M273 unstable idling performance

#26

this is an article that was written for bikes, but the control is the same - this just explains how you make it safe to ride a bike

Petrol Engine "Lambda, fueling and AF-XIED for Dummies" by knutk on ukgser's site, with minor tweaks by me

Emission regulations require engines to limit pollution. It's a fairly complex picture, but let's focus on the subject that annoys us, the fueling of the engine, or rather, a lack of fuel it needs to run well.

Background: Lambda vs AFR (air fuel ratio)

In an ideal world, perfect combustion for an engine is when every drop of gasoline finds an oxygen molecule to bond with, so when the mixture is ignited, every drop of gasoline burns, with no excess.

To understand how well the vehicle is coping (with the fueling its receiving from the various parameters its measuring, mapped to a list of what to inject under which conditions), it analyses the combustion. To do this the manufacturer installs an O2 sensor in the exhaust system. The O2 sensor reacts to the amount of vacant (unused) oxygen molecules. And when there's no remaining oxygen in the exhaust, this condition is defined as Lambda 1.0. For a gasoline engine, Lambda 1.0 will be reached when the AFR is at the stoichiometric 14.7:1, i.e 14.7g of air to 1g of gasoline.

So why mess with Lambda, rather than the AFR?

The O2 sensor is searching for excessive oxygen. Different types of gasoline (with ethanol etc) may offer different AFRs. However, regardless of what type of gasoline the engine is burning Lambda 1 will ALWAYS be the condition where all the oxygen is used up.

To reduce confusion, we'll stick to common gasoline offering an AFR of 14.7 for Lambda 1, and debate how a Narrow band (NB) O2 sensor works in BMW boxer engines up to the introduction of the 1250 shiftcam engine - (which uses a different sensor type.)

The Picture below is borrowed from NightRider who produce the AF-XIED. Its showing the output of a Narrow Band sensor when warm, where the O2 sensors emit voltage in accordance with this chart below.

The scales of AFR are adjusted to reflect gasoline that produces Lambda 1 at an AFR of 14.7, and the picture shows the varying O2 sensor voltage outputs when subjected to differing AFR values. The three different coloured curves show the voltage output also changes with temperature. Noting, when you look along the 0.5V line, all three curves deliver the same voltage around an AFR of 14.6 - 14.8.

The ECU uses this O2 sensor feedback to know if the engine is running too lean or too rich. Whilst expecting the standard engine map and its long term adaptions to land a voltage from the sensor around 0.5V / 0.6V (AFR 14.7). With a 0.8V output, the AFR is down to 14.2-ish. and from there on, the voltage reading vs AFR become less accurate. However the ECU isn't interested in the voltage and doesn't care if its above or below 0.5V. The ECU only sees richer than or leaner than the AFR 14.7 target (even when the voltage output slightly varies with AFR in a highly non-linear manner).

When running, the amount of fuel injected is calculated from tables inside the ECU (called maps, hence remapping means changing the value in these tables). The tables offer information on how long (time in milliseconds ) the injectors are to be opened, depending on RPM, throttle position etc. There are actually several maps, but for simplicity lets just say there are preinstalled maps.

So fuel is delivered according to the maps. However, in order to fine tune the fueling, the O2 sensor offers feedback on the combustion. These small adjustments, called for by the O2 sensor, are called Short Term Trim, and it is basically a number that adds or subtracts to whatever time value is being used opening the injectors.

But keep in mind, the exhaust reflects the result after the combustion, i.e the O2 sensor will not tell ECU what to do. It tells the ECU how it did. Let's say the air filter is clogging up, restricting the airflow to the cylinder. Now, the pre-determined values from the maps will give the engine too much fuel, since the engine gets less air than expected. And the O2 sensor will tell the engine that the fueling is too rich, thus it needs to trim down on the amount of fuel. In a steady condition, this will work pretty well, but it will always need a couple of strokes of the piston in order to first analyse, and then inform if too lean or rich in a continuous process on and on.

Now if its always getting things wrong and having to try and react, that's pretty stupid. So in comes the Long term trim (adaptions): At every condition (rpm vs throttle position) required Short term trim changes get saved in small steps to improve the starting point long term. So, if a given condition consistently calls for adjustment, its gets stored in the Long Term Trim table. This table thus becomes an element of the equation the ECU utilises alongside its other maps (cold temp, altitude variations, pressures, fuel quality etc.) of how best to provide its perception of the correct fueling for a given condition. BMW calls this Long Term Trim the Adaptive map. Its the map that gets zeroed out whenever BMW talks about restoring the adaptive values (wiping the adaptions), and will take around 250 miles before its close to optimal again.

So, what does the AF-XIED do, and how?

