Suggestions on Transmission and Engine Rebuild ?

#26

Push it a bit with your fingers and if it doesn´t pop off, it should be ok. But you might feel better with a new one..

-One tip while I´m at it.. I recommend replacing the B1 piston with a newer version. MB number 124 270 12 32. It´s self adjusting and not that expensive. No adjustment for the front brake band needed if you install it.

Cheers,

-One tip while I´m at it.. I recommend replacing the B1 piston with a newer version. MB number 124 270 12 32. It´s self adjusting and not that expensive. No adjustment for the front brake band needed if you install it.

Cheers,

#28

The pin actually guides the B3 piston into place. It doesn´t hold the pump in place. The B3 piston only fits one way and doesn´t rotate. When excessive B3 clutch wear is present, the B3 piston pushes too far outwards and starts nudging against the rotating K1 carrier, applying rotating force on the B3 piston. This is what commonly breaks the guiding pin.

Cheers,

Cheers,

#29

Super Member

Join Date: Nov 2002

Location: San Jose

Posts: 977

Received 0 Likes

on

0 Posts

300TE / 300E / 300CE

Anyone know if the later valve body fits the early transmissions? If I rebuild, I may as well upgrade to 1st gear start and any improvements...

#30

The pin actually guides the B3 piston into place. It doesn´t hold the pump in place. The B3 piston only fits one way and doesn´t rotate. When excessive B3 clutch wear is present, the B3 piston pushes too far outwards and starts nudging against the rotating K1 carrier, applying rotating force on the B3 piston. This is what commonly breaks the guiding pin.

Cheers,

Cheers,

#31

2wheelsoff, thanks for the link to the rebuild kit.

I've been studying the rebuild docs, think I'm going to give it a go. Couple questions maybe someone can help me with.

1. I see the rebuild kit does not include the B1 and B2 brake bands. Are the originals usually just reinstalled?

2. During dissasembly, are there any steps where upon taking something apart, the parts kinda fall out/scatter? I'm trying to anticipate as much as possible--If I can study things as they come apart, it should be easier to correctly reassemble. (remember, this will be my first tranny rebuild)

By the way, thanks to all who have shared info on this subject, posts like these are a big help when contemplating a "never done that before" project.

J. M. van Swaay

I've been studying the rebuild docs, think I'm going to give it a go. Couple questions maybe someone can help me with.

1. I see the rebuild kit does not include the B1 and B2 brake bands. Are the originals usually just reinstalled?

2. During dissasembly, are there any steps where upon taking something apart, the parts kinda fall out/scatter? I'm trying to anticipate as much as possible--If I can study things as they come apart, it should be easier to correctly reassemble. (remember, this will be my first tranny rebuild)

By the way, thanks to all who have shared info on this subject, posts like these are a big help when contemplating a "never done that before" project.

J. M. van Swaay

#33

The bands are usually not included in the kits, but replacing brake band b2 might be a smart move. Especially if there are visible cracks in it. Front brake band is seldom a problem.

But like ps2cho said.. go slow and keep it clean..

Cheers,

But like ps2cho said.. go slow and keep it clean..

Cheers,

#34

Super Member

Join Date: Nov 2002

Location: San Jose

Posts: 977

Received 0 Likes

on

0 Posts

300TE / 300E / 300CE

This is the comprehensive kit:

http://www.partsgeek.com/gbproducts/...ek+Google+Base

It looks complete, and is by far the cheapest I have seen that is complete. (no filter though). I will know more once I re assemble and let everyone know here if there is anything missing. So far i need some K1 Steels due to the wear, some springs and retainer. I am going to look for used ones.

If it is slipping definitely rebuild soon, that way you only need to replace seals and clutches. If metal gets around you may have more issues. I haven't found anything too traumatizing yet.

http://www.partsgeek.com/gbproducts/...ek+Google+Base

It looks complete, and is by far the cheapest I have seen that is complete. (no filter though). I will know more once I re assemble and let everyone know here if there is anything missing. So far i need some K1 Steels due to the wear, some springs and retainer. I am going to look for used ones.

