Mercedes-Benz EQC Officially Announced, On Sale in 2020

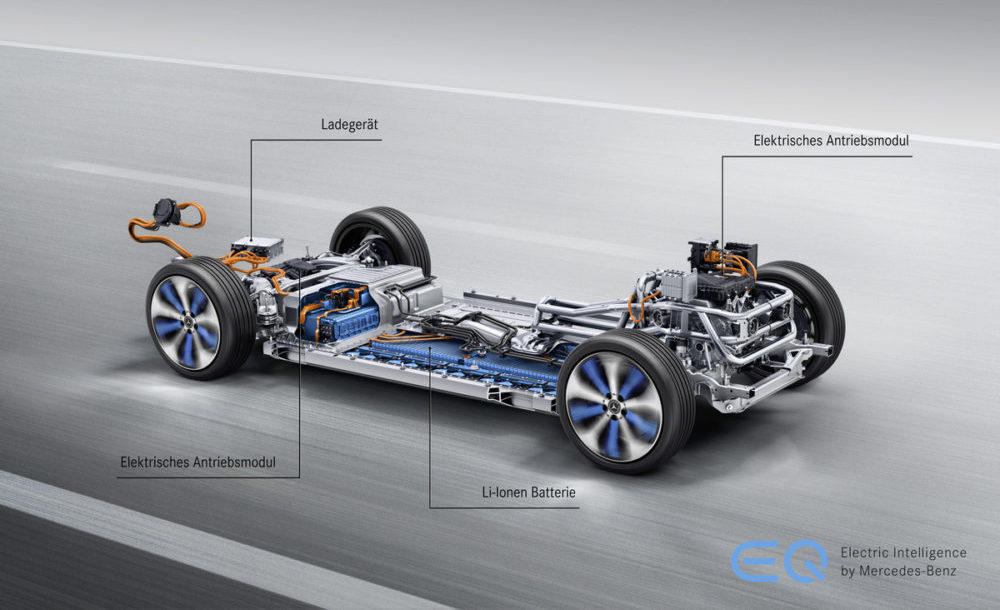

Mechanical protection of the battery: the high-safety design begins with the installation position of the high-voltage battery beneath the vehicle floor. The energy storage unit is surrounded by a stable frame that can absorb energy. Deformation elements are installed between the frame and the battery, and these are able to absorb additional forces in the event of a severe side impact. A battery guard in the front area of the battery is able to prevent the battery from being pierced by road debris.

Electrical protection of the high-voltage system: the extensive experience of Mercedes-Benz with high-voltage drive systems has led to a multi-stage safety concept that deploys in the event of an accident. The high-voltage system automatically shuts down, according to the severity of the accident. There are also shutdown points where emergency teams can deactivate the high-voltage system manually.

Endurance Tests Around the World

By market launch, 200 prototypes and pre-production vehicles of the Mercedes-Benz EQC will have covered several million miles across four continents (Europe, North America, Asia and Africa). The test program comprises more than 500 individual tests. Like all Mercedes-Benz vehicles, the EQC must pass all of the demanding test programs. There are also special tests for the electric powertrain, the battery, and the interplay of all powertrain components.

In the process the test experts are able to build upon the extensive findings from their digital testing work, used to ensure both the buildability of the vehicle and for the simulation of crash behavior, aerodynamics and NVH (noise, vibration, harshness). In addition there are intensive tests on numerous test rigs at the Mercedes-Benz Technology Center in Sindelfingen. The ratio between digital and real testing is roughly 35 to 65 percent.

Preparations in Full swing at Bremen plant

Production of the EQC will start in 2019 at the Mercedes-Benz plant in Bremen. The new Mercedes-Benz EQC will be integrated into ongoing series production as a fully electric vehicle, and the very latest production technologies will be employed.

In typical series production, the joining of the powertrain to the body is called the “marriage.” One decisive innovation is the battery-joining center where the EQC undergoes a second “marriage” following installation of the two electric motors in the bodyshell. This is where the EQCs are equipped with a battery for the first time. The body is suspended from a C-carrier and deposited on a frame. Support arms raise the battery to the vehicle’s floor from below, and an employee monitors the automatic bolting in place.

In parallel with this, production of our own batteries for the EQC is coming on stream at the expanded battery plant in Kamenz (near Dresden) Germany.