AMS Crank pulley - M112 - Discussion

#26

Senior Member

Join Date: Sep 2002

Location: San Diego

Posts: 268

Likes: 0

Received 1 Like

on

1 Post

ML430, Mini Cooper S and Porsche 911 Twin Turbo

off topic very briefly - apologies to all in advance...

Omey,

Please show me where I've ever made anything up and / or been deceitful in anyway and I'll willingly delete and offer a full public apology.

Otherwise I feel free to continue my contributions as I see fit.

PM me if you so desire so as not to pollute this thread with this side issue.

Please show me where I've ever made anything up and / or been deceitful in anyway and I'll willingly delete and offer a full public apology.

Otherwise I feel free to continue my contributions as I see fit.

PM me if you so desire so as not to pollute this thread with this side issue.

#28

Senior Member

Join Date: Sep 2002

Location: San Diego

Posts: 268

Likes: 0

Received 1 Like

on

1 Post

ML430, Mini Cooper S and Porsche 911 Twin Turbo

sorry - off topic again

Hi Omey - re your pm, so there's nothing I've made up then ? Just a request to delete the link in post #7 - why should I ? It's not made up, there's many more like it all over the web (started by others who also dispute your claims) and it's valid comment in my opinion. I suspect others might agree.

Maybe you should contact the author and or the mods to have it (and the others) deleted ;-) Maybe you've tried already ;-)

Let's continue this discussion, if you wish to, via PM.

I just wanted everyone to know there's nothing to be deleted that I've made up.

Edit - As I think I've made my point here I won't post anymore unless asked to - or provoked into posting by unfounded statements or accusations.

Edit - I think I will continue to post after Omey's rather disrespectful comment below :-) I may even post a few other inconvenient truths / links should the need arise.

Maybe you should contact the author and or the mods to have it (and the others) deleted ;-) Maybe you've tried already ;-)

Let's continue this discussion, if you wish to, via PM.

I just wanted everyone to know there's nothing to be deleted that I've made up.

Edit - As I think I've made my point here I won't post anymore unless asked to - or provoked into posting by unfounded statements or accusations.

Edit - I think I will continue to post after Omey's rather disrespectful comment below :-) I may even post a few other inconvenient truths / links should the need arise.

Last edited by timdf; 01-24-2009 at 12:25 AM.

#31

Super Moderator

Thread Starter

It has been. He was employed as a consultant during the mid 80's and as a full time employee from 94 till the end of 96

#33

Super Moderator

Thread Starter

Mu, I'll be back. We have guests over for a barbeque. My ladyfriend has banned me from "that damn forum"  until late tonight. At my age you don't argue with the ladyfriend for fear of being put on rations - if you know what I mean

until late tonight. At my age you don't argue with the ladyfriend for fear of being put on rations - if you know what I mean

until late tonight. At my age you don't argue with the ladyfriend for fear of being put on rations - if you know what I mean

until late tonight. At my age you don't argue with the ladyfriend for fear of being put on rations - if you know what I mean

#36

Super Moderator

Thread Starter

Crankshaft torsional vibration mitigation

I have agonised over what to post regarding crankshaft resonance & it’s mitigation as the subject can become very complex very quickly. I decided on as simple approach as possible with as many pictures as I can find.

Crankshaft resonance

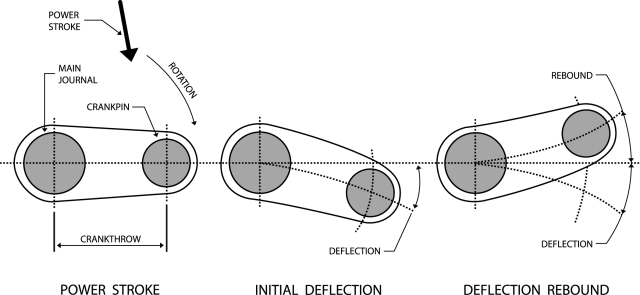

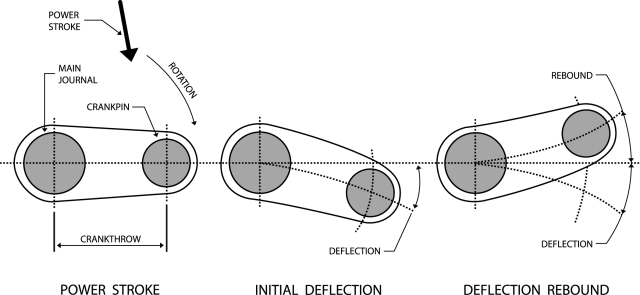

Let's start by asking what at first seems to be a daft question. If your car's engine idles smoothly at 800rpm, what speed is the crankshaft doing? No, it's not 800rpm, except perhaps for a millisecond or two. The rev counter only reads 800rpm because it only registers an average value. The real instantaneous speed fluctuates, in the case of the four-cylinder, between about 710 and 860rpm, during the course of one revolution. Why does this variation happen? One of the reasons is that the flywheel cannot do a perfect job. It has been designed to smooth the individual firing pulses and speed variation as much as possible, but can only be successful within certain limits, as dictated by its dimensions. Another reason is torsional vibration, the winding and unwinding of the crankshaft caused by the varying forces acting on it. At certain speeds, the crankshaft even writhes like a snake in the free space between the main bearings, causing eventual bell-mouthing of the main bearings.

