedia.org/wiki/Tacoma_Narrows_Bridge_%281940%29

From the time the deck was built, it began to move vertically in windy conditions ... Several measures aimed at stopping the motion were ineffective, and the bridge's main span finally collapsed ...

Neat Movie of the bridge oscillations and then collapsing:

https://upload.wikimedia.org/wikiped...estruction.ogv

Btw, a quick talk about the above bridge, along with showing the movie, is done in just about every Freshman year for Mechanical Engineering students and most Engineering students.

.

#12

Newbie

Thread Starter

Join Date: Jun 2016

Location: Lewisville (DFW area), TX

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

2003 C230 Kompressor

Thanks for the very interesting lesson. I'm replacing the harmonic balancer, so I should be good to go. It seems like they could come up with a better solution than something that is so important to the operation of the engine and yet is a common problem.

#13

MBWorld Fanatic!

Join Date: Dec 2003

Location: Vancouver, BC, Canada

Posts: 3,131

Likes: 0

Received 214 Likes

on

204 Posts

2003 C230K Coupe Orion Blue

RedGrey, thanks for posting. For balancing purposes I always thought of crankcase flex as a result of horizontal/vertical displacement, but never thought of harmonics from a torsional standpoint. Learned something new. Always thought it was strange why they would use something "weak" like a rubber ring on that harmonic balancer. This explains a lot.

The Tacoma Narrows video is classic. Definitely remember seeing it in high school physics class.

The Tacoma Narrows video is classic. Definitely remember seeing it in high school physics class.