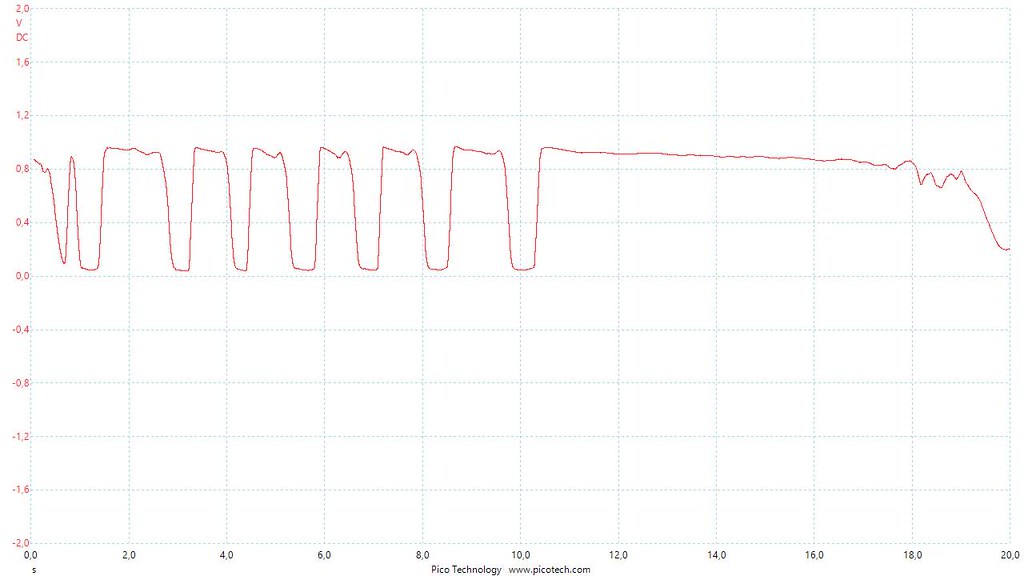

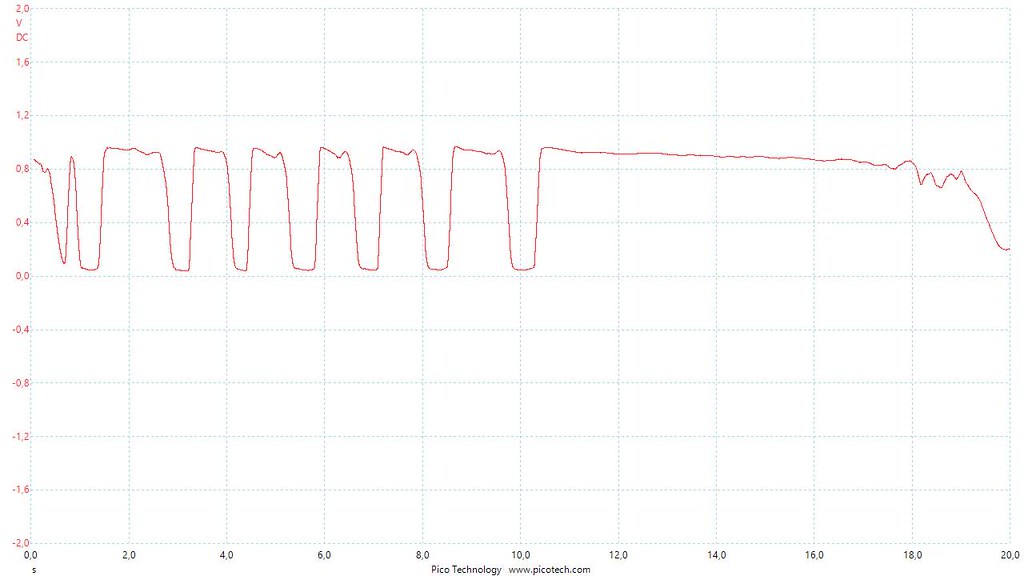

If we take a look at the curve below, the curve shows the voltage from a warm O2 sensor, and this is what the ECU receives. (Data from a -15 LC boxer) with time in seconds along the bottom

Up to 10 seconds, the engine is running on a steady throttle. After 10 seconds the engine is accelerating.

In the first 10 seconds, the voltage from O2 sensor flickers between 0.1V and up to 0.9V. When the voltage is < 0.5 V the ecu notices its 'Lean' and it will add a small amount of fuel. Then it keeps adding fuel until the O2 voltage reads >0.5V. Now it's too rich, so reduce the fueling. This is done by correcting the short term trim.

At the 10 second time mark, the throttle is opened up. Now we see that the voltage jumps up to a steady 0.9V. Refer to the table above of O2 sensor voltage output vs AFR. The green curve reflects the 1200F temp of the O2 sensor, a fairly common condition, i.e when adding throttle, the AFR is richened to 13.6.

What is the big deal about 13.6? Well, the world is not perfect, hence in order to utilise all the oxygen molecules, we actually need to throw in some extra fuel for good measure. Practical tests have shown that adding a bit more fuel will make sure all the O2 molecules get their share of gas, and more molecules with fuel + O2 mixed means a more powerful burn during combustion, i.e more power

Any tuning of the engine that only involves controlling the fuel to air mixture will offer very little additional top end power, as the ECU OEM fueling already offers the added "overfueling" at full throttle (as full throttle has never been the focus of emission control, even if that may change in the future). Tuning that's altering the manufacturer AFR, will be a benefit when the throttle isn't fully open. As in the condition in the first ten seconds of the chart above. And generally, when the throttle is opened up in the higher range (the limit varies depending of the type of engine).

Here is where the AF-XIED shines:

Have a look at the chart below. It shows what the AF-XIED at setting 8 does to the engine.

Red curve is the voltage from the O2 sensor and now being analyzed by the AF-XIED, the blue curve shows the voltage produced by the AF-XIED and transmitted to the engine.

The Voltage from the O2 sensor (the red line) is read by the AF-XIED, and it stops this data reaching the BMW ECU. Instead the AF-XIED analyse the voltage creating the blue curve, and transmits this to the ECU. The ECU has no knowledge about the fitment of the AF-XIED, and behaves as if its the direct feedback from the O2 sensor.

Remember: High voltage = Rich. Low Voltage = Lean.

If we amplify the red curve, we will notice that every time the red curve drops below a straight line, the AF-XIED signals a low voltage to the ECU (And Low voltage = Lean condition). The ECU gets a Lean condition signal and reacts to it by richening the fuel. However we don't want the fuel to go excessively rich, so when the red curve rises slightly above the straight line (hence going too rich), it's time to stop the ECU richening the fuel mix. And this is done by the AF-XIED increasing the voltage emulating the O2 sensor, where the AF-XIED voltage output follows the actual O2 sensor voltage and sends this to the ECU. The ECU will then react to this richer than 0.5 V condition by once again starting to lean the mix, and on and on....

As the AF-XIED tweaks can create over fueling when set up wrongly, it worth understanding how CATs operate.

The OEM variation between lean and rich being so slow actually does not reflect the Bosch ECU's ability for accurate control. Rather its a deliberate need to feed the CAT with oxygen (as CATs use oxygen to convert CO to CO2). This oxygen is delivered to the CAT through the exhaust gases and its controlled to produce periods with excessive O2 in order to feed the CAT. Hence the slow reaction time is to allow for periods with high levels of oxygen. So you should set the AF-XIED to a value rich enough for smooth running, and no more. It's why they recommend going from a low value and slowly increasing richness during set up, one step at a time. And the point of allowing time (100 miles or more) between each change, is that its allowing the ECU to rebuild the Long Term Trim each time the setting has been changed. Note: these only save to the ECUs adaptions if the key is off for 10 seconds (and I believe after reaching operating temperature and its been run through all gears).

.

Petrol Engine "Lambda, fueling and AF-XIED for Dummies" by knutk on ukgser's site, with minor tweaks by me

Emission regulations require engines to limit pollution. It's a fairly complex picture, but let's focus on the subject that annoys us, the fueling of the engine, or rather, a lack of fuel it needs to run well.

Background: Lambda vs AFR (air fuel ratio)

In an ideal world, perfect combustion for an engine is when every drop of gasoline finds an oxygen molecule to bond with, so when the mixture is ignited, every drop of gasoline burns, with no excess.

To understand how well the vehicle is coping (with the fueling its receiving from the various parameters its measuring, mapped to a list of what to inject under which conditions), it analyses the combustion. To do this the manufacturer installs an O2 sensor in the exhaust system. The O2 sensor reacts to the amount of vacant (unused) oxygen molecules. And when there's no remaining oxygen in the exhaust, this condition is defined as Lambda 1.0. For a gasoline engine, Lambda 1.0 will be reached when the AFR is at the stoichiometric 14.7:1, i.e 14.7g of air to 1g of gasoline.

So why mess with Lambda, rather than the AFR?

The O2 sensor is searching for excessive oxygen. Different types of gasoline (with ethanol etc) may offer different AFRs. However, regardless of what type of gasoline the engine is burning Lambda 1 will ALWAYS be the condition where all the oxygen is used up.

To reduce confusion, we'll stick to common gasoline offering an AFR of 14.7 for Lambda 1, and debate how a Narrow band (NB) O2 sensor works in BMW boxer engines up to the introduction of the 1250 shiftcam engine - (which uses a different sensor type.)