Here are a few definitions which will be helpful for this discussion.

1. A FREQUENCY is exactly what the word suggests: vibration at a specific number of cycles per second, as in 400 cycles per second or Hertz, or how frequently the oscillation occurs.

2. An ORDER is a specific multiple of a basic frequency. For example an even-firing eight-cylinder, four-stroke engine produces four torque pulses per revolution (a fourth order excitation). If the crankshaft in such an engine was operating at 6000 RPM, then the frequency of the fourth order excitation is 4 x 6000 / 60 = 400 hertz whereas the same 4th order excitation at 7200 RPM is a frequency of 480 hertz.

3. A DAMPER is a device which dissipates energy, mainly in the form of heat.

4. An ABSORBER is a device which is designed to oscillate in direct opposition to a vibration at either a specific frequency or a specific order, depending on the design.

A crankshaft made from a piece of high-strength steel is nearly a perfect spring, and it contains very little inherent damping, so it becomes important to provide some means of attenuating the torsional oscillations which occur near resonant frequencies, especially at the free end of the crankshaft. (Opposite end to the flywheel)

Many engines, including virtually all V6’s & V8’s use a device on the free end of the crankshaft to attenuate the amplitude of what could otherwise become destructive torsional oscillations of the crank. Without an appropriate absorber, the life expectancy of the crankshaft in a typical American V8 engine at full power can usually be measured in minutes.

Many of the automotive 4-cylinder engines don’t require such an absorber, primarily because of their inherently higher stiffness-to-mass ratios. However, several automotive manufacturers have initially omitted a torsional absorber from early engine runs, only to find that crankshaft life was unacceptably short. Nissan discovered this with the early 240-Z engines, which didn’t have an absorber, and therefore lasted only about 100 hours in automotive (i.e. VERY LIGHT DUTY) service.

Often, the vibration attenuating devices on the free end of an engine crankshaft are incorrectly referred to as "DAMPERS". In many cases, they are ABSORBERS.

Elastomeric Absorbers

The elastomeric ("metal-ring-on-rubber-spring") devices used by the automotive industry are ABSORBERS which are tuned to counteract vibration at the frequency where the particular engine generates its worst torsional excitation. They also add a small amount of damping to the system.

By design, this style of absorber has a single resonant frequency, which is tuned by means of the MMOI (mass moment of inertia) of the inertia ring and the durometer (stiffness) of the elastomers to the specific frequency (crankshaft RPM times excitation order) at which measurements have shown the crankshaft vibration amplitude to be the worst.

Unfortunately, there is often more than one strong excitation order. Current science shows that the predominant excitation in a two-plane V8 crankshaft is the 2.5 order, followed next by the (more intuitive) 4th order. There is a new development in the inertia-ring - elastomeric style damper which provides the ability to tune for more than one critical frequency.

Pendulum-Style Order-Absorbers

In addition to the elastomeric style of absorber, there is a type of absorber which by design, attenuates a particular order of vibration. This style is known as a pendulum absorber, and was developed in the nineteen thirties to solve serious torsional vibration problems in radial aircraft engines. Both Continental and Lycoming use this style of pendulum absorber in all their high-output engines.

