Mercedes-Benz C-Class: Why Are My Accessory Belts Noisy?

The accessory drive belt wears over time. It is in constant motion, and must make a number of bends by design to reach every pulley.

This article applies to the Mercedes-Benz C-Class w204 (2007-2014).

The accessory drive belt transfers rotary motion from the crankshaft to the air compressor, alternator, power steering, and, in some cases, the water pump pulleys. It is held in place by a calibrated spring found inside of the tensioner. The belt and pulleys are prone to a number of potential problems. Dirt and water can collect between the two, causing the commonly heard squeal. The bearings inside of the pulleys can become damaged, which creates noise and drag on the drive belt.

There are two different engines found in the Mercedes-Benz w204. The first being the M271 (a turbocharged 4-cylinder). The second is the M272 ( V-shaped, 6-cylinder).

Materials Needed

- T50 Torx socket

- T60 Torx

- 17mm socket

- E12 socket

- Flat head screwdriver

- Flex head

- Short extension

- 1/2" ratchet

- 3/8" ratchet

- Belt dressing

- Torque wrench (must go down to 15 ft/lb)

- Automotive stethoscope

Step 1 – Visually inspect the drive belt and pulleys

Look for cracks, stretching, and missing ribs on the drive belt.

Start the engine, and watch the pulleys as they rotate. If a pulley is wobbly, it may need to be tightened or could be damaged. By varying the revs as you watch, will help pinpoint the pulley.

Using an automotive stethoscope, listen to each pulley. If you hear rumbling or whirring sounds, the bearing in the pulley may be defective.

Be sure the engine splash shields are correctly installed. If they are not, water and dirt can enter between the pulley and belt, creating noise. Refer to the Related Article: How to Remove Splash Shields - MBWorld.org.

Figure 1. The M272 drive belt diagram. Number 1 indicates the idler pulley, and Number 3 indicates the tensioner.

Figure 2. The drive belt on the M271. The idler pulley is indicated by the blue circle, and the tensioner is indicated by the green circle.

Step 2 – Apply belt dressing to the drive belt

Belt dressing is made by several manufacturers (CRC for example), and can be found at many parts stores. It creates a tackiness between the belt and pulley that helps eliminate belt squeal.

Step 3 – Replace the accessory drive belt

If the results from Step 1 did not help you determine a problem with one of your pulleys, It's time to replace the drive belt.

If lubricating the belt didn't get the noise to go away, perhaps it is simply time to replace the serpentine belt. They have a service life of approximately 60,000 miles or 100,000 kilometers, but it is not uncommon for them to wear prematurely. Follow the Related Article: How to Replace Serpentine Belt - MBWorld.org.

Featured Video: How to Replace the Serpentine Belt and Tensioner

Step 4 – Replace the idler pulley and tensioner

If the drive belt did not fix your noise, replace both of these components.

Follow the Related Article in Step 3 for the drive belt removal. Once you get the belt removed, you will remove the idler pulley by turning the E12 bolt counterclockwise on the M271.

The part numbers for the M271 are:

- Tensioner Pulley: 271 200 05 70

- Idler Pulley: 271 206 00 19

Read more in the Related Discussion: M271 Idler and Tensioner Pulley - MBWorld.org

Then, loosen the T60 Torx bolt holding the tensioner to the engine.

Figure 4. Removing the tensioner on the M271.

Figure 5. The blue circle shows the bolt location of the removed tensioner on the M271.

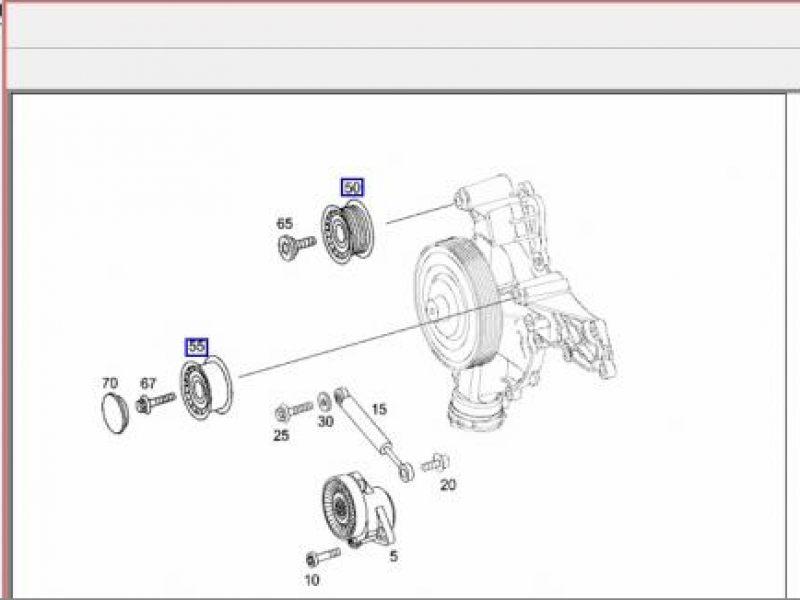

For the M272, the procedure is very similar. In Figure 6, #50 and #55 are idler pulleys. #5 is the tensioner.

There is a plastic cover that must be popped off on the idler and tensioner pulleys. Once removed, the bolt holding the pulleys to the engine will be visible.

Re-install the pulleys by carefully tightening them. If you have access to a torque wrench, tighten the idler pulley bolts to 15 ft/lb. Tighten the tensioner bolt(s) to 20 ft/lb.

Related Discussions

- Belt Slipping, Screeching Sounds - MBWorld.org

- Sound Coming From Belts - MBWorld.org

- V-Belt Tensioner Replacement - MBWorld.org