If it is slipping definitely rebuild soon, that way you only need to replace seals and clutches. If metal gets around you may have more issues. I haven't found anything too traumatizing yet.

here's a seal kit from AutohausAZ

Last edited by pifcat2; 05-30-2010 at 02:42 PM.

#35

Junior Member

Thread Starter

Join Date: Mar 2009

Location: Santa Monica

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

W124's; 92-2.6, 94-wagon

I will not ge to rebuilding till after the 8th of june due to work sched. I will keep you posted once I get through it and see if I notice any visible difference in clutches or material. I am hoping with proper care I should get another 150,000 miles from this tranny...but you never know.

#36

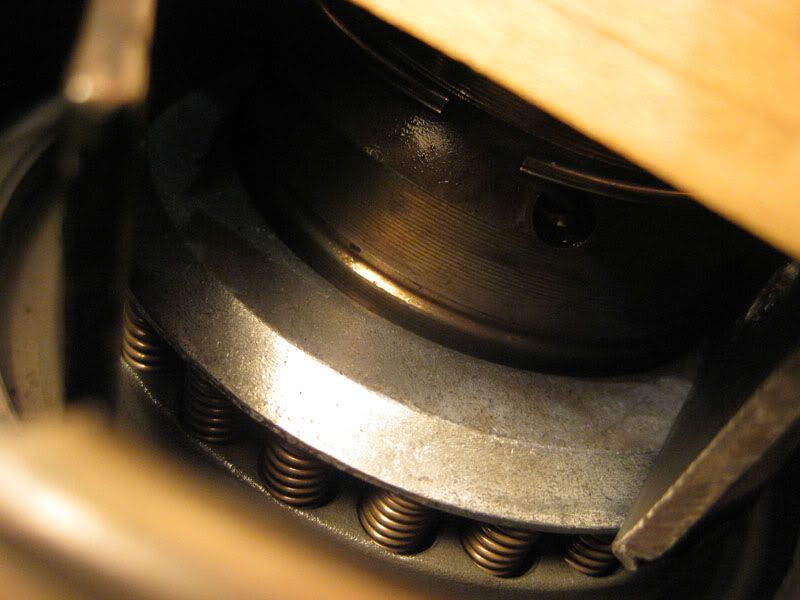

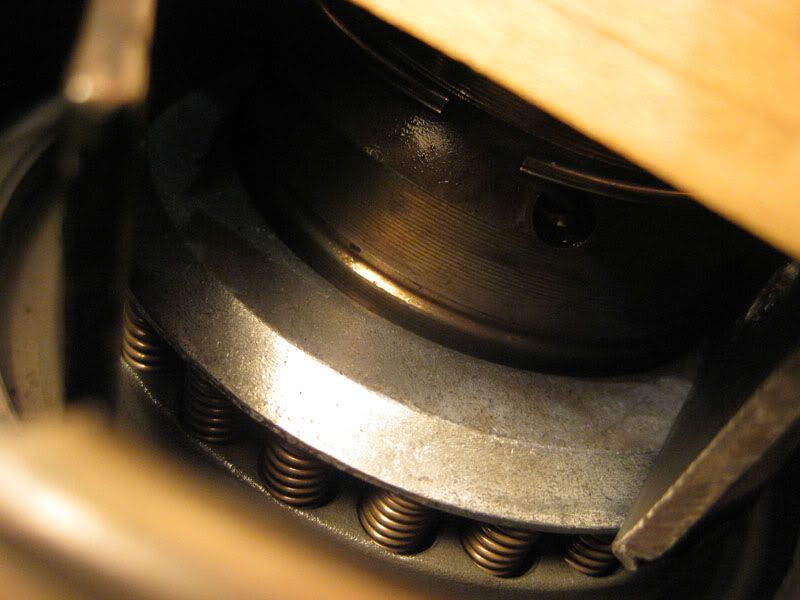

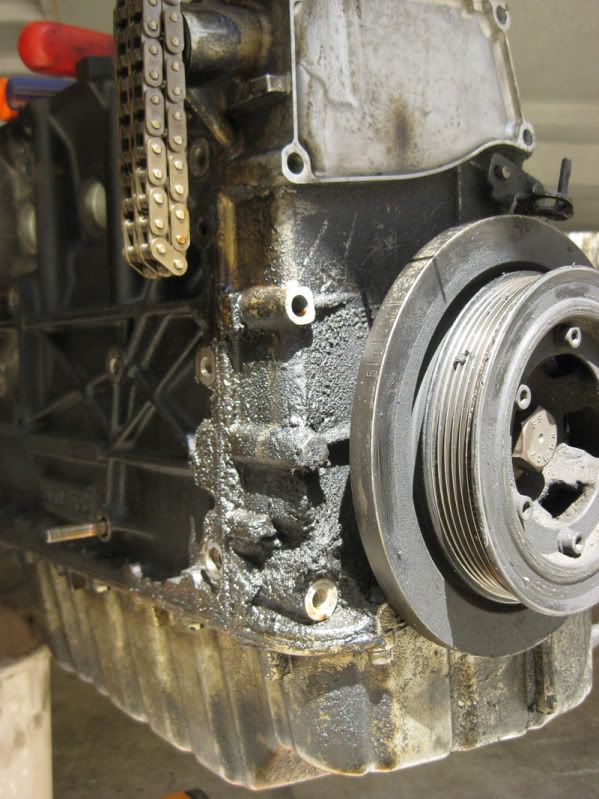

Transmission is out and partially disassembled. I have the B3 piston to K1 clutch contact damage, see picture.

I posted on Peachparts but thought I'd followup here as well.

J. M. van Swaay

I posted on Peachparts but thought I'd followup here as well.

J. M. van Swaay

#37

Junior Member

Thread Starter

Join Date: Mar 2009

Location: Santa Monica

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

W124's; 92-2.6, 94-wagon

Parts came in from Peter Schmid Trans in CA. thanks to Compress Ignite posted on ps2cho's post in peachparts forum for the lead.

2 5mm steels

20 springs

1 spring retainer

all new - shipped just under $100

I'll start the build tomorrow. Not too much free time, but should have it together pretty quickly. Then I start tearing into the motor.

2 5mm steels

20 springs

1 spring retainer

all new - shipped just under $100

I'll start the build tomorrow. Not too much free time, but should have it together pretty quickly. Then I start tearing into the motor.

#38

