Mercedes-AMG Engine Handbuilding Process Is Sensory Bliss

Two builders at the AMG Affalterbach engine plant go to work on the brand’s new turbo-four and the 63 Series V8.

Mercedes-AMG is the epitome of Teutonic performance. The monsters to have emerged from Affalterbach over the decades have dominated every track and highway in their path, fueled by the insane engines under their hoods. The mad scientists behind each mill certainly know all of the right chemistry to make these concoctions a possibility.

But what’s better than experiencing the magnificence of an AMG engine with your ears? Seeing one built with your eyes. YouTube channel GommeBlog.it: Car & Performance followed two of Affalterbach’s engine builders, Michad Giltler and Jammick Stahl, as they each work on AMG’s new turbo-four and an 63 Series V8.

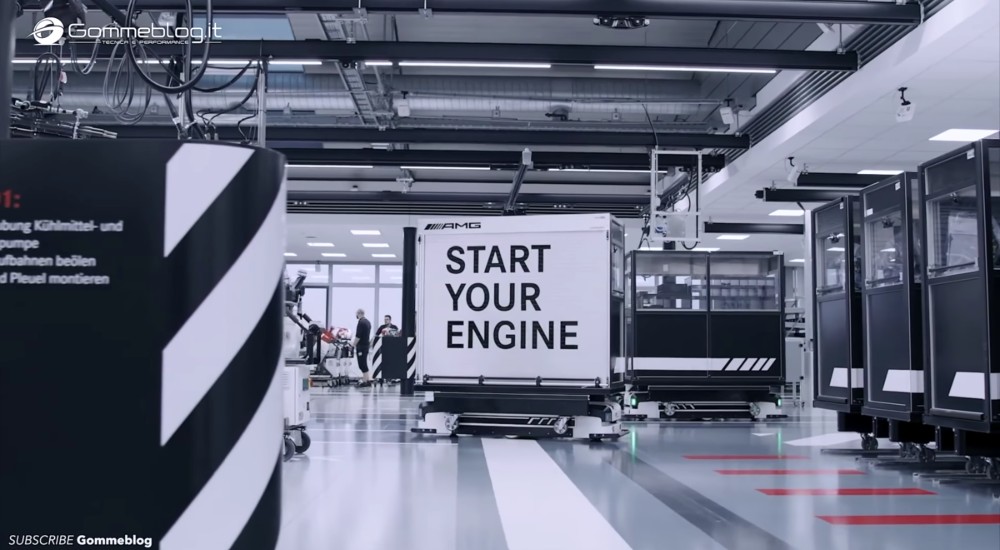

The 20-minute meditation begins with a robot cart telling Giltler to begin work on his engine, the 2.0-liter M139 turbo-four, the most powerful turbocharged four-pot in the world, producing up to 421 horses and 368 lb-ft of torque, depending upon the application.

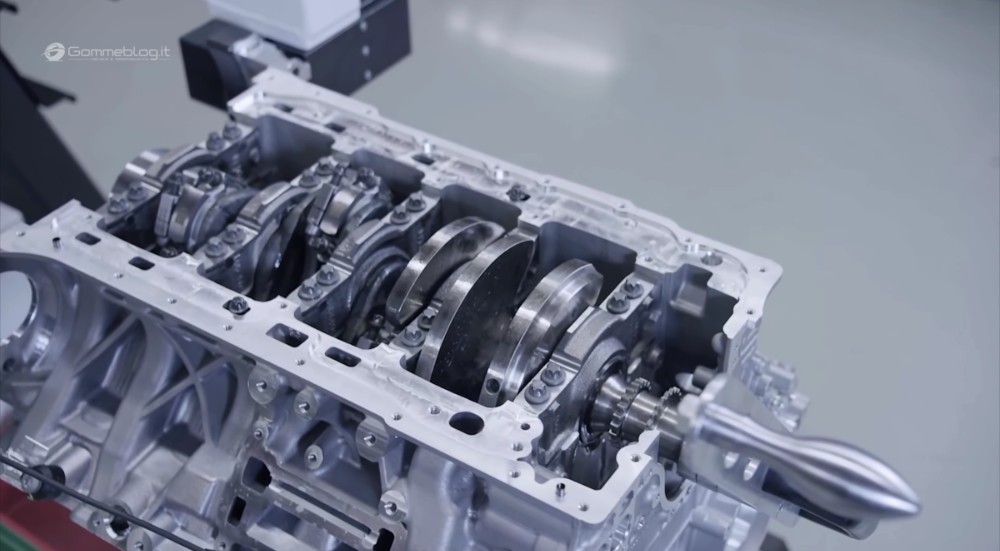

From there, both builders go to work on their respective AMG motors, first by cleaning out any dust that may have found its way into the bare blocks. Not long after, cylinder heads are lubed with drizzles of oil, and slid into place through the cylinder positioner.

Next, the AMG blocks are rotated so that the heads and crankshaft are secured into place, followed by manual cranking to check the cylinders and to lubricate the sleeves. The process thus far is very zen, to say the least.

Soon, heads are placed on the AMG masterpieces, but not before gaskets are laid down, and the heads are given a quick once-over. Camshafts enter the picture, as do ignition coils, transmission plates, timing chains and accessory belts, all placed by hand and screwed down by automation.

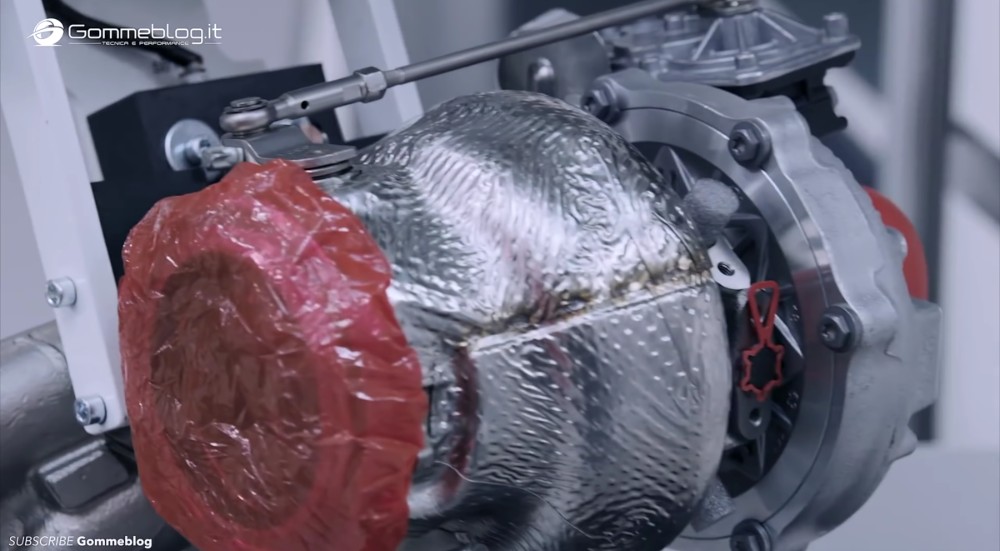

Later on, the big V8 and small inline-four receive their respective AMG turbos: a single unit for the latter, a twin hot-V for the former. Each turbo’s opening is sealed one way or another to keep out unwanted dust, continuing the clean build process all the way to the end.

And of course, each engine receives a plaque denoting who built it, in keeping with AMG’s ‘One Man – One Engine’ philosophy. It’s an amazing process to witness, one that pays dividends on the road.