thoughts on Alusil cylinder's

#1

MBWorld Fanatic!

Thread Starter

thoughts on Alusil cylinder's

So have been digging for information on the Alusil block's with the M113 engine and have gotten some interesting feed back.My possible plan is to Cryogenic the rods and plasma the pistons and was told by a very reputable machine shop that specializes in the Alusil blocks that with low miles up to 60-70k you can just throw in a new set of rings and they will seat. I find this a little hard to grasp but they where adamant about it.. They said they can redue the cylinders but that would take two thousands off the cylinder walls. I can correct this buy having the piston skirts coated to bring back the correct clearance if that is the case.

Long story short this could possibly save $3,500.00 dollars in the end if I don't sleeve the block and buy pistons.

Any thoughts??

Long story short this could possibly save $3,500.00 dollars in the end if I don't sleeve the block and buy pistons.

Any thoughts??

#2

MBWorld Fanatic!

Join Date: Aug 2003

Location: In my garage

Posts: 8,424

Received 1,003 Likes

on

810 Posts

E55, GLS450, GL63, GLE350

Getting a piston coating that will work within an Alusil bore is tricky. There are some that say they can do it but, from my experience, the only reliable coating is from Mahle or Kolbenschmidt and they will only sell you the pistons and will not coat your provided pistons. Granted, it's been a decade or so since I've done piston coating experimentation so things may have changed. Your best bet is to either have your engine sleeved or use the above providers and order your pistons.

When you say plasma the pistons, are you talking about tin coating the piston or is this the Swain Tech process? Tin coating the aluminum is what is typically recommended in the Alusil bore. Your options if you keep the stock bore is to coat the bore or coat the piston. I have heard many with good results from Nikasil on the piston walls.

Having built some engines with Alusil bores and having done my share of experimentation, I can only recommend the OE piston suppliers or sleeving your block. If you sleeve, you can run a cheaper piston and more boost without fear the cylinder walls will mushroom under high boost. If you keep the Alusil, you will get much better longevity. Do you want the engine to last 400k miles or 150k miles before you need to rebuild or are you doing this for maximum hp?

When you say plasma the pistons, are you talking about tin coating the piston or is this the Swain Tech process? Tin coating the aluminum is what is typically recommended in the Alusil bore. Your options if you keep the stock bore is to coat the bore or coat the piston. I have heard many with good results from Nikasil on the piston walls.

Having built some engines with Alusil bores and having done my share of experimentation, I can only recommend the OE piston suppliers or sleeving your block. If you sleeve, you can run a cheaper piston and more boost without fear the cylinder walls will mushroom under high boost. If you keep the Alusil, you will get much better longevity. Do you want the engine to last 400k miles or 150k miles before you need to rebuild or are you doing this for maximum hp?

#3

Member

Join Date: Jan 2010

Location: Atlanta

Posts: 86

Likes: 0

Received 23 Likes

on

17 Posts

2009 E63, 1984 500SEL AMG, 1984 500SEC AMG Widebody

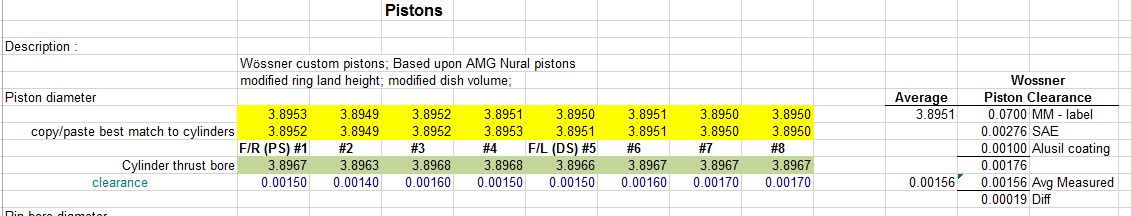

Wossner forged pistons with wrist pins and rings. Four of the eight.

Coating for Alusil block

When I rebuilt my M117 AMG engine (5.4L SOHC), I had the block slightly bored to remove some scratches in the cylinder walls. Had new modern pistons/rings made due to the 0.5mm increase in bore. Wossner made my pistons and coated the skirts so they would be compatible with Alusil.

#4

MBWorld Fanatic!