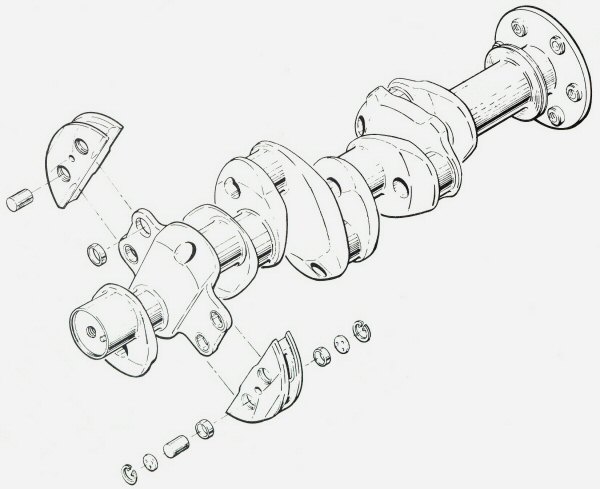

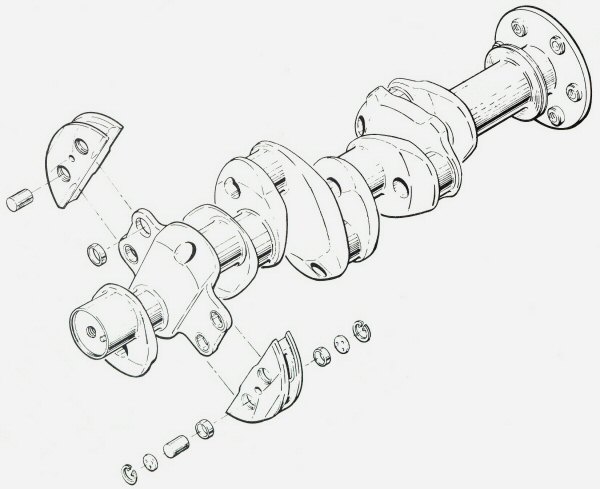

This style of internal absorber consists of pendulous counterweights attached to the crankshaft cheeks by loose pins in hard bushings, as shown below. It is a tuned absorber whose natural frequency is directly proportional to the rotational speed of the crankshaft.

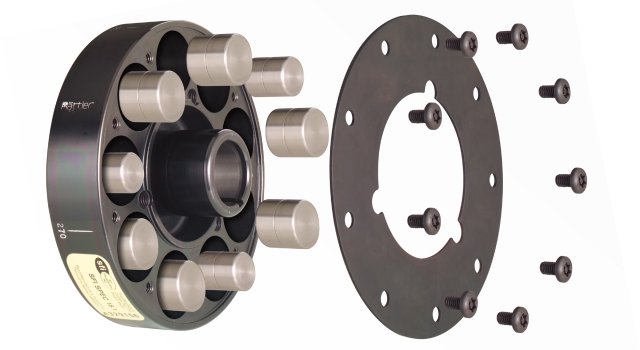

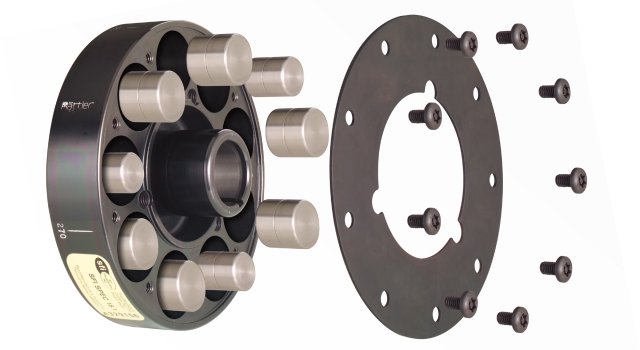

There is an aftermarket product (The Rattler™) which attempts to implement this method of order-absorption by means of heavy-metal cylinders which fit inside appropriately-sized longitudinal cylindrical bores in a round device attached to the nose of the crankshaft.

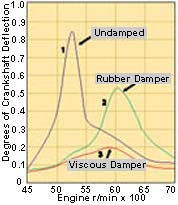

In contrast to an absorber, the advantage of a pure damper is that it will tend to reduce the amplitude of any frequency. The disadvantage is that the energy is dissipated as heat, so a suitable amount of cooling must be provided.

Frictional & Fluid dampers

There are frictional dampers as well as inertia-ring-in-high-viscosity-fluid dampers available in the aftermarket,