The Picture below is borrowed from NightRider who produce the AF-XIED. Its showing the output of a Narrow Band sensor when warm, where the O2 sensors emit voltage in accordance with this chart below.

The scales of AFR are adjusted to reflect gasoline that produces Lambda 1 at an AFR of 14.7, and the picture shows the varying O2 sensor voltage outputs when subjected to differing AFR values. The three different coloured curves show the voltage output also changes with temperature. Noting, when you look along the 0.5V line, all three curves deliver the same voltage around an AFR of 14.6 - 14.8.

The ECU uses this O2 sensor feedback to know if the engine is running too lean or too rich. Whilst expecting the standard engine map and its long term adaptions to land a voltage from the sensor around 0.5V / 0.6V (AFR 14.7). With a 0.8V output, the AFR is down to 14.2-ish. and from there on, the voltage reading vs AFR become less accurate. However the ECU isn't interested in the voltage and doesn't care if its above or below 0.5V. The ECU only sees richer than or leaner than the AFR 14.7 target (even when the voltage output slightly varies with AFR in a highly non-linear manner).

When running, the amount of fuel injected is calculated from tables inside the ECU (called maps, hence remapping means changing the value in these tables). The tables offer information on how long (time in milliseconds ) the injectors are to be opened, depending on RPM, throttle position etc. There are actually several maps, but for simplicity lets just say there are preinstalled maps.

So fuel is delivered according to the maps. However, in order to fine tune the fueling, the O2 sensor offers feedback on the combustion. These small adjustments, called for by the O2 sensor, are called Short Term Trim, and it is basically a number that adds or subtracts to whatever time value is being used opening the injectors.

But keep in mind, the exhaust reflects the result after the combustion, i.e the O2 sensor will not tell ECU what to do. It tells the ECU how it did. Let's say the air filter is clogging up, restricting the airflow to the cylinder. Now, the pre-determined values from the maps will give the engine too much fuel, since the engine gets less air than expected. And the O2 sensor will tell the engine that the fueling is too rich, thus it needs to trim down on the amount of fuel. In a steady condition, this will work pretty well, but it will always need a couple of strokes of the piston in order to first analyse, and then inform if too lean or rich in a continuous process on and on.

Now if its always getting things wrong and having to try and react, that's pretty stupid. So in comes the Long term trim (adaptions): At every condition (rpm vs throttle position) required Short term trim changes get saved in small steps to improve the starting point long term. So, if a given condition consistently calls for adjustment, its gets stored in the Long Term Trim table. This table thus becomes an element of the equation the ECU utilises alongside its other maps (cold temp, altitude variations, pressures, fuel quality etc.) of how best to provide its perception of the correct fueling for a given condition. BMW calls this Long Term Trim the Adaptive map. Its the map that gets zeroed out whenever BMW talks about restoring the adaptive values (wiping the adaptions), and will take around 250 miles before its close to optimal again.

So, what does the AF-XIED do, and how?

If we take a look at the curve below, the curve shows the voltage from a warm O2 sensor, and this is what the ECU receives. (Data from a -15 LC boxer) with time in seconds along the bottom

Up to 10 seconds, the engine is running on a steady throttle. After 10 seconds the engine is accelerating.

In the first 10 seconds, the voltage from O2 sensor flickers between 0.1V and up to 0.9V. When the voltage is < 0.5 V the ecu notices its 'Lean' and it will add a small amount of fuel. Then it keeps adding fuel until the O2 voltage reads >0.5V. Now it's too rich, so reduce the fueling. This is done by correcting the short term trim.

At the 10 second time mark, the throttle is opened up. Now we see that the voltage jumps up to a steady 0.9V. Refer to the table above of O2 sensor voltage output vs AFR. The green curve reflects the 1200F temp of the O2 sensor, a fairly common condition, i.e when adding throttle, the AFR is richened to 13.6.

What is the big deal about 13.6? Well, the world is not perfect, hence in order to utilise all the oxygen molecules, we actually need to throw in some extra fuel for good measure. Practical tests have shown that adding a bit more fuel will make sure all the O2 molecules get their share of gas, and more molecules with fuel + O2 mixed means a more powerful burn during combustion, i.e more power

Any tuning of the engine that only involves controlling the fuel to air mixture will offer very little additional top end power, as the ECU OEM fueling already offers the added "overfueling" at full throttle (as full throttle has never been the focus of emission control, even if that may change in the future). Tuning that's altering the manufacturer AFR, will be a benefit when the throttle isn't fully open. As in the condition in the first ten seconds of the chart above. And generally, when the throttle is opened up in the higher range (the limit varies depending of the type of engine).

Here is where the AF-XIED shines:

Have a look at the chart below. It shows what the AF-XIED at setting 8 does to the engine.

Red curve is the voltage from the O2 sensor and now being analyzed by the AF-XIED, the blue curve shows the voltage produced by the AF-XIED and transmitted to the engine.

The Voltage from the O2 sensor (the red line) is read by the AF-XIED, and it stops this data reaching the BMW ECU. Instead the AF-XIED analyse the voltage creating the blue curve, and transmits this to the ECU. The ECU has no knowledge about the fitment of the AF-XIED, and behaves as if its the direct feedback from the O2 sensor.

Remember: High voltage = Rich. Low Voltage = Lean.

If we amplify the red curve, we will notice that every time the red curve drops below a straight line, the AF-XIED signals a low voltage to the ECU (And Low voltage = Lean condition). The ECU gets a Lean condition signal and reacts to it by richening the fuel. However we don't want the fuel to go excessively rich, so when the red curve rises slightly above the straight line (hence going too rich), it's time to stop the ECU richening the fuel mix. And this is done by the AF-XIED increasing the voltage emulating the O2 sensor, where the AF-XIED voltage output follows the actual O2 sensor voltage and sends this to the ECU. The ECU will then react to this richer than 0.5 V condition by once again starting to lean the mix, and on and on....

As the AF-XIED tweaks can create over fueling when set up wrongly, it worth understanding how CATs operate.

The OEM variation between lean and rich being so slow actually does not reflect the Bosch ECU's ability for accurate control. Rather its a deliberate need to feed the CAT with oxygen (as CATs use oxygen to convert CO to CO2). This oxygen is delivered to the CAT through the exhaust gases and its controlled to produce periods with excessive O2 in order to feed the CAT. Hence the slow reaction time is to allow for periods with high levels of oxygen. So you should set the AF-XIED to a value rich enough for smooth running, and no more. It's why they recommend going from a low value and slowly increasing richness during set up, one step at a time. And the point of allowing time (100 miles or more) between each change, is that its allowing the ECU to rebuild the Long Term Trim each time the setting has been changed. Note: these only save to the ECUs adaptions if the key is off for 10 seconds (and I believe after reaching operating temperature and its been run through all gears).

.

Last edited by BOTUS; 09-13-2023 at 01:11 PM.