Thread Starter

Getting a piston coating that will work within an Alusil bore is tricky. There are some that say they can do it but, from my experience, the only reliable coating is from Mahle or Kolbenschmidt and they will only sell you the pistons and will not coat your provided pistons. Granted, it's been a decade or so since I've done piston coating experimentation so things may have changed. Your best bet is to either have your engine sleeved or use the above providers and order your pistons.

When you say plasma the pistons, are you talking about tin coating the piston or is this the Swain Tech process? Tin coating the aluminum is what is typically recommended in the Alusil bore. Your options if you keep the stock bore is to coat the bore or coat the piston. I have heard many with good results from Nikasil on the piston walls.

Having built some engines with Alusil bores and having done my share of experimentation, I can only recommend the OE piston suppliers or sleeving your block. If you sleeve, you can run a cheaper piston and more boost without fear the cylinder walls will mushroom under high boost. If you keep the Alusil, you will get much better longevity. Do you want the engine to last 400k miles or 150k miles before you need to rebuild or are you doing this for maximum hp?

When you say plasma the pistons, are you talking about tin coating the piston or is this the Swain Tech process? Tin coating the aluminum is what is typically recommended in the Alusil bore. Your options if you keep the stock bore is to coat the bore or coat the piston. I have heard many with good results from Nikasil on the piston walls.

Having built some engines with Alusil bores and having done my share of experimentation, I can only recommend the OE piston suppliers or sleeving your block. If you sleeve, you can run a cheaper piston and more boost without fear the cylinder walls will mushroom under high boost. If you keep the Alusil, you will get much better longevity. Do you want the engine to last 400k miles or 150k miles before you need to rebuild or are you doing this for maximum hp?

#5

MBWorld Fanatic!

Join Date: Aug 2003

Location: In my garage

Posts: 8,424

Received 1,003 Likes

on

810 Posts

E55, GLS450, GL63, GLE350

From my experiences, I would go with the steel sleeves and whatever is the strongest & lightest piston/ring setup and pump up the boost. Dealing with the Alusil bore can be tricky but, on the other hand, it will last a very long time with little wear if done right. The manufacturers who can get the piston/coating right are very expensive so going with the steel sleeves may be no more expensive than the custom pistons with correct coating. Go with max displacement, steel sleeves, heavy boost, and hold on.

#6

Member

Join Date: Jan 2010

Location: Atlanta

Posts: 86

Likes: 0

Received 23 Likes

on

17 Posts

2009 E63, 1984 500SEL AMG, 1984 500SEC AMG Widebody

From my experiences, I would go with the steel sleeves and whatever is the strongest & lightest piston/ring setup and pump up the boost. Dealing with the Alusil bore can be tricky but, on the other hand, it will last a very long time with little wear if done right. The manufacturers who can get the piston/coating right are very expensive so going with the steel sleeves may be no more expensive than the custom pistons with correct coating. Go with max displacement, steel sleeves, heavy boost, and hold on.

Last edited by W126AMG; 05-12-2019 at 10:56 PM.

#7

MBWorld Fanatic!

Thread Starter

Thank for all the input. I will still research this for a while.

You know then again here we have Eurocharge running 9 second times with a 160,000 mile M113 stock engine so one has to wonder LOL !!!

You know then again here we have Eurocharge running 9 second times with a 160,000 mile M113 stock engine so one has to wonder LOL !!!

The following users liked this post:

ChrisVannoy (03-18-2022)

Trending Topics

#8

Super Member

The following users liked this post:

ChrisVannoy (03-18-2022)

#9

MBWorld Fanatic!

Everyone who makes the "custom" pistons for the M113k is just spraying on a coating. Mahle actually has a product that is iron based, but it is a sticker, or really a screen print of a coating on the skirt.

The durability of the coatings for pistons in alusil bores is spoken of all over the interwebs. No real objective data I have found in years of looking (for other alusil platforms before this one).

The wossner is clearly a sprayed on coating. Depending on the roughness of the bore surface in your engine, and the clearance of the pistons, you will or will not succeed. Not to mention, I am not even sure what you are showing us, as those are for 4 valves per cylinder, and the M113k is a 3 valve engine.

The post talking about "OE" or steel sleeves is mostly correct. Technically, Mahle is OE, but their "gold" skirt coating is also hit and miss if you spend more than 10min in google. The thing that works is an ORIGINAL iron or ferrous coated piston (like the ones that come out of your engine) in an alusil bore.