Junior Member

Thread Starter

Join Date: Mar 2009

Location: Santa Monica

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

W124's; 92-2.6, 94-wagon

K1 rebuild + B3 assembly without specialty tools +K2 to rebuild or not.

Tomorrow turned into a a 2 week delay due to schedule craziness.

I started a couple nights ago...decided to do a full build including the lower seals in the K1 drum since it came with the kit. Had to figure out the lower snap ring removal...use a pick to pry outward, slide in a flatblade screwdriver, swivel screwdriver and pry upward on snapring, and work around groove. For re installation use a pick and work your way around the seal or else it can get pinched.

Pic of rebuild kit (note: I didn't include pic of clutches..it comes with one extra for the K1, and i am assuming the same for K2 and B3)

B3 snap ring install without specialty tools. You can do this with another set of hands, but frankly this took 3 minutes to engineer, and I didn't have an extra set of hands at the time:

K1 Removal and install of snap ring...again easy to do with some spacing tools and wood clamps. I used a leftover piece of metal scrap from our Lemons racecar front airdam that got trashed...yes I keep everything just in case.

Now I have to figure out if I am really going to drill out the rivets in the K2 to replace the lower seal. The rebuild kit includes countersunk screws (I am guessing for this purpose).

Any suggestions?

I started a couple nights ago...decided to do a full build including the lower seals in the K1 drum since it came with the kit. Had to figure out the lower snap ring removal...use a pick to pry outward, slide in a flatblade screwdriver, swivel screwdriver and pry upward on snapring, and work around groove. For re installation use a pick and work your way around the seal or else it can get pinched.