#27

Junior Member

Thread Starter

this is an article was written for bikes, but the control is the same - this just explains how you make it safe to ride a bike

Petrol Engine "Lambda, fueling and AF-XIED for Dummies" by knutk on ukgser's site, with minor tweaks by me

Emission regulations require engines to limit pollution. It's a fairly complex picture, but let's focus on the subject that annoys us, the fueling of the engine, or rather, a lack of fuel it needs to run well.

Background: Lambda vs AFR (air fuel ratio)

In an ideal world, perfect combustion for an engine is when every drop of gasoline finds an oxygen molecule to bond with, so when the mixture is ignited, every drop of gasoline burns, with no excess.

To understand how well the vehicle is coping (with the fueling its receiving from the various parameters its measuring, mapped to a list of what to inject under which conditions), it analyses the combustion. To do this the manufacturer installs an O2 sensor in the exhaust system. The O2 sensor reacts to the amount of vacant (unused) oxygen molecules. And when there's no remaining oxygen in the exhaust, this condition is defined as Lambda 1.0. For a gasoline engine, Lambda 1.0 will be reached when the AFR is at the stoichiometric 14.7:1, i.e 14.7g of air to 1g of gasoline.

So why mess with Lambda, rather than the AFR?

The O2 sensor is searching for excessive oxygen. Different types of gasoline (with ethanol etc) may offer different AFRs. However, regardless of what type of gasoline the engine is burning Lambda 1 will ALWAYS be the condition where all the oxygen is used up.

To reduce confusion, we'll stick to common gasoline offering an AFR of 14.7 for Lambda 1, and debate how a Narrow band (NB) O2 sensor works in BMW boxer engines up to the introduction of the 1250 shiftcam engine - (which uses a different sensor type.)

The Picture below is borrowed from NightRider who produce the AF-XIED. Its showing the output of a Narrow Band sensor when warm, where the O2 sensors emit voltage in accordance with this chart below.

The scales of AFR are adjusted to reflect gasoline that produces Lambda 1 at an AFR of 14.7, and the picture shows the varying O2 sensor voltage outputs when subjected to differing AFR values. The three different coloured curves show the voltage output also changes with temperature. Noting, when you look along the 0.5V line, all three curves deliver the same voltage around an AFR of 14.6 - 14.8.

The ECU uses this O2 sensor feedback to know if the engine is running too lean or too rich. Whilst expecting the standard engine map and its long term adaptions to land a voltage from the sensor around 0.5V / 0.6V (AFR 14.7). With a 0.8V output, the AFR is down to 14.2-ish. and from there on, the voltage reading vs AFR become less accurate. However the ECU isn't interested in the voltage and doesn't care if its above or below 0.5V. The ECU only sees richer than or leaner than the AFR 14.7 target (even when the voltage output slightly varies with AFR in a highly non-linear manner).

When running, the amount of fuel injected is calculated from tables inside the ECU (called maps, hence remapping means changing the value in these tables). The tables offer information on how long (time in milliseconds ) the injectors are to be opened, depending on RPM, throttle position etc. There are actually several maps, but for simplicity lets just say there are preinstalled maps.

So fuel is delivered according to the maps. However, in order to fine tune the fueling, the O2 sensor offers feedback on the combustion. These small adjustments, called for by the O2 sensor, are called Short Term Trim, and it is basically a number that adds or subtracts to whatever time value is being used opening the injectors.

But keep in mind, the exhaust reflects the result after the combustion, i.e the O2 sensor will not tell ECU what to do. It tells the ECU how it did. Let's say the air filter is clogging up, restricting the airflow to the cylinder. Now, the pre-determined values from the maps will give the engine too much fuel, since the engine gets less air than expected. And the O2 sensor will tell the engine that the fueling is too rich, thus it needs to trim down on the amount of fuel. In a steady condition, this will work pretty well, but it will always need a couple of strokes of the piston in order to first analyse, and then inform if too lean or rich in a continuous process on and on.

Now if its always getting things wrong and having to try and react, that's pretty stupid. So in comes the Long term trim (adaptions): At every condition (rpm vs throttle position) required Short term trim changes get saved in small steps to improve the starting point long term. So, if a given condition consistently calls for adjustment, its gets stored in the Long Term Trim table. This table thus becomes an element of the equation the ECU utilises alongside its other maps (cold temp, altitude variations, pressures, fuel quality etc.) of how best to provide its perception of the correct fueling for a given condition. BMW calls this Long Term Trim the Adaptive map. Its the map that gets zeroed out whenever BMW talks about restoring the adaptive values (wiping the adaptions), and will take around 250 miles before its close to optimal again.

So, what does the AF-XIED do, and how?

If we take a look at the curve below, the curve shows the voltage from a warm O2 sensor, and this is what the ECU receives. (Data from a -15 LC boxer) with time in seconds along the bottom

Up to 10 seconds, the engine is running on a steady throttle. After 10 seconds the engine is accelerating.

In the first 10 seconds, the voltage from O2 sensor flickers between 0.1V and up to 0.9V. When the voltage is < 0.5 V the ecu notices its 'Lean' and it will add a small amount of fuel. Then it keeps adding fuel until the O2 voltage reads >0.5V. Now it's too rich, so reduce the fueling. This is done by correcting the short term trim.

At the 10 second time mark, the throttle is opened up. Now we see that the voltage jumps up to a steady 0.9V. Refer the table of O2 sensor voltage output vs AFR. The green curve reflects the 1200F temp of the O2 sensor, a fairly common condition, i.e when adding throttle, the AFR is richened to 13.6.

What is the big deal about 13.6? Well, the world is not perfect, hence in order to utilise all the oxygen molecules, we actually need to throw in some extra fuel for good measure. Practical tests have shown that adding a bit more fuel will make sure all the O2 molecules get their share of gas, and more molecules with fuel + O2 mixed means a more powerful burn during combustion, i.e more power

Any tuning of the engine that only involves controlling the fuel to air mixture will offer very little additional top end power, as the ECU OEM fueling already offers the added "overfueling" at full throttle (as full throttle has never been the focus of emission control, even if that may change in the future). Tuning that's altering the manufacturer AFR, will be a benefit when the throttle isn't fully open. As in the condition in the first ten seconds of the chart above. And generally, when the throttle is opened up in the higher range (the limit varies depending of the type of engine).

Here is where the AF-XIED shines:

Have a look at the chart below. It shows what the AF-XIED at setting 8 does to the engine.

Red curve is the voltage from the O2 sensor and now being analyzed by the AF-XIED, the blue curve shows the voltage produced by the AF-XIED and transmitted to the engine.

The Voltage from the O2 sensor (the red line) is read by the AF-XIED, and it stops this data reaching the BMW ECU. Instead the AF-XIED analyse the voltage creating the blue curve, and transmits this to the ECU. The ECU has no knowledge about the fitment of the AF-XIED, and behaves as if its the direct feedback from the O2 sensor.

Remember: High voltage = Rich. Low Voltage = Lean.