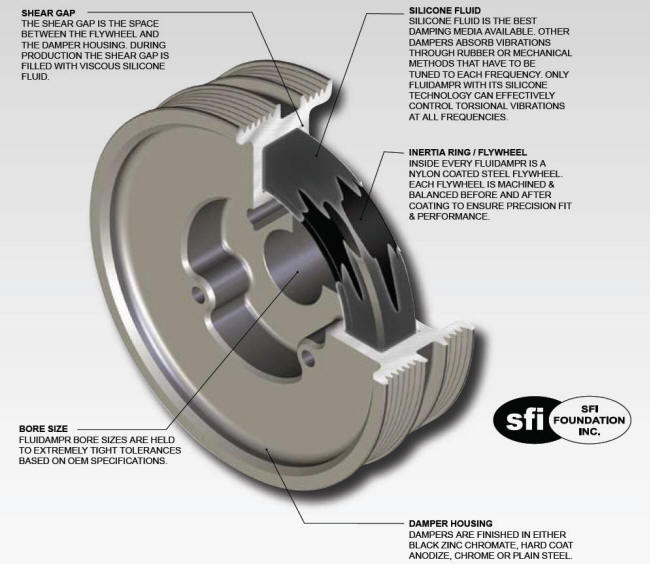

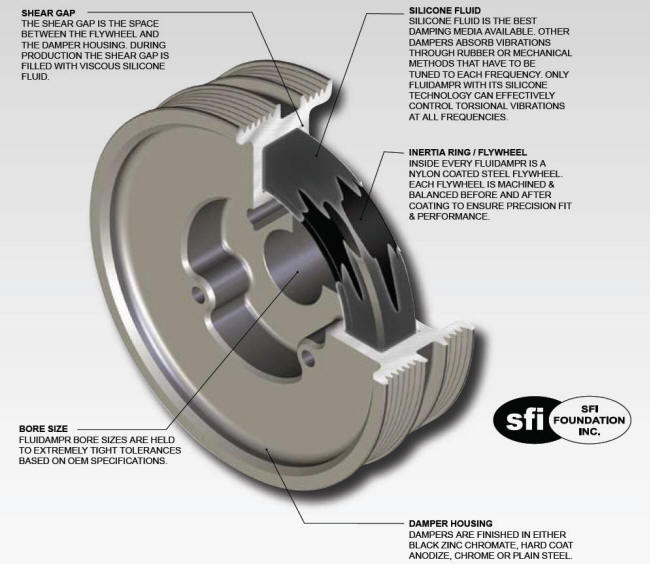

One aftermarket device, the Fluidampr™, is an example of a damper. It dissipates energy by transforming it into heat by shearing action in a high viscosity fluid. (usually silicone)

It is obvious that modifications to an original engine design which affect crankshaft stiffness and / or system MMOI (stroke, counterweights, bobweight {therefore counterweight} mass, clutch and flywheel MMOI, etc) will change the system resonant frequency. In order to determine the correct solution for a particular engine combination, the engine designer must a) do the measurements to determine the critical frequencies in your application and (b) and design or obtain an absorber tuned for the correct order or frequency, as fits with the application.

Some comments from authoritative scribes

“One crankshaft manufacturer describes torsional absorbers / dampers as "a great hoax", based on two observations he has made in his experience: (1) A crankshaft which has an absorber tuned to the wrong frequency has a very short life expectancy, and (2) Certain aftermarket absorber / damper products installed on a crankshaft pose extreme difficulties in balancing the assembly.”

“Internal combustion engine construction makes it susceptible to resonant torsional oscillation of the crankshaft. When it is operated near a critical speed [a speed at which the pulsations produced by each cylinder excite the natural frequency of the crankshaft] excessive torsional amplitudes are developed which may seriously damage the engine. The crankshaft damper is fitted to minimise the influence of torsional vibrations developing in the crankshaft. This keeps material stresses arising from these vibrations within permissible design limits. The damper, by reducing oscillations in the crankshaft to low amplitude, prevents premature failures of the crankshaft and driven equipment.”

“Torsional vibration peaks occur when a frequency component of the piston firing and reciprocating torques gets close to one of the built in frequencies of the crank. When the inputs get close to a natural frequency, the system goes resonant and the twist angle gets magnified about 6 – 10 times the normal amount in a very sharp “peak” that is only a few hundred rpm wide. This magnified twist is what does the damage in crank stress and bearing wear. It is dangerous in that it builds up fatigue stress cycles very quickly because it is such a high frequency. The vibratory torques at these resonant peaks can get much higher than the drive torque going out the flywheel. The first natural frequency of typical V8 & V6’s are usually in the 300 – 450 cycles/second range.”

Crankshaft resonance

Let's start by asking what at first seems to be a daft question. If your car's engine idles smoothly at 800rpm, what speed is the crankshaft doing? No, it's not 800rpm, except perhaps for a millisecond or two. The rev counter only reads 800rpm because it only registers an average value. The real instantaneous speed fluctuates, in the case of the four-cylinder, between about 710 and 860rpm, during the course of one revolution. Why does this variation happen? One of the reasons is that the flywheel cannot do a perfect job. It has been designed to smooth the individual firing pulses and speed variation as much as possible, but can only be successful within certain limits, as dictated by its dimensions. Another reason is torsional vibration, the winding and unwinding of the crankshaft caused by the varying forces acting on it. At certain speeds, the crankshaft even writhes like a snake in the free space between the main bearings, causing eventual bell-mouthing of the main bearings.

Here are a few definitions which will be helpful for this discussion.

1. A FREQUENCY is exactly what the word suggests: vibration at a specific number of cycles per second, as in 400 cycles per second or Hertz, or how frequently the oscillation occurs.

2. An ORDER is a specific multiple of a basic frequency. For example an even-firing eight-cylinder, four-stroke engine produces four torque pulses per revolution (a fourth order excitation). If the crankshaft in such an engine was operating at 6000 RPM, then the frequency of the fourth order excitation is 4 x 6000 / 60 = 400 hertz whereas the same 4th order excitation at 7200 RPM is a frequency of 480 hertz.

3. A DAMPER is a device which dissipates energy, mainly in the form of heat.

4. An ABSORBER is a device which is designed to oscillate in direct opposition to a vibration at either a specific frequency or a specific order, depending on the design.

A crankshaft made from a piece of high-strength steel is nearly a perfect spring, and it contains very little inherent damping, so it becomes important to provide some means of attenuating the torsional oscillations which occur near resonant frequencies, especially at the free end of the crankshaft. (Opposite end to the flywheel)

Many engines, including virtually all V6’s & V8’s use a device on the free end of the crankshaft to attenuate the amplitude of what could otherwise become destructive torsional oscillations of the crank. Without an appropriate absorber, the life expectancy of the crankshaft in a typical American V8 engine at full power can usually be measured in minutes.