I am rebuilding my engine now. I have done what I have done before with alusil - An30 paste, felt pads, 60 seconds up and down at 200rpm, and new rings on original unworn pistons (since they don't seem to wear much anyway). Yes, I then have swain coat my pistons, but that is above the iron coating, and it is not sacrificed on the skirt (at least I sure hope not).

The ONE OPTION that I have not seen is the Line-2-line coating that is made to wear in. Again - since alusil is so sensitive, its an expensive test.

Piston clearance with the aftermarket forged pistons is quite the pivot on this. Too much or too little, it doesn't matter what coating you have. Ask yourself why no german oem uses an iron sleeve in the last 30 years, but all of our American V8s have them.

The durability of the coatings for pistons in alusil bores is spoken of all over the interwebs. No real objective data I have found in years of looking (for other alusil platforms before this one).

The wossner is clearly a sprayed on coating. Depending on the roughness of the bore surface in your engine, and the clearance of the pistons, you will or will not succeed. Not to mention, I am not even sure what you are showing us, as those are for 4 valves per cylinder, and the M113k is a 3 valve engine.

The post talking about "OE" or steel sleeves is mostly correct. Technically, Mahle is OE, but their "gold" skirt coating is also hit and miss if you spend more than 10min in google. The thing that works is an ORIGINAL iron or ferrous coated piston (like the ones that come out of your engine) in an alusil bore.

I am rebuilding my engine now. I have done what I have done before with alusil - An30 paste, felt pads, 60 seconds up and down at 200rpm, and new rings on original unworn pistons (since they don't seem to wear much anyway). Yes, I then have swain coat my pistons, but that is above the iron coating, and it is not sacrificed on the skirt (at least I sure hope not).

The ONE OPTION that I have not seen is the Line-2-line coating that is made to wear in. Again - since alusil is so sensitive, its an expensive test.

Piston clearance with the aftermarket forged pistons is quite the pivot on this. Too much or too little, it doesn't matter what coating you have. Ask yourself why no german oem uses an iron sleeve in the last 30 years, but all of our American V8s have them.

#10

Member

Join Date: Jan 2010

Location: Atlanta

Posts: 86

Likes: 0

Received 23 Likes

on

17 Posts

2009 E63, 1984 500SEL AMG, 1984 500SEC AMG Widebody

Everyone who makes the "custom" pistons for the M113k is just spraying on a coating. Mahle actually has a product that is iron based, but it is a sticker, or really a screen print of a coating on the skirt.

The durability of the coatings for pistons in alusil bores is spoken of all over the interwebs. No real objective data I have found in years of looking (for other alusil platforms before this one).

The wossner is clearly a sprayed on coating. Depending on the roughness of the bore surface in your engine, and the clearance of the pistons, you will or will not succeed. Not to mention, I am not even sure what you are showing us, as those are for 4 valves per cylinder, and the M113k is a 3 valve engine.

The post talking about "OE" or steel sleeves is mostly correct. Technically, Mahle is OE, but their "gold" skirt coating is also hit and miss if you spend more than 10min in google. The thing that works is an ORIGINAL iron or ferrous coated piston (like the ones that come out of your engine) in an alusil bore.

I am rebuilding my engine now. I have done what I have done before with alusil - An30 paste, felt pads, 60 seconds up and down at 200rpm, and new rings on original unworn pistons (since they don't seem to wear much anyway). Yes, I then have swain coat my pistons, but that is above the iron coating, and it is not sacrificed on the skirt (at least I sure hope not).

The ONE OPTION that I have not seen is the Line-2-line coating that is made to wear in. Again - since alusil is so sensitive, its an expensive test.

Piston clearance with the aftermarket forged pistons is quite the pivot on this. Too much or too little, it doesn't matter what coating you have. Ask yourself why no german oem uses an iron sleeve in the last 30 years, but all of our American V8s have them.

The durability of the coatings for pistons in alusil bores is spoken of all over the interwebs. No real objective data I have found in years of looking (for other alusil platforms before this one).

The wossner is clearly a sprayed on coating. Depending on the roughness of the bore surface in your engine, and the clearance of the pistons, you will or will not succeed. Not to mention, I am not even sure what you are showing us, as those are for 4 valves per cylinder, and the M113k is a 3 valve engine.