If we amplify the red curve, we will notice that every time the red curve drops below a straight line, the AF-XIED signals a low voltage to the ECU (And Low voltage = Lean condition). The ECU gets a Lean condition signal and reacts to it by richening the fuel. However we don't want the fuel to go excessively rich, so when the red curve rises slightly above the straight line (hence going too rich), it's time to stop the ECU richening the fuel mix. And this is done by the AF-XIED increasing the voltage emulating the O2 sensor, where the AF-XIED voltage output follows the actual O2 sensor voltage and sends this to the ECU. The ECU will then react to this richer than 0.5 V condition by once again starting to lean the mix, and on and on....

As the AF-XIED tweaks can create over fueling when set up wrongly, it worth understanding how CATs operate.

The OEM variation between lean and rich being so slow actually does not reflect the Bosch ECU's ability for accurate control. Rather its a deliberate need to feed the CAT with oxygen (as CATs use oxygen to convert CO to CO2). This oxygen is delivered to the CAT through the exhaust gases and its controlled to produce periods with excessive O2 in order to feed the CAT. Hence the slow reaction time is to allow for periods with high levels of oxygen. So you should set the AF-XIED to a value rich enough for smooth running, and no more. It's why they recommend going from a low value and slowly increasing richness during set up, one step at a time. And the point of allowing time (100 miles or more) between each change, is that its allowing the ECU to rebuild the Long Term Trim each time the setting has been changed. Note: these only save to the ECUs adaptions if the key is off for 10 seconds (and I believe after reaching operating temperature and its been run through all gears).

Petrol Engine "Lambda, fueling and AF-XIED for Dummies" by knutk on ukgser's site, with minor tweaks by me

Emission regulations require engines to limit pollution. It's a fairly complex picture, but let's focus on the subject that annoys us, the fueling of the engine, or rather, a lack of fuel it needs to run well.

Background: Lambda vs AFR (air fuel ratio)

In an ideal world, perfect combustion for an engine is when every drop of gasoline finds an oxygen molecule to bond with, so when the mixture is ignited, every drop of gasoline burns, with no excess.

To understand how well the vehicle is coping (with the fueling its receiving from the various parameters its measuring, mapped to a list of what to inject under which conditions), it analyses the combustion. To do this the manufacturer installs an O2 sensor in the exhaust system. The O2 sensor reacts to the amount of vacant (unused) oxygen molecules. And when there's no remaining oxygen in the exhaust, this condition is defined as Lambda 1.0. For a gasoline engine, Lambda 1.0 will be reached when the AFR is at the stoichiometric 14.7:1, i.e 14.7g of air to 1g of gasoline.

So why mess with Lambda, rather than the AFR?

The O2 sensor is searching for excessive oxygen. Different types of gasoline (with ethanol etc) may offer different AFRs. However, regardless of what type of gasoline the engine is burning Lambda 1 will ALWAYS be the condition where all the oxygen is used up.

To reduce confusion, we'll stick to common gasoline offering an AFR of 14.7 for Lambda 1, and debate how a Narrow band (NB) O2 sensor works in BMW boxer engines up to the introduction of the 1250 shiftcam engine - (which uses a different sensor type.)

The Picture below is borrowed from NightRider who produce the AF-XIED. Its showing the output of a Narrow Band sensor when warm, where the O2 sensors emit voltage in accordance with this chart below.

The scales of AFR are adjusted to reflect gasoline that produces Lambda 1 at an AFR of 14.7, and the picture shows the varying O2 sensor voltage outputs when subjected to differing AFR values. The three different coloured curves show the voltage output also changes with temperature. Noting, when you look along the 0.5V line, all three curves deliver the same voltage around an AFR of 14.6 - 14.8.

The ECU uses this O2 sensor feedback to know if the engine is running too lean or too rich. Whilst expecting the standard engine map and its long term adaptions to land a voltage from the sensor around 0.5V / 0.6V (AFR 14.7). With a 0.8V output, the AFR is down to 14.2-ish. and from there on, the voltage reading vs AFR become less accurate. However the ECU isn't interested in the voltage and doesn't care if its above or below 0.5V. The ECU only sees richer than or leaner than the AFR 14.7 target (even when the voltage output slightly varies with AFR in a highly non-linear manner).

When running, the amount of fuel injected is calculated from tables inside the ECU (called maps, hence remapping means changing the value in these tables). The tables offer information on how long (time in milliseconds ) the injectors are to be opened, depending on RPM, throttle position etc. There are actually several maps, but for simplicity lets just say there are preinstalled maps.

So fuel is delivered according to the maps. However, in order to fine tune the fueling, the O2 sensor offers feedback on the combustion. These small adjustments, called for by the O2 sensor, are called Short Term Trim, and it is basically a number that adds or subtracts to whatever time value is being used opening the injectors.

But keep in mind, the exhaust reflects the result after the combustion, i.e the O2 sensor will not tell ECU what to do. It tells the ECU how it did. Let's say the air filter is clogging up, restricting the airflow to the cylinder. Now, the pre-determined values from the maps will give the engine too much fuel, since the engine gets less air than expected. And the O2 sensor will tell the engine that the fueling is too rich, thus it needs to trim down on the amount of fuel. In a steady condition, this will work pretty well, but it will always need a couple of strokes of the piston in order to first analyse, and then inform if too lean or rich in a continuous process on and on.

Now if its always getting things wrong and having to try and react, that's pretty stupid. So in comes the Long term trim (adaptions): At every condition (rpm vs throttle position) required Short term trim changes get saved in small steps to improve the starting point long term. So, if a given condition consistently calls for adjustment, its gets stored in the Long Term Trim table. This table thus becomes an element of the equation the ECU utilises alongside its other maps (cold temp, altitude variations, pressures, fuel quality etc.) of how best to provide its perception of the correct fueling for a given condition. BMW calls this Long Term Trim the Adaptive map. Its the map that gets zeroed out whenever BMW talks about restoring the adaptive values (wiping the adaptions), and will take around 250 miles before its close to optimal again.

So, what does the AF-XIED do, and how?

If we take a look at the curve below, the curve shows the voltage from a warm O2 sensor, and this is what the ECU receives. (Data from a -15 LC boxer) with time in seconds along the bottom

Up to 10 seconds, the engine is running on a steady throttle. After 10 seconds the engine is accelerating.

In the first 10 seconds, the voltage from O2 sensor flickers between 0.1V and up to 0.9V. When the voltage is < 0.5 V the ecu notices its 'Lean' and it will add a small amount of fuel. Then it keeps adding fuel until the O2 voltage reads >0.5V. Now it's too rich, so reduce the fueling. This is done by correcting the short term trim.

At the 10 second time mark, the throttle is opened up. Now we see that the voltage jumps up to a steady 0.9V. Refer the table of O2 sensor voltage output vs AFR. The green curve reflects the 1200F temp of the O2 sensor, a fairly common condition, i.e when adding throttle, the AFR is richened to 13.6.