Many of the automotive 4-cylinder engines don’t require such an absorber, primarily because of their inherently higher stiffness-to-mass ratios. However, several automotive manufacturers have initially omitted a torsional absorber from early engine runs, only to find that crankshaft life was unacceptably short. Nissan discovered this with the early 240-Z engines, which didn’t have an absorber, and therefore lasted only about 100 hours in automotive (i.e. VERY LIGHT DUTY) service.

Often, the vibration attenuating devices on the free end of an engine crankshaft are incorrectly referred to as "DAMPERS". In many cases, they are ABSORBERS.

Elastomeric Absorbers

The elastomeric ("metal-ring-on-rubber-spring") devices used by the automotive industry are ABSORBERS which are tuned to counteract vibration at the frequency where the particular engine generates its worst torsional excitation. They also add a small amount of damping to the system.

By design, this style of absorber has a single resonant frequency, which is tuned by means of the MMOI (mass moment of inertia) of the inertia ring and the durometer (stiffness) of the elastomers to the specific frequency (crankshaft RPM times excitation order) at which measurements have shown the crankshaft vibration amplitude to be the worst.

Unfortunately, there is often more than one strong excitation order. Current science shows that the predominant excitation in a two-plane V8 crankshaft is the 2.5 order, followed next by the (more intuitive) 4th order. There is a new development in the inertia-ring - elastomeric style damper which provides the ability to tune for more than one critical frequency.

Pendulum-Style Order-Absorbers

In addition to the elastomeric style of absorber, there is a type of absorber which by design, attenuates a particular order of vibration. This style is known as a pendulum absorber, and was developed in the nineteen thirties to solve serious torsional vibration problems in radial aircraft engines. Both Continental and Lycoming use this style of pendulum absorber in all their high-output engines.

This style of internal absorber consists of pendulous counterweights attached to the crankshaft cheeks by loose pins in hard bushings, as shown below. It is a tuned absorber whose natural frequency is directly proportional to the rotational speed of the crankshaft.

There is an aftermarket product (The Rattler™) which attempts to implement this method of order-absorption by means of heavy-metal cylinders which fit inside appropriately-sized longitudinal cylindrical bores in a round device attached to the nose of the crankshaft.

In contrast to an absorber, the advantage of a pure damper is that it will tend to reduce the amplitude of any frequency. The disadvantage is that the energy is dissipated as heat, so a suitable amount of cooling must be provided.

Frictional & Fluid dampers

There are frictional dampers as well as inertia-ring-in-high-viscosity-fluid dampers available in the aftermarket,

One aftermarket device, the Fluidampr™, is an example of a damper. It dissipates energy by transforming it into heat by shearing action in a high viscosity fluid. (usually silicone)

It is obvious that modifications to an original engine design which affect crankshaft stiffness and / or system MMOI (stroke, counterweights, bobweight {therefore counterweight} mass, clutch and flywheel MMOI, etc) will change the system resonant frequency. In order to determine the correct solution for a particular engine combination, the engine designer must a) do the measurements to determine the critical frequencies in your application and (b) and design or obtain an absorber tuned for the correct order or frequency, as fits with the application.

Some comments from authoritative scribes

“One crankshaft manufacturer describes torsional absorbers / dampers as "a great hoax", based on two observations he has made in his experience: (1) A crankshaft which has an absorber tuned to the wrong frequency has a very short life expectancy, and (2) Certain aftermarket absorber / damper products installed on a crankshaft pose extreme difficulties in balancing the assembly.”

“Internal combustion engine construction makes it susceptible to resonant torsional oscillation of the crankshaft. When it is operated near a critical speed [a speed at which the pulsations produced by each cylinder excite the natural frequency of the crankshaft] excessive torsional amplitudes are developed which may seriously damage the engine. The crankshaft damper is fitted to minimise the influence of torsional vibrations developing in the crankshaft. This keeps material stresses arising from these vibrations within permissible design limits. The damper, by reducing oscillations in the crankshaft to low amplitude, prevents premature failures of the crankshaft and driven equipment.”

“Torsional vibration peaks occur when a frequency component of the piston firing and reciprocating torques gets close to one of the built in frequencies of the crank. When the inputs get close to a natural frequency, the system goes resonant and the twist angle gets magnified about 6 – 10 times the normal amount in a very sharp “peak” that is only a few hundred rpm wide. This magnified twist is what does the damage in crank stress and bearing wear. It is dangerous in that it builds up fatigue stress cycles very quickly because it is such a high frequency. The vibratory torques at these resonant peaks can get much higher than the drive torque going out the flywheel. The first natural frequency of typical V8 & V6’s are usually in the 300 – 450 cycles/second range.”

Last edited by Glyn M Ruck; 01-26-2009 at 05:51 PM.