Pic of rebuild kit (note: I didn't include pic of clutches..it comes with one extra for the K1, and i am assuming the same for K2 and B3)

B3 snap ring install without specialty tools. You can do this with another set of hands, but frankly this took 3 minutes to engineer, and I didn't have an extra set of hands at the time:

K1 Removal and install of snap ring...again easy to do with some spacing tools and wood clamps. I used a leftover piece of metal scrap from our Lemons racecar front airdam that got trashed...yes I keep everything just in case.

Now I have to figure out if I am really going to drill out the rivets in the K2 to replace the lower seal. The rebuild kit includes countersunk screws (I am guessing for this purpose).

Any suggestions?

#39

Junior Member

Thread Starter

Join Date: Mar 2009

Location: Santa Monica

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

W124's; 92-2.6, 94-wagon

on to the engine

K2 was drilled and tapped and Trans is rebuilt. Total rebuild time was 5 hours for tear down and 10-12 hours for rebuild.

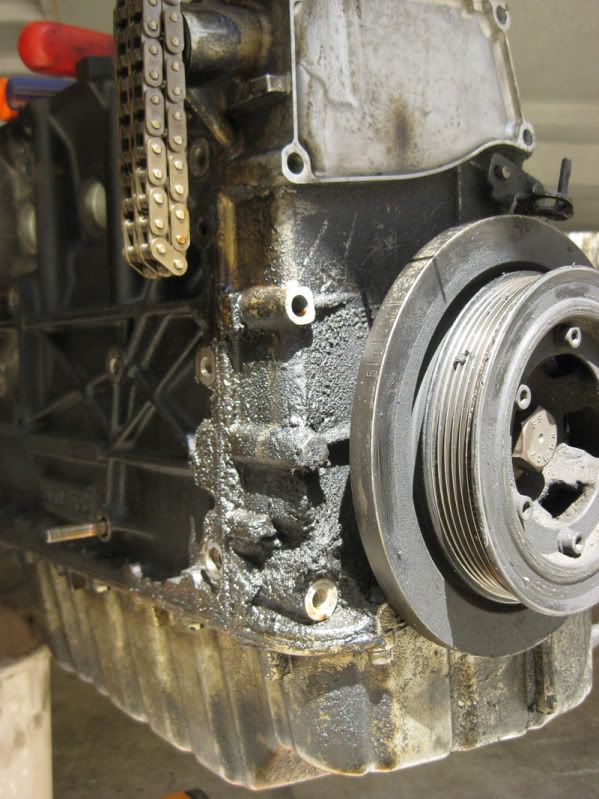

Engine time.... Head gasket has a severe engine leak in the passenger rear.

