For anyone who has had there pulleys come off...

#26

Senior Member

I am concerned about the key being tall enough -- hard to tell from the pictures -- but looks as if the OEM key was half the length but twice as tall as the one you put in ... If thats the case -- You better make that new key taller.... other wise it looks great - good luck

#27

Senior Member

Join Date: Jun 2008

Location: Germany

Posts: 369

Likes: 0

Received 0 Likes

on

0 Posts

c200k

"Aftermarket" is the key here. Parallel keys are not typically used stock to increase the strength and longevity of the crank and to avoid cracking and/or splitting over time, either by loads placed on the crank via the pulley, or thermal cycling and tolerances. The smaller stock keys have proven strong enough for decades now, and also proven to not induce problems of their own- such as being significant weak points in the designs of cranks, leading to their destruction.

#28

MBWorld Fanatic!

Join Date: Jun 2007

Location: Philadelphia, PA

Posts: 2,949

Likes: 0

Received 0 Likes

on

0 Posts

2008 A8L, 2002 996TT X50, 2009 X5

"Aftermarket" is the key here. Parallel keys are not typically used stock to increase the strength and longevity of the crank and to avoid cracking and/or splitting over time, either by loads placed on the crank via the pulley, or thermal cycling and tolerances. The smaller stock keys have proven strong enough for decades now, and also proven to not induce problems of their own- such as being significant weak points in the designs of cranks, leading to their destruction.

Last edited by c32AMG-DTM; 03-29-2011 at 09:08 AM.

#29

MBWorld Fanatic!

Thread Starter

Join Date: Jun 2010

Location: Puerto Rico

Posts: 4,173

Likes: 0

Received 5 Likes

on

4 Posts

2005 E55 AMG

Just to add... my understanding was that the woodruff key wasn't really intended to withstand the shearing forces imparted by a loose crank pulley. Tightening a fresh OEM crank pulley bolt to 200 nM, plus an additional 90* turn, is the only way to ensure that it is torqued sufficiently and properly. Other installation methods (i.e. impact gun) might work, but how do you verify the bolt received the proper torque? If you gun it to 200 nM (around 150 ft lbs)... you haven't even come close to the actual spec.

Again...I'm not saying this is BETTER than oem. It's just better than a new crankshaft or engine ( hopefully anyways ).

Last edited by GT-ER; 03-29-2011 at 08:57 AM.

#30

MBWorld Fanatic!

Join Date: Jun 2007

Location: Philadelphia, PA

Posts: 2,949

Likes: 0

Received 0 Likes

on

0 Posts

2008 A8L, 2002 996TT X50, 2009 X5

You are correct...the woodruff key isn't designed for high shearing forces. It relies on a high clamping force to allow for the shearing forces to be as low as possible. In my case I doubt I can get to high clamping force due to the shaft being worn down...so I now need to rely on something that can take high sheering forces. Another thing is that the oem system is designed to allow for easy disassembly and reassembly with generally zero alignment issues. The parallel key will usually clamp on pretty hard and usually makes a puller necessary. I may also take more than one try to make sure the pulley doesn't wobble.

Again...I'm not saying this is BETTER than oem. It's just better than a new crankshaft or engine ( hopefully anyways ).

Again...I'm not saying this is BETTER than oem. It's just better than a new crankshaft or engine ( hopefully anyways ).

But I get your point. Good luck with your repairs. Saw in the other thread that you're supposed to torque EC's pulley to 275 ft/lbs (373 Nm), plus the additional 90* turn. That's gonna be tough... good luck; keep us posted on how it goes.

But I get your point. Good luck with your repairs. Saw in the other thread that you're supposed to torque EC's pulley to 275 ft/lbs (373 Nm), plus the additional 90* turn. That's gonna be tough... good luck; keep us posted on how it goes.

#31

MBWorld Fanatic!

Thread Starter

Join Date: Jun 2010

Location: Puerto Rico

Posts: 4,173

Likes: 0

Received 5 Likes

on

4 Posts

2005 E55 AMG

Our definition of "easy" must be different.  But I get your point. Good luck with your repairs. Saw in the other thread that you're supposed to torque EC's pulley to 275 ft/lbs (373 Nm), plus the additional 90* turn. That's gonna be tough... good luck; keep us posted on how it goes.

But I get your point. Good luck with your repairs. Saw in the other thread that you're supposed to torque EC's pulley to 275 ft/lbs (373 Nm), plus the additional 90* turn. That's gonna be tough... good luck; keep us posted on how it goes.

But I get your point. Good luck with your repairs. Saw in the other thread that you're supposed to torque EC's pulley to 275 ft/lbs (373 Nm), plus the additional 90* turn. That's gonna be tough... good luck; keep us posted on how it goes.

But I get your point. Good luck with your repairs. Saw in the other thread that you're supposed to torque EC's pulley to 275 ft/lbs (373 Nm), plus the additional 90* turn. That's gonna be tough... good luck; keep us posted on how it goes.

#33

MBWorld Fanatic!

Am I correct in assuming that the wobble is caused by not bottoming the hub on the crank snout?