#37

Super Moderator

Thread Starter

See above.

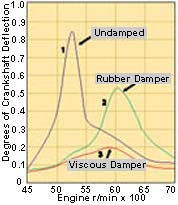

I ran out of permitted attachments. These complete the picture

Frictional Damper X-section;

Hybrid Fluid/Elastomeric damper

Effects of absorbers & dampers

Frictional Damper X-section;

Hybrid Fluid/Elastomeric damper

Effects of absorbers & dampers

Last edited by Glyn M Ruck; 01-26-2009 at 05:45 PM.

#39

Moderator Alumni

Some comments from authoritative scribes

“One crankshaft manufacturer describes torsional absorbers / dampers as "a great hoax", based on two observations he has made in his experience: (1) A crankshaft which has an absorber tuned to the wrong frequency has a very short life expectancy, and (2) Certain aftermarket absorber / damper products installed on a crankshaft pose extreme difficulties in balancing the assembly.”

“Internal combustion engine construction makes it susceptible to resonant torsional oscillation of the crankshaft. When it is operated near a critical speed [a speed at which the pulsations produced by each cylinder excite the natural frequency of the crankshaft] excessive torsional amplitudes are developed which may seriously damage the engine. The crankshaft damper is fitted to minimise the influence of torsional vibrations developing in the crankshaft. This keeps material stresses arising from these vibrations within permissible design limits. The damper, by reducing oscillations in the crankshaft to low amplitude, prevents premature failures of the crankshaft and driven equipment.”

“Torsional vibration peaks occur when a frequency component of the piston firing and reciprocating torques gets close to one of the built in frequencies of the crank. When the inputs get close to a natural frequency, the system goes resonant and the twist angle gets magnified about 6 – 10 times the normal amount in a very sharp “peak” that is only a few hundred rpm wide. This magnified twist is what does the damage in crank stress and bearing wear. It is dangerous in that it builds up fatigue stress cycles very quickly because it is such a high frequency. The vibratory torques at these resonant peaks can get much higher than the drive torque going out the flywheel. The first natural frequency of typical V8 & V6’s are usually in the 300 – 450 cycles/second range.”

“One crankshaft manufacturer describes torsional absorbers / dampers as "a great hoax", based on two observations he has made in his experience: (1) A crankshaft which has an absorber tuned to the wrong frequency has a very short life expectancy, and (2) Certain aftermarket absorber / damper products installed on a crankshaft pose extreme difficulties in balancing the assembly.”

“Internal combustion engine construction makes it susceptible to resonant torsional oscillation of the crankshaft. When it is operated near a critical speed [a speed at which the pulsations produced by each cylinder excite the natural frequency of the crankshaft] excessive torsional amplitudes are developed which may seriously damage the engine. The crankshaft damper is fitted to minimise the influence of torsional vibrations developing in the crankshaft. This keeps material stresses arising from these vibrations within permissible design limits. The damper, by reducing oscillations in the crankshaft to low amplitude, prevents premature failures of the crankshaft and driven equipment.”

“Torsional vibration peaks occur when a frequency component of the piston firing and reciprocating torques gets close to one of the built in frequencies of the crank. When the inputs get close to a natural frequency, the system goes resonant and the twist angle gets magnified about 6 – 10 times the normal amount in a very sharp “peak” that is only a few hundred rpm wide. This magnified twist is what does the damage in crank stress and bearing wear. It is dangerous in that it builds up fatigue stress cycles very quickly because it is such a high frequency. The vibratory torques at these resonant peaks can get much higher than the drive torque going out the flywheel. The first natural frequency of typical V8 & V6’s are usually in the 300 – 450 cycles/second range.”

)...

)...So in short, it would be very difficult to build something that eliminates ALL resonate torsional oscillations, but the idea of the dampers/absorbers is to minimize the influences the oscillations have on the crankshaft.

Even if the engine dampers / absorbers are still present, it doesn't mean that we cant reach the natural frequency where things can get ugly. It just means that it'll be HARDER cause damage IF we do reach the natural frequency.

300-450 cycles/second results in 18000 - 27000 RPM... Even if that "typical" v6/v8 is fudged some, I would have to be revving my car 15000+ rpm to reach a harmful resonate frequency and maintain that rpm for a short period to serious harm. I dont think Ive ever seen my car over 5000....

Glyn, thanks for the summary! And if I didnt quiet get it right... please do correct me

#40

With that said, I too have run non-dampened pulleys in the past ages ago, but the harmonic sound 6800+ did become bothersome. Put about 20k on it with no problems, but none the less it inspired me long time ago to come up with an aftermarket solution that was harmonic dampened.

With that said, I think that proves that our pulleys are safe (contrary to what people may bash/trash otherwise).

Last edited by AMS Performance; 01-26-2009 at 07:39 PM.

#41

Glyn deserves  Very informative and very in depth. It obviously took you a long time to write that so in that regard you deserve a round of applause.