The post talking about "OE" or steel sleeves is mostly correct. Technically, Mahle is OE, but their "gold" skirt coating is also hit and miss if you spend more than 10min in google. The thing that works is an ORIGINAL iron or ferrous coated piston (like the ones that come out of your engine) in an alusil bore.

I am rebuilding my engine now. I have done what I have done before with alusil - An30 paste, felt pads, 60 seconds up and down at 200rpm, and new rings on original unworn pistons (since they don't seem to wear much anyway). Yes, I then have swain coat my pistons, but that is above the iron coating, and it is not sacrificed on the skirt (at least I sure hope not).

The ONE OPTION that I have not seen is the Line-2-line coating that is made to wear in. Again - since alusil is so sensitive, its an expensive test.

Piston clearance with the aftermarket forged pistons is quite the pivot on this. Too much or too little, it doesn't matter what coating you have. Ask yourself why no german oem uses an iron sleeve in the last 30 years, but all of our American V8s have them.

If you read my post, I said my pistons are for an M117 engine, SOHC. The valve reliefs are on both sides of the piston so the pistons could be used on either side of the engine. The discussion in this thread is about Alusil coated pistons.

"Roughness of the bore surface"?? What are you talking about? My block was properly lapped and honed with the correct lapping paste and technique that is mandatory and specified for Alusil blocks. The clearance between the coated piston and cylinder bore was specified by Wossner and my block was bored to within .00019" of Wossner spec. My engine was built correctly by me and my brother. You build your engine your way.

Last edited by W126AMG; 05-14-2019 at 10:23 PM.

#11

MBWorld Fanatic!

Great. So you are in the wrong forum. And you are talking about “alusil coated pistons”. Which don’t exist.

All my comments other than about your valve reliefs stand. Piston coatings for alusil bore walls other than oem are unproven and data is not objective.

Last edited by BC928; 05-14-2019 at 10:23 PM.

#14

PLATINUM SPONSOR

I prefer Nickasil or even better, steel sleeves.

__________________

E63 Biturbo, UPD Cold Air induction kit, UPD performance crank pulley and UPD adjustable rear suspension with ride height adjustment.

CL55 UPD Cold Air Boost kit, UPD 3000 stall converter, UPD 77mm SC clutched pulley and beltwrap kit, Custom long tubes, UPD crank pulley , UPD suspension kit, UPD SC pulley, Aux. HE, Trunk tank w/rule 2000 pump, Mezeire pump, UPD 5pc idler set, Aluminum rotor hats.

www.ultimatepd.com

instagram @ultimate_pd

facebook.com/ultimatepd

E63 Biturbo, UPD Cold Air induction kit, UPD performance crank pulley and UPD adjustable rear suspension with ride height adjustment.

CL55 UPD Cold Air Boost kit, UPD 3000 stall converter, UPD 77mm SC clutched pulley and beltwrap kit, Custom long tubes, UPD crank pulley , UPD suspension kit, UPD SC pulley, Aux. HE, Trunk tank w/rule 2000 pump, Mezeire pump, UPD 5pc idler set, Aluminum rotor hats.

www.ultimatepd.com

instagram @ultimate_pd

facebook.com/ultimatepd

#15

MBWorld Fanatic!

Join Date: Aug 2003

Location: In my garage

Posts: 8,424

Received 1,003 Likes

on

810 Posts

E55, GLS450, GL63, GLE350

Yes, much easier to work on. Many with Alusil bores have them coated with Nikasil since you can then run an uncoated aluminum piston. Remember, you need the separation of material since the piston and cylinder have to be dissimilar metals to work properly. That's why the piston coating is so important in an Alusil bore.

#17

MBWorld Fanatic!

Depends on the people you work with I’d say. The steel liners are a very different expansion rate than the aluminum block and aluminum pistons. But Chevy and Ford make it work fine.

#18

MBWorld Fanatic!

Are you guys measuring piston to wall clearance or just dropping them in and going?

At the dealer people would rebuild engines with no measuring of anything at any point in time. The new 2.0 turbo engines have so much piston to wall clearance that you can rock them in the bore. I was amazed by that, but no one else even seemed to understand what I was trying to show them.

At the dealer people would rebuild engines with no measuring of anything at any point in time. The new 2.0 turbo engines have so much piston to wall clearance that you can rock them in the bore. I was amazed by that, but no one else even seemed to understand what I was trying to show them.

The following users liked this post:

ChrisVannoy (03-18-2022)