What is the big deal about 13.6? Well, the world is not perfect, hence in order to utilise all the oxygen molecules, we actually need to throw in some extra fuel for good measure. Practical tests have shown that adding a bit more fuel will make sure all the O2 molecules get their share of gas, and more molecules with fuel + O2 mixed means a more powerful burn during combustion, i.e more power

Any tuning of the engine that only involves controlling the fuel to air mixture will offer very little additional top end power, as the ECU OEM fueling already offers the added "overfueling" at full throttle (as full throttle has never been the focus of emission control, even if that may change in the future). Tuning that's altering the manufacturer AFR, will be a benefit when the throttle isn't fully open. As in the condition in the first ten seconds of the chart above. And generally, when the throttle is opened up in the higher range (the limit varies depending of the type of engine).

Here is where the AF-XIED shines:

Have a look at the chart below. It shows what the AF-XIED at setting 8 does to the engine.

Red curve is the voltage from the O2 sensor and now being analyzed by the AF-XIED, the blue curve shows the voltage produced by the AF-XIED and transmitted to the engine.

The Voltage from the O2 sensor (the red line) is read by the AF-XIED, and it stops this data reaching the BMW ECU. Instead the AF-XIED analyse the voltage creating the blue curve, and transmits this to the ECU. The ECU has no knowledge about the fitment of the AF-XIED, and behaves as if its the direct feedback from the O2 sensor.

Remember: High voltage = Rich. Low Voltage = Lean.

If we amplify the red curve, we will notice that every time the red curve drops below a straight line, the AF-XIED signals a low voltage to the ECU (And Low voltage = Lean condition). The ECU gets a Lean condition signal and reacts to it by richening the fuel. However we don't want the fuel to go excessively rich, so when the red curve rises slightly above the straight line (hence going too rich), it's time to stop the ECU richening the fuel mix. And this is done by the AF-XIED increasing the voltage emulating the O2 sensor, where the AF-XIED voltage output follows the actual O2 sensor voltage and sends this to the ECU. The ECU will then react to this richer than 0.5 V condition by once again starting to lean the mix, and on and on....

As the AF-XIED tweaks can create over fueling when set up wrongly, it worth understanding how CATs operate.

The OEM variation between lean and rich being so slow actually does not reflect the Bosch ECU's ability for accurate control. Rather its a deliberate need to feed the CAT with oxygen (as CATs use oxygen to convert CO to CO2). This oxygen is delivered to the CAT through the exhaust gases and its controlled to produce periods with excessive O2 in order to feed the CAT. Hence the slow reaction time is to allow for periods with high levels of oxygen. So you should set the AF-XIED to a value rich enough for smooth running, and no more. It's why they recommend going from a low value and slowly increasing richness during set up, one step at a time. And the point of allowing time (100 miles or more) between each change, is that its allowing the ECU to rebuild the Long Term Trim each time the setting has been changed. Note: these only save to the ECUs adaptions if the key is off for 10 seconds (and I believe after reaching operating temperature and its been run through all gears).

#28

Super Member

Join Date: Jun 2013

Location: Staten Island, NY

Posts: 777

Received 65 Likes

on

53 Posts

2011 GL 550, 2010 MB S550, 2004 BMW 645Cic 1988 Corvette

Just because you don't have a CEL doesn't mean there isn't a misfire. Go to the auto parts store, get yourself one spark plug, and one coil pack, and change each one out one at a time. Start at cylinder 1 and work your way up. You are killing yourself with graphs and charts. Go with the most common issues. Vacuum leak, you found and fixed. Check the plugs and coil packs.

#30

Junior Member

Thread Starter

- After replacing the hose A2730180582 the hose itself became very noisy, as if there is a huge hole in it, but it is completely sealed. The noise comes exactly from the intense air movement inside the hose. If the recirculation valve is switched off (plugged) - the noise remains. If you squeeze the hose in any place - the noise disappears. Who knows if it’s normal? I understand that the vacuum creates a lot of pressure and perhaps it should be so, but it is very unusual by ear. After I turn off the engine, the air noise is still audible for a while and at the end it makes a "spit" as a compressor usually does when bleeding air. You can hear it clearly on this short video. Please tell me if this is normal.

#31

MBWorld Fanatic!

Join Date: Jun 2020

Posts: 1,823

Received 651 Likes

on

448 Posts

04 E55 AMG (totaled), 07 S550 4Matic, 14 E63S

I understand it pretty well. But you are doing advanced diagnostics on something you learned about a few days ago and as others have suggested, isn't where you should be focusing at this time.

The following users liked this post:

Plato (09-13-2023)

#32

Have you had the engine carbon cleaned? It's needed every 60K miles.

I've used these guys, and it works great.

https://www.hhocarboncleansystems.com/

I've used these guys, and it works great.

https://www.hhocarboncleansystems.com/

#34

it actually works - u can do much the same with a 50 50 water methanol mixture atomised and pushed in after the air cleaners.... (garden sprayer works well) as the mixture explodes into steam on its way through it gives things a proper clean out... tuners use it all the time to get combustion temps down so you can tune things harder

#36

MBWorld Fanatic!

Join Date: Jun 2020

Posts: 1,823

Received 651 Likes

on

448 Posts

04 E55 AMG (totaled), 07 S550 4Matic, 14 E63S

I have seen zero evidence that it removes direct injection-related intake valve buildup, which is the only kind that really matters. There are plenty of existing products that work for the other parts of an engine that can suffer deposits.

Walnut blasting/Carbon intake clean? - MBWorld.org Forums

Also a brand new user who just happens to recommend this product nearly snapped the needle off my BS meter. It's possible the system does "something" but that is a long way from what I'm interested in. And if they have a pyramid marketing scheme, I may have trouble concentrating on the intended message.

Walnut blasting/Carbon intake clean? - MBWorld.org Forums

Also a brand new user who just happens to recommend this product nearly snapped the needle off my BS meter. It's possible the system does "something" but that is a long way from what I'm interested in. And if they have a pyramid marketing scheme, I may have trouble concentrating on the intended message.

Last edited by kevm14; 09-15-2023 at 03:07 PM.

The following users liked this post:

vettebk (07-11-2024)

#37

Junior Member

Thread Starter

Changed 2 rear O2 sensors. Everything works smoothly! Winning!))))