Very informative and very in depth. It obviously took you a long time to write that so in that regard you deserve a round of applause.

+1 on the textbook

Very informative and very in depth. It obviously took you a long time to write that so in that regard you deserve a round of applause.

Very informative and very in depth. It obviously took you a long time to write that so in that regard you deserve a round of applause. +1 on the textbook

#42

MBWorld Fanatic!

Nice explanation, thanks. I never realized how important (and difficult!) the design of a crankshaft pulley is. It's also apparent that unless you get a properly engineered pulley you are adversely affecting the crank and main bearings.

#43

Super Moderator

Thread Starter

Thinking out loud (and not in crazy glyn language  )...

)...

So in short, it would be very difficult to build something that eliminates ALL resonate torsional oscillations, but the idea of the dampers/absorbers is to minimize the influences the oscillations have on the crankshaft.

Even if the engine dampers / absorbers are still present, it doesn't mean that we cant reach the natural frequency where things can get ugly. It just means that it'll be HARDER cause damage IF we do reach the natural frequency.

300-450 cycles/second results in 18000 - 27000 RPM... Even if that "typical" v6/v8 is fudged some, I would have to be revving my car 15000+ rpm to reach a harmful resonate frequency and maintain that rpm for a short period to serious harm. I dont think Ive ever seen my car over 5000....

Glyn, thanks for the summary! And if I didnt quiet get it right... please do correct me

)...

)...So in short, it would be very difficult to build something that eliminates ALL resonate torsional oscillations, but the idea of the dampers/absorbers is to minimize the influences the oscillations have on the crankshaft.

Even if the engine dampers / absorbers are still present, it doesn't mean that we cant reach the natural frequency where things can get ugly. It just means that it'll be HARDER cause damage IF we do reach the natural frequency.

300-450 cycles/second results in 18000 - 27000 RPM... Even if that "typical" v6/v8 is fudged some, I would have to be revving my car 15000+ rpm to reach a harmful resonate frequency and maintain that rpm for a short period to serious harm. I dont think Ive ever seen my car over 5000....

Glyn, thanks for the summary! And if I didnt quiet get it right... please do correct me

Last edited by Glyn M Ruck; 01-27-2009 at 02:47 AM. Reason: typo

#45

MBworld Guru

Join Date: Apr 2002

Location: Diamond Bar, CA

Posts: 22,007

Likes: 0

Received 6 Likes

on

6 Posts

white and whiter

You must have a massive pair

With that said, I too have run non-dampened pulleys in the past ages ago, but the harmonic sound 6800+ did become bothersome. Put about 20k on it with no problems, but none the less it inspired me long time ago to come up with an aftermarket solution that was harmonic dampened.

With that said, I think that proves that our pulleys are safe (contrary to what people may bash/trash otherwise).

With that said, I too have run non-dampened pulleys in the past ages ago, but the harmonic sound 6800+ did become bothersome. Put about 20k on it with no problems, but none the less it inspired me long time ago to come up with an aftermarket solution that was harmonic dampened.

With that said, I think that proves that our pulleys are safe (contrary to what people may bash/trash otherwise).

although i'm not that convinced same size pulley except in lighter weight will return much HP is any except that on the initial throttle response.

Last edited by FrankW; 01-27-2009 at 02:44 AM.

#46

Super Moderator

Thread Starter

It's interesting and maybe timely - just got our monthly auto mag "CAR" in the mail. In the technical section is a tale of woe from a school teacher who has just experienced crankshaft breakage at the rear main journal on his BMW 328i. It was found that the BMW OE absorber had suffered elastomer failure due to prolonged exposure to heat and that it's inertia ring was about to separate completely from the assembly.

I guess this serves as a warning. These dampers/absorbers do not last forever. If you ever feel any unexplained vibration from the vehicle it is a part that requires to be checked for integrity sooner rather than later. This poor school teacher explains that he was experiencing vibration that increased on hard acceleration (higher torque) and that the dealer had diagnosed the problem as propshaft vibration & recommended balancing & a U joint checkup.

That said, I speculate that Benz build bullet proof fairly short throw cranks (high torque, long throw designs are more problematic) and have engineered the crankshaft system to resonate crucially outside the normal useable rev range of the engine. Another reason that removing rev limiters is not clever. Toyota's wonderful old 4 AGE twincam engine would rev to 10,000 RPM with the limiter out , but if you did not rev it through the 7700RPM mark quickly it would wipe the bearings because of resonance.

I guess this serves as a warning. These dampers/absorbers do not last forever. If you ever feel any unexplained vibration from the vehicle it is a part that requires to be checked for integrity sooner rather than later. This poor school teacher explains that he was experiencing vibration that increased on hard acceleration (higher torque) and that the dealer had diagnosed the problem as propshaft vibration & recommended balancing & a U joint checkup.