and the front cover and radial seal is leaking

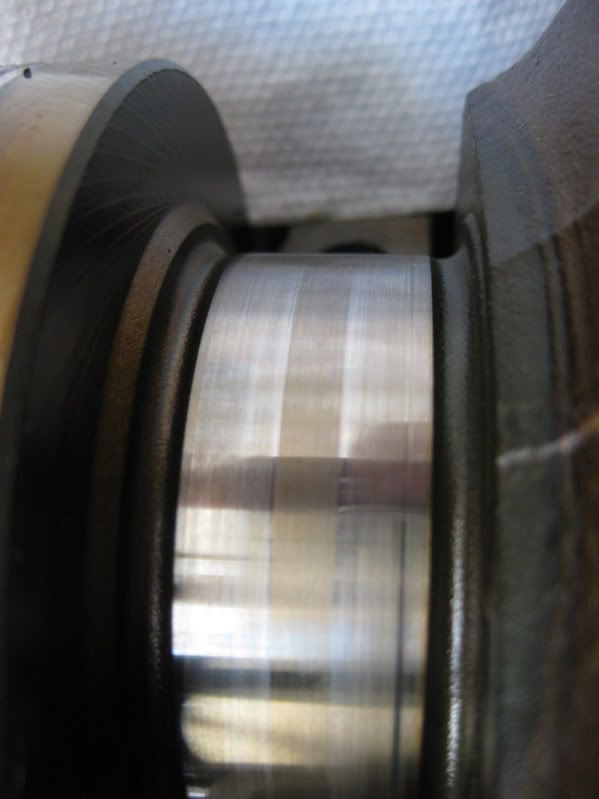

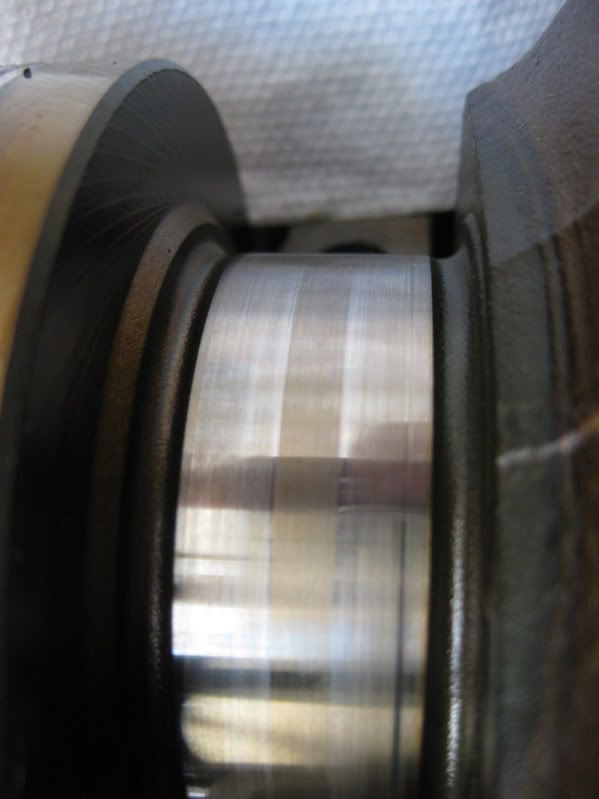

I checked the rearmost main bearing and the #6 rod bearing (what showed the most wear in the bmw engines I have seen) for wear or heat scoring and they look really good to me.

Crankshaft looks good too.

Parts on order are timing chain guide rails (all have grooves worn into them <1mm.) I already have the head gasket seal set, the lower engine seal set, the valve cover set, the tensioner and hoses. I need to replace to two vacuum hoses because both cracked when trying to remove them.

Any other wear items I should look at?

Engine time.... Head gasket has a severe engine leak in the passenger rear.

and the front cover and radial seal is leaking

I checked the rearmost main bearing and the #6 rod bearing (what showed the most wear in the bmw engines I have seen) for wear or heat scoring and they look really good to me.

Crankshaft looks good too.

Parts on order are timing chain guide rails (all have grooves worn into them <1mm.) I already have the head gasket seal set, the lower engine seal set, the valve cover set, the tensioner and hoses. I need to replace to two vacuum hoses because both cracked when trying to remove them.

Any other wear items I should look at?

#40

Junior Member

Thread Starter

Join Date: Mar 2009

Location: Santa Monica

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

W124's; 92-2.6, 94-wagon

Update -

Engine and Trans are finished and back in the car. It runs well and shifts well with one exception - no downshift / kickdown on full throttle. I have played withthe adjustment on the bowden cable and there is no change. Vacuum lines are hooked up correctly (99.9% certain).

124-Fan I did change the brake band piston as well. thanks for the suggestion.

Any ideas on starting points to figure out downshifting?

Engine and Trans are finished and back in the car. It runs well and shifts well with one exception - no downshift / kickdown on full throttle. I have played withthe adjustment on the bowden cable and there is no change. Vacuum lines are hooked up correctly (99.9% certain).

124-Fan I did change the brake band piston as well. thanks for the suggestion.

Any ideas on starting points to figure out downshifting?