Bottom line:

Thanks everyone))))

Thanks everyone))))

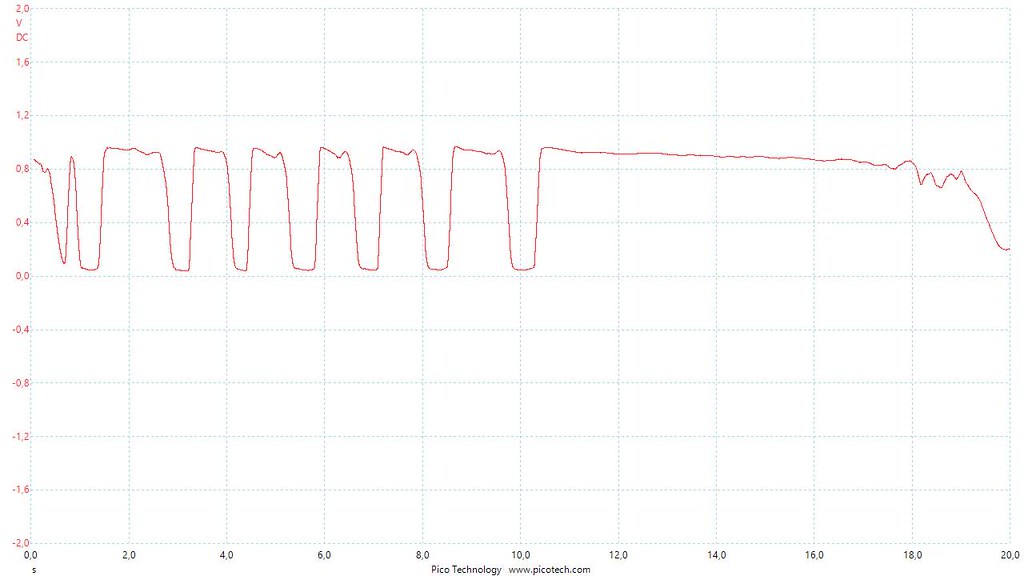

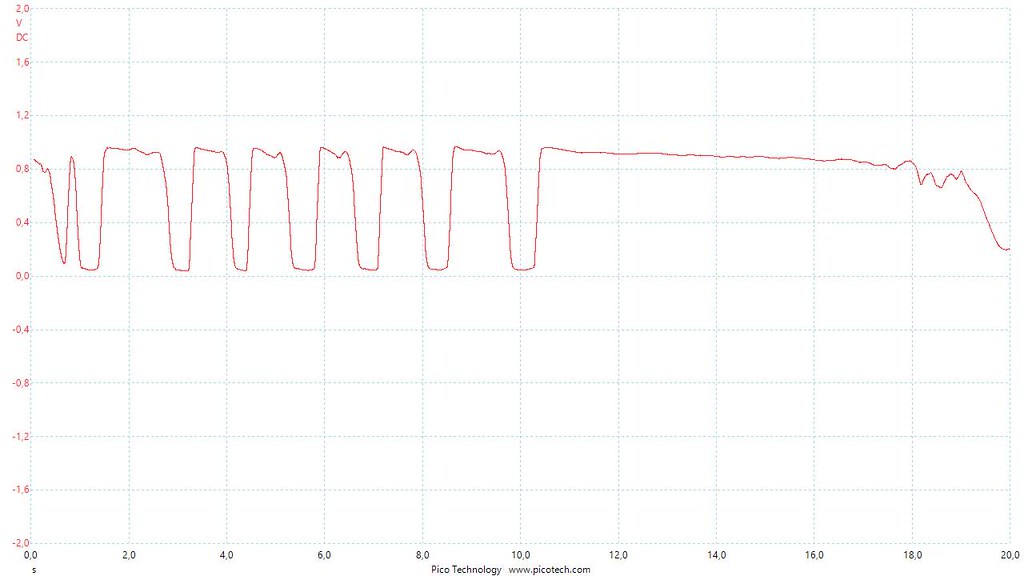

PS: Attaching graphs of correct O2 adjustment/correction:

At idle, warmed up engine

At idle, when pressing the gas pedal pedal

Bottom line:

- Unjustified replacements: throttle (used), MAFS (aftermarket, ended up putting mine back in place).

- Replacements not affecting the problem, but desirable as a scheduled maintenance: coolant temperature sensor (leaks over time), recirculation valve.

- Repairs that had to be done anyway and that "sharpened" the localization of the main problem: Elimination of air leaks (replacement of oil divider, recirculation hose, pipes around the recirculation valve, replacement of gaskets before and after MAFS, and before the throttle).

- Fixing the main problem: replaced 2 rear O2 sensors

Thanks everyone))))

Thanks everyone))))PS: Attaching graphs of correct O2 adjustment/correction:

At idle, warmed up engine

At idle, when pressing the gas pedal pedal

Last edited by Plato; 10-18-2023 at 09:18 AM.

#38

Senior Member

Join Date: Jan 2018

Location: Atlanta GA

Posts: 468

Received 149 Likes

on

119 Posts

2012 E350 Cabriolet now SOLD to my son

So the real solution was replacing the rear 02 sensors. Did you do both sides ? IIRc the graph you showed did not show nice flat square wave patterns on it which is interesting. In my experience failing 02 sensors do not fail completely. but do not throw codes unless failed completely such as when the heater in them goes south. ( four or more wires type ) .

Crappy fuel can mess with them too and they wont necessarily throw a code.

I guess the moral of the story is O2 sensors should be considered a maintenance item esp with cold start issues.

Crappy fuel can mess with them too and they wont necessarily throw a code.

I guess the moral of the story is O2 sensors should be considered a maintenance item esp with cold start issues.

Last edited by WRC-LVR; 10-17-2023 at 06:46 PM.

The following users liked this post:

vettebk (07-11-2024)

#39

Junior Member

Thread Starter

So the real solution was replacing the rear 02 sensors. Did you do both sides ? IIRc the graph you showed did not show nice flat square wave patterns on it which is interesting. In my experience failing 02 sensors do not fail completely. but do not throw codes unless failed completely such as when the heater in them goes south. ( four or more wires type ) .

Crappy fuel can mess with them too and they wont necessarily throw a code.

I guess the moral of the story is O2 sensors should be considered a maintenance item esp with cold start issues.

Crappy fuel can mess with them too and they wont necessarily throw a code.

I guess the moral of the story is O2 sensors should be considered a maintenance item esp with cold start issues.

#40

Junior Member

Thread Starter

Unfortunately it seems that I was in a hurry. A few days on warming up everything was smooth, today the rear O2 sensors started to float again => thus front O2 sensors and engine speed too. Everything is back to previous state. However, when the car warmed up well, the rear O2 sensors went to zero as after the replacement and everything began to work smoothly. I don't know where to go from here. Maybe because I bought used O2 they behave like this (at the end of life). It could be catalysers too. There are two options I see: try to replace rear O2 sensors again but buy new one. Or remove rear O2 from the firmware.

#41

usually the rears are just there to confirm the real ones upstream are doing their job

and they do wear out - allegedly aliexpress has a shop selling NGK ones for almost nothing

and they do wear out - allegedly aliexpress has a shop selling NGK ones for almost nothing

The following users liked this post:

chassis (10-21-2023)

#42

Super Member

Join Date: Oct 2021

Location: Iowa

Posts: 767

Received 336 Likes

on

210 Posts

2008 CL550, 2022 EQB300, 2022 EQS580

Would it not be best to stick w/ Bosch for new O2 sensors? At Rock Auto, Walker are 1/2 the price, but wonder if they would court trouble. Also, any opinions on when O2 sensors should be be replaced based on mileage/time?

The following users liked this post:

chassis (11-23-2023)

#43

Out Of Control!!