Can you post a picture of the inside of the hub/pulley, where it mates to the front of the crank snout? Is the keyway on the hub/pulley f ucked up? (can't believe f uck is censored)

How are you installing the hub/pulley? Pulling it on with the bolt? When installing, are you not aligning the keyway properly with the key? How are you keeping it from moving before engaging the key in the keyway on the hub/pulley?

Can you post a picture of the inside of the hub/pulley, where it mates to the front of the crank snout? Is the keyway on the hub/pulley f ucked up? (can't believe f uck is censored)

How are you installing the hub/pulley? Pulling it on with the bolt? When installing, are you not aligning the keyway properly with the key? How are you keeping it from moving before engaging the key in the keyway on the hub/pulley?

#34

Senior Member

Join Date: Jun 2008

Location: Germany

Posts: 369

Likes: 0

Received 0 Likes

on

0 Posts

c200k

#35

MBWorld Fanatic!

I get that you are trying to fix it yourself without having to replace major engine componets. Further, you acknowledge that this is not the "correct" fix.

Regardless of wether I believe this is the right move or not, I can't help but think of the next guy.......

Provided you can actually get this to hold, When you eventually sell the car what are you going to tell the new owner?

Good luck!

Regardless of wether I believe this is the right move or not, I can't help but think of the next guy.......

Provided you can actually get this to hold, When you eventually sell the car what are you going to tell the new owner?

Good luck!

#36

MBWorld Fanatic!

If anyone has the bad luck I've had and has had their pulleys come off...this may be your solution.

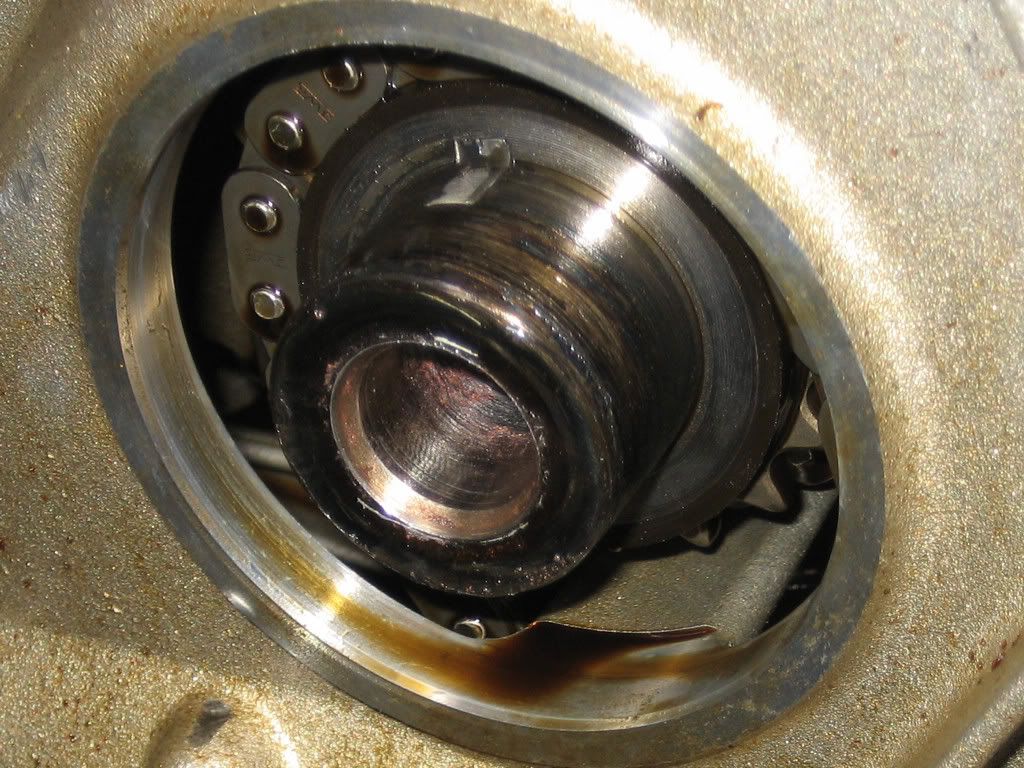

This is what it looked like when my pulley came off....you can see the stock key sheered off:

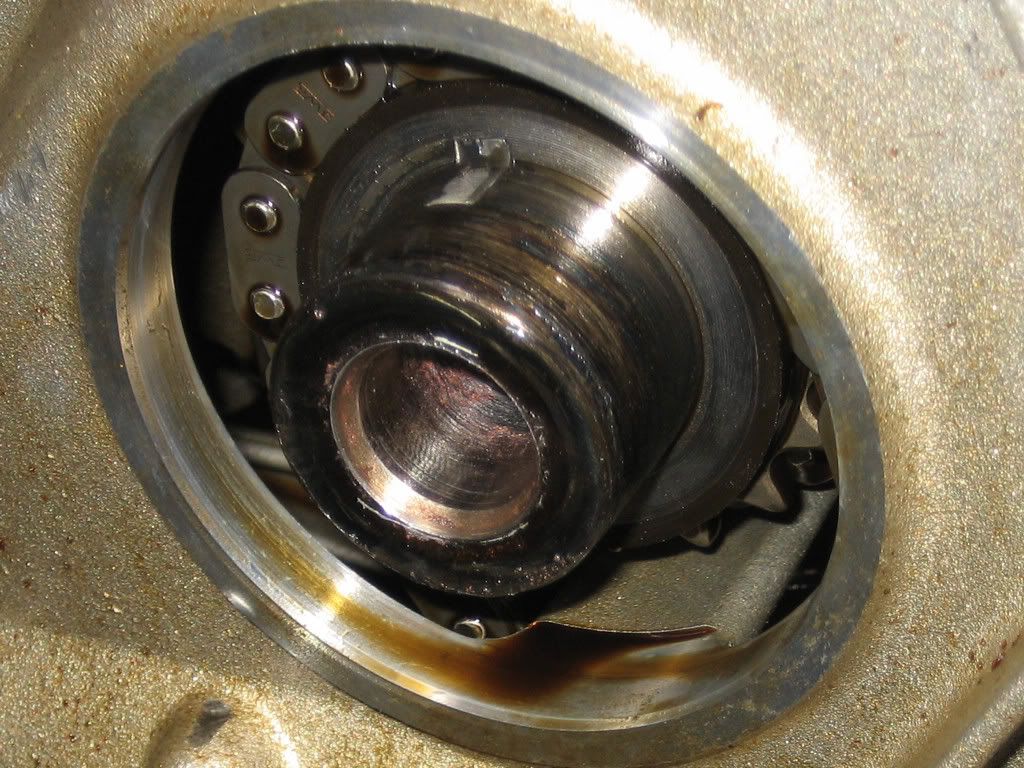

This is what I did now:

I used my dremel with a tungsten carbide bit to make a canal and installed a parallel style key. The key is not only twice as long as the oem key...it's also about twice as think in the end points ( woodruffs are half moon shaped, this one is just rectangular ). It looks like it protrudes in the picture, but it doesn't...it's flush with the tip on the crankshaft.

As soon as I get a new bolt and seal...it's time to bolt on the damper AGAIN and see how this new key holds up. I honestly can't see this failing but I guess we'll find out eh?

This is what it looked like when my pulley came off....you can see the stock key sheered off:

This is what I did now:

I used my dremel with a tungsten carbide bit to make a canal and installed a parallel style key. The key is not only twice as long as the oem key...it's also about twice as think in the end points ( woodruffs are half moon shaped, this one is just rectangular ). It looks like it protrudes in the picture, but it doesn't...it's flush with the tip on the crankshaft.

As soon as I get a new bolt and seal...it's time to bolt on the damper AGAIN and see how this new key holds up. I honestly can't see this failing but I guess we'll find out eh?

#38

Senior Member

#40

MBWorld Fanatic!

#43

Senior Member

#45

Senior Member

Join Date: Jan 2006

Posts: 291

Likes: 0

Received 1 Like

on

1 Post

06 E55, 03FORD P/S,01 E320-4M,99 ML320,O4 E55,05 RUBICON UNLIMITED,

So here's my .02,if when you orig. replaced the key,didn't replace the whole key,just kinda made your own to fit the area that broke and installed the pulley I'm not suprised it broke again.To do this repair correctly you should be replacing the whole key not part of it,a modified keyway like the one you're doing would really be strong.That may mean pulling the front cover off ,timing chain gear,etc.,I think that will be the end all solution.Having done 60+ pulley swaps on benz's,I have never seen these problems personally,I would would also rec. that to you and all others when installing a pulley on these cars,heat the pulley snout and it will slide on easier.Trying to run the pulley down with bolt does put excess strain on the keyway and failure is more likely to occur.I would also apply some sealant in the keyway area at the end to prevent any oil leaks,checking the pulley balance is also a good idea as JAKPRO mentioned,best of luck and keep us updated,although I fear you may still have problems(fingers crossed).Also for info purposes, there is only 1 key for both pulley and timing gear,part # n 006888 005005.

#46

Wouldn't the heat make the metal in the pulley snout expand and actually decrease the size of the opening? I don't see how heating it would help, but I also don't doubt what you're saying. I just don't get how it helps?

#48

MBWorld Fanatic!

#49

Super Member

Same as a cylinder sleeve for an engine block. You put the sleeve in a freezer to make it smaller. Both the inside hole and outside diameter shrink. Same here on the pulley, the heat expands the inside hole and outside diameter but you did ask a good question. You were probably thinking that if the metal expanded it would close the hole slightly?

#50

MBWorld Fanatic!

Since you don't think a parallel key or pinning the crank is acceptable, what is your solution? Have you ever personally dealt with this type of issue before? What do you think the MB solution would be for this? They would tell you to replace the motor. Dealerships techs are parts changers, thats it ( some good innovative guys like MBTEK are out there thankfully). You seem to bash the common aftermarket solution to this type of problem, an aftermarket which is responsible for some incredible feats of engineering. Look no further than the Texas Mile thread for proof of what aftermarket engineers are capable of.

You sit there and criticize tempts to come up with a creative solution to a problem that this guy is going through. If you don't have anything helpful to add screw off already...