That said, I speculate that Benz build bullet proof fairly short throw cranks (high torque, long throw designs are more problematic) and have engineered the crankshaft system to resonate crucially outside the normal useable rev range of the engine. Another reason that removing rev limiters is not clever. Toyota's wonderful old 4 AGE twincam engine would rev to 10,000 RPM with the limiter out , but if you did not rev it through the 7700RPM mark quickly it would wipe the bearings because of resonance.

#47

It's interesting and maybe timely - just got our monthly auto mag "CAR" in the mail. In the technical section is a tale of woe from a school teacher who has just experienced crankshaft breakage at the rear main journal on his BMW 328i. It was found that the BMW OE absorber had suffered elastomer failure due to prolonged exposure to heat and that it's inertia ring was about to separate completely from the assembly.

I guess this serves as a warning. These dampers/absorbers do not last forever. If you ever feel any unexplained vibration from the vehicle it is a part that requires to be checked for integrity sooner rather than later. This poor school teacher explains that he was experiencing vibration that increased on hard acceleration (higher torque) and that the dealer had diagnosed the problem as propshaft vibration & recommended balancing & a U joint checkup.

I guess this serves as a warning. These dampers/absorbers do not last forever. If you ever feel any unexplained vibration from the vehicle it is a part that requires to be checked for integrity sooner rather than later. This poor school teacher explains that he was experiencing vibration that increased on hard acceleration (higher torque) and that the dealer had diagnosed the problem as propshaft vibration & recommended balancing & a U joint checkup.

#48

Super Member

Join Date: Dec 2008

Location: MD

Posts: 526

Likes: 0

Received 1 Like

on

1 Post

2007 C230 and 1985 Monte SS

Wow Glyn!

What are your thoughts on running a viscous damper on a street driven, internally balanced 350 small block chevy? It seems that the fluidamper type dampers are very effective, but will heat up. I'm wondering if prolonged use (as on road trips) would cause it to overheat and cause problems, such as a problematic decrease in the silicone viscosity.

To AMS- I read in another thread that you claimed fuel mileage gains by the addition of your pulley, and this claim was supported by a picture of the mpg reading on the dashboard of your car, and a little later, the following claim:

And you later said that it was level ground as well.

Steady 70 mph means a constant RPM.

Now correct me if I'm wrong here (I'm not trying to attack your claims, I just dont understand how this is possible) but if the RPM of the engine (and therefore the pulley) is not changing, then how can the pulley be affecting the engine's efficiency. The change in mass of the pulley changes the MMOI, which in turn makes the pulley easier or harder to accelerate radially. But, if the motor is spinning at a constant speed, the only energy required to keep the pulley spinning is due to friction.

I just dont see how a change in mass of the pulley will affect the power required to keep it spinning at a constant speed, and therefore the power saved by the motor which can be converted to fuel savings.

Thanks for any input.

What are your thoughts on running a viscous damper on a street driven, internally balanced 350 small block chevy? It seems that the fluidamper type dampers are very effective, but will heat up. I'm wondering if prolonged use (as on road trips) would cause it to overheat and cause problems, such as a problematic decrease in the silicone viscosity.

To AMS- I read in another thread that you claimed fuel mileage gains by the addition of your pulley, and this claim was supported by a picture of the mpg reading on the dashboard of your car, and a little later, the following claim:

Originally Posted by omeyhomey

nope, no cheating, thats 100% honest look at the mph average, you can't cheat that (hence the picture). Thats a true 15 mile avg @ cruising at a steady 70 mph

Steady 70 mph means a constant RPM.

Now correct me if I'm wrong here (I'm not trying to attack your claims, I just dont understand how this is possible) but if the RPM of the engine (and therefore the pulley) is not changing, then how can the pulley be affecting the engine's efficiency. The change in mass of the pulley changes the MMOI, which in turn makes the pulley easier or harder to accelerate radially. But, if the motor is spinning at a constant speed, the only energy required to keep the pulley spinning is due to friction.

I just dont see how a change in mass of the pulley will affect the power required to keep it spinning at a constant speed, and therefore the power saved by the motor which can be converted to fuel savings.

Thanks for any input.

Last edited by SickSpeedMonte; 01-27-2009 at 12:48 PM.

#49

Super Moderator

Thread Starter

#50

Super Moderator

Thread Starter

Wow Glyn!

What are your thoughts on running a viscous damper on a street driven, internally balanced 350 small block chevy? It seems that the fluidamper type dampers are very effective, but will heat up. I'm wondering if prolonged use (as on road trips) would cause it to overheat and cause problems, such as a problematic decrease in the silicone viscosity.

What are your thoughts on running a viscous damper on a street driven, internally balanced 350 small block chevy? It seems that the fluidamper type dampers are very effective, but will heat up. I'm wondering if prolonged use (as on road trips) would cause it to overheat and cause problems, such as a problematic decrease in the silicone viscosity.

See fluid degradation.

Normal fluid

Deterioration starting

Time for change

Too damn late