Join Date: Sep 2018

Location: unbegrenzt

Posts: 13,340

Received 3,931 Likes

on

3,095 Posts

2017 GLE350 4MATIC

I hold the view that any electrical part, including spark plugs, should be purchased from an MB dealer. Otherwise the risk of shoddy second-rate parts is too great.

There are too many cheap and counterfeit electrical parts on the market, it's not worth the hassle for the false economy.

There are too many cheap and counterfeit electrical parts on the market, it's not worth the hassle for the false economy.

#44

MBWorld Fanatic!

Join Date: Jun 2020

Posts: 1,823

Received 651 Likes

on

448 Posts

04 E55 AMG (totaled), 07 S550 4Matic, 14 E63S

Funny. I was going to say the same thing. I will make exceptions but on a case by case basis.

Back in my GM days, AC Delco was the only way to go for most engine control items. Bosch O2 sensors were notoriously poor performing.

Back in my GM days, AC Delco was the only way to go for most engine control items. Bosch O2 sensors were notoriously poor performing.

The following users liked this post:

chassis (11-23-2023)

#45

they are probably NTK sensors part of NGK (which is a grown up Japanese spark plug brand) not budget Bosch rubbish that's designed to fail junk

when you take them off have a look around the nut section - these days much of the stuff is in boxes saying one thing but made by another - I deliberately paid more for a Gates idler pulley as this is grown up USA company and not a bunch of german criminals making rubbish and upon open I find its budget INA rubbish which is the OEM Merc crap but available at half price - and all three names Merc, INA and Gates is the same part made in France....

#46

Senior Member

Join Date: Jan 2018

Location: Atlanta GA

Posts: 468

Received 149 Likes

on

119 Posts

2012 E350 Cabriolet now SOLD to my son

Get new ones and you might consider replacing the front two as well at the same time especially if they are the originals and have lots of miles. on them. one thing past that is the cats themselves. If they are not doing their job then the rear sensors will be subjected to exhaust not in spec...YMMV

#47

Senior Member

Join Date: Jan 2018

Location: Atlanta GA

Posts: 468

Received 149 Likes

on

119 Posts

2012 E350 Cabriolet now SOLD to my son

OP...one of your posts did say the car had been running LPG ?

" Was done a year ago when I removed LPG from the car from previous owner."

This is why you did the smoke test then to rule out leaks from the repair to straight petrol....

" Was done a year ago when I removed LPG from the car from previous owner."

This is why you did the smoke test then to rule out leaks from the repair to straight petrol....

Last edited by WRC-LVR; 11-24-2023 at 10:37 AM.

#48

Are any of you guys hearing about Merc dieselgate and the hell of dodgy NOx sensors on the tractor engined mercs ?

UK owners are being utterly stitched up by Merc UK ? EU law has mandated Merc must retrospectively make all their cars meet the original emission control standard the cars were sold as having during its original production

AKA fix all cars still on the road - but there's the issue - much of the emission control sensors were dysfunctional in the original design and then all locked in to deliberate software switches to rip off owners with a diagnostic charge and loads of owner repair costs 4 years down the line - this backfired as the first cars were failing inside warranty so Merc rushed out a bad software update with a mk2 NOx sensor that was in many cases a bigger headache as they didn't work either - but it really messed up what parts you should fit, what software a car might have and it still had fake faults hidden in the software and it still didn't function correctly - however some owners lost thousands on dodgy repairs and indy garages didn't understand anything anymore ...

And then Merc got caught out worldwide cheating.... So now rather than the correct (costly for Merc) fix - in the UK with our bent government, they agreed to allow Merc to rob customers to pay for the recall work... many E class cars from 2014 to 2019 are all getting a mandatory recall and are just given a software bodge that isn't suitable and doesn't work. Within a week or so (and LOTS have had it as they drive off the forecourt post repair) the emission light comes on - where Merc stand their ground and do not entertain customer objections - claiming its an unrelated failure and they must pay £900 ($1100) to fit two new NOx sensors

When they know the only way to really fix the cars is

1) a vdoc update - Perform a retrofit of special equipment code ‘30o’ giving your car the alternate (AKA correct) parts list - now the parts records identify the car should have a mk3 NOx sensor - once you know these parts exist (the cover up merc UK are peddling) you need to get these functional NOx sensors on the car, where

2) this allows the three correct software updates to be flashed to the car, so the Engine ECU, SCR and Adblue all start to function as they should have many years ago - and - it removes all the fake software switches

.

UK owners are being utterly stitched up by Merc UK ? EU law has mandated Merc must retrospectively make all their cars meet the original emission control standard the cars were sold as having during its original production

AKA fix all cars still on the road - but there's the issue - much of the emission control sensors were dysfunctional in the original design and then all locked in to deliberate software switches to rip off owners with a diagnostic charge and loads of owner repair costs 4 years down the line - this backfired as the first cars were failing inside warranty so Merc rushed out a bad software update with a mk2 NOx sensor that was in many cases a bigger headache as they didn't work either - but it really messed up what parts you should fit, what software a car might have and it still had fake faults hidden in the software and it still didn't function correctly - however some owners lost thousands on dodgy repairs and indy garages didn't understand anything anymore ...

And then Merc got caught out worldwide cheating.... So now rather than the correct (costly for Merc) fix - in the UK with our bent government, they agreed to allow Merc to rob customers to pay for the recall work... many E class cars from 2014 to 2019 are all getting a mandatory recall and are just given a software bodge that isn't suitable and doesn't work. Within a week or so (and LOTS have had it as they drive off the forecourt post repair) the emission light comes on - where Merc stand their ground and do not entertain customer objections - claiming its an unrelated failure and they must pay £900 ($1100) to fit two new NOx sensors

When they know the only way to really fix the cars is

1) a vdoc update - Perform a retrofit of special equipment code ‘30o’ giving your car the alternate (AKA correct) parts list - now the parts records identify the car should have a mk3 NOx sensor - once you know these parts exist (the cover up merc UK are peddling) you need to get these functional NOx sensors on the car, where

2) this allows the three correct software updates to be flashed to the car, so the Engine ECU, SCR and Adblue all start to function as they should have many years ago - and - it removes all the fake software switches

.

Last edited by BOTUS; 11-24-2023 at 03:31 PM.

#49

Junior Member

Thread Starter

The story continues...all oxygen sensors have been replaced. Installed a new engine control unit today! The problem hasn't gone.

In short, when you physically turn off the rear oxygen sensors, everything works smoothly. When the oxygen sensors are turned on, when the rear pair “comes into play,” the engine begin to float and with them the long-term correction of the front oxygen sensors. All 4 sensors have been replaced, the engine control unit has been replaced. No air leaks. What to do next?

In short, when you physically turn off the rear oxygen sensors, everything works smoothly. When the oxygen sensors are turned on, when the rear pair “comes into play,” the engine begin to float and with them the long-term correction of the front oxygen sensors. All 4 sensors have been replaced, the engine control unit has been replaced. No air leaks. What to do next?